- DL manuals

- A.O. Smith

- Water Heater

- 2000

- Instruction manual

A.O. Smith 2000 Instruction manual

1

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or loss of life.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

— Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

PRINTED 0710

317294-000

INSTRUCTION MANUAL

MODELS:

VB/VW 1500, 2000

SERIES 100/101

GAS-FIRED COPPER BOILERS FOR

HYDRONIC HEATING AND HOT WATER SUPPLY

•

Installation

•

Operation

•

Maintenance

•

Limited Warranty

500 Tennessee Waltz Parkway

Ashland City, TN 37015

500 Tennessee Waltz Parkway

Ashland City, TN 37015

www.hotwater.com

Summary of 2000

Page 1

1 warning: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. — do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. — what to do if you smel...

Page 2: Table Of Contents

2 vertical installation requirements .............................................18 horizontal installation requirements ........................................18 direct vent installation requirements ......................................18 installation requirements for the commonwealth of mass ....

Page 3: Approvals

3 the proper installation, use and servicing of this boiler is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your boiler to warn you and others of a potential injury hazard. Read and obey all safety...

Page 4: General Safety

4 general safety breathing hazard - carbon monoxide gas special consideration must be taken with installation above 4500 feet. Please contact an a. O. Smith qualified service agent to obtain the proper setup and instructions before lighting. Failure to implement the proper setup will result in impro...

Page 5: General Safety

5 general safety grounding instructions this boiler must be grounded in accordance with the national electrical code, canadian electrical code and/or local codes. Boiler is polarity sensitive; correct wiring is imperative for proper operation. This boiler must be connected to a grounded metal, perma...

Page 6: Introduction

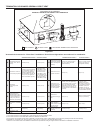

6 dimension and capacity data vb/vw dimensions vw pump mount dimensions figure 1. This design complies with the current edition of the ansi z21.13 - csa 4.9 standard for gas fired low pressure steam and hot water boilers. Compliance under this standard implies that when the boiler underwent test, th...

Page 7

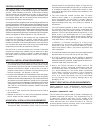

7 table 1. Gas and electrical characteristics models manifold pressure maximum supply pressure minimum supply pressure type of gas inches w.C. Kpa inches w.C. Kpa inches w.C. Kpa vb/vw-1500,2000 natural -.2 to - 4.9 -.04 to - 1.22 14.0 3.49 4.0 1.0 vb/vw-1500,2000 propane -.2 to - 4.9 -.04 to - 1.22...

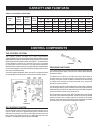

Page 8: Capacity And Flow Data

8 capacity and flow data table 3. Recovery capacities model no. Input rating (btu/hr) output rating (btu/hr) water flow temperature rise - Δt °f (°c) 20 40 60 80 90 100 120 140 (11) (22) (33) (44) (50) (56) (67) (78) vw-1500 1,500,000 1,260,000 gph 7,560 3,780 2,520 1,890 1,680 1,512 1,260 1,080 lph...

Page 9

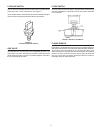

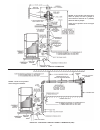

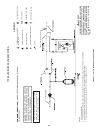

9 low gas switch this vf boiler is available with a low gas pressure switch which meets the csd-1 code requirements, see figure 5. The low gas pressure switch (lgps) is normally closed and remains closed unless the pressure falls below the preset pressure. Figure 5. Low gas pressure switch. Gas valv...

Page 10: Caution

10 water temperature limit controls the “v(b/w)” models incorporate an outlet water probe consisting oftwolimitcontrols: 1. A manual reset high limit control that can be set as high as either 210°f (99°c) or 235°f (113°c), depending on the application. 2. A fixed manual high limit, factory set at 24...

Page 11: General

11 the discharge pipe: • should not be smaller in size than the outlet pipe size of the valve, or have any reducing couplings or other restrictions. • should not be plugged or blocked. • should not be exposed to freezing temperatures. • should be of material listed for hot water distribution. • shou...

Page 12

12 boilerisapprovedforinstallationoncombustibleflooringinan alcovewithminimumclearancestocombustiblesof: 12” (305mm) rear; 4” (102mm) top and sides; 6” (152mm) vent. 2” (51mm) clearance is allowable from combustible construction for hot water pipes. Sufficientareashouldbeprovidedatthefrontandrearoft...

Page 13

13 airtotheconfinedspaceandthetotalbtu/hrinputratingofall appliances installed in the space. Direct vent appliances appliances installed in a direct vent configuration that derive all air for combustion from the outdoor atmosphere through sealed intake air piping are not factored in the total applia...

