- DL manuals

- A.O. Smith

- Water Heater

- BFC-120

- Installation, User And Service Manual

A.O. Smith BFC-120 Installation, User And Service Manual

Summary of BFC-120

Page 1

0311753 innovation has a name. Installation, user and service manual condensing high efficiency gas-solar water heater sgs - 28/30/50/60/80/100/120 sgs 3017 - changes reser ved..

Page 2: Your Installer

A.O. Smith uk, unit b8 amstrong mall, southwood business park, farnborough, hampshire gu14 0nr www.Aosmith.Co.Uk “a.O. Smith water heaters” is a trading name of advance services (sales) ltd. Reg. Your installer.

Page 3: Preface

Preface copyright copyright © 2016 a.O. Smith water products company all rights reserved. Nothing from this publication may be copied, reproduced and/or published by means of printing, photocopying or by whatsoever means, without the prior written approval of a.O. Smith water products company. A.O. ...

Page 4: Regulations

Regulations gas safety (installations and use) regulations 1998 (as amended). It is law that all gas appliances are installed by competent persons, in accordance with the above regulations. Failure to install appliances correctly could lead to prosecution. It is in your own interest and that of safe...

Page 5: Contact Information

Contact information if you have any comments or questions, please contact: a.O. Smith water products company adress: po box 70 5500 ab veldhoven the netherlands telephone: 0870 - aosmith (free) 0870 - 267 64 84 general: +31 40 294 25 00 fax: +31 40 294 25 39 e-mail: info@aosmith.Nl website: www.Aosm...

Page 6

6.

Page 7: About This Manual

About this manual scope this manual gives information about safe and correct use of the water heater and how installation, maintenance and service activities have to be done correctly. You must obey the instructions in this manual. Caution read this manual carefully before you start the water heater...

Page 8: Document Identification

This manual contains the following text styles/symbols for situations that may endanger users/engineers, cause damage to equipment or need special attention: note a note gives more information on a topic. Caution obey the caution instructions to prevent damage of the water heater. Warning obey the w...

Page 9: Table of Contents

Table of contents preface........................................................................................ 3 copyright.......................................................................... 3 trademarks....................................................................... 3 warranty.........

Page 10

4 use............................................................................................ 25 4.1 turn on the water heater...................................................25 4.1.1 the appliance's heating cycle............................................. 25 4.2 turn off the water heater.......

Page 11

7.2 conditions....................................................................... 53 7.2.1 ambient conditions........................................................... 53 7.2.2 maximum floor load.......................................................... 53 7.2.3 water composition..................

Page 12

9.2.4 display the selected water heater....................................... 84 9.2.5 setting the service interval................................................ 85 9.2.6 service mode...................................................................85 9.2.7 setting legionella prevention............

Page 13: User Part

User part 0311753_sgs_28-120_ii_ukuk_v2.0 , 2017-05-03 13.

Page 14

14.

Page 15: Introduction

1 introduction the sgs water heater stores and heats water for sanitary purposes. Cold water enters the bottom of the tank through the water inlet (1). The heated water leaves the tank at the top through the hot water outlet (2). To operate the water heater, the operator interface (3) and control sw...

Page 16

16 user part.

Page 17: Safety

2 safety a.O. Smith cannot be held responsible for damages or injuries leading back to: failure to follow the instructions provided in this manual. Carelessness during use or maintenance of the water heater. Every user has to study the user part of this manual and has to follow the instructions in t...

Page 18

18 user part.

Page 19: Interface

3 interface 3.1 operator interface the operator interface is completely menu-driven, and comprises: a 4-line display with 20 characters per line; 6 buttons for controlling the water heater (below the display); 6 graphical symbols (above the display); a connector for a service pc; a control switch. T...

Page 20: 3.3

Name explanation solar heating system solar energy is heating the water 3.3 control switch the control switch of the controller turns the water heater on and off. Note that in the off position the water heater remains electrically live, in order for the continuous pump to stay running. After switchi...

Page 21: 3.5

3.5 pc connection the pc connection is exclusively intended to enable technicians from a.O. Smith to read the status and history of the water heater. These details can be important for troubleshooting and/or resolving complaints. 3.6 status of the water heater during operation, the display shows the...

Page 22

3.6.1.4 prog in this mode a preset week program is active, and the water heater responds continually to demand within the time periods set in the week program. There are two distinct situations possible in this mode: the current time falls within a set time period of the week program. The figure sho...

