- DL manuals

- A.O. Smith

- Water Heater

- BTH-120 through BTH-500

- Instruction Manual

A.O. Smith BTH-120 through BTH-500 Instruction Manual

commercial gas water heaters

instruction manual

PRINTED 1012

197727-003

place these instructions adjacent to heater and notify owner to keep for future reference.

Thank you for buying this energy efficient water heater.

We appreciate your confidence in our products.

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

This manual must remain with the

water heater.

models

Bth-120/150/199/250

series 100 & 101

installation - operation - serVice

- maintenance - limited warranty

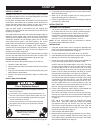

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do

not use any phone in your building.

Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot reach your gas supplier,

call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

•

•

•

•

500 Tennessee Waltz Parkway

Ashland City, TN 37015

www.hotwater.com

Summary of BTH-120 through BTH-500

Page 1

Commercial gas water heaters instruction manual printed 1012 197727-003 place these instructions adjacent to heater and notify owner to keep for future reference. Thank you for buying this energy efficient water heater. We appreciate your confidence in our products. Read and understand this instruct...

Page 2: Table Of Contents

2 direct vent installation ..................................................................... 25 vertical termination installation ....................................................... 27 sidewall termination installation...................................................... 29 concentric termi...

Page 3: Approvals

3 safe installation, use and service the proper installation, use and servicing of this water heater is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and others of ...

Page 4: General Safety Information

4 precautions do not use this water heater if any part has been under water. Immediately call a qualified service agency to inspect the water heater and to make a determination on what steps should be taken next. If the unit is exposed to the following, do not operate heater until all corrective ste...

Page 5: General Safety Information

5 general safety information fire hazard do not install water heater on carpeted floor. Do not operate water heater if flood damaged. For continued protection against risk of fire: fire or explosion hazard read instruction manual before installing, using or servicing water heater. Avoid all ignition...

Page 6: Introduction

6 thank you for purchasing this water heater. Properly installed and maintained, it should give you years of trouble free service. Abbreviations used abbreviations found in this instruction manual include : • ansi - american national standards institute • asme - american society of mechanical engine...

Page 7: Features And Components

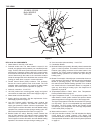

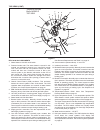

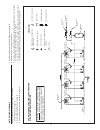

7 basic operation the water heaters covered in this manual have a helical coil shaped heat exchanger that is submerged in the storage tank. The water heater’s main burner is a radial design burner, it is mounted on the top and fires downward through the heat exchanger. This is a forced draft burner;...

Page 8

8 10. Vent connection (exhaust elbow) - 3 inch pvc. 11. Combustion blower. 12. Blocked exhaust (vent) switch. Normally closed contacts that open on a rise in pressure. This switch is used to insure the exhaust (vent) piping connected to the water heater is not restricted. The control system monitors...

Page 9

9 gas pressure requirements and table 3 on page 12. 10. Vent connection (exhaust elbow) - 3 inch pvc. 11. Intake air connection - 3 inch pvc. 12. Blocked exhaust (vent) switch. Normally closed contacts that open on a rise in pressure. This switch is used to insure the exhaust (vent) piping connected...

Page 10

10 9. Temperature-pressure relief valve discharge pipe - see t&p valve discharge pipe requirements: on page 16. 10. Lower temperature probe, 1 of 2 temperature probes. The water heater’s control system monitors this probe to detect water temperature in the lower portion of the storage tank. 11. Wate...

Page 11: Installation Considerations

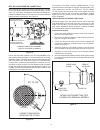

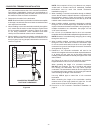

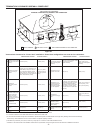

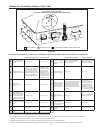

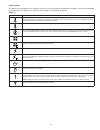

11 rough in dimensions installation considerations front back cleanout t & p valve 3/4” npt drain 1 1/2” npt water inlet vent connection 3 inch pvc (exhaust elbow) condensate drain connection 1/2 inch pvc intake air connection 3 inch pvc supply gas connection e h d c a i g f b water outlet height th...

Page 12: Caution

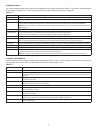

12 storage capacities table 2 model u. S. Gallons liters bth 120 60 227 bth 150 100 379 bth 199 100 379 bth 250 100 379 gas line connection size table 1 † model series natural gas propane gas bth 120 100/101 3/4 "npt 3/4 "npt bth 150 100/101 3/4 "npt 3/4 "npt bth 199 100/101 3/4 "npt 3/4 "npt bth 25...

