Place these instructions adjacent to heater and notify owner to keep for future reference. Printed 0307 97373-003 cyclone xi ® model bth 300a, 400a, 500a commercial gas water heater gas-fired power burner for domestic hot water thank you for buying this energy efficient water heater from a.O. Smith ...

These designs comply with the current edition of the american national standard for gas water heaters, volume iii, ansi z21.10.3 / csa 4.3 as an automatic circulating tank water heater, and automatic storage water heaters. Detailed installation diagrams are found in this manual. These diagrams will ...

3 danger this water heater is equipped with an adjustable thermostat to control water temperature. Hot water temperatures required for automatic dishwasher and laundry use can cause scald burns resulting in serious personal injury and/or death. The temperature at which injury occurs varies with the ...

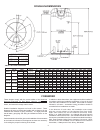

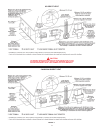

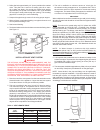

4 “at a glance” bth 300/400/500 quick installation tips horizontal sidewall venting vertical rooftop venting.

5 the temperature may be adjusted from 80°f/27°c to 180°f/82°c. The temperature was adjusted to 120°f/49°c before the heater was shipped from the factory. It is recommended that lower water temperatures be used to avoid the risk of scalding. It is further recommended, in all cases, that the water te...

6 the heater shall be located or protected so it is not subject to physical damage by a moving vehicle. Do not locate the heater where noise from the exhaust or intake will be objectionable. This includes locations close to or across from windows and doors. Avoid anchoring the vent and intake pipes ...

7 clearances these heaters are approved for installation on combustible flooring in an alcove when the minimum clearances from any combustion construction are followed as indicated in figure 4. In all installations the minimum combustible clearances from any vent piping shall be 0". Vent piping pass...

8 installation requirements for the commonwealth of massachusetts for all side wall terminated, horizontally vented power vent, direct vent, and power direct vent gas fueled water heaters installed in every dwelling, building or structure used in whole or in part for residential purposes, including ...

9 us direct vent canadian direct vent figure 5. Caution to prevent exhausting products from circulating to the air intake in windy/cold areas, the maximum practical distance between these two terminals is recommended..

0 us horizontal vent canadian horizontal vent figure 6. Caution to prevent exhausting products from circulating to the air intake in windy/cold areas, the maximum practical distance between these two terminals is recommended..

Warning never operate the heater unless it is vented to the outdoors and has adequate air supply to avoid risks of improper operation, fire, explosion or asphyxiation. Vent pipe termination note: before installing venting, determine place of vent pipe termination. See figure 5 and 6 before proceedin...

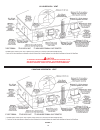

2. The horizontal centerline of the intake vent terminal may not be located lower than the horizontal centerline of the exhaust vent terminal (see figure 9). Figure 9. Installation sequence for installations in the city of los angeles, california category iv pvc pipe such as that manufactured by bro...

3 2. Drill a pilot hole approximately 1/4" (6 mm) outside of the marked circle. This pilot hole is used as a starting point for a saws- all or sabre saw blade. Cut around the marked circle staying approximately one quarter inch outside the line. (this will allow the vent pipe to easily slide through...

14 vent pipe preparation . Initial preparation a. Make sure the solvent cement you are planning to use is designed for the specific application you are attempting. B. Know the physical and chemical characteristics and limitations of the pvc, pvc cellular core, abs or cpvc piping materials that you a...

5 caution the water heater is polarity sensitive. Before applying electricity to this heater be certain that supply neutral wire to ground check indicates zero voltage. Hot surface igniter the hot surface igniter is a device that ignites the main burner by high temperature (>1800°f or >982°c). When ...

16 to prevent damage, care must be taken not to apply too much torque when attaching gas supply pipe to gas valve inlet. Apply joint compounds (pipe dope) sparingly and only to the male threads of pipe joints. Do not apply compound to the first two threads. Use compounds resistant to the action of l...

7 codes or contact the water supplier or local plumbing inspector on how to control this situation. Water (potable) heating and space heating 1. All piping components connected to this unit for space heating applications shall be suitable for use with potable water. 2. Toxic chemicals, such as those...

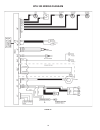

8 figure 15. Bth 300 wiring diagram.

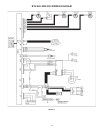

9 figure 16. Bth 400 and 500 wiring diagram.

0 operation sequence of operation typical control/appliance operating sequence 1. When the control is powered, it should display the unit model, water temperature, setting temperature and heater status. 2. If the control determines that the actual water temperature inside the tank is below the progr...

