- DL manuals

- A.O. Smith

- Water Heater

- ADM - 115

- Installation & Service Manual

A.O. Smith ADM - 115 Installation & Service Manual

Summary of ADM - 115

Page 3

Instruction manual adm 3 gis read this manual carefully warning read this manual carefully before starting up the water heater. Failure to read this manual and to follow the instructions in this manual may lead to accidents, personal injury, and damage to the appliance. Copyright © 2008 a.O. Smith w...

Page 4

4 instruction manual adm gis.

Page 5: Table of Contents

Instruction manual adm 5 table of contents 1 introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - 7 1.1 about the appliance - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7 1.2 what to do if you smell gas- - - - - - - - - - - - - - - - - - - - - - - - - 7 1.3 regulations - - -...

Page 6

Table of contents 6 instruction manual adm 8 status of the appliance - - - - - - - - - - - - - - - - - - - - - 49 8.1 introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49 8.2 operating modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49 8.3 error conditions ...

Page 7: Introduction

Instruction manual adm 7 gis 1 introduction 1.1 about the appliance this manual describes how to install, service and use the adm appliance. The adm appliance is a gas-fired open boiler without fan. Adm appliances are equipped with a flue gas backflow safeguard. The adm is an appliance of type b 11b...

Page 8

Introduction 8 instruction manual adm 1 gis furthermore, the installation must comply with the manufacturer's instructions. Note later amendments and/or additions to all regulations, requirements and guidelines published on or prior to the moment of installing, will apply to the installation. 1.4 ta...

Page 9

Instruction manual adm 9 gis 1.7 overview of this document the table provides an overview of the contents of this document. Contents of this document chapter target groups description working principle of the appliance this chapter describes how the appliance functions. Installation this chapter des...

Page 10

Introduction 10 instruction manual adm 1 gis.

Page 11: Working Principle of

Instruction manual adm 11 gis 2 working principle of the appliance 2.1 introduction topics covered in this chapter: • general working principle of the appliance ; • the appliance's heating cycle ; • protection for the appliance ; • safety of the installation . 2.2 general working principle of the ap...

Page 12

Working principle of the appliance 12 instruction manual adm 2 gis in this appliance, the cold water enters the bottom of the tank through the cold water inlet (14). The heat of combustion is conducted to the water by the combustion chamber (8) and heat exchanger (11). The heated tap water leaves th...

Page 13

Instruction manual adm 13 gis 2.4.2 water temperature protection by means of the frost, high-limit and safety thermostats, the burner control monitors three temperatures that are important for safety. The table explains the working principle of the thermostats with sensors. Temperature protection 2....

Page 14

Working principle of the appliance 14 instruction manual adm 2 gis 2.5.2 unvented installation with an unvented installation, an expansion valve valve and expansion vessel prevent the buildup of excessive pressure in the tank. This prevents damage being caused to the enamelled coating (in the applia...

Page 15: Installation

Instruction manual adm 15 is 3 installation warning installation work should be carried out by an approved installation engineer in compliance with the general and local regulations imposed by the gas, water and power supply companies and the fire service. The appliance may only be installed in a ro...

Page 16

Installation 16 instruction manual adm 3 is air humidity and ambient temperature specifications 3.3.2 maximum floor load in connection with the appliance's weight, take account of the maximum floor loading, refer to the table. 3.3.3 water composition the appliance is intended for heating drinking wa...

Page 17

Instruction manual adm 17 is working clearances 3.4 technical specifications the appliance is supplied without accessories. Check the dimensions (3.4.1 "dimensions of the appliance") , gas data (3.4.3 "gas data") and other specifications (3.4.2 "general and electrical specifications") of any accesso...

Page 18

Installation 18 instruction manual adm 3 is 3.4.1 dimensions of the appliance plan and elevation of the appliance legend see the table. 10º 37º 45º f e a d h g b m r k p s n j 6 1 3 4 6 2 5 imd-0135 r2.

Page 19

Instruction manual adm 19 is dimensions (all measurements in mm unless otherwise indicated) 3.4.2 general and electrical specifications general and electrical specifications dime nsion description adm 40 adm 50 adm 60 adm 80 adm 90 adm 115 adm 135 a total height 1900 2100 1900 2100 2000 2085 2085 b ...

Page 20

Installation 20 instruction manual adm 3 is 3.4.3 gas data gas data description ii 2h3+ unit adm 40 adm 50 adm 60 adm 80 adm 90 adm 115 adm 135 gas category 2h: general orifice diameter mm 3.20 3.20 3.10 2.95 3.20 3.20 3.90 (1) = blank plate (2) = burner pressure regulator (3) = high/low regulator 1...

