- DL manuals

- A.O. Smith

- Water Heater

- 200 Series

- Instruction Manual

A.O. Smith 200 Series Instruction Manual

1

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or loss of life.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

— Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

PRINTED 0911

320856-001

INSTRUCTION MANUAL

MODELS:

VB/VW-500, 750 AND 1000

SERIES 200/201

GAS-FIRED COPPER BOILERS FOR

HYDRONIC HEATING AND HOT WATER SUPPLY

•

Installation

•

Operation

•

Maintenance

•

Limited Warranty

MC BEE, SC., RENTON, WA.,

STRATFORD-ONTARIO, VELDHOVEN-THE NETHERLANDS,

NANJING, CHINA

www.hotwater.com / email: parts@hotwater.com

Summary of 200 Series

Page 1

1 warning: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. — do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. — what to do if you smel...

Page 2

2 safe installation, use and service the proper installation, use and servicing of this boiler is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your boiler to warn you and others of a potential inju...

Page 3: General Safety

3 general safety.

Page 4

4 minimum clearances to combustibles: •4”(102mm)rear •0”(0mm)top&sides •6”(152mm)vent table 1. - gas and electrical characteristics manifold pressure maximum supply pressure minimum supply pressure model type of gas inches w.C. Kpa inches w.C. Kpa inches w.C. Kpa vb/vw-500, 750, 1000 natural -2 to -...

Page 5: Capacity And Flow Data

5 capacity and flow data table 3. Recovery capacities. Table 4. Pumping performance guide. Vb models - flow, head loss and temperature rise 20f° (11°c) t 30f° (17°c) t 40f° (22°c) t maximum flow rate minimum flow rate model gpm lph p ft p m gpm lph p ft p m gpm lph p ft p m gpm lph p ft p m t °f t °...

Page 6: Contents

6 this design complies with the current edition of the ansi z21.13 low-pressure boiler standard. Compliance under this standard implies that when the boiler underwent test, the gas manifold and control assembly pro vided on the boiler met safe lighting and other performance criteria. Detailed instal...

Page 7

7 grounding instructions this boiler must be grounded in accordance with the national electrical code and/or local codes. Boiler is polarity sensitive; correct wiring is imperative for proper operation. This boiler must be connected to a grounded metal, permanent wiring system, or an equipment groun...

Page 8: Control Components

8 the control system the control system consists of four basic components: 1) modulation control board (mcb); 2) power distribution board(pdb);3)variablefrequencydrive(vfd),seefigure 2; user interface module, see figure 20. The modulation control board and the power distribution board are located in...

Page 9: Caution

9 water temperature limit controls the“v(b/w)”modelsincorporateanoutletwaterprobeconsisting of two limit controls: 1. A manual reset high limit control that can be set as high as either 210°f(99°c)or235°f(113°c),dependingontheapplication. 2. A fixed manual high limit, factory set at 244°f (118°c). I...

Page 10: General

10 the discharge pipe: • shall not be smaller in size than the outlet pipe size of the valve, or have any reducing couplings or other restrictions. • shall not be plugged or blocked. • shall not be exposed to freezing temperatures. • shall be of material listed for hot water distribution. • shall be...

Page 11

11 figure 8. Chemical vapor corrosion boiler corrosion and component failure can be caused by the heating and breakdown of airborne chemical vapors. Spray can propellants, cleaning sol vents, refrigerator and air conditioning refrig erants, swimming pool chemicals, calcium and sodium chloride(waters...

Page 12

12 for the openings that provide fresh air into confined spaces only. Do not refer to these illustrations for the purpose of vent installation. See venting installation on page 18 for complete venting installation instructions. Outdoor air through two openings figure 9a. The confined space should be...

Page 13

13 air from other indoor spaces figure 9e. The confined space should be provided with two permanent openings,onecommencingwithin12inches(300mm)ofthetop andonecommencingwithin12inches(300mm)ofthebottomof the enclosure. See figure 9e. Each opening should communicate directly with an additional room(s)...

Page 14

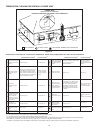

14 termination clearances sidewall power vent v x vent terminal air supply inlet area where terminal is not permitted v v a g v fixed closed fixed closed operable operable v c b b b b f b v v a j v h m x x v v k b e d l power vent (using room air for combustion) exterior clearances for sidewall vent...

Page 15

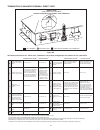

15 termination clearances sidewall direct vent v x vent terminal air supply inlet area where terminal is not permitted v v a g v fixed closed fixed closed operable operable v c b b b b f b v v a j v h m x x v v k b e d l direct vent (using outdoor air for combustion) exterior clearances for sidewall...

