1 with electronic intermittent pilot ignition and installations warning: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. — do not store or use gasoline or other flammable vapors and liquids in the vic...

2 foreword caution text printed or outlined in red contains information relative to your safety. Please read thoroughly before using appliance. Detailed installation diagrams are in this manual. These diagrams will serve to provide the installer with a reference for the materials and method of pipin...

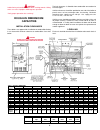

3 warning an ample supply of air must be provided for proper combustion and ventilation. Minimum clearances to combustibles water blank top side side rear vent front all models 12" (305mm) 18" (457mm) 6" (155mm) 6" (155mm) 6" (155mm) alcove caution label all wires prior to disconnection when servici...

4 warning your dura-max boiler is not designed to operate with a boiler inlet water temperature of less than 100°f (38°c). Colder inlet water temperatures will result in significant condensation developing on the heat exchanger. This situation can cause a corrosive environment for the heat exchanger...

5 features important only qualified personnel shall perform the initial firing of the heater. At this time the user should not hesitate to ask the individual any questions regarding the operation and maintenance of the unit. Lighting and operating instructions are included at the rear of this manual...

6 automatic reset high temperature limit control caution limit controls are not to be used as thermostats. All models - this limit is a safety device wired in series with the ignition system. Set the limit control dial to a minimum of 10°f (6°c) above the maximum designed system temperature. If the ...

7 installation instructions required ability installation or service of this boiler requires ability equivalent to that of a licensed tradesman in the field involved. Plumbing, air supply, venting, gas supply and electrical work are required. Warning the inlet/outlet water manifold on your a. O. Smi...

8 if the confined space is within a building of tight construction, air for combustion, ventilation, and draft hood dilution must be obtained from outdoors. When directly communicating with the outdoors or communicating with the outdoors through vertical ducts, two permanent openings, located in the...

9 warning failure to correct back drafts may cause air contamination and unsafe conditions. Vent connectors serving appliances vented by natural draft shall not be connected into any portion of mechanical draft systems operating under positive pressure. 3. Connecting boiler to a common vent do not c...

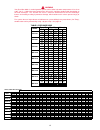

10 table 5 multipliers to be used with table 1 when applying the gravity factor to other than .60 specific gravity specific specific gravity multiplier gravity multiplier .35 1.31 1.00 .78 .40 1.23 1.10 .74 .45 1.16 1.20 .71 .50 1.10 1.30 .68 .55 1.04 1.40 .66 *.60 (nat.) 1.00 *1.50 (prop.) .63 .65 ...

11 applications of the gravity factor converts the figures given in table 1 to capacities with another gas of different specific gravity. Such application is accomplished by multiplying the capacities given in table 1 by the multipliers shown in table 5. To determine the size of each section of gas ...

12 if any of the original wire, as supplied with the appliance, must be replaced, it must be replaced with type 105°c wire or its equivalent, except for the flame sensor and ignition cable which are 250°c. Servicing wiring and/or control caution label all wires prior to disconnection when servicing ...

13 the flow switch shall be mounted in the top opening of the reducing tee and provide adequate paddle length in the flow stream. For example in a 2" pipe installation use a 2" x 2" x 1" reducing tee. For 2" or 3" pipe use the paddle segments as supplied. For other pipe sizes (i.E. 2-1/2") trim the ...

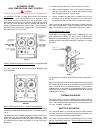

14 thereafter, during the heating season, lubricate the three oil cups at least once every four months. Combination heating/cooling systems or water heating (cer-temp) systems should be lubricated every four months year-round. Use 2 or 3 teaspoonfuls in bearing oil cups, fig. 9, and 10 or 12 drops i...

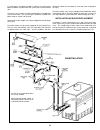

15 a system bypass should be installed as shown in fig. 10 to prevent boiler circulation starvation when the system zones call for reduced flow. This bypass may also be used with multiple boilers manifolded for reverse-return flow. The system bypass would be installed from boiler outlet to suction s...

16 notes: 1. Building temperature controls supply electric power to building circulator. 2. Main flow switch proves main water flow before energizing, sequencing and resetting controls. 3. Outdoor thermostat required if building controls do not provide automatic shut-down of reset controls during wa...

17 bypass balancing with systems where water temperature can be expected to drop appreciably due to long standby periods, or heavy draw down, a bypass pipe of at least 1" size with a balancing cock should be installed between the boiler inlet and outlet (see fig. 10). When the system first starts, t...

18 generator type boilers establish temperature rises. The deciding factor in choice of boiler temperature rise relates to the boiler inlet temperature. Boiler outlet, minus system temperature drop, is boiler inlet temperature. The boiler temperature rise should not raise the outlet temperature up t...

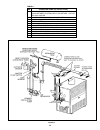

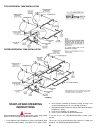

19 figure 14 no. Suggested items for installation 1. Short pipe nipple and pair of boiler loop tees in piping between system supply and return - one set per each boiler 2. Boiler pipe loop (see piping sizing data table 3.) 3. Boiler circulating pump (see piping sizing data table 3.) 4. Thermometer 5...