Page 21

Instruction manual adm 21 is 3.5 installation diagram 3.5.1 installation this figure shows the installation diagram. This diagram is used in the sections in which the actual connection process is described. Installation diagram legend only applicable numbers are mentioned. 1. Pressure reducing valve...

Page 22

Installation 22 instruction manual adm 3 is 3.6 water connections, vented warning the installation should be carried out by an authorised installation engineer, in compliance with general and local regulations (1.3 "regulations") . 3.6.1 cold water side see (a) in the installation diagram (3.5 "inst...

Page 23

Instruction manual adm 23 is 3.6.5 circulation pipe see (c) in the installation diagram (3.5 "installation diagram") . If an immediate flow of hot water is required at draw-off points, a circulation pump can be installed. This improves comfort and reduces water wastage. 1. Fit a circulation pump (6)...

Page 24

Installation 24 instruction manual adm 3 is 3.7.5 circulation pipe see (c) in the installation diagram (3.5 "installation diagram") . If an immediate flow of hot water is required at draw-off points, a circulation pump can be installed. This improves comfort and reduces water wastage. 1. Fit a circu...

Page 25

Instruction manual adm 25 is 3.9 chimney flue warning the installation should be carried out by an authorised installation engineer, in compliance with general and local regulations (1.3 "regulations") . 3.9.1 introduction the separately-supplied draught diverter must be used when connecting the app...

Page 26

Installation 26 instruction manual adm 3 is 8. Screw the draught diverter tightly in place. 9. Fit: - a 45° bend (7) onto the outlet of the draught diverter, followed by: - a corrosion-resistant vertical chimney pipe (8) of at least 0.5 metres in length, - the remaining flue components. Note use flu...

Page 27

Instruction manual adm 27 is 3.10.1 preparations caution the appliance is phase-sensitive. It is absolutely essential to connect the mains live (l) to the live of the appliance, and the mains neutral (n) to the neutral of the appliance. Caution there must also be no potential difference between neut...

Page 28

Installation 28 instruction manual adm 3 is the connector block (c) is now visible. Note please consult (14.2 "electrical diagrams adm") the appropriate electrical diagram for details of the connections of the electrical components. Terminal block 3.10.2 connecting the mains power the appliance is s...

Page 29

Instruction manual adm 29 is gas control for adm 40 through 115 legend only applicable numbers are mentioned. 1. Burner pressure regulator 2. Burner pressure regulator cap 3. Burner pressure regulator adjustment screw 4. Gas control connector 5. Blank plate 6. Supply pressure test nipple 7. Gas cont...

Page 30

Installation 30 instruction manual adm 3 is gas control for adm 135 3.11.1 preparations 1. Isolate the appliance from the power supply (10.3 "isolating the appliance from the mains") . 2. There are two test nipples on the gas control. Test nipple (6) is used to check the supply pressure. The other t...

Page 31

Instruction manual adm 31 is 10. Use the pressure gauge to read the supply pressure at test nipple (6). Refer to the gas data table (3.4.3 "gas data") . Note consult the mains gas supply company if the supply pressure is not correct. 11. Use the pressure gauge to read the burner pressure at nipple (...

Page 32

Installation 32 instruction manual adm 3 is.

Page 33: Conversion to A

Instruction manual adm 33 is 4 conversion to a different gas category caution the conversion may only by carried out by an authorised installation engineer. If the appliance must operate on a family of gases (lp gas or natural gas) or other gas category than that for which the appliance has been set...

Page 34

Conversion to a different gas category 34 instruction manual adm 4 is exchanging orifices 4.1 conversion to different category adm 40 through 115 1. Isolate the appliance from the power supply (10.3 "isolating the appliance from the mains") . 2. Shut off the gas supply. Caution the burner can be hot...

Page 35

Instruction manual adm 35 is 7. Select and fit the correct orifices from the conversion kit, based on the gas data table (3.4.3 "gas data") . The orifice diameter is stamped on the orifice itself, see (3). 8. Re-fit the burners back in their original position. 9. Re-fit the retaining strips. 10. If ...

Page 36

Conversion to a different gas category 36 instruction manual adm 4 is 13. Check the supply pressure and burner pressure (3.11 "checking the supply pressure and burner pressure") . 14. Remove the sticker showing the new gas category from the conversion kit, and attach it below the appliance's rating ...

Page 37

Instruction manual adm 37 is 4.2.2 conversion from lp gas to natural gas installing and removing add-on components legend only applicable numbers are mentioned. 4. Timers 5. Bracket 6. 6-contact terminal strip 7. Strain relief 8. 9-contact terminal strip 9. Metric strain relief 10. High-low control ...