Page 13

13 there is a risk in using fuel burning appliances such as gas water heaters in rooms, garages or other areas where gasoline, other flammable liquids or engine driven equipment or vehicles are stored, operated or repaired. Flammable vapors are heavy and travel along the floor and may be ignited by ...

Page 14: Installation Requirements

14 1. Positive lock-up gas pressure regulators must be rated at or above the input btu/hr rating of the water heater they supply. 2. Supply gas regulators shall have inlet and outlet connections not less than the minimum supply gas line size for the water heater they supply. See table 8, page 23. 3....

Page 15

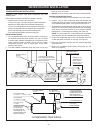

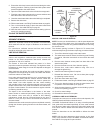

15 hot water outlet to tank inlet check valve mixing valve cold water inlet tempered water outlet 12” to 15” (30-38 cm) check valve figure 8 the national sanitation foundation also recommends circulation of 180°f (82°c) water. Where this is done, the circulation should be very gentle so that it does...

Page 16: Caution

16 water in adequate quantities should circumstances demand. If the discharge pipe is not connected to a drain or other suitable means, the water flow may cause property damage. Water damage hazard temperature-pressure relief valve discharge pipe must terminate at adequate drain. • caution t&p valve...

Page 17

17 condensate drain the water heaters covered in this manual are condensing appliances and require a building drain to be located in close proximity to allow the condensate to drain safely. Condensate drains from the water heater at the exhaust elbow located at the bottom. The field installed conden...

Page 18

18 unusually tight construction in unconfined spaces in buildings, infiltration may be adequate to provide air for combustion, ventilation and dilution of flue gases. However, in buildings of unusually tight construction (for example, weather stripping, heavily insulated, caulked, vapor barrier, etc...

Page 19

19 alternatively a single permanent opening, commencing within 12 inches (300 mm) of the top of the enclosure, shall be provided. See figure 11. The water heater shall have clearances of at least 1 inch (25 mm) from the sides and back and 6 inches (l50 mm) from the front of the water heater. The ope...

Page 20

20 when ducts are used, they shall be of the same cross sectional area as the free area of the openings to which they connect. The minimum dimension of rectangular air ducts shall be not less than 3 inches (7.62 cm). Air from other indoor spaces figure 14 the confined space shall be provided with tw...

Page 21

21 commonwealth of massachusetts for all side wall terminated, horizontally vented power vent, direct vent, and power direct vent gas fueled water heaters installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the co...

Page 22: Venting Installation

22 2. If the water heater is to be installed in a beauty shop, barber shop, cleaning establishment, a laundry with dry cleaning equipment or any space with contaminated air it is imperative that the water heater(s) be installed in a direct vent configuration so that all air for combustion is derived...

Page 23

23 the intake air tee fitting is factory installed with the 1/2 inch branch and hose barb angled to the right at approximately 130° when viewed from the end, see figure 16. The tee fitting's 1/2 inch branch and hose barb must not be angled any lower (towards the ground) than this factory specificati...

Page 24

24 equivalent feet (36.5 m). Ie: on direct vent installations both pipes can be up to 120 equivalent feet (36.5 m). Minimum equivalent lengths three inch pipe the water heaters covered in this manual are certified to a minimum length of 3 inch pipe for the vent (exhaust) of 7 equivalent feet (2.1 m)...

Page 25

25 9. All vent (exhaust) pipes must be pitched a minimum of a 1/4 inch per foot back to the water heater (to allow drainage of condensate). 10. If installing 3 inch vent pipe connect the vent pipe to the exhaust elbow on the water heater. 11. If installing 4 inch pipe transition to 3 inch pipe at th...

Page 26

26 14. If installing 3 inch intake air pipe connect the intake air pipe to the intake air connection on the water heater. 15. If installing 4 inch intake air pipe transition to 3 inch pipe at the intake air connection on the water heater as shown in figure 20. The field installed 3” pipe between the...

Page 27

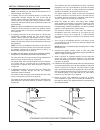

27 vertical termination installation 1. Determine the location for the termination(s). Note: the standard vent and intake air terminations are of different design, see figure 22. 2. If installing only the vent (exhaust) piping in a power vent configuration vertically through the roof; ensure that al...

Page 28

28 2” (5 cm) maximum factory supplied standard termination pointed down towards the ground vertical termination(s) installation intake air and/or vent (exhaust) field supplied 90° elbow field supplied strap/support field supplied plumbing roof boot or flashing maintain 12” (30 cm) 18” (45 cm) for ca...

