1 printed 0107 197569-000 models bt- 80 and 100 300/301 series place these instructions adjacent to heater and notify owner to keep for future reference. Commercial gas water heater glass-lined tank-type water heater • installation • operation • service • maintenance • limited warranty thank you for...

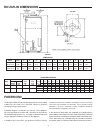

2 foreword the design of models bt-80 and 100 comply with the current edition of ansi z21.10.3-csa 4.3 as automatic storage or automatic circulating tank type water heaters. Installation diagrams are found in this manual. These diagrams will serve to provide the installer with a reference for the ma...

3 general safety information precautions do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the appliance and to replace any part of the control system and any gas control which has been under water. If the unit is exposed to the fo...

4 if you experience an out-of-gas situation, do not try to relight appliances yourself, ask your lp delivery person to relight pilots for you. Only trained lp professionals should conduct the required safety checks in accordance with industry standards. Extended non-use periods warning hydrogen gas ...

5 drain pans suitable for these heaters are available from your distributor or a. O. Smith water products company, 500 tennessee waltz parkway, ashland city, tn 37015. Water heater life depends upon water quality, water pressure and the environment in which the water heater is installed. Water heate...

6 insulation, caulking, vapor barrier, etc.), air for combustion, ventilation and draft hood dilution must be obtained from outdoors. The installation instructions for confined spaces in tightly constructed buildings must be followed to ensure adequate air supply. Confined space when drawing combust...

7 vent connection vent connections must be made to an adequate stack or chimney. Size and install proper size vent pipe. Do not reduce pipe size to less than that of the draft hood outlet. Horizontal runs of vent pipe must have a minimum upward slope toward the chimney of 1/4 inch per foot. Dampers ...

8 gas piping contact your local gas service company to ensure that adequate gas service is available and to review applicable installation codes for your area. Size the main gas line in accordance with table 1. The figures shown are for straight lengths of pipe at 0.5 in. W.C. Pressure drop, which i...

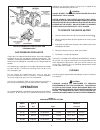

9 figure 6-thermostat for natural and propane gases gas pressure regulator the gas pressure regulator is built into the gas valve and is equipped to operate on the gas specified on model and rating plate. The regulator is factory adjusted to deliver gas to burner at correct water column pressure all...

10

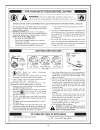

11 for your safety read before lighting • if you cannot reach your gas supplier, call the fire department. C. Use only your hand to push down or turn the gas control knob. Never use tools. If the knob will not push down or turn by hand, don’t try to repair it, call a qualified service technician. Fo...

12 it is recommended that lower water temperatures be used to avoid the risk of scalding. It is further recommended, in all cases, that the water temperature dial be set for the lowest temperature which satisfies your hot water needs. This will also provide the most energy efficient operation of the...

13 warning failure to correct back drafts may cause air contamination and unsafe conditions. • if the back draft cannot be corrected by the normal method or if a suitable draft cannot be obtained, a blower type flue gas exhauster must be employed to assure proper venting and correct combustion. High...

14 table 3 input check time required to consume 1 cu. Ft. Of gas type of btu per approx. Time required to model gas cu. Ft. Consume 1 cu. Ft. Of gas bt-80 natural 1050 50.3 sec. Propane 2500 119.8 sec. Bt-100 natural 1050 50.3 sec. Propane 2500 119.8 sec. Use this formula to “clock” the meter. Be su...

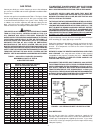

15 preventive maintenance recommended procedure for periodic removal of lime deposits from tank type commercial water heaters the amount of calcium carbonate (lime) released from water is in direct proportion to water temperature and usage, see chart. The higher the water temperature or water usage,...

16 deliming using flo-jug method un•lime in the 5 gallon size is recommended for deliming of the bt-80 and 100 models. Un•lime with the necessary hoses and fittings to delime your heater is also available as a kit: up-n-down transfer kit. Contact your local a.O. Smith dealer, distributor or, a.O. Sm...

17 if excessive, can drip into the floor shield. Also, during normal operation there may be occasions when large quantities of water are drawn, chilling the tank bottom. This too can result in condensation. • condensation, appearing in the vent pipe (water dripping from draft diverter) during heater...

18 model bt limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable w...

19.

20 a.O. Smith water products company 500 tennessee waltz parkway • ashland city, tn 37015 phone: 1-800-527-1953 www.Aosmithwaterheaters.Com • e-mail: parts@hotwater.Com.