Page 38

Conversion to a different gas category 38 instruction manual adm 4 is 1. Carry out (4.1 "conversion to different category adm 40 through 115") steps 1 through 10 . 2. Detach the high-low control (9). 3. Fit the burner pressure regulator (1) including the sealing gasket from the conversion kit. Attac...

Page 39

Instruction manual adm 39 is 11. Remove the sticker showing the new gas category from the conversion kit, and attach it below the appliance's rating plate. This clearly indicates that the appliance may no longer be run on the gas for which it was originally supplied. 12. Start the appliance (9 "star...

Page 40

Conversion to a different gas category 40 instruction manual adm 4 is.

Page 41: Filling

Instruction manual adm 41 gis 5 filling installation diagram legend only applicable numbers are mentioned. 1. Pressure reducing valve (mandatory) 3. T&p valve (mandatory) 4. Stop valve (recommended) 5. Non-return valve (mandatory) 6. Circulation pump (optional) 7. Top to bottom circulation pump (opt...

Page 42

Filling 42 instruction manual adm 5 gis 5.1 filling unvented installations to fill the appliance, proceed as follows: 1. Open the stop valve (11) in the hot water pipe and, if present, the stop valves (4) for the circulation pump (6). 2. Close the drain valve (9). 3. Open the nearest hot water draw-...

Page 43: Draining

Instruction manual adm 43 gis 6 draining installation diagram legend only applicable numbers are mentioned. 1. Pressure reducing valve (mandatory) 3. T&p valve (mandatory) 4. Stop valve (recommended) 5. Non-return valve (mandatory) 6. Circulation pump (optional) 7. Top to bottom circulation pump (op...

Page 44

Draining 44 instruction manual adm 6 gis 6.1 draining unvented installations some service activities require the appliance to be drained. The procedure is as follows: 1. Shut down the appliance by setting the on/off switch on the control panel to position 0. 2. Isolate the water heater from the powe...

Page 45

Instruction manual adm 45 gis 6.2 draining vented installations some service activities require the appliance to be drained. The procedure is as follows: 1. Shut down the appliance by setting the on/off switch on the control panel to position 0. 2. Isolate the water heater from the power supply by p...

Page 46

Draining 46 instruction manual adm 6 gis.

Page 47: The Control Panel

Instruction manual adm 47 gis 7 the control panel 7.1 introduction topics covered in this chapter, in sequence: • control panel • explanation of icons • on/off switch • control thermostat • burner control reset button • flue gas thermostat reset button 7.2 control panel this figure shows the control...

Page 48

The control panel 48 instruction manual adm 7 gis 7.6 burner control reset button an error can cause the burner control to lock out. When this happens, the red led on the control panel will illuminate. After eliminating the cause of the error, you can reset the appliance using the reset button. Note...

Page 49: Status of The

Instruction manual adm 49 gis 8 status of the appliance 8.1 introduction topics covered in this chapter: • operating modes ; • error conditions ; 8.2 operating modes when running, the appliance has three basic operating modes, namely: • electrically isolated in this mode, the appliance is off and no...

Page 50

Status of the appliance 50 instruction manual adm 8 gis.

Page 51: Starting and Running

Instruction manual adm 51 gis 9 starting and running 9.1 introduction topics covered in this chapter: • starting the appliance ; • the appliance's heating cycle . 9.2 starting the appliance start the appliance as follows: 1. Fill the appliance (5 "filling") . 2. Open (3.5 "installation diagram") the...

Page 52

Starting and running 52 instruction manual adm 9 gis.

Page 53: Shutting Down

Instruction manual adm 53 gis 10 shutting down 10.1 introduction topics covered in this chapter: • shutting down the appliance for a brief period (off mode) ; • isolating the appliance from the mains ; • shutting the appliance down for a long period . 10.2 shutting down the appliance for a brief per...

Page 54

Shutting down 54 instruction manual adm 10 gis.

Page 55: Troubleshooting

Instruction manual adm 55 gis 11 troubleshooting 11.1 introduction this chapter deals with the following problems with the appliance: • gas smell. • water leakage. • explosive ignition. • poor flame profile. • no hot water. • insufficient hot water. 11.2 error conditions if the water heater goes int...

Page 56

Is instruction manual adm 56 11.3 troubleshooting table for general errors warning maintenance may only be performed by a qualified service and maintenance engineer. General faults and failures symptom cause precautions comment gas smell gas leak warning close the main gas valve immediately. Warning...

Page 57

Is instruction manual adm 57 11.4 adm troubleshooting table - no hot water warning maintenance may only be performed by a qualified service and maintenance engineer. No hot water symptom cause precautions comment green led off and red led on no supply voltage present 1. Check if the isolator is on. ...