Page 29

29 sidewall termination installation 1. Determine the location for the termination(s). Note: the standard vent and intake air terminations are of different design, see figure 22 on page 27. 2. If installing only vent (exhaust) piping in a power vent configuration through a sidewall; ensure that all ...

Page 30

30 note: if this required 10 foot (3 m) distance to a parapet, vertical wall or structure cannot be maintained, standard terminations must be used. See vertical termination installation on page 27. 5. When installing a concentric termination through a sidewall; ensure that all exterior sidewall clea...

Page 31

31 4 inch concentric termination installation 4 inch concentric termination kit four piece kit - field assembly required vent pipe intake air connection 3 inch pvc vent connection - 3 inch pvc intake air pipe y fitting assembly vent cap vent pipe assembly vent pipe is 2 1/2 inch sdr-26 pipe supplied...

Page 32

32 four concentric terminations 1. When installing four concentric terminations through a roof or through a sidewall in close proximity they may be arranged into stacked rows of two as shown in figure 34 or lateral rows of two as shown in figure 35. 2. Four is the maximum number of concentric termin...

Page 33

33 sidewall roof figure 38 eight concentric terminations eight concentric terminations may be installed in two stacked groups of four, in close proximity, as shown in figure 39. See figure 36 on page 32 for detailed information on clearances. Lateral groups of four as shown in figure 35 on page 32 m...

Page 34

34 venting arrangements power vent vertical figure 40 direct vent vertical figure 42 power vent horizontal figure 41 direct vent horizontal figure 43.

Page 35

35 venting arrangements direct vent vertical vent horizontal intake figure 44 direct vent vertical concentric figure 46 direct vent horizontal vent vertical intake figure 45 direct vent horizontal concentric figure 47.

Page 36

36 termination clearances sidewall power vent v x vent terminal air supply inlet area where terminal is not permitted v v a g v fixed closed fixed closed operable operable v c b b b b f b v v a j v h m x x v v k b e d l power vent (using room air for combustion) exterior clearances for sidewall vent...

Page 37

37 termination clearances sidewall direct vent v x vent terminal air supply inlet area where terminal is not permitted v v a g v fixed closed fixed closed operable operable v c b b b b f b v v a j v h m x x v v k b e d l direct vent (using outdoor air for combustion) exterior clearances for sidewall...

Page 38: Water Heater Installation

38 water heater installation than 1/2 inch pvc in size. 3. Do not remove, modify or alter the factory condensate trap. Installation instructions 1. Ensure the water heater’s on/off switch is in the “off” position. 2. Install a 1/2 inch pvc condensate drain line between the condensate drain connectio...

Page 39

39 supply gas line installation contact your local gas utility company to ensure that adequate gas service is available and to review applicable installation codes for your area. Be sure that the gas meter has sufficient capacity to supply the rated gas input of the water heater as well as the requi...

Page 40

40 gas line connection 1. The water heaters covered by this manual are shipped from the factory with 3/4 inch supply gas connections. The supply gas line must not be smaller than 3/4 inch. Connect the supply gas line to the water heater's 24 volt gas valve in accordance with all applicable local and...

Page 41

41 (ie: relay coil) to this circuit. This will damage the ccb and is not covered under the limited warranty. Connecting an external supervisory control the enable/disable circuit is accessed from the ccb’s j6 plug inside the ccb enclosure, see beginning on page 8 to locate the ccb enclosure. From th...

Page 42: Caution

42 t&p valve discharge pipe explosion hazard temperature-pressure relief valve must comply with ansi z21.22- csa 4.4 and asme code. Properly sized temperature- pressure relief valve must be installed in opening provided. Can result in overheating and excessive tank pressure. Can cause serious injury...

Page 43: Temperature Regulation

43 setting the operating set point at 120°f (49°c) will reduce the risk of scalds. Some states require settings at specific lower temperatures. Table 10 water temperature °f (°c) time for 1st degree burn (less severe burns) time for permanent burns 2nd & 3rd degree (most severe burns) 110 (43) (norm...

Page 44: Control System Operation

44 or cancel new user settings. The operational buttons are multifunctional, their current function is defined by the text that appears directly above each button on the lcd screen. The desktop screen during normal operation the control system will display the "desktop" screen on the lcd which is th...

Page 45

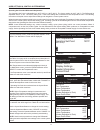

45 status icons the status icons are displayed on the desktop screen and convey operational and diagnostic information. The icons are described in the table below. See figure 56 on page 44 and the sequence of operation on page 58. Table 11 icon description water temperature in the tank has fallen. S...

