- DL manuals

- A.O. Smith

- Water Heater

- BTN 120 THRU 400/A Series

- Installation And Operaion Manual

A.O. Smith BTN 120 THRU 400/A Series Installation And Operaion Manual

1

MODELS BTN 120 THRU 400/A

Series 108

COMMERCIAL GAS, GLASS-LINED, TANK-TYPE WATER HEATER

•

INSTALLATION

•

OPERATION

•

MAINTENANCE

•

LIMITED WARRANTY

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER

AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

Printed in U.S.A. 0603

PART NO. 195714-000

A DIVISION OF A. O. SMITH CORPORATION

McBEE, SOUTH CAROLINA, USA

www.hotwater.com

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY. PLEASE READ

THOROUGHLY BEFORE INSTALLING AND USING THIS

APPLIANCE.

Thank you for buying this energy efficient water heater from

A.O. Smith Water Products Company. We appreciate your

confidence in our products.

Summary of BTN 120 THRU 400/A Series

Page 1

1 models btn 120 thru 400/a series 108 commercial gas, glass-lined, tank-type water heater • installation • operation • maintenance • limited warranty place these instructions adjacent to heater and notify owner to keep for future reference. Printed in u.S.A. 0603 part no. 195714-000 a division of a...

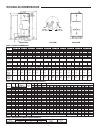

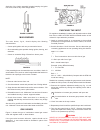

Page 2: Rough-In-Dimensions

2 rough-in-dimensions front view top view back view tank approx u.S gallons/hr. And litres/hr at temperature rise indicated capacity eff. F° 36f° 40f° 50f° 54f° 60f° 70f° 72f° 80f° 90f° 100f° 108f° 110f° 120f° 126f° 130f° 140f° model btuh kw u.S.Gal. Litres % c° 20c° 22c° 28c° 30c° 33c° 39c° 40c° 44...

Page 3: Table of Contents

3 table of contents rough-in-dimensions -------------------------------- 2 foreword ------------------------------------------------- 3 general safety information -------------------- 4 precautions --------------------------------------------------- 4 grounding instructions -------------------------...

Page 4: General Safety

4 general safety information precautions do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the appliance and to replace any part of the control system and any gas control which has been under water. If the unit is exposed to the fo...

Page 5: Features

5 high altitude installations warning installations above 2000 feet (610 meters) require replacement of the burner orifice in accordance with section 8.1.2 of the national fuel gas code (ansi z223.1). Failure to replace the orifice will result in improper and inefficient operation of the appliance r...

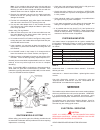

Page 6: Installation Instructions

6 the exhaust inducer is equipped with a gravity controlled damper to reduce the amount of heat loss through the flue, improving efficiency. Exhaust inducer figure 4 circulating pump a circulating pump is used when a system requires a circulating loop or there is a storage tank used in conjunction w...

Page 7

7 length and width at least 2" greater than the diameter of the heater and must be piped to an adequate drain. The pan must not restrict combustion air flow. Leveling if the unit is not level, insert the bolts which were used in crating into the legs to correct this condition. Clearances these heate...

Page 8

8 burners and flue tubes and creates a risk of asphyxiation. Where an exhaust fan is supplied in the same room with a heater, sufficient openings for air must be provided in the walls. Undersized openings will cause air to be drawn into the room through the chimney, causing poor combustion. Sooting ...

Page 9

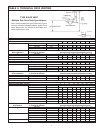

9 type b gas vent multiple gas fired tank-type heaters when venting multiple tank type heaters using type b vent pipe, follow the installation diagram (figure 4) and tables below which give sizing and data based upon nfpa 54/ansi z223. 1992. Table 6. Technical data venting model btn-120 input: 120,0...

Page 10

10 model btn-250 input: 250,000 btu/hr total vent height (feet) vent connector size: 6 inches 6 8 10 15 20 30 50 100 input btuh/hr rise vent connector diameter (inches) 250,000 1 ft 8 8 7 7 7 6 6 6 250,000 2 ft 7 7 7 7 6 6 6 6 250,000 3 ft 7 7 7 7 6 6 6 6 number combined input btn 250 of heaters in ...

Page 11

11 water line connections this manual provides detailed installation diagrams (see pages 13-19 of this manual) for typical methods of application for the water heater(s). The water heater may be installed by itself, or with a separate storage tank, on both single and two-temperature systems. When us...

Page 12

12 installation diagrams-top inlet/outlet usage use of the top inlet water connection requires installation of an inlet dip tube (refer to figure 8). The tube is supplied in the heater. Follow caution labels if applying heat to this fitting. Do not allow pipe dope to contact the plastic tube during ...

