- DL manuals

- A.O. Smith

- Water Pump

- Century Centurion

- Service Manual

A.O. Smith Century Centurion Service Manual - Motor Troubleshooting

4

Motor Troubleshooting

Motor Fails To Start (makes no sound). . . . . . . . . . . . . . . . . .1 9

Motor Fails To Start (hums, tries to start,

blows fuse or trips bre a k e r ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 0

Motor Starts But Shuts Down

(overload pro b l e m ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 1

Noisy Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 1

Motor Hot, Smoking Or Cycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 2

I n f o rmation Needed For Motor Replacement . . . . . . . . . . . . . .2 3

Troubleshooting A Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 3

Best Way To Use A Vo l t - A m m e t e r. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 4

How To Replace Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 4

S e rv i c e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 7

Wiring Diagrams’ Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 8

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 9 - 5 4

Date of Manufacture Ta b l e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 5

Summary of Century Centurion

Page 1

I n s t a l l a t i o n — ma i nte n a n ce — s e rv i c e — tro u b l e s h o o t i n g century ® pool & spa motor manual.

Page 2: Introduction

1 w elcome to a.O. Smith’s line of century ® motors. This pocket manual is designed for one purpose — to make it simple for you to install, maintain and troubleshoot century pool and spa motors. Contrary to what you may be thinking just n o w, your last name doesn’t have to be edison in order to p r...

Page 3: A.O. Smith

2 replacements for every brand. Every now and then you probably come across a motor that’s beyond re p a i r. When you do, remember that a.O. Smith manufacture s replacement pool and spa motors for practically every brand you’ll ever encounter in the field. So save yourself some time and eff o rt an...

Page 4: I N S T A L L A T I O N

3 c e n t u ry pump motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 design feature s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 nameplate inform a ...

Page 5: Motor Troubleshooting

4 motor troubleshooting motor fails to start (makes no sound). . . . . . . . . . . . . . . . . .1 9 motor fails to start (hums, tries to start, blows fuse or trips bre a k e r ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 0 motor starts but shuts down (overload pro b l e ...

Page 6: C E N T U R I O N

5 c e n t u r i o n ® , c-flange switchless “1081” motor • standard eff i c i e n c y • e-plus, high eff i c i e n c y • 1 ⁄ 2 – 5 hp • no switch, no govern o r • single phase or three phase • suitable for operation at 50 hz, 1.0 service factor • aluminum or cast iron nema “c” mounting brackets • tr...

Page 7: C E N T U R I O N

6 c e n t u r i o n ® , square flange switchless “1081” motor • standard eff i c i e n c y • e-plus, high eff i c i e n c y • 1 ⁄ 2 – 5 hp • no switch, no govern o r • 303 stainless steel t h readed shaft • suitable for operation at 50 hz, 1.0 service factor • single or three phase • true nema 56-fr...

Page 8: Centurion

7 flex-48™ single-speed motors, thru-bolt mount suitable for jetted tubs and above-ground pools and spas. • 1 ⁄ 2 - 3 hp • 56-frame conversion base • 3- 1 ⁄ 2 ” shaft height • 3 ⁄ 8 ” threaded shaft • auto-reset overload p ro t e c t i o n • 1.0 service factor flex-48™ two-speed low amp start & run ...

Page 9: Centurion

8 2 . All threaded shafts are 303 stainless steel for superior c o rrosion resistance. Keyed shaft of carbon steel is iron phosphate treated to prevent rust. Stainless steel shafts p rovided on cast iron c-flange, keyed shaft pro d u c t . 3 . Double-sealed high thrust bearings protect against dirt ...

Page 10: Nameplate Information

W hen you need information about the motor y o u ’ re servicing, you’ll always be able to find it printed on the motor nameplate. On a.O. Smith motors the nameplate is usually found on the side of the m o t o r, below the capacitor. Shown below is a sample pool motor identification nameplate. As you...

