- DL manuals

- A.O. Smith

- Water Heater

- CONSERVATIONIST BTPV-650A

- Installation & Operation Manual

A.O. Smith CONSERVATIONIST BTPV-650A Installation & Operation Manual

1

MODELS BTP(V)-540A, 650A AND 740A

COMMERCIAL GAS, GLASS-LINED, TANK-TYPE LOW NOx

WATER HEATER

CONSER

CONSER

CONSER

CONSER

CONSERV

V

V

V

VA

A

A

A

ATIONIST

TIONIST

TIONIST

TIONIST

TIONIST

®

®

®

®

®

PART NO. 195033-000

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS IN-

FORMATION RELATIVE TO YOUR SAFETY. PLEASE

READ THOROUGHLY BEFORE INSTALLING AND USING

THIS APPLIANCE.

A DIVISION OF A.O.SMITH CORPORATION

MCBEE, SOUTH CAROLINA

www.aosmithwaterheaters.com

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

• INSTALLATION • OPERATION • MAINTENANCE • LIMITED WARRANTY

PRINTED IN U.S.A. 1004

Summary of CONSERVATIONIST BTPV-650A

Page 1

1 models btp(v)-540a, 650a and 740a commercial gas, glass-lined, tank-type low nox water heater conser conser conser conser conserv v v v va a a a ationist tionist tionist tionist tionist ® ® ® ® ® part no. 195033-000 caution text printed or outlined in red contains in- formation relative to your sa...

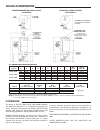

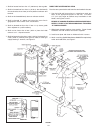

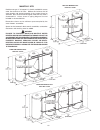

Page 2: Rough-In Dimensions

2 foreword the design of the btp 540a through 740a models complies with ansi z21.10.3/csa 4.3 as an automatic circulating tank and an automatic instantaneous type heater. The btpv 540a through 740a models are designed for sidewall venting and direct venting applications and are certified under ul 79...

Page 3

3 are different from natural gas models. A natural gas heater will not function safely on lp gas and no attempt should be made to convert a heater from natural gas to lp gas. Btp(v)-540a, 650a & 740a models are not available for use with liquefied petroleum or lp gas. If you have obtained a btp(v)-5...

Page 4

4 and sodium chloride (water softener salt), waxes, and process chemicals are typical compounds which are potentially corrosive. Do not store products of this sort near the heater. Also, air which is brought in contact with the heater should no contain any of these chemicals. If necessary, uncontami...

Page 5

5 continued manual resetting of high limit control, preceded by higher than usual water temperature is evidence of high limit switch operation. The following are possible reasons for high limit switch operation. • a malfunction in the thermostatic controls would allow the gas valve to remain open ca...

Page 6

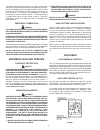

6 units, which are to be installed on combustible flooring, must be supported by a full layer of hollow concrete blocks, from 8” (203.2 mm) to 12” (304.8 mm) thick and extending 12” (304.8 mm) minimum beyond the heater in all directions. The concrete blocks must provide an unbroken concrete surface ...

Page 7

7 heater must be protected from freezing downdrafts during shutdown periods. The btp 540a, 650a and 750a water heater are classified as a category i appliance (non-positive vent pressure, non- condensing) when installed with the supplied barometric draft control assembly in a vertical vent installat...

Page 8

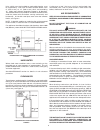

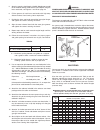

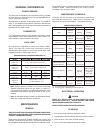

8 refer to table 2 for limitations of venting system design for horizontal venting. Table 2 btpv-540a-740a flue outlet dia. (inches/mm) 9” (228.6) flue reducer 9” x 8” dimensions -supplied (inches/mm) 228.6 x 203.2 minimum outlet vent dia. (inches/mm) 8” (203.2) maximum number 90° 4 of elbows 45° 8 ...

Page 9

9 direct venting - for btpv models all exhaust vent terminal, flue reducer, and intake vent terminal are supplied with any unit intended for direct venting. These parts must be installed without alteration. This heater is category iii appliance when used in a direct vent application. All national an...

Page 10

10 1. Shall be located not less than 12” (304.8 mm) above grade. 2. Shall be located not less than 3 (.9144 m) feet horizontally from and not less than 3 feet (.9144 m) below an exhaust vent terminal. 3. Shall not be located directly above an exhaust terminal. 4. Shall be located 12” (304.8 mm) abov...

Page 11

11 5. Attach a properly sized length of selkirk metalbestos model ps or model g venting to the exhaust vent adapter using the inner vee bands, see figures 7 and 7b on page 10. 6. Fill the grooves in both inner vee bands with high-temp silicone sealant, dow corning 736 or equivalent. 7. Position the ...

Page 12

12 table 9a maximum capacity of pipe in cubic feet of gas per hour (based upon a pressure drop of 0.5 inch water column and 0.5 specific gravity gas and max. Gas press. Of .5 psig) length in nominal iron pipe sizes, millimeters meters 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 4" 3.0 51 105 199 410 615...