Page 14

14 the confined space should be provided with two permanent horizontal ducts, one commencing within 12 inches (300 mm) of the top and one commencing within 12 inches (300 mm) of the bottom of the enclosure. The horizontal ducts should communicate directly with the outdoors. See figure 9c. Each duct ...

Page 15

15 termination clearances sidewall power vent v x vent terminal air supply inlet area where terminal is not permitted v v a g v fixed closed fixed closed operable operable v c b b b b f b v v a j v h m x x v v k b e d l power vent (using room air for combustion) exterior clearances for sidewall vent...

Page 16

16 termination clearances sidewall direct vent v x vent terminal air supply inlet area where terminal is not permitted v v a g v fixed closed fixed closed operable operable v c b b b b f b v v a j v h m x x v v k b e d l direct vent (using outdoor air for combustion) exterior clearances for sidewall...

Page 17: Venting

17 venting vent sizing, installation and termination should be in accordance with this installation manual. All electrical power and gas must be turned off prior to any installation of the venting system. Special installation considerations this boiler is a category iv appliance that can be vented u...

Page 18

18 venting supports care must be taken in the installation of the venting system that adequate support is maintained throughout the installation process. When extending more than 10 feet (3.0m) vertically, vertical support kits are required once every 10 feet (3.0m) of vertical run. Vertical support...

Page 19

19 notes: if the exhaust vent terminal is within 10’ (3.0m) of a wall or parapet, it must extend a minimum of 2’ (610mm) above the wall or parapet. Joints are not joined to show vent pipe orientation. Figure 11. Vertical termination. Figure 11a. Horizontal through the wall termination (twt). Notes: ...

Page 20

20 important the labels in the direct vent kit must be affixed to the boiler in locations specified by the instruction sheet provided in the kit. The following are requirements for the air-intake terminal (ait): 1. The air-intake system (ais) must ter minate with the venting equipment pro vided with...

Page 21

21 figure 12. Direct vent horizontal. Figure 12a. Direct vent vertical. Caution direct venting into dead air spaces such as; alleys, atriums and inside corners can cause recirculation of flue gases. Recirculation of flue gases will cause sooting, premature failure of the heat exchanger and icing of ...

Page 22

22 figure 12b. Direct vent, vertical vent termination with horizontal intake. Figure 12c. Direct vent using twt with vertical intake. Option b (figures 11b & 11c) assures no recirculation of flue gases. 70 equivalent feet (27.4m) of venting (max.) al 29-4c ® horizontal air intake pvc pipe 70 equival...

Page 23: System Installation

23 system installation general ifthesystemistobefilledwithwaterfortestingorotherpurposes during cold weather and before actual operation, care must be taken to prevent a downdraft entering the boiler or freezing air from contacting the system. Failure to do so may cause the water in the system to fr...

Page 24

24 8. Primary system control all vf boiler installations require a “primary system control” that senses and reacts to water temperature inside the storage tank on domestic water applications or in the return line on primary/ secondary hydronic heating systems. The primary system control will activat...

Page 25

25 it is essential that all water piping be installed and connected as shown on the diagrams. Check the diagrams to be used thoroughly before starting installation to avoid possible errors and to minimize time and material cost. It is essential that all water piping be installed and connected as sho...

Page 26

26 z223.1/nfpa 54 or the natural gas and propane installation code, can/csa b149.1 • table 7 is based on a pressure drop of 0.5 inches water column (0.124kpa),andagaswithaspecificgravityof0.60andaheating value of 1,000 btu/ft 3 , approximately that of natural gas. • table 8 is based on a pressure dr...

Page 27

27 table 8. Suggested pipe size for multiple gas appliances (propane gas). Nominal maximum capacity of pipe in btu/hr and kw for gas pressures of 14 in. W .C. (0.5 psi) or less and iron pipe a pressure drop of 0.5 in. W .C. (based on 0.60 specific gravity gas w/heating v alue of 1,000 btu’ s/ft3) si...

Page 31

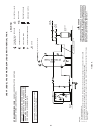

31 figure 16 - schematic diagram vb/vw 1500/2000 schematic diagram hot 120vac on/off switch 20 amp fuse (pdb – f2) pump relay contacts circulating pump (vw units only) neutral 120vac rtn 10 amp fuse (pdb – f6) k8 (mcb-ii) pump relay coil r igniter k11 (mcb-ii) gas valve k5 (mcb-ii) k4 (mcb-ii) k6 (m...

Page 32

32 figure 17. Connection diagram mcb-ii detail a part of j-box vb/vw 1500/2000 wiring diagram on/off main power switch input 120vac power f2-20a 1 2 3 4 5 6 j1 f3-3a 1 2 3 6 7 j2 1 2 3 4 5 6 15 j3 f7-15a f6-10a power distribution board (pdb) blower fuse pump fuse xformer fuse mcb-ii fuse tb1 transfo...