Page 11

1 .C at no (catalog number): this number indicates that the motor is a stock rating, readily available f rom standard inventory as a replacement pool m o t o r. 2 . Pa rt: this identifies the motor’s specific design by part number. 3 .Fr (frame): the frame identifies the mounting and shaft configura...

Page 12: Nameplate Information

Identify motors not specified by nema mounting and shaft standards. 4 .T y p e : the electrical design of the motor is shown by its type. A.O. Smith uses “cx” to identify its switchless design. Other codes include “cs” for c a p a c i t o r- s t a rt, “s p” for split-phase and “cp” for capacitor sta...

Page 13

Maximum horsepower (hp x sf). 1 2 .T i m e : time indicates the duty cycle of the motor. Pool and spa motors are generally rated for continuous duty. 1 3 .Amb (ambient te m p e r a t u re ) : the maximum ambient (surrounding) temperature in which the motor is designed to operate. This temperature is...

Page 14: T I P :

The number one enemy of a motor is heat. Overheating always re s u l t s whenever there is a lack of clean, continually-circ u l a t i n g air for a motor. Heat can damage a motor’s windings, insulation, bearing lubricant and run capacitor. In short , heat can quickly decrease the service life of a ...

Page 15

C e n t u ry and neptune motors have superior resistance to moisture, but you should avoid placing the motor where it can be splashed. Avoid installing the motor in low spots where it could collect water and be flooded. In fact, it’s probably a good idea to elevate the motor at least two inches off ...

Page 16

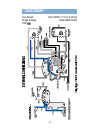

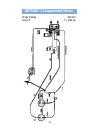

The task of wiring your motor is fairly simple. The wiring diagrams shown on the following pages are color- c o d e d for easy reading. The appropriate part number is listed in each illustration, just in case you need to order the complete wiring diagram or connection label sticker for your motor. M...

Page 17: 115V Power Line

1 6 115v power line maximum distance from fuse box to motor motor hp 5 0 ’ 1 0 0 ’ 1 5 0 ’ 2 0 0 ’ 1 ⁄ 3 1 4 1 4 1 2 1 2 1 ⁄ 2 1 4 1 2 1 0 1 0 3 ⁄ 4 1 2 1 2 1 0 8 1 1 2 1 0 8 8 1 - 1 ⁄ 2 1 0 1 0 8 6 2 1 0 8 6 6 3 — — — — 230v power line maximum distance from fuse box to motor motor hp 5 0 ’ 1 0 0 ’ ...

Page 18: .O. Smith

1 7 w ith a few simple tools, you’ll be ready for just about any kind of basic motor service. To make your job easier when installing or servicing a pool or spa motor, make sure that you have these tools in your toolbox before you begin working... • s t a n d a rd scre w d r i v e r • wide blade scr...

Page 19: Maintenance

1 8 an operating motor is usually too hot to touch by hand. It should be located away from direct sunlight and other heat sources, such as laundry appliances and water heaters. Provide for ample air circulation around the m o t o r. Clean the air inlets as re q u i red, making sure that the power is...

Page 20: Motor Troubleshooting

1 9 b e f o re you even touch the m o t o r, make sure the power is off. Always turn the power off at the electrical service entrance fuse or breaker box, to p revent possible electric shock. To prevent electrical shock when touching the motor, be sure windings and capacitor are securely grounded to...

Page 21

2 0 voltage is within the proper range, check for continuity through the pro t e c t o r. 5 .Check for overloading from other appliances on the same circuit as the motor. 6 .Inspect the motor windings for continuity. 7 . If voltage is proper at terminals and the motor is cold, remove the motor and t...

Page 22: Noisy Motor

2 1 capacitor using an ohmmeter (see “ troubleshooting a capacitor” page 23). 5 . Rotate the motor shaft. If you hear a grinding sound, disassemble the motor and check: the conditions of bearings, a rotor rubbing the stator, c o rrosion, a cracked frame, clogged fan or o b s t ruction(s). Repair or ...