Page 13

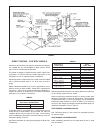

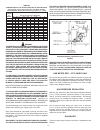

13 robertshaw ® 7000 derhc gas control valve figure 10. Water line connections following are detailed installation diagrams for typical methods of application for the water heaters. The water heater may be installed by itself, or with a separate storage tank, on both single and two-temperature syste...

Page 14

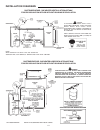

14 installation diagrams one temperature - one heater vertical storage tank forced circulation with or without building recirculation danger if building cold water supply has a backflow preventer, check valve or water meter with check valve, provisions for thermal expansion of water in the hot water...

Page 15

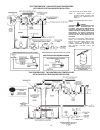

15 two temperature - one heater high temperature with or without building recirculation two temperature - two heaters high temperature with or without building recirculation *pipe relief valve to open drain note: if tempered water is recirculated, return line should be connected at point “a”. Instal...

Page 16

16 caution: if building cold water supply has a backflow preventer, check valve or water meter with check valve, provisions for thermal expansion of water in the hot water system must be provided. Two temperature - three heaters (two pre-heaters/one booster) with or without building recirculation tw...

Page 17

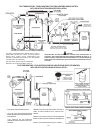

17 two temperature - one heater high temperature with recirculation of sanitizing loop caution: if building cold water supply has a backflow preventer, check valve or water meter with check valve, provisions for thermal expansion of water in the hot water system must be provided. Danger temperature ...

Page 18

18 manifold kits precision cut type “l” all copper a. O. Smith manifold kits assure water flow balance of all units. Without this balance, the full water heating and storage potential of the system cannot be achieved. Plus, the units with the higher water flow may have a shortened life. Unions shown...

Page 19

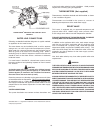

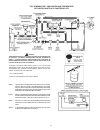

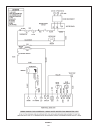

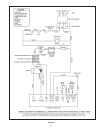

19 heater wiring if any of the original wire as supplied with the appliance must be replaced, it must be replaced with 105°c wire or its equivalent, except in the burner housing use 200°c wire. The power burner is wired to the heater as shown in figure 11 for btp models and figure 12 for btpv models...

Page 20

20 figure 11..

Page 21

21 figure 12..

Page 22

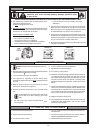

22 for your safety read before lighting 1. Remove thermostat control cover. 2. Set thermostat to lowest setting. 3. Turn burner switch to “off”. Warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This ...

Page 23

23 sequence of operation – power on. – heater in standby mode. – thermostat calls for heat. – blower motor starts. – blower operation closes the normally open blower prover/ blocked outlet safety pressure switch. – on proof of airflow, honeywell s8680j flame control module energized. – 45 seconds pr...

Page 24

24 1. Check gas line pressure with a manometer. Set initial gas line pressure at 9-10” w.C. Before turning the heater “on”. Read gas line pressure and gas manifold pressure when the heater main gas is “on”. Adjust gas line regulator setting if the gas line pressure drops below 8” w.C. When heater ma...

Page 25

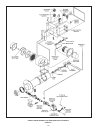

25 premix low nox burner - exploded view for btp models figure 13..

Page 26

26 premix low nox burner - exploded view for btpv models figure 14..

Page 27

27 general information power burner the initial start-up procedure of the gas power burner is provided on page 18 thru 21. Refer to figure 12, burner exploded view for burner components location. The sequence of operation of the power burner is provided on page 15. For detailed power burner operatio...

Page 28

28 draining the heater must be drained if it is to be shut down and exposed to freezing temperatures. Maintenance and service procedures may also require draining the heater. 1. Turn off the heater electrical disconnect switch. 2. Close the cold water inlet valve to heater. 3. Open a nearby hot wate...

Page 29: Information

29 above all, do not plug the temperature and pressure relief valve. This is not a solution and can create a hazardous situation. Circulating pump the water heating system may include a circulating pump. Where used, it should be lubricated as directed by the circulator manufacturer. Low emission pow...

Page 30

30 2. Check the fuses. • the electrical disconnect switch usually contains fuses. 3. The capacity of the heater may have been exceeded by a large demand for hot water. 4. Colder incoming water temperature will lengthen the time required to heat water to the desired temperature. • if the heater was i...

Page 31

31 refer to the sequence of operation and burner exploded view, see figure 12 and the wiring diagram located on page 20, and the troubleshooting section of burner manual before continuing. Make sure the appliance is connected to a 120 vac power supply, burner switch is “on” and manual gas valve is i...

Page 32

32 • do not proceed to step 5 unless 24v is detected at “24v” terminal of the honeywell module. 5. As soon as the pilot gas valve is energized, check for the burner pilot flame through the burner peek-hole. If the pilot flame is established inside the burner, then proceed to step 6. • turn the burne...

Page 33

33 model btp(v) limited warranty a.O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this water heater. 1. The tank if the glass-lined tank in this water heater shall prove upon examination by the warrantor to have leaked due to the natural corrosion from po...

Page 34

34 notes.

Page 35

35 notes.

Page 36

36 replacement parts 5621 w. 115th street, alsip, il 60803 phone: 800-433-2545 fax: 800-433-2515 www.Aosmithwaterheaters.Com e-mail: parts@hotwater.Com.