Page 23

3.6.3 service conditions the figure shows the message service required. If this message appears, the water heater needs a service and maintenance inspection. In this case, contact your service and maintenance engineer. Note regular maintenance extends the service life of the water heater. Note the m...

Page 24

24 user part.

Page 25: Use

4 use 4.1 turn on the water heater start the water heater as follows: fill the water heater (see section 7.9.1). Open the manual gas valve. Switch on the power to the water heater using the isolator between the water heater and the power supply. Switch the controller on by setting the control switch...

Page 26

Once demand is registered, the fan is started to vent any gases that may be present. This phase is called pre-purge and lasts about 15 seconds. The icon is activated. The message pre purge appears. During the pre-purge, the pressure switch closes. The icon is activated. The message pressure switch a...

Page 27: 4.2

Following the post-purge, the fan stops and the pressure switch opens: the icons and are dimmed. The message post purge vanishes. With any subsequent heat demand, the heating cycle will resume from step 1. 4.2 turn off the water heater 4.2.1 turn off for a short period to decommission the water heat...

Page 28: 4.3

Isolate the water heater from the power supply by setting the isolator between the water heater and the mains power supply to position 0. Note setting the main switch between the water heater and the electricity mains to 0 will switch off the power supply to the potentiostat; there is then no longer...

Page 30

4.3.4 week program using the week program, you can set the water temperature for the days and times you want. If the appliance is running under a week program, then this is indicated on the display by the text prog on the first line (see the figure). The second line shows the time of day, the day of...

Page 31

The display shows the menu for the week program, see the figure below. With the default setting, the program switches on and off every day at 00:00 and 23:59 respectively, the water temperature is 65ºc and the pump is switched on (p). Example as an example, we will set the switch-on time for sunday ...

Page 32

4.3.6.2 week program: setting the switch-off time use [ ] and [ ] to set the hours. In the example, this is 12. Confirm with [enter]. The cursor moves to the minute digits, which will blink. Use [ ] and [ ] to set the minutes. In the example, this is 45. Confirm with [enter]. The cursor moves to the...

Page 35

The lines showing switch-on/off times are replaced by the text delete block?. See the figure. Confirm with [enter]. (or use [reset] to cancel). The switching period has been deleted. You will return now to the week program menu. The cursor points to the first programmed period. Scroll with [ ] to st...

Page 36

Setting the switch-on time use [ ] and [ ] to set the day. In the example this is su. Confirm with [enter]. The cursor moves to the hour digits, which will blink. Use [ ] and [ ] to set the switch-on hour to the desired value. In the example, this is 08. Confirm with [enter]. The cursor moves to the...

Page 37

The cursor moves to start. Confirm with [enter]. The extra period has been programmed. Note once the extra period has completed running, the controller returns to the mode on, off or week program. The following week, the extra period will not be automatically switched back on. 4.3.10 settings using ...

Page 38

4.3.10.2 setting day and time to enter the time and day: call up the menu for entering the day and time as follows: [ ]: settings. Confirm with [enter]. The display shows the menu for settings. Scroll with [ ] and [ ] to day/time. Confirm with [enter]. The display shows the sub-menu for adjusting th...

Page 39

4.3.10.3 displaying water heater specifications note this category is solely intended for the installation engineer and/or service and maintenance engineer. The corrected data is shown in the table of general and electrical data (see section 12.1). Call up the menu to display the water heater specif...

Page 40

40 user part.

Page 41: Part

Installation, maintenance and service part 0311753_sgs_28-120_ii_ukuk_v2.0 , 2017-05-03 41.

Page 42

42 user part.

Page 43: Introduction

5 introduction 5.1 about the water heater the sgs water heater is intended for heating water for sanitary purposes. The sgs is a condensing gas–fired storage water heater with a fan in the air intake. The flue gasses transfer their heat to the water through an efficient heat exchanger. The water hea...

Page 44

Transferred to the cooler water, thereby increasing the performance of the unit. The condensate yielded by this process is discharged via the condens trap (23). Heat losses are prevented by the insulating layer (24) in both the storage tank and the water heater itself. Both are enamel-coated on the ...

