- DL manuals

- A.O. Smith

- Water Heater

- BTR(C)120 THRU 500A

- Installation Operation & Maintenance

A.O. Smith BTR(C)120 THRU 500A Installation Operation & Maintenance

1

MODELS BTR(C)120 THRU 500A

COMMERCIAL GAS, GLASS-LINED, TANK-TYPE WATER HEATER

•

INSTALLATION

•

OPERATION

•

MAINTENANCE

•

LIMITED WARRANTY

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER

AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PART NO. 195779-000

PRINTED IN U.S.A. 2576 0903

SUPERSEDES PART NO. 194421-000

A DIVISION OF A. O. SMITH CORPORATION

McBEE, SOUTH CAROLINA, USA

STRATFORD, ONTARIO, CANADA

www.aosmithwaterheaters.com

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY. PLEASE READ

THOROUGHLY BEFORE INSTALLING AND USING THIS

APPLIANCE.

Thank you for buying this energy efficient water heater from

A.O. Smith Water Products Company. We appreciate your

confidence in our product.

Summary of BTR(C)120 THRU 500A

Page 1

1 models btr(c)120 thru 500a commercial gas, glass-lined, tank-type water heater • installation • operation • maintenance • limited warranty place these instructions adjacent to heater and notify owner to keep for future reference. Part no. 195779-000 printed in u.S.A. 2576 0903 supersedes part no. ...

Page 2: Rough-In-Dimensions

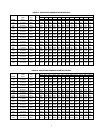

2 rough-in-dimensions see models below figure 1 models btr(c) 120 through 500 btr models 120 through 500a - table 1a model input approx. Gas h vent connections approximate rate tank inlet dia inlet outlet ship. Weight btu/hr. Cap. A b c d e f g i j top front back top front back std. Asme btr120 120,...

Page 3

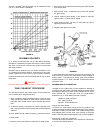

3 table 1c - heater performance data btr models input approx. Recovery rating capacities (gph and lph) rate gal eff. 30° f 40° f 50° f 60° f 70° f 80° f 90° f 100° f 110° f 120° f 130° f 140° f model btuh cap. % (-) 1 c 4 c 10 c 15 c 21 c 27 c 32 c 38 c 43 c 49 c 54 c 60 c btr 120,000 btuh 71 gal 80...

Page 4: Table of Contents

4 table of contents rough-in-dimensions ---------------------------------------- 2-3 table of contents ---------------------------------------------- 4 foreword ----------------------------------------------------------- 4 general safety information ------------------------------ 5 chemical vapor co...

Page 5: General Safety

5 general safety information precautions do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the appliance and to replace any part of the control system and any gas control which has been under water. If the unit is exposed to the fo...

Page 6: Features

6 • do not cover the instruction manual. Keep it on the side of the water heater or nearby for future reference. • do not allow insulation to come within 2” (5 cm) of the burners, to prevent blockage of combustion air flow to the burners. • do not allow insulation to come within 9” (23 cm) of floor,...

Page 7

7 continued manual resetting of high limit control, preceded by higher than usual water temperature is evidence of high limit switch operation. The following is a possible reason for high limit switch operation. • a malfunction in the thermostatic controls would allow the gas valve to remain open ca...

Page 8: Installation Instructions

8 the national sanitation foundation also recommends circulation of 180 0 f (82°c) water. Where this is done, the circulation should be very gentle so that it does not cause any unnecessary turbulence inside the water heater. The circulation should be just enough to provide 180 0 f (82°c) water at t...

Page 9

9 a service clearance of 24" (61cm) should be maintained from serviceable parts, such as relief valves, flue baffles, flue damper devices, thermostats, cleanout openings or drain valves. Installation on combustible flooring the btr/btrc 500 is approved for installations on combustible flooring when ...

Page 10

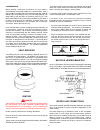

10 confined space when drawing combustion and dilution air from inside a conventionally constructed building to a confined space, such a space shall be provided with two permanent openings, one in or within 12 inches (30.5cm) of the enclosure top and one in or within 12 inches (30.5cm) of the enclos...

Page 11

11 model btr(c)-120 input: 120,00btuh total vent height (feet) draft hood: 5” 6 8 10 15 20 30 50 100 input btuh rise vent connector diameter (inches) 120,000 1 ft. 7 7 7 6 6 6 6 6 120,000 2 ft. 6 6 6 6 6 6 6 5 123,000 3 ft. 6 6 6 6 6 5 5 5 number combined input of heaters in thousands of btuh manifo...

Page 12

12 model btr(c)-250, 251 input: 250,000, 251,000 total vent height (feet) draft hood: 6” 6 8 10 15 20 30 50 100 input btuh rise vent connector diameter (in inches) 250/251,000 1 ft. - - - - - - 8 8 250/251,000 - - - 8 8 8 8 8 250/251,000 3 ft. - 8 8 8 - 8 7 7 number combined input of heaters in thou...

Page 13

13 if a water heater is installed in a closed water system, contact the water supplier or local plumbing inspector on how to control this situation. Water (potable) heating and space heating 1. All piping components connected to this unit for space heating applications shall be suitable for use with...

Page 14

14 gage- 3.5 kpa) supply gas pressure. Exposure to higher supply pressure may cause damage to the gas valve which could result in fire or explosion. If overpressure has occurred such as through improper testing of gas lines or emergency malfunction of the supply system, the gas valve must be checked...