Page 16: Venting

16 venting vent sizing, installation and termination shall be in accordance with this installation manual. All electrical power and gas must be turned off prior to any installation of the venting system. Special installation considerations this boiler is a category iv appliance that can be vented us...

Page 17

17 venting supports care must be taken in the installation of the venting system that adequate support is maintained throughout the installation process. Whenextendingmorethan10feet(3.0m)vertically,verticalsupport kitsarerequiredonceevery10feet(3.0m)ofverticalrun.Vertical supportisalsorequiredimmedi...

Page 18

18 notes: if the exhaust vent terminal is within 10’ (3.0m) of a wall or parapet, it must extend a minimum of 2’ (610mm) above the wall or parapet. Joints are not joined to show vent pipe orientation. Figure 11. Vertical termination. Figure 11a. Horizontal through the wall termination (twt). Notes: ...

Page 19

19 direct vent installation requirements follow the guidelines in the “horizontal installation requirements” section for the exhausting of flue products. Important the labels in the direct vent kit must be affixed to the boiler in locations specified by the instruction sheet provided in the kit. The...

Page 20

20 figure 12. Direct vent horizontal. Figure 12a. Direct vent vertical. Caution direct venting into dead air spaces such as; alleys, atriums and inside corners can cause recirculation of flue gases. Recirculation of flue gases will cause sooting, premature failure of the heat exchanger and icing of ...

Page 21

21 figure 12b. Direct vent, vertical vent termination with horizontal intake. Figure 12c. Direct vent using twt with vertical intake. Option b (figures 12b & 12c) assures no recirculation of flue gases. 70 equivalent feet (27.4m) of venting (max.) al 29-4c ® horizontal air intake pvc pipe 70 equival...

Page 22: System Installation

22 system installation general if the system is to be filled with water for testing or other purposes during cold weather and before actual operation, care must be taken to prevent a downdraft entering the boiler or freezing air from contacting the system. Failure to do so may cause the water in the...

Page 23

23 7. System controller controlling of these systems is decided mainly by the type of building system controlling desired. A single boiler installation might be controlled directly from space temperaturethermostat(s).Multipleboilerinstallationsare more effective when the boilers are sequenced in and...

Page 24

24 this is accomplished by changing two dipswitch settings on the mcb.First,dipswitch“4”mustbesettothe“on”positionto designate the remote probe as the controlling probe. Second, dipswitch “1” must be set to the “off” position to limit the maximum remote probe temperature for vw applications. Also, m...

Page 25

25 figure 13. Typical primar y, secondar y piping. • inst all in accordance with all local codes. • when blow down v al ve is required, inst all in place of the drain v al ve shown. Danger temper atur e settin g sh ou ld n ot exc eed safe use tempera ture at fixtures. If h igh er prehea t temper a t...

Page 26

26 danger tempera ture setti ng sho uld no t exceed safe use tempera ture at fixtures. If higher prehea t tempera tures are necessar y t o o bt ai n adeq ua te booster output , add an anti-scald v al ve for hot w ater supplied t o fixtures, see t able 8. One vf (model vw) hot w ater suppl y boiler w...

Page 27

27 one vf (model vw) hot w ater suppl y boiler with hori zont al t ank danger tempera ture setting should no t e xce ed s af e us e t em pe ra ture at fixtur es. If higher pr ehea t tempera tures are necessar y to obt ain adequa te booster o ut put , add an ant i-scal d val ve for hot w ater supplie...

Page 28

28 wiring label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. Strict adherence to the wiring diagrams is required to prevent constant pump operation whenthesystemcontrollerissatisfied.Other...

Page 29

29 suggested pipe sizing tables table 7. Suggested pipe size for multiple gas appliances (propane gas). Nominal maximum capacity of pipe in btu/hr and kw for gas pressures of 14 in. W .C. (0.5 psi) or less and iron pipe a pressure drop of 0.5 in. W .C. (based on 0.60 specific gravity gas w/heating v...

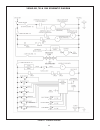

Page 30: Wiring Diagram

30 wiring diagram figure 17. Connection diagram.

Page 31: Wiring Diagram

31 wiring diagram.

Page 32

32 figure 18. - schematic diagram vb/vw-500, 750 & 1000 schematic diagram.

