- DL manuals

- A.O. Smith

- Water Heater

- BTC 151

- Instruction Manual

A.O. Smith BTC 151 Instruction Manual

commercial gas water heaters

instruction manual

PRINTED 0912

196308-002

place these instructions adjacent to heater and notify owner to keep for future reference.

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

This manual must remain with the

water heater.

models Btr(c) 151, Btr(c) 201

series 100/101

installation - operation - serVice

- maintenance - limited warranty

500 Tennessee Waltz Parkway

Ashland City, TN 37015

Low Lead Content

Thank you for buying this energy efficient water heater.

We appreciate your confidence in our products.

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do

not use any phone in your building.

Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot reach your gas supplier,

call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

•

•

•

•

Summary of BTC 151

Page 1

Commercial gas water heaters instruction manual printed 0912 196308-002 place these instructions adjacent to heater and notify owner to keep for future reference. Read and understand this instruction manual and the safety messages herein before installing, operating or servicing this water heater. F...

Page 2: Table Of Contents

2 outdoor air through two vertical ducts .......................................... 17 air from other indoor spaces ......................................................... 17 technical data venting .................................................................... 18 water heater installation .....

Page 3: Approvals

3 safe installation, use and service the proper installation, use and servicing of this water heater is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and others of ...

Page 4: General Safety Information

4 general safety information fire hazard do not install water heater on carpeted floor. Do not operate water heater if flood damaged. For continued protection against risk of fire: fire or explosion hazard read instruction manual before installing, using or servicing water heater. Avoid all ignition...

Page 5: General Safety Information

5 precautions do not use this water heater if any part has been under water. Immediately call a qualified service agency to inspect the water heater and to make a determination on what steps should be taken next. If the unit is exposed to the following, do not operate heater until all corrective ste...

Page 6: Introduction

6 thank you for purchasing this water heater. Properly installed and maintained, it should give you years of trouble free service. Abbreviations used abbreviations found in this instruction manual include : • ansi - american national standards institute • asme - american society of mechanical engine...

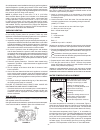

Page 7: Features And Components

7 the eliminator (self-cleaning system) these units include the eliminator (self-cleaning system) installed in the front water inlet, see figure 1. The eliminator inlet tube can only be used in the front water inlet connection. Do not install the eliminator inlet tube in either the top or back inlet...

Page 8: Installation Considerations

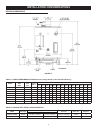

8 rough in dimensions table 2. Gas and electrical characteristics model gas type gas supply pressure gas manifold pressure volts / hz amperes minimum maximum btr(c) 151/201 natural 5.6" w.C. (1.39 kpa) 14" w.C. (3.48 kpa) 3.5" w.C. (0.87 kpa) 120/60 btr(c) 151/201 propane 11" w.C. (2.74 kpa) 14" w.C...

Page 9: Caution

9 is not subject to physical damage by a moving vehicle. Flammable items, pressurized containers or any other potential fire hazardous articles must never be placed on or adjacent to the heater. Open containers or flammable material should not be stored or used in the same room with the heater. The ...

Page 10

10 insulation blanket do not obstruct water heater air intake with insulating blanket. Gas and carbon monoxide detectors are available. Install water heater in accordance with the instruction manual. Breathing carbon monoxide can cause brain damage or death. Always read and understand instruction ma...

Page 11

11 breathing hazard - carbon monoxide gas breathing carbon monoxide can cause brain damage or death. Always read and understand instruction manual. Under no circumstances should the input exceed the rate shown on the water heater’s rating label. Overfiring could result in damage to the water heater ...

Page 12: Installation Requirements

12 5. When installing multiple water heaters in the same gas supply system it is recommended that individual positive lock-up gas pressure regulators be installed at each unit. Power supply the water heaters covered in this manual require a 120 vac, 1Ø (single phase), 60hz, 15 amp power supply and m...

Page 13

13 hot water outlet to tank inlet check valve mixing valve cold water inlet tempered water outlet 12” to 15” (30-38 cm) check valve figure 10. Dishwashing machines all dishwashing machines meeting the national sanitation foundation requirements are designed to operate with water flow pressures betwe...

Page 14: Caution

14 no valve or other obstruction is to be placed between the temperature-pressure relief valve and the tank. Do not connect discharge piping directly to the drain unless a 6” (15.2 cm) air gap is provided. To prevent bodily injury, hazard to life, or property damage, the relief valve must be allowed...

Page 15: Venting Installation

15 for the openings is dependent on the method used to provide fresh air to the confined space and the total btu/hr input rating of all appliances installed in the space. Exhaust fans where exhaust fans are installed, additional air shall be provided to replace the exhausted air. When an exhaust fan...

Page 16

16 vent with an oil burning furnace, the vent pipe should enter the smaller common vent or chimney at a point above the large vent pipe. Multiple heater manifold figure 12 and table 6 should be used for horizontally manifolding two or more heaters. Figure 12. Fresh air openings for confined spaces t...

Page 17

17 when ducts are used, they shall be of the same cross sectional area as the free area of the openings to which they connect. The minimum dimension of rectangular air ducts shall be not less than 3 inches. Air from other indoor spaces figure 17. The confined space shall be provided with two permane...

Page 18

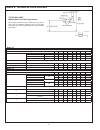

18 technical data venting type b gas vent multiple gas fired tank-type heaters when venting multiple tank type heaters using type b vent pipe, follow the installation diagram (figure 12) and tables below which give sizing and data based upon nfpa 54/ansi z223. 2006. Table 6. Technical data venting m...

Page 19: Water Heater Installation

19 water heater installation remote storage tank that may be installed and piped to a water heating appliance must also have its own properly sized, rated and approved temperature-pressure relief valve installed. Call the toll free technical support phone number listed on the back cover of this manu...

Page 20

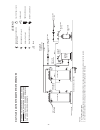

20 installation diagrams - top inlet/outlet usage use of the top inlet water connection requires an inlet dip tube (refer to figure 18). The tube is supplied in the heater. Follow caution labels if applying heat to this fitting. Do not allow pipe dope to contact the plastic tube during installation....

Page 21

21 heater wiring all electrical work must be installed in accordance with the latest version of the national electrical code ansi/nfpa no. 70 and must conform to all local code authority having jurisdiction. An electrical ground is required to reduce risk of electrical shock or possible electrocutio...

Page 22

22 gas piping contact your local gas service company to ensure that adequate gas service is available and to review applicable installation codes for your area. Size the main gas line in accordance with table 7. The figures shown are for straight lengths of pipe at 0.5 in. W.C. Pressure drop, which ...

Page 23: Start Up

23 prior to start up installation and start up of this water heater requires abilities and skills equivalent to that of a licensed tradesman in the field involved, see qualifications on page 6. Do not place the water heater in operation if any part has been under water. Immediately call a qualified ...

Page 24

24 checking the input for appliance installation locations with elevations above 2000 feet, refer to high altitude installations section of this manual for input reduction procedure. 1. Attach a pressure gauge or a manometer to the manifold pressure tap on the gas valve and refer to table 3, for cor...

Page 25: Sequence Of Operation

25 sequence of operation the following information will describe the sequence of operation for this appliance. 1. Switch power on to unit. 2. Thermostat calls for heat. 3. Ignition control board performs diagnostic check on system components. 4. On completion of diagnostics check, the ignition contr...

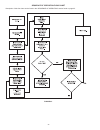

Page 26

26 sequence of operation flow chart description of this flow chart can be found in the “sequence of operation” section found on page 25. Figure 23..

Page 27: Maintenance

27 maintenance check the igniter assembly and main burners at least once a year, check the igniter assembly, figure 24, and the main burner, figure 25, for proper operation. Refer to the following igniter assembly and main burner sections. Igniter assembly for access to igniter assembly, unfasten tw...

Page 28: Caution

28 explosion hazard temperature-pressure relief valve must comply with ansi z21.22- csa 4.4 and asme code. Properly sized temperature- pressure relief valve must be installed in opening provided. Can result in overheating and excessive tank pressure. Can cause serious injury or death. Hot water odor...

Page 29

29 lime accumulation not only reduces the life of equipment but also reduces efficiency of the heater and increases fuel consumption. The usage of water softening equipment greatly reduces the hardness of the water. However, this equipment does not always remove all of the hardness (lime). For this ...

Page 30

30 threads. Tighten firmly by hand and use wrench or adjustable pliers to check for secure connection. Do not over tighten to avoid damage to threads and fittings. Prepare the up-n-down transfer kit the next step is the preparation on the up-n-down transfer kit, if you have not already done so: 1. W...

Page 31: Service

31 service the installer may be able to observe and correct certain problems which may arise when the unit is put into operation. However, it is recommended that only qualified service agents, using appropriate test equipment, be allowed to service the heater. As preliminary step, check wiring again...

Page 32: For Your Information

32 start up conditions smoke/odor it is not uncommon to experience a small amount of smoke and odor during the initial start-up. This is due to burning off of oil from metal parts, and will disappear in a short while. Strange sounds possible noises due to expansion and contraction of some metal part...

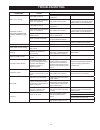

Page 33: Troubleshooting

33 troubleshooting complaint cause remedy user qualified service agency *water not hot enough thermostat set too low. Set thermostat dial to a higher temperature upper and/or lower temperature probe out of calibration. Call qualified service agency check continuity and resistance (ohms) of upper and...

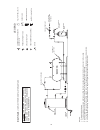

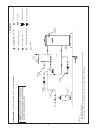

Page 34: Water Piping Diagrams

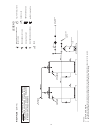

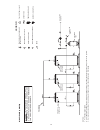

34 water piping diagrams n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4...

Page 35

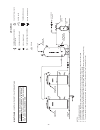

35 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4. The t ank t empera t...

Page 36

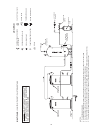

36 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4. The t ank t empera t...

Page 37

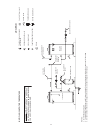

37 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4. The t ank t empera t...

Page 38

38 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4. The t ank t empera t...

Page 39

39 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4. The t ank t empera t...

Page 40

40 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4. The t ank t empera t...

Page 41

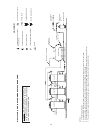

41 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . Mu lti flue (2 units) t...

Page 42

42 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . Mu lti f lue (2 units) ...

Page 43

43 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . Mu lti-f lue (3 units) ...

Page 44

44 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4. The t ank t empera t...

Page 45

45 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4. The t ank t empera t...

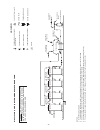

Page 46

46 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . Mu lti f lue f lue (4 u...

Page 47

47 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4. The t ank t empera t...

Page 48

48 n otes : 1. P re ferred piping diagram . 2. The tempera ture and pre ss ure relie f valve se tting shall no t exceed pressure ra ting o f any componen t in the sys tem . 3. S ervi ce v al ves are s hown for ser vicing uni t. Howeve r, local codes shall govern their usage . 4. The t ank t empera t...

Page 49: Manifold Kits

49 manifold kits manifold kits two unit manifold kit (part no. 9003426205) three unit manifold kit (part no. 9003427205) four unit manifold kit (part no. 9003428205) model dimensions "a" 151/201 45.0".

Page 50: Limited Warranty

50 limited warranty limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from p...

Page 51: Notes

51 notes.

Page 52

Www.Hotwater.Com 500 tennessee waltz parkway, ashland city, tn 37015 tech support: 800-527-1953 parts: 800-433-2545 copyright © 2012 a. O. Smith water heater company, all rights reserved..