Page 58

Is instruction manual adm 58 symptom cause precautions comment (a) three unsuccessful start attempts in a row 1. No gas: - check that the gas valve is open - check whether the gas control is opening (clicking of the gas control) - check the leads of the gas control 2. No ignition: - check whether th...

Page 59

Is instruction manual adm 59 11.5 troubleshooting table - 'insufficient hot water' warning maintenance may only be performed by a qualified service and maintenance engineer. Insufficient hot water symptom cause precautions comment insufficient hot water water temperature setting (t set ) is too low ...

Page 60

Is instruction manual adm 60

Page 61: Performing

Instruction manual adm 61 s 12 performing maintenance 12.1 introduction caution maintenance may only by carried out by an approved service and maintenance engineer. At each service, the appliance undergoes maintenance on both the water side and the gas side. The maintenance must be carried out in th...

Page 62

Performing maintenance 62 instruction manual adm 12 s 12.3 water-side maintenance 12.3.1 introduction the following steps must be carried out on the water side: 1. Checking the anodes . 2. Descaling and cleaning the tank . 12.3.2 checking the anodes timely replacement of the anodes extends the servi...

Page 63

Instruction manual adm 63 s to simplify the task of descaling and cleaning the tank, the appliance is equipped with two cleaning openings. 1. Remove the cover plate (1) on the outer jacket (see the figure). 2. Carefully remove the insulation layer (2) and set it to one side. This will be needed agai...

Page 64

Performing maintenance 64 instruction manual adm 12 s 12.4.1 introduction the following steps must be carried out on the gas side: 1. Clean the burner(s) . 2. Clean the orifice(s) . 3. Checking the flue baffles . 12.4.2 clean the burner(s) 1. Detach the burner(s) 2. Remove all contamination present ...

Page 65: Warranty (Certificate)

Instruction manual adm 65 gis 13 warranty (certificate) to register your warranty, you should complete and return the enclosed warranty card after which a warranty certificate will be sent to you. This certificate gives the owner of a appliance supplied by a.O. Smith water products company b.V. Of v...

Page 66

Warranty (certificate) 66 instruction manual adm 13 gis i. The appliance is at all times fitted with cathodic protection. If sacrificial anodes are used for this, these must be replaced and renewed when, and as soon as, they are 60% or more consumed. When electric anodes are used, it is important to...

Page 67: Appendices

Instruction manual adm 67 is 14 appendices 14.1 introduction this section gives the electrical diagrams for: • electrical diagram for adm 40 to 135 natural gas and 40 to 115 lpg • electrical diagram 135 - lp gas.

Page 68

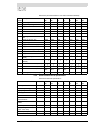

Appendices 68 instruction manual adm 14 is 14.2 electrical diagrams adm 14.2.1 electrical diagram for adm 40 to 135 natural gas and 40 to 115 lpg 1 = brown, 2 = blue, 3 = yellow/green, 4 = black, 5 = white (flat cable) i 0 l 24v n n l m 4 2 1 3 4 12 12 1 4 1 2 3 1 4 2 1 2 1 4 4 4 3 3 3 4 3 4 4 11 h ...

Page 69

Instruction manual adm 69 is terminal strip connections: earth n neutral l 1 phase input of controller l 2 phase input of flue gas thermostat l 3 phase output of flue gas thermostat components: a two-pole isolator switch b flue gas thermostat c "error" signalling d "operational" signalling e reset b...

Page 70

Appendices 70 instruction manual adm 14 is 14.2.2 electrical diagram 135 - lp gas 1 = brown, 2 = blue, 3 = yellow/green, 4 = black, 5 = white (flat cable) 3 l 1 l 2 1 a 2 1 1 5 3 2 3 4 4 4 6 4 9 8 7 6 5 4 3 2 1 4 1 4 2 3 c d e n l b l 1 3 2 1 n 2 1 1 3 2 3 4 4 2 l l 4 4 5 4 a 50hz 230v ac 4 2 3 1 ho...

Page 71

Instruction manual adm 71 is terminal strip connections: earth n neutral l 1 phase input of controller l 2 phase input of flue gas thermostat l 3 phase output of flue gas thermostat components: a two-pole isolator switch b flue gas thermostat c "error" signalling d "operational" signalling e reset b...

Page 72

Appendices 72 instruction manual adm 14 is.

Page 73: Index

Instruction manual adm 73 index a ambient temperature 15 b burner pressure 28 c claims 66 connect circulation piping 23, 24 cold water side 22, 23 electrical 26, 28 gas 24 hot water side 23 shut pipe 22, 23 connecting circulation pipe 23, 24 connecting cold water side 22, 23 connecting hot water sid...

Page 74

0306 132 4.0 uk index instruction manual adm.