- DL manuals

- A.O. Smith

- Water Heater

- Burkay HW-300

- Installation & Operation Manual

A.O. Smith Burkay HW-300 Installation & Operation Manual

PLACE THESE INSTRUCTIONS ADJACENT TO BOILER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE

PRINTED 0210

317693-000

GAS-FIRED COMMERCIAL COPPER BOILERS FOR

HYDRONIC HEATING AND HOT WATER SUPPLY

• INSTALLATION • OPERATION • MAINTENANCE • LIMITED WARRANTY

• INDOOR ONLY

MODELS HW 300, 399, 420, 520, 610, 670

UP-FLOW MODELS

WARNING: If the information in this manual

is not followed exactly, a fire or explosion

may result causing property damage,

personal injury or death.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas supplier,

call the fire department.

— Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

500 Tennessee Waltz Parkway

Ashland City, TN 37015

www.hotwater.com

Summary of Burkay HW-300

Page 1

Place these instructions adjacent to boiler and notify owner to keep for future reference printed 0210 317693-000 gas-fired commercial copper boilers for hydronic heating and hot water supply • installation • operation • maintenance • limited warranty • indoor only models hw 300, 399, 420, 520, 610,...

Page 2

2 important definitions • qualified installer: a qualified installer must have ability equivalent to a licensed tradesman in the fields of plumbing, air supply, venting and gas supply, including a thorough understanding of the requirements of the national fuel gas code or the natural gas and propane...

Page 3: General Safety

3 general safety.

Page 4: Table of Contents

4 safe installation, use and service.......................................................................................................................................................................... 2 general safety................................................................................

Page 5

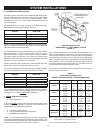

5 extra opening for thermometer and relief valve hw-520, 610 and hw--670 dimensions and capacity data table 1 dimensions in inches models hw-300 hw-399 hw-420 hw-520 propane hw-610/670 natural hw-610/670 a overall height 65 (1651) 57-1/8 (1451) 57-1/8 (1451) 68-5/16 (1735) 67 (1702) 64-3/4 (1645) b ...

Page 6

6 table 2, recovery capacities model input °f 20 40 50 60 70 80 btuh (kw) °c 11.1 22.2 27.7 33.3 38.8 44.4 hw 300 300,000 (88) gph 1439 719 576 480 411 360 lph 5448 2724 2179 1816 1556 1362 hw 399 399,000 (117) gph 1914 957 765 638 547 478 lph 7245 3623 2898 2415 2070 1811 hw 420 420,000 (123) gph 2...

Page 7: Introduction

7 introduction this design complies with the current edition of the ansi z21.13 low-pressure boiler standard. Compliance under this standard implies that when the boiler underwent test, the gas manifold and control assembly pro vided on the boiler met safe lighting and other performance criteria. De...

Page 8: Controls And Function

8 high altitude installations in canada acceptance of these models for use at altitudes above 2000 feet (600 m) is based on field test of the individual installation by the provincial/state authority having jurisdiction. In the u.S.A. Warning installations above 2000 feet require replacement of the ...

Page 9

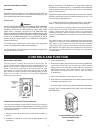

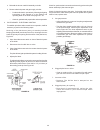

9 thermal balancer figure 4 shows the internal wiring of the thermal balancer. The device may be tested after disconnecting the four leads from their respective terminals on the unit. 1. Apply a test light to the yellow and red leads. • the lamp should light as the contact in this circuit is normall...

Page 10

10 caution paddle must be trimmed at the dotted arc. It must not touch the pipe or have any restriction when installed. Figure 6. To adjust the flow rate setting: 1. Remove the flow switch cover. 2. For higher flow rate - turn the range adjusting screw clockwise. 3. For lower flow rate - turn the ra...

Page 11

11 code, section iv or csa b51, as applicable. Select a relief valve with a discharge not less than the boiler input, and a pressure rating not exceeding the working pressure of any component in the system. A. O. Smith supplies a 125 psi relief valve for hot water supply systems and 50 psi relief va...

Page 12: General

12 water temperature time to produce 2nd & 3rd degree burns on adult skin over: 170°f (77°c) 160°f (71°c) 150°f (65°c) 140°f (60°c) 130°f (54°c) 120°f (49°c) nearly instantaneous about 1/2 second about 1-1/2 seconds less than 5 seconds about 30 seconds more than 5 minutes use anti-scald valve(s) in ...