Page 45: 5.4

5.4 operating cycle the water temperature (t 1 ) at the top of the water heater is used to control when the gas burner is started and stopped. The temperature changes in the water heater are used for switching the solar heating system on and off (using t 1 and s 2 ). T 1 is the curve shown in the fi...

Page 46

Note t 1 can rise above t set . However, this is only possible if t solar limit is increased via the service menu. N 46 installation, maintenance and service part.

Page 47: Safety

6 safety 6.1 safety instructions for safety instructions about the use of the water heater, refer to safety (see section 2) in the user part of this manual. Warning installation, maintenance and service must be carried out by a qualified engineer in compliance with the general and local regulations ...

Page 48: 6.2

Caution the anode protection remains active when the water heater is in off mode and the control switch is set to 0. Note any leakage from the tank and/or connections can cause damage to the immediate environment or floors below the level of the boiler room. Install the water heater above a waste wa...

Page 49: 6.3

6.3 safety devices 6.3.1 protection for the water heater 6.3.1.1 water temperature protection using temperature sensors t 1 (7) and t 2 (13), the controller monitors three temperatures that are important for safety. The table explains the functioning of the temperature sensors. Safety description an...

Page 50

Closes. Refer to the general and electric specifications in the appendices (see section 12) for the trip point for each water heater. Note the trip point of the pressure switch is not adjustable. 6.3.1.6 flame probe to ensure that no gas can flow when there is no combustion, the water heater is fitt...

Page 51

6.3.3 protection for the solar heating system 6.3.3.1 drain-back tank the solar heating system may optionally be equipped with a drain-back tank. The tank fills itself with the heating fluid when there is no heat demand. This avoids overheating of the solar heating system. The high insulation factor...

Page 52: 6.4

6.4 environmental aspects 6.4.1 recycling the packaging material is environmentally friendly, recyclable and relatively easy to discard. 6.4.2 disposal old end-of-life appliances contain materials that need to be recycled. When you discard devices at the end of their service life, you must obey loca...

Page 53: Installation

7 installation warning the installation must be done by a qualified person, in compliance with general and local applicable regulations. Caution the water heater may not be used in rooms where chemical substances are stored or used because of the risk of explosion and corrosion of the water heater. ...

Page 54

Bear in mind that the total weight of the installation always comprises a water heater complete with storage tank (completely filled with water). This maximum floor load may be between 400 and 4500 kg. This depends on the type of storage tank. 7.2.3 water composition the water must comply with the r...

Page 55

7.2.5 storage tank working clearances for access to the storage tank, it is recommended that the following clearances are observed: all sides of the storage tank: 50 cm. Above the storage tank (space for anode replacement): 100 cm. Note when installing the storage tank, be aware that any leakage can...

Page 56: 7.3

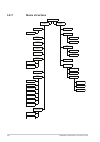

7.3 installation diagram fig. Installation diagram im d -0 7 8 7 r 0 v e n t e d u n v e n t e d a 4 1 9 1 8 e h 1 7 c s 1 3 7 11 11 1 2 1 2 t t 2 6 4 2 1 4 1 4 1 4 q t 6 8 5 5 4 4 4 4 s 4 9 9 9 g 3 3 f b s 2 s 3 d 1 0 2 1 3 1 6 c s 1 3 7 11 1 2 1 2 t t 2 6 4 2 1 4 1 4 1 4 q t 6 8 5 5 4 4 4 4 s 4 9 ...

Page 57: 7.4

Caution the installation diagram shows a pump station with an integrated non-return valve. This type of pump unit may only be used with closed systems. In systems with drain-back, installation of a pump unit with non-return valve is prohibited. There are special pump units for these systems. Please ...

Page 58

7.4.1.4 condensation drain fit a sloping waste water pipe to the condens trap (13) for condensation drainage and connect this via an open connection to the waste water discharge. Caution if the condensation drain is not fitted to the waste water discharge using an open connection, this can cause fau...

Page 59: 7.5

7.5 gas connection caution make sure that the gas supply pipe has the correct diameter and length to supply sufficient capacity to the water heater. Caution make sure that the gas supply pipe is clean. Contamination in the pipe can cause damage to the gas control valve, during operation. Caution ins...

Page 60

Installation type version description c43 closed water heaters on common air inlet and flue gas outlet (concentric and/or parallel) in a multiple floor building. C53 closed separate air inlet and flue gas outlet terminal types mixed. Air inlet and flue gas outlet termination may be in different pres...

