A.O. Smith 160M Operation Manual

1

PART NO. 212626-000

PRINTED IN U.S.A. 0905

SUPERSEDES PART NO. 192011- 000 REV. 4

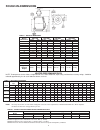

MODELS HW-120M, 160M, 200M, 225M

COMMERCIAL GAS COPPER HEAT EXCHANGER WATER HEATER

BURKAY UP-FLOW MODELS

Including Models with Intermittent Pilot Ignition (I.I.D.)

A DIVISION OF A.O. SMITH CORPORATION

McBEE, SOUTH CAROLINA, USA

RENTON, WA, USA

STRATFORD, ONTARIO, CANADA

VELDHOVEN, THE NETHERLANDS

www.hotwater.com

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER

AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE

•

Installation

•

Operation

•

Maintenance

•

Limited Warranty

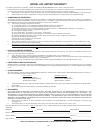

WARNING: If the information in these

instructions are not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

—Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

—WHAT TO DO IF YOU SMELL GAS

•

Do not try to light any appliance.

•

Do not touch any electrical switch;

do not use any phone in your

building.

•

Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

•

If you cannot reach your gas

supplier, call the fire department.

— Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY. PLEASE READ

THOROUGHLY BEFORE USING APPLIANCE.