Page 13

13 permit operation of gas appliances if installed 18 inches or more above the floor. This may reduce the risk if location in such an area cannot be avoided. Warning flammable items, pressurized containers or any other potential fire hazardous articles must never be placed on or adjacent to the boil...

Page 14: Venting

14 installation clearances these boilers are approved for installation on combustible flooring in an alcove with minimum clearance to combustibles of: table 4 hw 300 hw 399 hw 420 hw 520 hw 610 & 670 top 28" (711.2) 32" (812.8) 24" (609.6) 24" (609.6) 24" (609.6) sides 6" (152.4) 6" (152.4) 24" (609...

Page 15

15 building materials must not come in contact with combustion products from stack or chimney, due to the degradating properties of flue products. Flue products must have a minimum clearance of 4 feet (1.22m) horizontally from, and in no case above or below, unless a 4-foot (1.22m) horizontal distan...

Page 16

16 4. Multiple vent table table 5 on page 17 has been compiled to show the material sizes in a type b doublewall combined vent system. Refer to can/csa b149 .1 (current edition), or the ashrae 1983 equipment volume for further information. A combined vent system is one in which two or more boilers a...

Page 17

17 table 5, combined vent sizing tables model hw-300 boiler input: 300,000 btuh draft hood outlet 8" required connector or smoke pipe diameter connector rise in feet total vent height (measured in feet above draft hood) 10 15 20 30 40 50 60 80 100 connector diameter (in inches) 1 10 10 10 10 10 10 1...

Page 18: System Installations

18 1. Conventional installations all modern hydronic type boilers are exceptionally fast heating units. The low water volumes in relation to firing rates require special attention to water flow rates for smooth, efficient operation. These considerations for the a. O. Smith copper heat exchanger boil...

Page 19

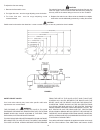

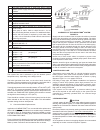

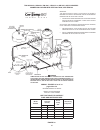

19 no. Suggested items for installation 1 short pipe nipple and pair of boiler loop tees in piping between system supply and return. One set per each group of boilers. 2 boiler pipe loop. See piping sizing data. 3 boiler circulator. See pump sizing data. 4 thermometer. 5 theraltimeter. 6 plug cock t...

Page 20: Gas Connections

20 5. Vent valves it is recommended that automatic, loose key or screwdriver type vent valves be installed at each convector or radiator. 6. Manifold headers split systems with individual supply and return lines from the boiler room should normally have this piping connected to supply and return man...

Page 21

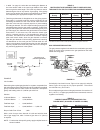

21 use table 7, or can/csa b149.1 (current edition) to size iron pipe or equivalent gas supply line. Table 7 is based on a pressure drop of 0.3 inches of water and a specific gravity of 0.60 approximately that of natural gas. (lp gas has an s.G. Of about 1.53). If the service pressure is five inches...

Page 22

22 • in table 7 on page 21, select the row showing the distance to the most remote outlet or the next longer distance if the table does not give the exact length. This is the only distance used in determining the size of any section of gas piping. If the gravity factor is to be applied, the values i...

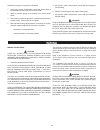

Page 23: Wiring

23 adjustment, if required, is performed as follows: 1. Set primary system temperature control dial (thermostat) at lowest setting so that boiler will not call for heat. 2. Attach a pressure gauge to the tapping in the control string elbow. 3. Reset primary system temperature control dial (thermosta...

Page 24

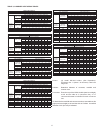

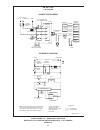

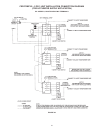

24 120 vac 60 hz l1 (hot) l2 (neutral) l1 (hot) l2 (neutral) 120 vac 60 hz 120v 24v high limit ignition module chassis ground ignitor wire to pilot note: if replacing any factory wiring, use type 105°c wire or equivalent, except for the ignition wire which uses 250°c wire and the coil limit which us...

Page 25

25 2. Linear-temp installations control for these systems is decided mainly by the type of building system controlling that is desired. A single boiler installation might be controlled directly from space temperature thermostat(s). Multiple boiler installations are more effective when the boilers ar...