Page 61

7.7.1 c13/c33 concentric systems use a wall terminal set or a roof terminal set to install a c13 or a c33 concentric venting system. Description concentric venting material sgs 28 - 60 sgs 80 - 120 manufacture venting material muelink & grol muelink & grol construction concentric concentric material...

Page 62

Fig. Example concentric venting system imd-0791 r0 caution during installation, obey the instructions delivered with the sets of air supply components and the flue gas discharge components. Make sure that the venting system does not exceed the maximum number of 45º and 90º bends and the maximum pipe...

Page 63

Roof terminal (2) 0311463 0306390 adapter box concentric to parallel - terminal side 0307142 0306801 adapter box concentric to parallel - water heater side 0304204 0309605 parallel pipe 500 mm 0307160 0306804 parallel pipe 1000 mm 0307161 0306802 parallel bend 45° 0310197 0308082 parallel bend 90° 0...

Page 64

2 - when the maximum total length for the default diameter of 130 mm is insufficient, diameter 150 mm should be used. Any diameter enlargement must be carried out on both air inlet and flue gas outlet. Caution always make sure the installation is in compliance with the requirements stated in this ta...

Page 65: 7.8

Concentric systems refer to the table for the correct pipe dimensions of the c43, c53 and c63 concentric systems. Description sgs 28 - 60 sgs 80 - 120 manufacture venting material muelink & grol muelink & grol construction concentric concentric material flue gas outlet thick walled aluminum thick wa...

Page 66

Fig. Terminal block a. Screws b. Cover c. Terminal block 7.8.1 preparation in preparation, you must first remove the two covers, and the cover of the electrical section. Undo the screws of the covers. Carefully remove the covers from the water heater. The electrical section is now visible. Loosen th...

Page 67

7.8.3 optional electrical connections optionally, it is possible to: connect an isolating transformer (see section 7.8.3.1). Connect a program-controlled pump (see section 7.8.3.2). Connect an external on mode switch (see section 7.8.3.3). Connect an additional error signal (see section 7.8.3.4) to ...

Page 68

7.8.3.5 communication cable to solar heating system you must connect a communication cable between the controllers of the water heater and the solar heating system. Connect the cables (x5 and x6) to terminals 23 and 24 as shown in the table (see section 7.8). Fit the cable in the strain relief. If y...

Page 69

Fit the cables in the strain relief. Continue (see section 7.8.4.4). 7.8.4.4 connecting solar collector note this sensor must be mounted in the solar collector;refer to the solar collector installation manual. Connect the sensor (s1) to the water heater as follows: connect the sensor to terminal 2 a...

Page 70: 7.9

7.8.4.8 connecting q/t sensor note you can optionally add a q/t sensor to the installation. This enables you to calculate the energy contribution of the system. For more information or to order the q/t sensor, please contact your supplier. Connect the 5v to j12-1. Connect sensor s4 to j12-2. Connect...

Page 71

The water heater is now under water supply pressure. There should now be no water coming out of the inlet combination expansion valve or (if used) out of the t&p valve (3). If there is, the cause might be: the water supply pressure is greater than the specified value (see section 12.1). Rectify this...

Page 72

Use the service menu to switch the pump on (see section 9.2.8.2). Note to ensure that the solar heating system is properly filled, the pump in the solar heating system can be switched on for 2 minutes using the service menu. Repeat steps 6 through 9 until glycol runs out of the air bleed (26). Note ...

Page 73

Imd-1097a r0 open the gas supply and vent the gas supply line via the test nipple. Connect a pressure gauge to the test nipple as soon as gas starts to flow from it. Switch on the power to the appliance using the isolator on the appliance. Switch the controller on by setting the 0/i switch to positi...

Page 74

If there is nothing else you need to check or adjust, you can put the covers back on the appliance. 7.9.3 procedure for checking the gas control valve pressure the procedure for checking the gas control valve pressure is only applicable to appliances that have a pressure-reducing valve. If the appli...

Page 75

Fig. Gas control valve pressure adjustment imd-1096b r0 7.9.4 co 2 adjustment to check the co 2 value under full load and partial load and to adjust it if necessary, proceed as follows: isolate the appliance from the power supply (see section 4.2.2). Carefully remove the covers from the appliance. T...

