- DL manuals

- A.O. Smith

- Water Heater

- COF-199

- Installation, User And Service Manual

A.O. Smith COF-199 Installation, User And Service Manual

Innovation has a name.

Installatie-, Gebruikers- en Servicehandleiding

Installation, User and Service Manual

Installations-, Benutzer- und Wartungsanleitung

Manuel d’installation, Mode d’emploi, Manual d’entretien

Manual de Instalación, Usuario y Servicio

Manual de Instalação, Utilização e Manutenção

Manuale Installazione, d’uso e manutenzione

Instrukcja Serwisu, Obs ugi I Montazu

,

ł

Εγκατάσταση Χρηστών και Εγχειρίδιο Σέρβις

0311962

COF 199

COF 245

COF 315

COF 385

COF 455

COF 700

4215

-

Changes

Reser

ved.

United Kingdom & Ireland

OIL AND GAS FIRED WATER HEATER

Summary of COF-199

Page 1

Innovation has a name. Installatie-, gebruikers- en servicehandleiding installation, user and service manual installations-, benutzer- und wartungsanleitung manuel d’installation, mode d’emploi, manual d’entretien manual de instalación, usuario y servicio manual de instalação, utilização e manutençã...

Page 2

2 before attempting to install this water heater please read the installation instructions. Read the users manual before igniting the heater. Failure to follow these instructions meticulously could lead to the risk of an explosion and/or a fire and can cause material and/or physical injuries. An acc...

Page 3

3 contents page 1. General ............................................................................................................................4 1.1 description of the heater ...............................................................................................................4 1.1....

Page 4

4 1. General 1.1 description of the heater construction of the heater is in accordance with the european standards for gas-fired water heaters for sanitary use (en 89). The heaters therefore comply with the european guidelines for gas heaters and are permitted to carry the ce mark. They are atmosphe...

Page 5: 1. General

5 1.2 technical safety equipment 1.2.1 control box the temperature control for the water heater is situated in the control box (see figure 1), which is fitted to the heater cover. The water heater has been fitted with three thermostats: - a control thermostat, - a high-limit thermostat - an overheat...

Page 6

6 1.3 technical description 1.3.1 dimensions (see figure 2). Cof 199 cof 245 cof 315 cof 385 cof 455 cof 700 a mm 1900 1900 1900 1900 1900 1900 d mm 705 705 705 705 705 705 e1 mm 725 725 725 725 725 725 e2 mm g mm 150 13 200 200 200 200 250 13 k mm 295 295 295 295 295 330 m mm 685 685 685 640 640 76...

Page 7

7 figure 2 - dimensions imd-0011.

Page 8

8 8 1.3.2 burners the water heaters are suitable for both gas-fired and oil- fired burners. The water heaters have been examined and tested with the following front-mounted burners from riello: the burners for the cof 700 heaters must be fitted with a special fire tube in view of the higher temperat...

Page 9

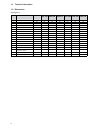

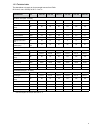

9 1.3.3 technical data the data below only apply to front-mounted burners from riello oil: fuel oil, max. Viscosity at 20°c: 6 mm 2 /s description unit cof 199 cof 245 cof 315 cof 385 cof 455 cof 700 natural gas (g20 - 20 mbar): burner model [-] bs 2 bs 2 bs 3 bs 3 bs 3 bs 3 burner type [-] 912 t1 9...

Page 10

10 description unit cof 199 cof 245 cof 315 cof 385 cof 455 cof 700 oil data burner model [-] rg 2 rg 2 rg 3 rg 3 rg 3 rg 3 burner type [-] 377 t1 377 t1 393 t1 393 t1 393 t1 396 t1 nozzle (delavan) [-] 1.25 x 80b 1.5 x 80b 1.75 x 80b 2.25 x 80b 2.75 x 80b 2.0 x 80b nominal load (lower value) kw 62....

Page 11

11 11 1.3.4 air-proving switch this section is only applicable, if the heater has been equipped with a gas-fired burner. The air-proving switch monitors the air flow to the burner during the pre-purge cycle and operating cycle of the water heater. If the air flow drops below a threshold value, the a...