20 use ony type 105°c thermoplastic or its equivalent if any of the original wires as supplied must be replaced. Use ony type 105°c thermoplastic or its equivalent if any of the original wires as supplied must be replaced. Boiler conventional system figure 15 one boiler linear-temp system figure 16.

21 dura-max - pump mount - single stage - schematic diagram dura-max - single stage firing - united states models with pump. 120 volt system controller.

22 dura-max - pump mount - dual stage - schematic diagram dura-max - dual stage firing - united states models with pump. 120 volt system controller.

23 dura-max - pump mounted - modulating - schematic diagram dura-max - modulated firing - united states models with pump. 120 volt system controller.

24 dura-max - single stage firing - schematic diagram dura-max - single stage firing - united states & canadian models without pump. 120 volt system controller.

25 dura-max - dual stage firing - schematic diagram dura-max - dual stage firing - united states & canadian models without pump. 120 volt system controller.

26 dura-max - modulated firing - schematic diagram dura-max - modulated firing - united states & canadian models without pump. 120 volt system controller.

27 hot water supply applications cer-temp 80 recovery systems water line connections this section provides detailed installation diagrams for typical methods of application for the unit using a cer-temp 80 recovery system (for one temperature water). This equipment must be protected against loss of ...

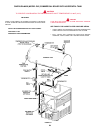

28 one dura-max (model dw) commercial boiler with horizontal tank caution to prevent condensation the minimum boiler inlet temperature is 100°f (38°c) important safety flow switch as shown to protect the boiler in case of water service interruption or circulator failure. Caution pump must be rated f...

29 two dura-max (model dw) hot water supply boilers with vertical tank caution to prevent condensation the minimum boiler inlet temperature is 100°f (38°c) see page 31 for additional piping information. Caution pump must be rated for system operating temperature and pressure . * safety relief valve ...

30 two dura-max (model dw) hot water supply boilers with horizontal tank caution to prevent condensation the minimum boiler inlet temperature is 100°f (38°c) important the installation of safety flow switches as shown is required to protect the boiler in case of water service interruption or circula...

31 figure 24 manifolding of model tjv-120m & tjv-200m tanks note: pipe sizes between manifolds and boiler(s) to be selected from the cer-temp 80 diagram for the heater model to be installed. All piping from tees to be equidistant to tanks. Install in accordance with all local codes. Pressure relief ...

32 start-up and operating instructions warning after placing boiler into operation, the ignition system safety shutoff device must be tested by the following test method. 1. Reset manual high temperature safety limit control (high limit) to the lowest setting. (see figures 3 or 4, pages 5 or 6). 2. ...

33 lighting and operating instructions warning: hot water can produce 3rd degree burns in 6 seconds at 140° f. (60° c). In case of power failure do not attempt to operate boiler. Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury or loss ...

34 internal contaminants the system must be internally cleaned and flushed after a new or replacement unit has been installed to remove contaminants that may have accumulated during installation. This is doubly important when a replacement unit is installed into an existing system where stop leak or...

35 1. Remove main burners from unit. 2. Check that burner venturi and ports are free of foreign matter. 3. Clean burners with bristle brush and/or vacuum cleaner 3/4" do not distort burner ports or pilot location. 4. Reinstall burners in unit. Making sure front and rear of burners are installed corr...

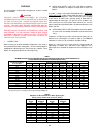

36 checking honeywell s8600h or s8610m (nat. Gas) intermittent ignition controls no spark at pilot burner no replace ignition module is voltage (24 vac) across the 24 v terrminals on module during “call for heat”? Yes is voltage (24 vac) across the pv & mv/pv terminals on “call for heat”? No note: s...

37 spark at pilot burner but pilot will not light ensure all manual shutoff valves are fully open; all filters are clean; all gas connections are gas tight; pilot tubing is not damaged, obstructed or kinked; and pilot orifice is unclogged. Check for air in gas line, purge (bleed) line if necessary. ...

38 pilot burner lights but main burner does not light correct the situation by consulting no the installation or user’s manual does the pilot flame cover 3/8° to 1/2" on how to adjust pilot flame. (10 mm to 12 mm) of igniter/sensor rod? Yes replace ignition no no module. Is voltage (24 vac) across d...

39 caution do not use a nylon brush or other static creating material to clean dust and carbon deposits from heating surfaces and vent. Such deposits are flammable and may be ignited by static electricity. Use a metal brush to minimize the danger of explosion 1. Turn off the electrical power, main m...

40 the time between cleaning will vary from two to six months depending upon water conditions and usage. A change of approximately 5°f in the normal temperature rise through the boiler is usually an indication that scale should be removed. For long life, copper or brass is recommended for all valves...

41 dura-max limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this hydronic boiler: 1. If within ten years after initial installation of the boiler, the heat exchanger shall prove upon examination by the warrantor to be defective in mater...

42.

43.

44 replacement parts 5621 w. 115th street, alsip, il 60803 phone: 800-433-2545 fax: 800-433-2515 www.Hotwater.Com e-mail: parts@hotwater.Com.