Page 33: Operation

33 operation important onlyqualifiedpersonnelshallperformtheinitialfiringoftheboiler. At this time the user should not hesitate to ask the service agent any questions regarding the operation and maintenance of the unit. If you still have questions, please contact the factory or your local a.O. Smith...

Page 34

34 the boiler should be located in an area that is inaccessible to the general public. Never allow small children to use a hot water tap or to draw their own bath water. Never leave a child or handicapped person unat- tended in a bathtub or shower. Table 8. Risk of scalds. Water temperature timetopr...

Page 35

35 mcb - ten position dipswitch: dipswitchconfigurationsareread only on power up. These switches are only to be set at the factory or by authorized trained personnel! Once set the boiler will operate according to the chosen options. If a switch is changed, power must be cycled before the change will...

Page 36

36 lighting & operation instructions for models vb/vw 500, 750 and 1000:.

Page 37

37 adjustment theremustbesufficientloadtooperatetheboilerathighfireto perform the following adjustments. Start the boiler and observe proper operating parameters for the system. Required tools: torx ® t40 or 5mm hex wrench 3mm or 7/64in hex wrench combustion analyzer the vf 500, 750, and 1000 boiler...

Page 38

38 inputs to mcb temperature sensors: temperature probes (mcb-outletandeitherinletortankare required): the mcb accepts analog temperature inputs from uptothreesensors(inlet,outlet,andtank). Mrhl(manualresethighlimit):themrhlisahi-limitswitch located inside the outlet probe. It is a normally closed s...

Page 39

39 note: if the unit powers up with the number of stages selected by dip switches exceeding the number of fcbs, the mcb will detect this condition and go into a hard lockout. After changing the dipswitches, the power must be cycled off and back on to accept any changes. Exampleofdipswitchconfigurati...

Page 40

40 uim operating procedures figure 20. Uim, user interface module the uim receives commands from the user and displays operational informationtotheuserviaanlcd(liquidcrystaldisplay)uptoeleven led’s,andfivetouchswitches.Thelcdprovidesinformationto the user by the use of 10 menu-activated screens. Wit...

Page 41

41 theprocesswaitsinthisstateuntilthecallforheatissatisfied,the thermostatinputisopened,orafaultoccurs.Whenheatissatisfied, the sequence continues to post-purge and then back to idle. If three tries for ignition has been selected on the mcb dipswitch and flameisnotdetectedattheappropriatetime,thenth...

Page 42

42 use the following procedure to change the automatically resettable high limit setpoint: 1. Press the menu key. 2. Scrollthe“>”withthedownkeynexttousersettingscreen. 3. Press the select key. 4. Scrollthe“>”withthedownkeyuntilitispointingtohigh limit setpoint. 5. Press the select key. 6. Use the up...

Page 43

43 • up and down keys: these keys are used to move upwards and downwards in screens to reach a desired item and to change setpoints and user settings. They have an auto increment/decrement feature for some of the configurations and values. When you first press one of the keys and value changes by 1 ...

Page 44

44 troubleshooting ignition system faultmessagesandlockoutstatus(*=stagenumber:1,2,3,or4) fault displayed description red led lockout “display fail” communications with uim interrupted continuous auto reset check communication cable to uim. Try moving to other internal communications connector on mc...

Page 45: Preventative Maintenance

45 troubleshooting gas valve problem: non-linear co 2 curve on adjusted boiler (deviation more than 3-6%) 1. Possible blockage at the air inlet that prevents uniform, constantairflow. 2. The gas inlet pressure is too low at full load. Problem: unstable co 2 level at minimum load theminimumload(lowfi...

Page 46

46 any safety devices including low water cutoffs used in conjunction with this boiler should receive periodic (every six months) inspection to assure proper operation. A low water cutoff device of thefloattypeshouldbeflushedeverysixmonths.Periodicchecks, at least twice a year, should be made for wa...

Page 47

47 lines with air or water and clear or replace the blocked portions of the line as necessary. Note that areas of the drain line which include a sag or low spot in the line will also form a condensate trap which can be removed by levelling the tube and does not indicate a blocked system. Inspect the...

Page 48: Notes

48 notes.

Page 49: Notes

49 notes.

Page 50: Notes

50 notes.

Page 51

51 limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this boiler: 1. If within ten years after initial installation of the boiler, a heat exchanger or gas burner shall prove upon examination by the warrantor to be defective in mate- rial ...

Page 52

52 500 tennessee waltz parkway, ashland city, tn 37015 phone: 800-433-2545 www.Hotwater.Com e-mail: parts@hotwater.Com.