Page 23

2 2 1 .Mounting, motor coupling and brackets. Tighten loose nuts, bolts or set scre w s . 2 . If a noticeable drag is present, check the bearings and bearing load spring. 3 .Make sure motor fan moves freely and rotor isn’t rubbing stator. Look for loose or binding parts inside the motor or pump. 4 ....

Page 24: 2 . H O R S E P O W E R

6 . Check the start switch for broken contact welds or a broken spring. 7 . Check the capacitor with an ohmmeter. A bulged capacitor indicates failure on most motors. But with a centurion, the only way to verify a failed capacitor is with the ohmmeter. I n f o r m ation needed for motor replacement ...

Page 25: For Voltage Check

Best way to use a volt-ammeter for voltage check 1 . Attach leads to the volt-ammeter and select the proper voltage scale. 2 .Test voltage at the motor line terminals and verify that it’s within limits while the motor is operating. 3 .Voltage should be within ±10% of the design voltage specified on ...

Page 26: 1.Turn The Power Off

Bearings because this could damage the motor and cause a re t u rn service call. 1.Turn the power off 2 .Remove the cover from the motor and disconnect the electrical supply leads from the terminal board. Then remove the electrical cable or conduit from the end frame. 3 . Remove the motor from the p...

Page 27

6 . Remove the bearing(s) from the motor shaft, following these steps as necessary : a )remove shaft collars used to secure bearings. D o n ’t reuse a bearing that is removed from the shaft. 7 .Install the new shaft bearing(s). It is important to press only on the bearing inner race. The bearing wil...

Page 28: Service

I f your pool or spa motor should need attention while still under warr a n t y, we re q u i re that you have it serviced at a authorized a.O. Smith service center to qualify for warranty coverage. When ordering part s , refer to the part number and serial number on the motor nameplate. For your con...

Page 29: C E N T U R I O N

2 8 c e n t u r i o n ® switchless (easy connect) . . . . . . . . . . . . . . . . . . 29, 30 c e n t u r i o n ® switchless (mfg. Prior 11/91) . . . . . . . 31, 32, 45 10 81, wishbone (old style) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33, 34, 35 10 81, single arm switch (old style...

Page 30: Centurion

For motors manufactured in/after nov., 1991 (serial #bj11) dual vo l t a g e type cx- 1 ⁄ 2 to 1 1 ⁄ 2 h p 230/115 vo l t s w i t c h l e s s 2 9 centurion ® /se/ii.

Page 31: Centurion

3 0 for motors manufactured in/after nov., 1991 (serial #bj11) single vo l t a g e type cx-1 1 ⁄ 2 - 5 h p 230 vo l t s w i t c h l e s s centurion ® /se/ii.

Page 32: Centurion

3 1 dual vo l t a g e 115/230 vo l t type cx– 1 ⁄ 2 to 1 1 ⁄ 2 h p switchless for motors manufactured prior to nov. 1991. (serial #bj11) centurion ®.

Page 33: Centurion

3 2 single vo l t a g e 230 vo l t type cx–2, 3 & 4 hp switchless for motors manufactured prior to nov. 1991. (serial #bj11) centurion ®.

Page 34: 1081

3 3 115/230 vo l t type cs– 1 ⁄ 2 to 1 1 ⁄ 2 h p wishbone (old style) 1081.

Page 35: 1081

3 4 115/230 vo l t type cp–2 hp wishbone (old style) 1081.

Page 36: 1081

3 5 230 vo l t type cp–3 hp wishbone (old style) 1081.

Page 37: 1081

3 6 115/230 vo l t type cs– 1 ⁄ 2 to 1 1 ⁄ 2 h p single arm switch (old style) 1081.

Page 38: 1081

3 7 115/230 vo l t type cp–2 hp single arm switch (old style) 1081.

Page 39: E-Plus

3 8 230 vo l t type cx–2 and 3 hp switchless (old style) e-plus ®.