Page 46

46 operating states the current operational state of the water heater is displayed on the desktop screen as the "status." the common operational states are described in the table below. See figure 56 on page 44 and the sequence of operation on page 58. Table 12 state description standby the water he...

Page 47

47 user settings & control system menus temperatures menu operating set point and differential adjustment the operating set point is adjustable from 90°f (42°c) to 180°f (82°c). The factory setting is 120°f (49°c). The differential is adjustable from 2° to 20°. The factory setting is 8°. These user ...

Page 48

48 temperatures menu (cont) description/action display • tank temperature - non adjustable - control system sensed temperature (averaged from upper and lower temperature probes). • upper temperature - non adjustable - control system sensed temperature from the upper temperature probe. • lower temper...

Page 49

49 display settings description/action display select display settings from the main menu and press the operational button under "select" to enter this menu. This menu contains adjustable display options for viewing information on the uim’s lcd screen. Use the up & down buttons to navigate the menu....

Page 50

50 current fault description/action display select current fault from the main menu and press the operational button under "select" to enter this menu. This menu contains non adjustable operational information. Use the up & down buttons to navigate the menu. This menu contains the current fault or a...

Page 51

51 service contact information the control system has a discrete menu that installing contractors and/or service agents can access to enter contact information for their customers. This contact information will be displayed with all fault and alert messages. Description/action display from the deskt...

Page 52: Start Up

52 prior to start up installation and start up of this water heater requires abilities and skills equivalent to that of a licensed tradesman in the field involved, see qualifications on page 6. Do not place the water heater in operation if any part has been under water. Immediately call a qualified ...

Page 53

53 8. Compare the actual supply gas pressure reading recorded above to the required minimum/maximum values given in table 3 on page 12. Adjust supply gas pressure as necessary, see supply gas pressure adjustment on page 54. 9. When complete turn off gas to the water heater, see instructions on page ...

Page 54

54 supply gas pressure adjustment fire and explosion hazard turn off gas lines during installation. Contact a qualified installer or service agency for installation and service. Excessive gas pressure to gas valve can cause serious injury or death. Do not use water heater with any gas other than the...

Page 55

55 checking the firing rate if firing rate adjustment is required follow these instructions to determine the actual firing rate of the water heater: 1. Ensure there are no other gas fired appliances connected to the gas meter firing during this test. 2. Contact the gas supplier to determine the heat...

Page 56: Lighting The Water Heater

56 lighting the water heater off reg adjust on f l o w for your safety read before operating to turn off gas to appliance operating instructions wait five (5) minutes to clear out any gas. If you then smell gas, stop! Follow “b” in the safety information above on this label. If you don’t smell gas, ...

Page 57: Lighting The Water Heater

57 tank temperature 103°f operating set point 120°f status: heating menu help up dn gas off o n model information on/off switch for your safety read before operating to turn off gas to appliance operating instructions if you do not follow these instructions exactly a fire or explosion may result cau...

Page 58: Troubleshooting

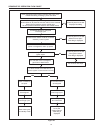

58 sequence of operation read the sequence of operation below before attempting to correct any operational problems. Refer to the features and components section beginning on page 7 for the location of various water heater components described below. See the sequence of operation flow chart on page ...

Page 59

59 sequence of operation flow chart yes no water is heated to set point 24 volt gas valve de-energized 30 second inter-purge cycle 24 volt gas valve de-energized retries up to two more times 30 second post-purge cycle control system locks out “ignition failure” fault msg is displayed water heater go...

Page 60: Caution

60 • excessive manifold gas pressure - see table 3 on page 12 and manifold gas pressure adjustment on page 54. • vent (exhaust) gas recirculation at the vent and intake air pipe terminations on direct vent installations - see direct vent installation on page 25. • excessive equivalent lengths of int...

Page 61

61 alert conditions when the control system declares an alert condition it will display an alert message on the control system's lcd with a question "?" mark. The water heater will continue to operate during an alert condition but the water heater must be serviced by a qualified service agent as soo...

Page 62

62 fault and alert messages call the technical support phone number listed on the back cover for further technical assistance or to locate a qualified service agent in your area. Possible causes - check/repair displayed fault/alert message • the water heater’s control system is polarity sensitive an...

Page 63

63 fault and alert messages (cont) call the technical support phone number listed on the back cover for further technical assistance or to locate a qualified service agent in your area. Possible causes - check/repair displayed fault/alert message • the control system has detected the blower prover s...