Page 15

15 installation diagrams-top inlet/outlet usage general the type, size and location of the relief valves must be in accordance with local codes. The locations of the relief valves shown in the installation diagrams are typical. The heater has a factory installed high temperature limit switch and tem...

Page 16

16 vertical storage tank and forced circulation danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 27. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti- scald valve for hot water supp...

Page 17

17 danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 27. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti- scald valve for hot water supplied to fixtures. Two temperature - one heate...

Page 18

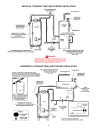

18 installation diagrams-side inlet/outlet usage danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 27. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti- scald valve for hot water sup...

Page 19

19 one or two temperature - one heaters,high temperature storage with or without recirculation heater with or without mixing valve heater with mixing valve and recirculated sanitizing loop note 1: toggle switch controls 180°f (82°c) water circulation. Install on or close to dishwashing machine. Togg...

Page 20

20 two temperature - two pre-heaters with mixing valve or booster heater with or without builing recirculation two pre-heaters with mixing valve two pre-heaters with booster heater danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on...

Page 21

21 medium temperature - one heater with auxiliary storage tank forced circulation with or without building recirculation vertical storage tank horizontal storage tank danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 27. If h...

Page 22: Manifold Kits

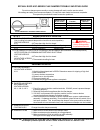

22 manifold kits two unit manifold kit (part no. 195686) three unit manifold kit (part no. 195687) four unit manifold kit (part no. 195688) dimensions “a” inches (cm) model low profile vertical hood “a” btr models btrc models 120 69.75” (177cm) 69.75” (177cm) 154 73.00” (185cm) 73.00” (185cm) 180 67...

Page 23: Mechanical Venting

23 mechanical venting single unit installation when mechanical venting of these heaters is desired, the following kits are available. Btr(c) 120 through the btr(c) 200/a a. O. Smith part number 193933 btr(c) 250/a through the btr(c) 500/a a. O. Smith part number 193933-1 where an approved power vent...

Page 24: Operation

24 operation important a qualified person must perform the initial firing of the heater. At this time the user should not hesitate to ask the individual any questions which they may have in regard to the operation and maintenance of the unit. An operational checklist is included at the rear of this ...

Page 25

25 1. Rotate thermostat dial -by hand- counterclockwise to lowest setting. See step 5 above. 2. Turn off all electrical power to the appliance if service is to be performed. 3. Remove control access panel. 4. Turn knob of gas control valve clockwise to “off” position. See step 4 above and diagrams. ...

Page 26

26 1. Rotate thermostat dial -by hand- counterclockwise to lowest setting. See step 5 above. 2. Turn off all electrical power to the appliance if service is to be performed. 3. Remove control access panel. 4. Turn knob of gas control valve clockwise to “off” position. See step 4 above and diagrams. ...

Page 27

27 adjustments on initial startup some adjustments are necessary. 1. Check manifold and inlet gas pressures. 2. To adjust pilot flame - follow “pilot burner” procedure under “preventive maintenance”. Water temperature control warning this water heater is equipped with an adjustable thermostat to con...

Page 28: Preventive Maintenance

28 2. Inspect the venting system for proper size and horizontal pitch, as required in the national fuel gas code, ansi z223.1 or the can/cga b149 installation codes and these instructions. Determine that there is no blockage or restriction, leakage, corrosion and other deficiencies which could cause...

Page 29

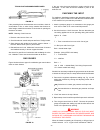

29 typical pilot and main burner flames figure 17 if the preceding burner characteristics are not evident, check for accumulation of lint or other foreign material that restricts or other foreign material that restricts or blocks the air openings to the burner or heater. Note: cleaning of main burne...

Page 30

30 venting system examine the venting system every six months for obstructions and/or deterioration of the vent piping. Remove all soot or other obstructions from chimney which will retard free draft. Remote storage tank temperature control the water temperature in the storage tank (if used) is cont...

Page 31

31 cleanout. Un•lime ® and the booklet may be obtained through your a. O. Smith dealer or distributor. Figure 19 deliming solvents a. O. Smith recommends the use of un•lime for deliming. Un•lime is a patented food grade acid which is safe to handle and does not create the harmful fumes which are ass...

Page 32: Service

32 1. With the 5 gallon up-n-down container in the vertical position, unscrew the plastic vent cap in the handle and pierce the plastic membrane over the vent boss under the cap to allow the container to vent. Note: if your container does not have the vent cap and vent boss, drill a 3/16" hole in th...

Page 33

33 pin end view 24 v.A.C. Normal sequence of operation b. Damper has opened, no combustion voltage across: 4 & 1; 4 & 2; 4 & 3: 1. Check for power at ignition module terminals. If 24vac power is present damper is working properly. 2. Defective component in appliance after the flue damper. 3. If 24 v...

Page 34

34 operational checklist this checklist in conjunction with “troubleshooting” and the “sequence of operation” should be used as an on-the-job troubleshooting guide to identify the cause of incorrect system operation and suggest a remedy for its correction. Because improper piping and wiring can resu...

Page 35

35 model btr(c) limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potab...

Page 36

36 5621 w. 115th street, alsip, il 60803 phone: 800-433-2545 fax: 800-433-2515 www.Aosmithwaterheaters.Com replacement parts.