Page 40: 2-Speed

3 9 115 vo l t type csm– 1 ⁄ 2 to 3 ⁄ 4 h p wishbone (old style) 2-speed.

Page 41: 2-Speed

4 0 230 vo l t type csm–1 and 1 1 ⁄ 2 h p wishbone (old style) 2-speed.

Page 42: 2-Speed

4 1 230 vo l t type cpm–2 hp wishbone (old style) 2-speed.

Page 43: Micro-Switch Motor

4 2 ( f o rmerly identified as g o u l d - g u a rd ) 115/230 vo l t type cs– 1 ⁄ 2 to 1 hp (old style) micro-switch motor.

Page 44: Switchless Motor

4 3 ( f o rmerly identified as g o u l d - g u a rd ) 230 vo l t type cx–1 1 ⁄ 2 h p switchless (old style) switchless motor.

Page 45: Switchless Motor

4 4 ( f o rmerly identified as g o u l d - g u a rd ) 230 vo l t type cx–2 and 3 hp switchless (old style) switchless motor.

Page 46: Centurion

4 6 two-speed single vo l t a g e 115 vo l t type cxpm– 1 ⁄ 2 /.06 to 3 ⁄ 4 /.10 hp solid-state switch centurion ®.

Page 47: Centurion

4 7 two-speed single vo l t a g e 230 vo l t type cxpm–1/.12 to 2/.25 hp solid-state switch centurion ®.

Page 48: E-Plus

4 8 dual vo l t a g e 115/230 vo l t type cx– 3 ⁄ 4 to 1 1 ⁄ 2 h p switchless e-plus ® switchless.

Page 49: E-Plus

4 9 single vo l t a g e 230 vo l t type cx–2 and 3 hp switchless e-plus ® switchless.

Page 50: Flex 48

5 0 two speed single vo l t a g e 115 vo l t type spm– 3 ⁄ 4 /.10 hp flex 48 ® frame.

Page 51: Flex 48

5 1 two-speed single vo l t a g e 115 or 230 vo l t type cxsm 1 1 ⁄ 2 /.18 hp type cxsm 2.0/.25 hp t h rough 4.5/.50 spl hp flex 48 ® frame.

Page 52: Flex 48

5 2 two-speed single vo l t a g e 115 or 230 vo l t type csm 1.0/.12 hp 115 vo l t type csm 1.0/.16 hp 115 vo l t type csm 1.5/.18 hp 230 vo l t type csm 2.0/.25 hp 230 vo l t flex 48 ® frame.

Page 53: Flex 48

5 3 single vo l t a g e 115 vo l t type sp– 1 ⁄ 2 to 1 1 ⁄ 2 h p flex 48 ®.

Page 54: Flex 48

5 4 dual vo l t a g e 230/115 vo l t type cs–1 1 ⁄ 2 to 4 spl hp flex 48 ®.

Page 55: Serial Bh 1 1 - 1 6

5 5 for century pool, spa or jetted tub motors to identify the month and year your century pool, spa or jetted tub motor was manufactured you need to know the serial code. The serial code on the nameplate is made up of thre e p a rts: serial letter (year), serial number (month), and manufacturing se...

Page 56: N E P T U N E

5 6 single vo l t a g e 230 vo l t type cp 1 1 ⁄ 2 2&3 hp n e p t u n e ® 2 compartment motors.

Page 57: N E P T U N E

5 7 dual voltage type cp 230/115 volt 1 ⁄ 2 -1 1 ⁄ 2 hp n e p t u n e ® 2 compartment motors.

Page 58: N E P T U N E

5 8 dual vo l t a g e type cs 230/115 vo l t 1 ⁄ 3 - 1 1 ⁄ 2 h p n e p t u n e ® 2 compartment motors.

Page 59

1 a.O. Smith 531 north fourth stre e t tipp city, oh 45371 9 3 7 - 6 6 7 - 6 8 0 0 fax (937) 667-5873 bulletin 2944 © a . O . Smith 2000 litho in usa #2944 11/00