Page 76

Fig. Co 2 adjustment (full load) imd-1095b r0 note turning to the left (anticlockwise) means more gas (higher co 2 level) and turning to the right (clockwise) means less gas (lower co 2 level). Note note after conversion, you must check that the gas control valve is gastight. If you have increased t...

Page 77

Fig. Sgs 28 to 60 - co 2 adjustment (partial load) imd-1095c r0 fig. Sgs 80 to 120 - co 2 adjustment (partial load) imd-1097b r0 note turning to the left (anticlockwise) means more less (lower co 2 level) and turning to the right (clockwise) means more gas (higher co 2 level). Note after conversion,...

Page 78: 7.10

Start the appliance (see section 4.1). The appliance will now run the heating cycle (see section 4.1.1). Read the pressure from the meter at the moment when the appliance switches from pre purge to pressure switch. At this point, the appliance's display will show: check whether the measured value ma...

Page 79

Open the drain valve (9). 7.10.2.2 draining vented installations some service activities require the water heater to be drained. The procedure is as follows: activate the menu with [ ]. Position the cursor in front of off. Confirm off with [enter]. Wait until the fan has stopped. The icon is then di...

Page 80

Remove the hose. Note dispose of the drained glycol in an environment-friendly manner, and according to local regulations. 14. N 80 installation, maintenance and service part.

Page 81: Conversion of Gas Type

8 conversion of gas type caution conversion of the water heater may only be carried out by a qualified person. Use a special conversion kit to converse the water heater when: the water heater has to operate on a different family of gases (liquid petroleum gas or natural gas). The water heater has to...

Page 82

82 installation, maintenance and service part.

Page 83: Settings

9 settings 9.1 operator interface the operator interface is completely menu-driven and enables the user to change settings and to verify the status and history of the water heater. For more information about how to use the operator interface, refer to operator interface (see section 3). 9.2 service ...

Page 84

Please refer to the table for the regulation interval and settings for each water heater. 9.2.2 display the error history display the error history as follows: [ ]: error history the controller will display an overview of "blocking errors" and "lock out errors". In both cases, note that the controll...

Page 85

9.2.5 setting the service interval the service interval is a feature of the controller to help the service and maintenance engineer set the frequency of maintenance. The service interval is determined by the number of months that the appliance has been running. This can be set to 6, 9 and 12 months....

Page 86

To create a heat demand, you can temporarily raise the set point using [ ] to e.G. 70ºc. Confirm with .[enter]. After adjusting for the co 2 value (see section 7.9.4), you must use [ ] to restore the set point to its original value. Press [ ] twice to return to the menu menu via the service operatio...

Page 87

Now set the day and time the same way as described for setting an extra period in the week menu (see section 4.3.9). In this case however, the pump will be automatically started. Select start to start. 9.2.8 solar heating system configuration use the solar heating system settings menu to reach the m...

Page 89

9.2.9 setting the central heating configuration use this menu to specify whether a central heating system is connected to the installation. Note this function is not yet available. [ ]: settings heating. N • 0311753_sgs_28-120_ii_ukuk_v2.0 , 2017-05-03 89.

Page 90

90 installation, maintenance and service part.

Page 91: Maintenance

10 maintenance the water heater needs maintenance at least once a year. The maintenance interval is determined by the water quality, the average burning time each day and the set water temperature. On the operator interface, the maintenance interval can be set as a reminder. The display shows servic...

Page 92: 10.2

The display will now show internal check for about 10 seconds, and will then go to the main menu. Activate on mode by going through the following steps: press once on the blue arrow [ ] to position the cursor beside on, then press [enter]. Confirm the selection start operation with [enter]. If there...

Page 93: 10.3

Fig. Cleaning opening 1 imd-0080 r1 remove the cover plate (1) on the outer jacket (see the figure). Undo the bolts. Remove the cover and the gasket. Inspect the tank and remove the loose scale deposits and contamination. If the scale cannot be removed by hand, descale the water heater with a descal...

Page 94: 10.4

10.4 solar collector maintenance see installation or users' manual for the solar collector. If this topic is not covered in the manual, then contact the supplier of the collectors. 10.5 finalization to finalize the maintenance, carry out the following steps: fill the water heater (see section 7.9.1)...

Page 95: Troubleshooting

11 troubleshooting 11.1 errors and warnings the water heater can have three different kinds of errors and warnings: general errors, which are not displayed displayed errors, which are divided in two different groups: lock out errors: when the cause is removed, you can reset the error to resume opera...

Page 96

11.1.1 general errors note for the coding of the connections, refer to the electrical wiring diagram. Indication cause measure gas smell there is a gas leak close the mains gas valve at once. Do not operate any switches. No naked flames. Ventilate the boiler room. Immediately contact your installati...

Page 97

Indication cause measure insufficient or no hot water the water heater is off. Turn on the water heater (see section 4.1). There is no supply voltage. Make sure that: the control switch is set to i. The isolator is in on position. There is power on the isolator. There is power to the electrical conn...

Page 98

Code and description cause measure s06 (blocking error) open circuit from temperature sensor s 3 at the top of the storage tank. Sensor is not (correctly) connected connect the sensor lead to j14 (ports 1 and 3) of the solar controller damaged cable and/or defective sensor replace the cable and/or s...

Page 99

Code and description cause measure f02 (lock out error) fan fails to run at correct speed. Defective motor and/or rotor. Check the motor and rotor replace the fan if the motor or rotor is defective. Reset controller • • • damaged wiring check the wiring between the fan and the controller. If any wir...

Page 100

Code and description cause measure f04 (lock out error) three unsuccessful ignition attempts. No gas open the main gas supply valve and/or the manual gas supply valve before the gas control valve check supply pressure to the gas control valve if necessary, restore the gas supply • • • air in the gas...

Page 101

Code and description cause measure f11 (blocking error) flame detection with closed gas control valve. Defective gas control valves see f07. F18 (blocking error) communication error no power supply at solar controller check that there is power to the solar heating system controller 2. The measured v...

Page 102

Code and description cause measure e03 (lock-out error) error in temperature sensor t 1 at the top of the tank. The two temperature sensors in the tank detect a difference of > 10°c over a period of at least 60 seconds. Check sensor position and wiring. Reset the controller if necessary. Replace the...

Page 103

Indication cause remark collector temperature too high temperature s 1 is greater than t collector max . You can let the message disappear automatically by allowing the heating fluid to cool down. You can also manually eliminate the message by pressing the reset and enter buttons simultaneously. Non...

Page 104

104 installation, maintenance and service part.

Page 105: Appendices

12 appendices 12.1 technical details description unit sgs 28 sgs 30 sgs 50 sgs 60 general contents litres 217 368 368 368 empty weight kg 202 239 239 239 maximum floor load kg 419 607 607 607 maximum operating pressure (vented) kpa (bar) 800 (8) 800 (8) 800 (8) 800 (8) maximum operating pressure (un...

Page 106

Description unit sgs 28 sgs 30 sgs 50 sgs 60 supply voltage (-15%, +10% vac) volts 230 230 230 230 mains frequency ( ± 1hz) hz 50 50 50 50 ip class - ip 20 ip 20 ip 20 ip 20 description unit value maximum mains pressure of cold water supply (vented) kpa (bar) 800 (8) maximum mains pressure of cold w...

Page 107

Description unit sgs 80 sgs 100 sgs 120 general contents litres 480 480 480 empty weight kg 40 5 40 5 40 5 maximum floor load kg 885 885 885 maximum operating pressure (vented) kpa (bar) 800 (8) 800 (8) 800 (8) maximum operating pressure (unvented) kpa (bar) 550 (5.5) 550 (5.5) 550 (5.5) control the...

Page 108

Description unit value maximum mains pressure of the protected cold supply setup kpa (bar) 500 (5) t&p overflow pressure kpa (bar) 700 (7) t&p overflow temperature °c 97 description unit sgs 80 sgs 100 sgs 120 load profile - 3xl 3xl 3xl energy efficiency class (energy label) - - - - energy efficienc...

Page 109: 12.2

12.2 dimensions size description unit sgs 28 sgs 30 sgs 50 sgs 60 a overall height mm 1485 2015 2015 2015 c position on pallet mm 490 490 490 490 d appliance diameter mm 705 705 705 705 e depth mm 925 925 925 925 f width mm 850 850 850 850 g diameter of flue gas discharge mm 100/150 100/150 100/150 ...

Page 110

Fig. Dimensions sgs 28, 30, 50, 60 110 installation, maintenance and service part.