Page 13

13 vertical storage tank and forced circulation danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 25. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti- scald valve for hot water supp...

Page 14

14 danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 25. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti- scald valve for hot water supplied to fixtures. Two temperature - one heate...

Page 15

15 installation diagrams-side inlet/outlet usage danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 25. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti- scald valve for hot water sup...

Page 16

16 one or two temperature - one heaters,high temperature storage with or without recirculation heater with or without mixing valve heater with mixing valve and recirculated sanitizing loop note 1: toggle switch controls 180°f (82°c) water circulation. Install on or close to dishwashing machine. Togg...

Page 17

17 two temperature - two pre-heaters with mixing valve or booster heater with or without builing recirculation two pre-heaters with mixing valve two pre-heaters with booster heater danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on...

Page 18

18 medium temperature - one heater with auxiliary storage tank forced circulation with or without building recirculation vertical storage tank horizontal storage tank danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 25. If h...

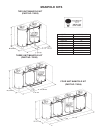

Page 19: Manifold Kits

19 model dimension “a” btn-120 63” btn-154 68” btn-180 72” btn-199 72” btn-200/a 72” btn-250/a 72” btn-275/a 72” btn-310/a 73” btn-366/a 73” btn-400/a 73” manifold kits two unit manifold kit (part no. 78692) three unit manifold kit (part no. 78593) four unit manifold kit (part no. 78694).

Page 20

20 heater wiring all electrical work must be installed in accordance with the latest version of the national electrical code ansi/nfpa no. 70, must conform to all local code authority having jurisdiction. An electrical ground is required to reduce risk of electrical shock or possible electrocution. ...

Page 21

21 gas piping contact your local gas service company to ensure that adequate gas service is available and to review applicable installation codes for your area. Size the main gas line in accordance with table 3. The figures shown are for straight lengths of pipe at 0.5 in. W.C. Pressure drop, which ...

Page 22: Operation

22 correct water column pressure allowing for a nominal pressure drop through the controls. The minimum gas supply pressure for input adjustment must not be less than 4.5" w.C. (1.12 kpa) for natural gas. Do not subject the combination gas valve to inlet gas pressures of more than 14.0" w.C. (3.48 k...

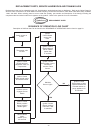

Page 23: Sequence of Operation

23 sequence of operation the following information will describe the sequence of operation for this appliance. 1. Switch power on to unit. 2. Thermostat calls for heat. 3. Ignition control board performs diagnostic check on system components. 4. On completion of diagnostics check, the ignition contr...

Page 24

24 a. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the burner. Do not try to light the burner by hand. B. Before operating smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is heavier than air a...

Page 25: Preventive Maintenance

25 water temperature control danger this water heater is equipped with an adjustable thermostat to control water temperature. Hot water temperatures required for automatic dishwasher and laundry use can cause scald burns resulting in serious personal injury and/ or death. The temperature at which in...

Page 26

26 servicing of the ignitor assembly includes keeping the ignitor free of lint, scale or any other foreign debris. Figure 11, ignitor main burner the main burner, fig.12, should display the following characteristics: • cause rapid ignition and carry across entire burner. • give reasonably quiet oper...

Page 27

27 when the heater is operating at full capacity, or full gas input, it should consume 1 cu. Ft. Of gas in time indicated on table 9. Venting system examine the venting system every six months for obstructions and/or deterioration of the vent piping. Remove all soot or other obstructions from chimne...

Page 28

28 hydrochloric base acids are not recommended for use on glass lined tanks. Caution observe handling instructions on label of product being used. Tank cleanout procedure the following practices will ensure longer life and enable the unit to operate at its designed efficiency: 1. Once a month the he...

Page 29: Service

29 note: if your container does not have the vent cap and vent boss, drill a 3/16" hole in the handle. When you have finished deliming you will be able to plug this drilled vent with the stainless steel screw that is supplied with the kit. 2. Remove the container's cap and cut the plastic membrane l...

Page 30

30 replacement parts, service handbooks and training aids replacement parts may be ordered through a.O. Smith dealers, authorized servicers or distributors. Refer to the yellow pages for where to call or contact the a.O. Smith water products company, product service division, 5621 west 115th street,...

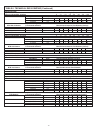

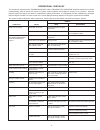

Page 31

31 operational checklist this checklist in conjunction with “troubleshooting” and the “sequence of operation” should be used as an on-the-job troubleshooting guide to identify the cause of incorrect system operation and suggest a remedy for its correction. Because improper piping and wiring can resu...

Page 32

32 model btn limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable ...