- DL manuals

- A.O. Smith

- Water Heater

- BTR 151 THRU 201/A

- Installation & Operation Manual

A.O. Smith BTR 151 THRU 201/A Installation & Operation Manual

1

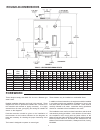

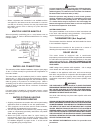

MODELS BTR 151 THRU 201/A

COMMERCIAL GAS, GLASS-LINED, TANK-TYPE WATER HEATER

• INSTALLATION

• OPERATION

• MAINTENANCE • LIMITED WARRANTY

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER

AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

Printed in U.S.A. 1004

PART NO. 196308-001

A DIVISION OF A. O. SMITH CORPORATION

McBEE, SOUTH CAROLINA, USA

www.aosmithwaterheaters.com

CAUTION

TEXT IN BLACK BOLD TYPE OR UNDERLINED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY. PLEASE READ

THOROUGHLY BEFORE INSTALLING AND USING THIS

APPLIANCE.

Thank you for buying this energy efficient water heater from

A.O. Smith Water Products Company. We appreciate your

confidence in our products.

Summary of BTR 151 THRU 201/A

Page 1

1 models btr 151 thru 201/a commercial gas, glass-lined, tank-type water heater • installation • operation • maintenance • limited warranty place these instructions adjacent to heater and notify owner to keep for future reference. Printed in u.S.A. 1004 part no. 196308-001 a division of a. O. Smith ...

Page 2: Foreword

2 foreword these designs comply with ansi z21.10.3 as a booster type water heater. Detailed installation diagrams are found in this manual. These diagrams will serve to provide the installer with a reference for the materials and methods of piping necessary. It is highly essential that all water, ga...

Page 3: General Safety Information

3 general safety information precautions do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the appliance and to replace any part of the control system and any gas control which has been under water. If the unit is exposed to the fo...

Page 4: Features

4 operation of these fans can produce a negative draft in the area of the water heater preventing the products of combustion from exhausting through the chimney or vent pipe. The venting of the water heater should be inspected by a qualified service technician at the time of installation and periodi...

Page 5

5 possibility of changing the orientation by accidentally overtightening the inlet supply. Improper orientation of the eliminator may cause temperature buildup issues or spells of colder than usual water temperatures. High limit switch the digital thermostat (see figure 3) contains the high limit (e...

Page 6: Installation Instructions

6 installation instructions required ability installation or service of this water heater requires ability equivalent to that of a licensed tradesman in the field involved. Plumbing, air supply, venting, gas supply and electrical work are required. Warning failure to follow these instructions can re...

Page 7

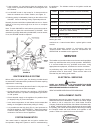

7 carboning or sooting of the combustion chamber, burners and flue tubes and creates a risk of asphyxiation. Where an exhaust fan is supplied in the same room with a heater, sufficient openings for air must be provided in the walls. Undersized openings will cause air to be drawn into the room throug...

Page 8

8 figure 7 • where a separate vent connection is not available and the vent pipe from the heater must be connected to a common vent with an oil burning furnace, the vent pipe should enter the smaller common vent or chimney at a point above the large vent pipe. Multiple heater manifold when horizonta...

Page 9

9 gas piping contact your local gas service company to ensure that adequate gas service is available and to review applicable installation codes for your area. Size the main gas line in accordance with table 2. The figures shown are for straight lengths of pipe at 0.5 in. W.C. Pressure drop, which i...

Page 10

10 do not subject the combination gas valve to inlet gas pressures of more than 14.0" w.C. - natural gas. A service regulator is necessary if higher gas pressures are encountered. Manifold gas pressure in inches of water column is 3.5. The gas pressure specified refers to flow pressure taken at pres...

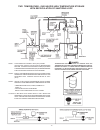

Page 11: Installation Diagrams

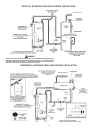

11 installation diagrams general the type, size and location of the relief valves must be in accordance with local codes. The locations of the relief valves shown in the installation diagrams are typical. The heater has a factory installed high temperature limit switch and temperature and pressure r...

Page 12

12 vertical storage tank and forced circulation danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 20. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti-scald valve for hot water suppl...

Page 13

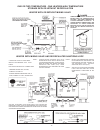

13 danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 20. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti-scald valve for hot water supplied to fixtures. Two temperature - one heater...

Page 14

14 installation diagrams-side inlet/outlet usage danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 20. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti-scald valve for hot water supp...

Page 15

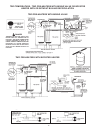

15 one or two temperature - one heaters,high temperature storage with or without recirculation heater with or without mixing valve heater with mixing valve and recirculated sanitizing loop note 1: toggle switch controls 180°f (82°c) water circulation. Install on or close to dishwashing machine. Togg...

Page 16

16 two temperature - two pre-heaters with mixing valve or booster heater with or without builing recirculation two pre-heaters with mixing valve two pre-heaters with booster heater danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on...

Page 17

17 medium temperature - one heater with auxiliary storage tank forced circulation with or without building recirculation vertical storage tank horizontal storage tank danger temperature setting should not exceed safe use temperature at fixtures. See water temperature control warning on page 20. If h...

Page 18: Operation

18 operation important a qualified person must perform the initial firing of the heater. At this time the user should not hesitate to ask the individual any questions which they may have in regard to the operation and maintenance of the unit. An operational checklist is included at the rear of this ...

Page 19

19 a. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the burner. Do not try to light the burner by hand. B. Before operating smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is heavier than air a...

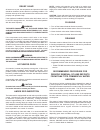

Page 20: Preventive Maintenance

20 set for 120° to 180°f water temperature, but 120°f is the recommended starting point. It is suggested the dial be placed on the lowest setting which produces an acceptable hot water supply. This will always give the most energy efficient operation. The temperature control has a 4°f (2°c) fixed di...

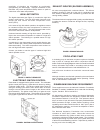

Page 21

21 note: 1. Remove main burners from unit. 2. Check that burner venturi and ports are free of foreign debris. 3. Clean burners with bristle brush and/or vacuum cleaner - do not distort burner ports or pilot location. 4. Reinstall burners in unit. Make sure front and rear of burners are installed cor...

Page 22

22 relief valve at least once a year, the temperature and pressure relief valve should be checked to ensure that it is in operating condition. Lift the lever at the top of the valve several times until the valve seats properly and operates freely. If the appliance installation includes other relief ...

Page 23

23 figure 14 deliming solvents a. O. Smith recommends the use of un•lime for deliming. Un•lime is a patented food grade acid which is safe to handle and does not create the harmful fumes which are associated with other products. Un•lime may be obtained from your dealer, distributor or the a. O. Smit...

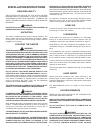

Page 24: Service

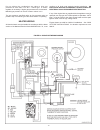

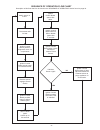

24 the appliance. The indicator codes on the ignition module are as follows: 1 flash system lockout (retries or cycles exceeded) 2 flashes pressure switch stuck close 3 flashes pressure switch stuck open 4 flashes open on high temperature limit switch (eco) 6 flashes 115 volt ac power reversed (chec...

Page 25

25 sequence of operation flow chart description of this flow chart can be found in the “sequence of operation” section found on page 18. Switch power on to unit. Thermostat calls for heat. Ignition control board performs diagnostic check on components ignition control board sends power to exhaust in...

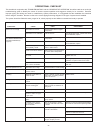

Page 26

26 operational checklist this checklist in conjunction with “troubleshooting” and the “sequence of operation” should be used as an on-the-job troubleshooting guide to identify the cause of incorrect system operation and suggest a remedy for its correction. Because improper piping and wiring can resu...

Page 27

27 model btr limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to natural corrosion from potable ...

Page 28

28 a.O. Smith water products company 5621 w. 115th street • alsip, illinois 60803 phone: 1-800-433-2545 • fax: 1-800-433-2515 www.Aosmithwaterheaters.Com • e-mail: parts@hotwater.Com.