Page 111

Size description unit sgs 80 sgs 100 sgs 120 a overall height mm 2060 2060 2060 c position on pallet mm 530 530 530 d appliance diameter mm 850 850 850 e depth mm 1000 1000 1000 f width mm 900 900 900 g diameter of flue gas discharge mm 130/200 130/200 130/200 h height of flue gas outlet/air supply ...

Page 112

Fig. Dimensions sgs 80, 100, 120 112 installation, maintenance and service part.

Page 113: 12.3

12.3 gas details description unit sgs 28 sgs 30 sgs 50 sgs 60 gas category 2h: g20 diameter of the venturi restrictor mm - - - - nominal load ( gross ) kw 32.2 33.3 52.2 63.3 nominal output kw 31.0 32.7 50.3 60.4 supply pressure mbar 20 20 20 20 co 2 (full load) vol% 9.0 ± 1.0 9.0 ± 1.0 9.0 ± 1.0 9....

Page 114

Description unit sgs 80 sgs 100 sgs 120 gas category 2h: g20 diameter of the venturi restrictor mm 8.60 8.60 8.60 nominal load ( gross ) kw 86.6 105.5 128.8 nominal output kw 84.2 100.7 121.8 supply pressure mbar 20 20 20 co 2 (full load) vol% 8.9 ± 1.0 8.9 ± 1.0 8.9 ± 1.0 o 2 (full load) vol% 5.0 ±...

Page 115: 12.4

12.4 week program card you can cut the week program card out and keep it near the water heater. Period day time t set pump 1 on ... ºc on / off off 2 on ... ºc on / off off 3 on ... ºc on / off off 4 on ... ºc on / off off 5 on ... ºc on / off off 6 on ... ºc on / off off 7 on ... ºc on / off off 8 ...

Page 116

18 on ... ºc on / off off 19 on ... ºc on / off off 20 on ... ºc on / off off 21 on ... ºc on / off off example period day time t set pump 1 on mo 14:30 70 ºc on / off off mo 16:15 116 installation, maintenance and service part.

Page 117: 12.5

12.5 electrical wiring diagram l n l n k aa 230vac 50hz e 1 2 3 4 5 6 10 7 8 9 d c b 4 4 3 x x 4 4 x x jp8 j29 x x x jp12 jp6 x x 6 x x 6 x x 6 jp2 j19 j21 x 3 x x x x x 2 1 3 x x x 4 4 x x x 2 j20 1 4 jp5 jp4 x 6 6 x 6 6 x x 6 6 x x 6 jp3 jp11 x 6 6 x f3 x 3 x 2 f1 1 x j2 q p o s 6 6 12 11 16 15 14...

Page 118

Cable colors: components: controller connections: 1 brown a control j2 power connection for controller 2 blue b flame probe j19 extra error signal connection 3 green c hot surface igniter j20 gas control valve connection 4 black d gas control valve j21 program-controlled pump connection 5 white e bu...

Page 119: 12.6

12.6 electrical wiring diagram solar heating system cable colors: components: controller connections: 1 brown aa control j12 connection of combined q/ t sensor (1-2-3-4) 2 blue bb [vac] solar heating system pump (modulating) (230 vac) 3 green j13 connection of temperature sensor s 1 (2-4) 4 black bb...

Page 120: 12.7

12.7 menu structure control service program main menu hysterese off hysterese down on history of errors start operation change setpoint appliance history week- program select appliance start operation service interval program overview service operation extra period full load partial load settings la...

Page 121: 12.8

12.8 declaration of conformity 0311753_sgs_28-120_ii_ukuk_v2.0 , 2017-05-03 121.

Page 122: 12.9

12.9 warranty to register your water heater, you can complete and return the enclosed warranty card. You can also register your water heater on-line through the a.O. Smith website. Article 1: general warranty if, after verification and at the sole discretion of a.O. Smith, a component or part (with ...

Page 123

Contaminants or other substances having been allowed to enter the tank; the conductivity of the water being less than 125 μs/cm and/or the hardness (alkaline earth ions) of the water being less than 1.00 mmol/litre; unfiltered, recirculated water flowing through or being stored in the water heater; ...

Page 124

124 installation, maintenance and service part.

Page 125: Index

Index a about this manual............................... 7 appendices..................................... 105 c copyright...........................................3 i installation....................................... 53 p preface.............................................. 3 t trademark..........

Page 126

126 installation, maintenance and service part.