Page 26

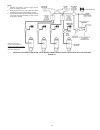

26 note: 1. Building temperature controls supply electric power to building circulator. 2. Main flow switch proves main water flow before energizing sequencing and resetting controls. 3. Outdoor thermostat required if building controls do not provide automatic shutdown of reset controls during warm ...

Page 27

27 note: 1. Building temperature controls supply electric power to building circulator. 2. Main flow switch proves main water flow before energizing sequencing and resetting controls. 3. Outdoor thermostat required if building controls do not provide automatic shutdown of reset controls during warm ...

Page 28

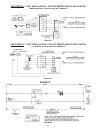

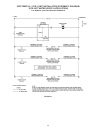

28 cer-temp 80 - 1 unit installation - for hot water supply application canadian models, junction box w/6 terminals figure 21. Figure 23. Cer-temp 80 - 1 unit installation - for hot water supply application u.S. Models, jucntion box w/4 terminals figure 22..

Page 29

29 cer-temp 80 - 2 or 3 unit installation - for hot water supply application canadian models, junction box w/6 terminals figure 24..

Page 30

30 schematic canadian models, junction box w/6 terminals figure 25..

Page 31

31 cer-temp 80 - 2 or 3 unit installation connection diagram (for hot water supply application) u.S. Models, junction box w/4 terminals figure 26..

Page 32

32 cer-temp 80 - 2 or 3 unit installation schematic diagram (for hot water supply application) u.S. Models, junction box w/4 terminals figure 27..

Page 33: Piping

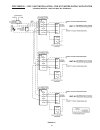

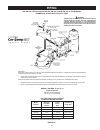

33 figure 28. Important the installation of safety flow switch as shown is required to protect the boiler in case of water service interruption or circulator failure. + piping and fittings between gate valves and boilers should be brass or bronze. Other piping should conform to local codes. Gate val...

Page 34

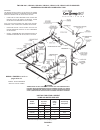

34 figure 29. One hw-300, hw-399, hw-420, hw-520, hw-610 or one hw-670 up-flow model commercial boiler with horizontal tank wiring - figures 16 and 17 on pages 24 and 25. Install in accordance with all local codes important the installation of safety flow switch as shown is required to protect the b...

Page 35

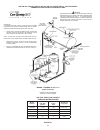

35 two hw-399's, hw-420's, hw-520's, hw-610's or hw-670's up-flow model commercial boiler with vertical tank, cer-temp 80 important the installation of safety flow switch as shown is required to protect the boiler in case of water service interruption or circulator failure. + piping and fittings bet...

Page 36

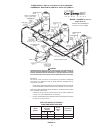

36 figure 31. Two hw-300's, hw-399's, hw-420's, hw-520's, hw-610's or hw-670's up-flow model commercial boiler with horizontal tank important the installation of safety flow switch as shown is required to protect the boiler in case of water service interruption or circulator failure. + piping and fi...

Page 37

37 three hw-520's, hw-610's or hw-670's up-flow model commercial boiler with vertical tank, cer-temp 80 important the installation of safety flow switch as shown is required to protect the boiler in case of water service interruption or circulator failure. + piping and fittings between gate valves a...

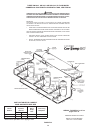

Page 38

38 three hw-520's, hw-610's or hw-670's up-flow model commercial boiler with horizontal tank, cer-temp 80 important the installation of safety flow switch as shown is required to protect the boiler in case of water service interruption or circulator failure. + piping and fittings between gate valves...

Page 39

39 warning after placing boiler into operation, the ignition system safety shutoff device must be tested by the following test method. 1. Reset high limit temperature control to lowest setting. (see figure 2 on page 8). 2. Reset system controller to maximum setting, causing a call for heat and allow...

Page 40

40 4. Reinstall the burner manifold assembly on boiler. 5. Restore electrical power and gas supply to boiler. • put the boiler back in operation by following the lighting instructions in this manual or on the lighting and operating label on the boiler. See pages 43 - 44. • check for gas leaks and pr...

Page 41

41 checking and adjusting the input 1. Follow steps 1 thru 6 of the operating instructions. 2. Attach a pressure gauge or a manometer to the manifold pressure tapping and refer to table 10 for correct manifold pressure. 3. Follow steps 7 thru 11 of the operating instructions. 4. Use this formula to ...