Page 12

12 12 1.3.5 gas-pressure switch this section is only applicable, if the heater has been equipped with a gas-fired burner. The gas-pressure switch monitors the gas pre-pressure to the gas block. If the gas pre-pressure drops below a threshold value, the gas block will close-off the gas supply to the ...

Page 13

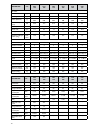

13 13 1.3.6 setting the burner head this section is applicable for heaters equipped with either gas-fired burners or oil-fired burners. The burner head is set as a function of the water heater’s required flow rate. During the commissioning of the water heater, the position of the burner head must be...

Page 14

14 14 1.3.7 setting the air valve this section is applicable for heaters equipped with either gas-fired burners or oil-fired burners. The air valve is set as a function of the water heater’s required flow rate. During the commissioning of the water heater, the position of the air valve must be set t...

Page 15

15 15 2. For the installer if possible, use a trolley or fork-lift truck to transport the heater. The heater must be vertical at all times during transportation. The installer must ensure that the required combustion air intake is not located in areas where chemical substances are stored and/or used...

Page 16

16 16 2.1.2.1 vented systems if the water heater is to be connected to a cold feed tank or cistern the hot water supply pipe must include an open vent which discharges over the cold feed cistern. The cold feed cistern must have an actual capacity of greater volume than the hourly recovery rate of th...

Page 17

17 17 2.1.2.2 unvented systems to install an a.O. Smith water heater on an unvented cold water supply system a kit of valves and fittings listed by the water research centre and complying with part g3 of the current building regulations and bs 7206 should be used. Installation should be carried out ...

Page 18

18 18 a.O. Smith water heaters are tested to a maximum pressure of 12 bar and a maximum working pressure of 8 bar. Dead legs on a hot water installation are undesireable. Where possible they should be avoided. Where the inclusion on the system of a dead leg is unavoidable the following restrictions ...

Page 19

19 19 the electricity supply must comply with the requirements below: supply voltage frequency fuse 230 v ac 50 hz 6 a (-15% / +10%) (+/- 2%) the electrical diagrams of all connections in the control box are shown in the appendix, (see figure 9: electrical diagram). 2.2 commissioning 2.2.1 filling t...

Page 20

20 20 control again as soon as the high-limit thermostat is deactivated. If the overheating cut-out is activated, it must be reset manually after the water has cooled down. Upon resetting, the water heater will resume its operation in the usual way. 2.5 setting the nominal load this section is only ...

Page 21

21 21 2.9 descaling calcium deposition depends on the type of water and the demand. In addition, calcium deposition increases at high water temperatures. A temperature setting of 60°c is recommended, which will keep calcium deposition to a minimum. Access covers are located on the right and left sid...

Page 22

22 22 3. For the user 3.1 instructions for use 3.1.1 lighting the heater warning: an accredited installer must install the heater and commission it. 3.1.2 filling the heater 1. Fit the drain cock and check that it is closed. 2. Open the cold-water tap to the heater and all hot- water outlets in orde...

Page 23

23 23 figure 8: resetting the overheating cut-out fault possible cause measure heater is off or chimney is blocked. Trace (or let trace) cause and rectify it. Does not ignite overheating cut-out is activated. Let water in heater cool down and set the water temperature to a lower value. Reset the ove...

Page 24

24 24 5. Warranty the following conditions form the guarantee agreement between a.O. Smith water products company (the warrantor) and the owner of the water heater. 5.1 guarantee in general if within one year of the original installation date of the water heater any part or component other than the ...

Page 25

25 25 figure 9: electrical diagram cof = brown = blue = yellow/green = black = earth n = neutral l = live a = ‘i/0’-switch b = overheating cut-out c = high-limit thermostat d = control thermostat e = male 7-pole connector 6. Appendix: 6.1 electrical diagram cof imd-0010 h1 = running time counter sb ...

Page 26

26 0311962 r0

Page 28

Uw installateur your installer ihr installateur votre installateur su instalador instalador ditta installatrice twój instalator eγκαταστάτη Σας nederland a.O. Smith water products company b.V. Postbus 70 5500 ab veldhoven 0800 - aosmith (2676484) info@aosmith.Nl www.Aosmith.Nl france a.O. Smith l’ea...