Page 33

33 mcb-ii detail a part of j-box vb/vw 1500/2000 wiring diagram on/off main power switch input 120vac power f2-20a 1 2 3 4 5 6 j1 f3-3a 1 2 3 6 7 j2 1 2 3 4 5 6 15 j3 f7-15a f6-10a power distribution board (pdb) blower fuse pump fuse xformer fuse mcb-ii fuse tb1 transformer 120/24 vac modulating con...

Page 34: Operation

34 operation important only a certified start-up agent should perform the initial firing of the boiler. At this time the user should not hesitate to ask the start-up technician any questions regarding the operation and maintenance of the unit. If you still have questions, please contact the factory ...

Page 35

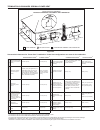

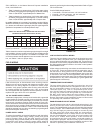

35 the boiler should be located in an area that is inaccessible to the general public. Never allow small children to use a hot water tap or to draw their own bath water. Never leave a child or handicapped person unat- tended in a bathtub or shower. Table 9. Risk of scalds. Water temperature time to ...

Page 36

36 lighting and operating instructions.

Page 37

37 adjustment theremustbesufficientloadtooperatetheboilerathighfireto perform the following adjustments. Start the boiler and observe proper operating parameters for the system. Required tools: torx ® t40 or 5mm hex wrench 3mm or 7/64in hex wrench combustion analyzer these boilers are equipped with ...

Page 38

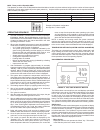

38 inputs to mcb temperature sensors: temperature probes (mcb - outlet and either inlet or tank are required): the mcb accepts analog temperature inputs from up to three sensors (inlet, outlet, and tank). Manual reset high limit(mcb-required):themrhlormanual reset high limit is a hi-limit switch loc...

Page 39

39 operating sequence 1. Theemcmodulationcontrollerhasfourmodesofoperation: initialization, standby, running/modulation, and service. The internal mcb micros control these modes through a sequence of steps (or states) which are further described in the “uim operating procedures” section. 2. When pow...

Page 40

40 • temperature screen: displays the sensed temperatures of the outlet, inlet, and tank probes. Also displayed is the calculated delta t (outlet minus inlet) for the system. Shorted (“short”) and disconnected (“----”) probes are also displayed. • system status screen: this screen is used to view st...

Page 41

41 this state until the mcb sends a command to clear the error, and the system returns to the idle state. • coldpurgestate cold purge occurs when the mcb micro commands the blower to go on before lighting to clear the unit of residual gases. This state normally lasts approximately 32 seconds but on ...

Page 42

42 the software revision level of the mcb. • current error screen: displays the last error that the system has detected plus a time stamp of when the error occurred. (the time stamp is based on the elapsed hours value at the time the error occurred. It is displayed in hours and minutes. This error r...

Page 43

43 troubleshooting ignition system faultmessagesandlockoutstatus(*=stagenumber:1,2,3,or4) fault displayed description red led lockout “display fail” communications with uim interrupted continuous auto reset check communication cable to uim. Try moving to other internal communications connector on mc...

Page 44: Preventative Maintenance

44 troubleshooting gas valve problem: non-linear co 2 curve on adjusted boiler (deviation more than 3-6%) 1. Possible blockage at the air inlet that prevents uniform, constantairflow. 2. The gas inlet pressure is too low at full load. Problem: unstable co 2 level at minimum load the minimum load (lo...

Page 45

45 any safety devices including low water cutoffs used in conjunction with this boiler should receive periodic (every six months) inspection toassureproperoperation.Alowwatercutoffdeviceofthefloat typeshouldbeflushedeverysixmonths.Periodicchecks,atleast twice a year, should be made for water leaks. ...

Page 46

46 lines with air or water and clear or replace the blocked portions of the line as necessary. Note that areas of the drain line which include a sag or low spot in the line will also form a condensate trap which can be removed by levelling the tube and does not indicate a blocked system. Inspect the...

Page 47: Limited Warranty

47 limited warranty a.O.Smithcorporation,thewarrantor,extendsthefollowinglimitedwarrantytotheownerofthisboiler: 1. If within ten years after initial installation of the boiler, a heat exchanger or gas burner should prove upon examination by the warrantor to be defective in material or workmanship, t...

Page 48

48 500 tennessee waltz parkway, ashland city, tn 37015 technicalsupport:800-527-1953•parts:800-433-2545•fax:800-644-9306 www.Hotwater.Com.