A.O. Smith BTP-140 Installation And Operation Manual

1

WARNING – PROPANE MODEL

Water heaters for propane gas are different from natural gas models. A natural gas heater will not function

safely on propane gas and no attempt should be made to convert a heater from natural gas to propane gas.

Propane gas must be used with great caution. It is highly explosive and heavier than air. It collects first in the

low areas making its odor difficult to detect. If propane gas is present or even suspected, do not attempt to

find the cause yourself. Ventilate the room, then call your gas supplier or service agent. Keep area clear until

a service agent has been called.

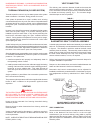

MODELS BTP-140-140 thru 600-2500

INCLUDING BTPD/BTPN/COF & COBT

COMMERCIAL GAS, OIL AND GAS/OIL TANK-TYPE WATER HEATERS

•

INSTALLATION

•

OPERATION

•

SERVICE

•

MAINTENANCE

•

LIMITED WARRANTY

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE

PART NO. 60047-008 REV.6

PRINTED IN U.S.A. 3882 1100

SUPERSEDES 60047-008 REV.5

A DIVISION OF A.O. SMITH CORPORATION

RENTON, WASHINGTON

www.hotwater.com

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY.

PLEASE READ THOUROUGHLY BEFORE USING

APPLIANCE.

CONSERVATIONIST

®

ASME