1 printed in u.S.A. 0901 part no. 194643-000 thank you for buying this energy efficient water heater from a.O. Smith water products company. We appreciate your confidence in our products. Caution text printed or outlined in red contains information relative to your safety. Please read thoroughly bef...

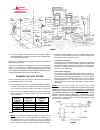

2 rough-in-dimensions foreword the design of model btf-75 complies with the latest version of ansi z21.10.3/csa 4.3 m98 as automatic storage or automatic circulating tank type water heaters. Installation diagrams are found in this manual. These diagrams will serve to provide the installer with a ref...

3 general safety information precautions do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the appliance and to replace any part of the control system and any gas control which has been under water. If the unit is exposed to the fo...

4 if you experience an out-of-gas situation, do not try to relight appliances yourself. Ask your lp delivery person to relight pilots for you. Only trained lp professionals should conduct the required safety checks in accordance with industry standards. Extended non-use periods warning hydrogen gas ...

5 the heater is design certified by the canadian standards for installation on combustible flooring in a closet having minimum clearances from combustible material of: 2" clearance from sides and rear, 6" from the front and 24" from the top. (standard clearance.) if clearances stated on the heater d...

6 closed water system a closed system will exist if a back-flow preventer (check valve), pressure reducing valve, or other similar device is installed in the cold water line between the water heater and the street main (or well). Excessive pressure may develop due to the thermal expansion of heated ...

7 5. The vent termination shall not be mounted directly above or within 3 feet horizontally from an oil tank vent or gas meter to avoid potential freeze-up from condensation. Plan the vent system layout so that proper clearances are maintained from plumbing and wiring. Vent pipes serving power vente...

8 pvc materials should use astm d-2564 grade cement; cpvc materials should use astm f-493 grade cement and abs materials should use astm d-2235 grade cement. Note: 1. For water heaters in locations with high ambient temperatures (above 100°f) and/or insufficient dilution air, it is recommended that ...

9 power vent wiring schematic - figure 7 a. Remove two screws that secure side plate on control box and remove plate. B. Cut flexible power cord on inside of control box, as close to inside wall as possible. C. If flexible cord and strain relief are removed, then opening in box must be covered. D. R...

10 installation of vent system, sidewall with the route of the venting system and selection of materials completed, as discussed in section of this manual titled planning the vent system, the through the wall vent terminal in place and the first section of piping, up to first elbow, installed at the...

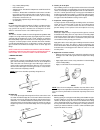

11 • rag - cotton (not synthetic) • primer and cleaner • solvent cement - pvc for pvc components and cpvc for cpvc components • containers - metal or glass to hold primer and cement. Select the type of pvc or cpvc materials to be used on the basis of their application with respect to chemical resist...

12 g. Cleanup and joint movement remove all excess cement from around the pipe and fitting with a dry cotton rag. This must be done while the cement is still soft. The joint should not be disturbed immediately after the cementing procedure, and sufficient time should be allowed for proper curing of ...

13 warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. • immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions. • if you cannot reach your gas supplier, call th...

14 purging gas line purging is required with new piping or systems in which air has entered. Caution purging should be performed by persons experienced in this type of gas service. To avoid risk of fire or explosion, purge discharge must not enter confined areas or spaces where ignition can occur. T...

15 high temperature cut-off switch the thermostat has a built-in temperature cut-off switch (tco), which will shut off gas to the burner in case of excessive water temperature. If the tco functions the valve will flash 4 times and the valve must be replaced. It is important that a serviceman be call...

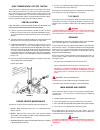

16 should the main burner or burner air openings require cleaning, remove the burner and clean with a soft brush. Clean main burner orifice with a suitable soft material. Check for good flow of combustion and ventilating air to the unit. Maintain a clear open area around the heater at all times. Do ...

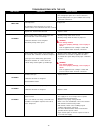

17 not enough or no hot water vent pipe too hot (above 170° f) yellow flame condensation water leaks leaking t&p valve hot water odors or color (refer to cathodic protection) problem possible malfunction service to be performed 1) blower will not run a ) “on/off” control switch turned off b) blower ...

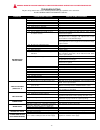

18 off brite - dm 1 flash 2 flashes 3 flashes 4 flashes 5 flashes 6 flashes led status indicates check/repair no power to system control. Normal operation this indication shows whenever the system is powered, unless some abnormal event has occurred. Setpoint error, internal failure detected. Airflow...

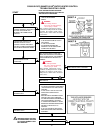

19 sv9560/sv9570 smartvalve ® water heater control troubleshooting guide start l check for proper voltage at control harness (see inset a). Voltage should be 120v between 120v common and 120v hot. Turn on gas supply plug harness into smartvalve ® control. Initiate a request for heat. Combustion blow...

20 a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable water therein, during the f...