3. Adjusting the operating set point the operating set point of this water heater determines the regulated temperature for the water in the tank. This parameter is adjusted in the temperature menu. Items in this menu allow you to monitor different temperature readings in the tank along with adjustin...

4. Changing the display units the display interface to the heater has the option of selecting between degrees and fahrenheit and degrees celsius for temperature displays. This can be found in the "display settings" menu. Also in this menu, you may adjust how the backlight operates and the contrast o...

3 • faults: this is a safety related condition that has been detected by the heater. Note: when these conditions occur, the water heater will not continue any further heating cycles and the water will no longer be heated until the condition is corrected and, in most cases, power has been cycled. Exa...

24 7. Viewing the fault history the controller for this water heater will store a history of ten of the last fault and warning conditions that occurred. This is stored in the fault history. Along with all the information about the fault, including a estimate time of when the fault occurred, informat...

5 do not use this heater if any part has been under water. Immediately call a qualified service technician to inspect the heater and to replace any part of the control system and any gas control which has been under water. Light the unit in accordance with the operating instructions label attached t...

26 c. Remove the pressure regulator cover screw (figure 16) and adjust the pressure by turning the adjusting screw with a small screwdriver. In this example, with heater running on natural gas, do not exceed 4.0" (0.996 kpa) water column. Clockwise to increase gas pressure and input rate. Counterclo...

7 warning under no circumstances should the input exceed the rate shown on the heater rating plate. Overfiring could result in damage or sooting of the heater. Cathodic protection caution hydrogen gas can be produced in a hot water system served by this heater that has not been used for a long perio...

8 flushing 1. Turn off the heater electrical disconnect switch. 2. Open the drain valve and allow water to flow until it runs clean. 3. Close the drain valve when finished flushing. 4. Turn on the heater electrical disconnect switch. Draining the heater must be drained if it is to be shut down and e...

9 powered anode system to insure a long, trouble-free operating life, bth 300, 400 and 500 are factory equipped with a powered anode system. The anodes are of a permanent design and do not need replacing unless damaged. Drain valve and access panels the heaters are equipped with a 3/4" drain valve. ...

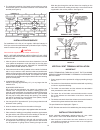

30 one temperature - one heater horizontal storage tank forced circulation with or without building recirculation danger temperature setting should not exceed safe temperature at fixtures. See water temperature control warning on page 3. If higher preheat temperatures are necessary to obtain adequat...

3 * pipe relief valve to open drain. N o t e : i f t e m p e r e d wat e r i s recirculated, return line should be connected at point “a”. Install in accordance with local codes. Two temperature - one heater high temperature with or without building recirculation danger temperature setting should no...

3 two temperature - two heaters high temperature with or without building recirculation two temperature - three heaters (two pre-heaters/one booster heater) with or without building recirculation must be identical heaters for multiple heater installation see manifold kit specifications, page 35. Cau...

33 * pipe relief valve to open drain ** 140°f (60°c)to 150°f (66°c) should be maximum water temperature maintained in the pre-heaters. 120°f (49°c) should be the minimum temperature of water in the pre-heaters. Connect circulating line from fixtures, if used, to cold water supply line of pre-heater....

34 note 1: toggle switch controls 180°f (82°c) water circulation. Install on or close to dishwasher. Toggle switch must be closed (on) during the rinse operation and open (off) when dishwasher is not operating or when on long standby. Note 2: install line temperature control in an uninsulated tee be...

35 multiple unit installations proper installation of multiple water heaters assures water flow balance of all units. Without this balance, the full water heating and storage potential of the system cannot be achieved. Plus, the units with the higher water flow may have a shortened life. Dimensions ...

36 checklist and service information important the installer may be able to observe and correct certain problems which might arise when the unit is put into operation or when it is re-fired after a prolonged shutdown. However, it is recommended that only qualified servicemen, using appropriate test ...

37 checking these four (4) items first will often result in a timely solution to the service call. Warning jumping out components and/or circuits during troubleshooting can cause serious problems with the unit’s operating sequence and ignition safety. If you do not have the proper test equipment, i....

38 note: always turn off and disconnect main supply wiring before servicing the unit. 4. Check connecting wire to the flame sensor. Verify that the flame sensor has not been damaged in any way. 5. Verify that the air supply is adequate. The air inlet screen or blower wheel may be restricted. Also, c...

39 model bth limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. . The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable w...

40 www.Hotwater.Com.