Page 42

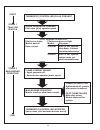

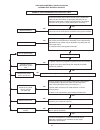

42 start stage 1 trial for ignition stage 2 main burner operation end thermostat (controller) calls for heat spark generator powered first valve (pilot) operator opens pilot burner operation pilot burner lights. Pilot burner does not light module senses module response flame current. S-8600m after 1...

Page 43: Warning:

43 for your safety read before lighting warning: flammable if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. C. D. What to do if you smell gas do not try to light any appliance. Do not touch any electric switch; ...

Page 44: Warning:

44 for your safety read before operating warning: flammable if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. B. This appliance is equipped with an ignition device which automatically lights the pilot. Do not ...

Page 45: General Maintenance

45 at the time of removal of an existing boiler, the following steps shall be followed with each appliance remaining connected to the common venting system placed in operation, while the other appliances remaining connected to the common venting system are not in operation. Seal any unused openings ...

Page 46: Pre-Troubleshooting

46 cleaning and flushing instructions internal contaminants the hydronic system must be internally cleaned and flushed after a new or replacement boiler has been installed to remove contaminants that may have accumulated during installation. This is doubly important when a replacement boiler is inst...

Page 47: Troubleshooting

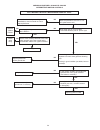

47 troubleshooting cer-temp 80 recovery system checkout procedure use this checkout for cer-temp 80 recovery systems. (for hot water supply application only) checkout sequence system operation cause remedy contact incorrect set tank temperature control (thermostat) 20°f (10°c) below tank water tempe...

Page 48

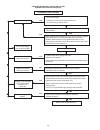

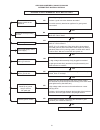

48 checking honeywell s-8600h or s-8610m intermittent ignition controls turn off gas supply. Is voltage (24 vac) across the 24 v terminals on module during “call for heat”? Turn off power supply. Is ignition cable firmly plugged into pilot assembly and module? Is ground wire firmly attached to pilot...

Page 49

49 checking honeywell s8600h or s-8610m intermittent ignition controls spark at pilot burner but pilot will not light ensure all manual shutoff valves are fully open; all filters are clean; all gas connections are gas tight; pilot tubing is not damaged, obstructed or kinked; and pilot orifice is unc...

Page 50

50 checking honeywell s-8600h or s8610m intermittent ignition controls pilot burner lights but main burner does not light does the pilot flame cover 3/8” to 1/2” of ingniter/sensor rod? Does spark stay on for more than 15 seconds after the pilot is “proven” (lit)? Ensure the ground wire and ignition...

Page 51

51 checking honeywell s8600h or s-8610m intermittent ignition controls no spark at pilot burner but pilot will not light turn off gas supply. Is there a good connection between terminals? Is module securely attached to appliance for good ground connection? Is voltage (24vac) across transformer posit...

Page 52

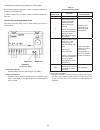

52 the following procedures are provided as a general guide. Any module should be replaced if it does not perform properly on checkout or troubleshooting. In addition, replace any module if it is wet or looks like it has ever been wet. Led status and troubleshooting the control has two leds; one for...

Page 53

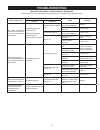

53 table 12. Continuous retry models c, m, e, and k only - green led status codes green led flash code (x+y) a indicates next system action recommended service action off no "call for heat" not applicable none flash fast startup - flame sense calibration not applicable none heartbeat normal operatio...

Page 54

54 table 13. Lockout models b, h, d and j only - green led status codes green led flash code (x+y) a indicates next system action recommended service action off no "call for heat" not applicable none flash fast startup - flame sense calibration not applicable none heartbeat normal operation not appl...

Page 55: Limited Warranty

55 a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this boiler. 1. If within ten years after initial installation of the boiler, a heat exchanger, coil or gas burner shall prove upon examination by the warrantor to be defective in material or workmanshi...

Page 56

500 tennessee waltz parkway, ashland city, tn 37015 technical support: 800-527-1953 • parts: 800-433-2545 • fax: 800-644-9306 www.Hotwater.Com.