Page 64: Maintenance

64 maintenance schedule table 14 component operation interval required tank sediment removal semi annually flushing tank lime scale removal semi annually un-lime® anode rods inspection cleaning annually clean scale deposits t&p valve test operation semi annually test vent system inspection annually ...

Page 65

65 tank cleanout opening cleanout cover cleanout gasket cleanout access panel figure 63 manual lime scale removal note: contact your local distributor or call the parts department phone number on the back cover of this manual to order a new cleanout gasket. Have the new gasket available before remov...

Page 66

66 discharge pipe temperature-pressure relief valve figure 64 if the temperature-pressure relief valve on the water heater weeps or discharges periodically, this may be due to thermal expansion. Note: excessive water pressure is the most common cause of temperature-pressure relief valve leakage. Exc...

Page 67: Diagrams

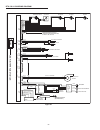

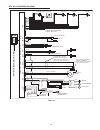

67 diagrams ccb - central control board layout 1 retry use yes type tstat spare ext input 3 retries no vent spare op en 1 2 3 4 3 2 1 6 5 4 9 8 7 12 11 10 15 14 13 j6 j7 3 2 4 1 1 2 j15 8 4 5 6 7 1 2 3 j13 3 4 1 2 j10 1 3 5 2 4 j1 1 3 4 2 j2 1 4 2 1 2 j3 j5 j4 s1 dipswitch j16 j9 j11 s1 dipswitch de...

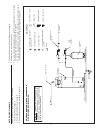

Page 68

68 bth 120 & 150 wiring diagram 2 green white red black 1 1 2 black 3 white combustion blower upper temperature probe 1 red (eco) 4 red (eco) 2 black 3 black 1 black120 vac hot 3 white 120 vac neutral 4 yel 24 vac 4 yel 24 vac lower temperature probe hot surface igniter flame sensor blocked air inta...

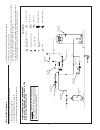

Page 69

69 bth 199 & 250 wiring diagram 2 green white red black 1 1 2 black 3 white combustion blower upper temperature probe 1 red (eco) 4 red (eco) 2 black 3 black 1 black120 vac hot 3 white 120 vac neutral 4 yel 24 vac 4 yel 24 vac lower temperature probe hot surface igniter flame sensor blocked air inta...

Page 70

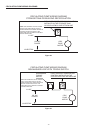

70 circulation pump wiring diagrams figure 68 figure 69 circulating pump wiring diagram storage tank or building recirculation field supplied temperature control installed in the storage tank or circulating loop return line circ pump motor l1 hot l2 neutral 120 vac power note: use separate 120 vac p...

Page 71

71 4. See closed systems and thermal expansion on page 15. 5. See w ater line connections on page 42. 6. If a pump is being installed between a water heater and storage tank or on a building recirculation loop wire according to figure 68 on page 70. 7. If a pump is being installed in a recirculation...

Page 72

72 4. See closed systems and thermal expansion on page 15. 5. See w ater line connections on page 42. 6. If a pump is being installed between a water heater and storage tank or on a building recirculation loop wire according to figure 68 on page 70. 7. If a pump is being installed in a recirculation...

Page 73

73 4. See closed systems and thermal expansion on page 15. 5. See w ater line connections on page 42. 6. If a pump is being installed between a water heater and storage tank or on a building recirculation loop wire according to figure 68 on page 70. 7. If a pump is being installed in a recirculation...

Page 74

74 4. See closed systems and thermal expansion on page 15. 5. See w ater line connections on page 42. 6. If a pump is being installed between a water heater and storage tank or on a building recirculation loop wire according to figure 68 on page 70. 7. If a pump is being installed in a recirculation...

Page 75

75 4. See closed systems and thermal expansion on page 15. 5. See w ater line connections on page 42. 6. If a pump is being installed between a water heater and storage tank or on a building recirculation loop wire according to figure 68 on page 70. 7. If a pump is being installed in a recirculation...

Page 76

76 4. See closed systems and thermal expansion on page 15. 5. See w ater line connections on page 42. 6. If a pump is being installed between a water heater and storage tank or on a building recirculation loop wire according to figure 68 on page 70. 7. If a pump is being installed in a recirculation...

Page 77

77 4. See closed systems and thermal expansion on page 15. 5. See w ater line connections on page 42. 6. If a pump is being installed between a water heater and storage tank or on a building recirculation loop wire according to figure 68 on page 70. 7. If a pump is being installed in a recirculation...

Page 78

78 limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable water ther...

Page 79

79.

Page 80

500 tennessee waltz parkway ashland city, tn 37015 www.Hotwater.Com.