1 part no. 183432-000 rev.1 printed in u.S.A. 2566 200 supersedes part no. 183323-000 keep this manual in the pocket on the heater for future reference whenever maintenance adjustment or service is required. Power vented gas models fpsh/fpcr/fpst with smartvalve tm , hot surface ignition & 2” pvc ve...

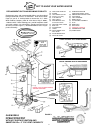

2 get to know your water heater (a) vent pipe-exhaust (b) anode (c) hot water outlet (d) outlet (115 vac) (e) flue baffle (f) gas supply (g) main manual gas shut off valve (h) ground joint union (j) dirt leg (k) outer door (l) union (m) inlet water shut off valve (n) cold water inlet (o) inlet dip t...

3 suspected, do not attempt to find the cause yourself. Go to a neighbor's house, leaving your doors open to ventilate the house, then call your gas supplier or service agent. Keep area clear until a service call has been made. At times you may not be able to smell an lp gas leak. One cause is odor ...

4 installation required ability installation or service of this water heater requires ability equivalent to that of a licensed tradesman in the field involved. Plumbing, air supply, venting and gas supply are required. General the installation must conform to these instructions and the local code au...

5 the heater should be located in an area where leakage of the tank or connections will not result in damage to the area adjacent to the heater or to lower floors of the structure. When such locations cannot be avoided, a suitable drain pan should be installed under the heater, see fig. 1. The pan s...

6 before placing the heater in operation, check for gas leakage. Use soap and water solution or other material acceptable for this purpose. Do not use matches candles, flame or other sources of ignition to locate gas leaks. Relief valve (p)-fig. 1 a new temperature and pressure relief valve complyin...

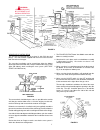

7 sequence of installation this unit can vent through two (2) or three (3) inch pvc pipe and fittings. The vent terminal supplied with the unit must be used for both two or three inch pipe. The vent pipe installation can be started from either the blower discharge or the termination wall. Keep in mi...

8 this unit is manufactured with an external control harness for easier replacement if the harness or connectors get damaged. 6. Do not plug in power cord until vent system is completely installed. The power vent operates on 110-120 vac, therefore a grounded outlet must be within reach of the six (6...

9 table for vent pipe length for fpsh/fpcr units two inch diameter pipe **number of 90° elbows **number of 45° elbows minimum pipe maximum pipe one (1) none 2 ft. 46 ft. One (1) one (1) 1 ft. 42 ft. Two (2) none 1 ft. 38 ft. Two (2) one (1) 1 ft. 34 ft. Three (3) none 1 ft. 30 ft. Three (3) one (1) ...

10 through the drain in the bottom of the housing. A plastic tube is furnished for the condensate to be drained away from the water heater. A method to keep the condensate from draining back to the blower, in a horizontal run, is to install the pipe with a slight downward slope. The pipe can slope 1...

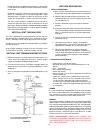

11 applicators select a suitable pure bristle type paint brush. Use a proper width brush or roller to apply the primer and cement (see chart below). Speedy application of cement is important due to its fast drying characteristics. Important note: a dauber type applicator should only be used on pipe ...

12 f. Joint assembly working quickly, insert the pipe into the fitting socket bottom and give the pipe or fitting a 1/4" turn to evenly distribute the cement. Do not continue to rotate the pipe after it has hit the bottom of the fitting socket. A good joint will have sufficient cement to make a bead...

13 for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the b...

14 time to produce 2nd & 3rd temperature setting degree burns on adult skin very hot= approx. 160*f about 1/2 second c = approx. 150*f about 1-1/2 seconds b = approx. 140*f less than 5 seconds a = approx. 130*f about 30 seconds hot = approx. 120*f more than 5 minutes low = approx. 80*f - - - - - - -...

15 maintenance warning disconnect from electrical supply before servicing unit. For your safety, water heater service should be performed only by a qualified service technician. Read the general safety information section first. Users of this appliance should be aware that gas components wear out ov...

16 forming droplets, these drip into the fire or run out on the floor. This is common at the time of startup after installation, during periods of time when incoming water is very cold, or the heater may be undersized for the requirements. Droplets from the bottom of the flue may be due to corrosive...

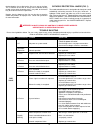

17 problem cause solution 1) blower will not run. A) “on/off” control switch turned off. Turn switch to the “on” position. B) blower unplugged. Plug blower back into 115 vac. Outlet. C) no power at outlet. Repair service to outlet. D) thermostat defective. Replace thermostat. E) control harness defe...

18 this warranty is applicable to the original owner only. If the glass lined tank in this water heater shall prove upon examination by a. O. Smith corporation (the warrantor) to have leaked during the warranty period in normal residential use, due to natural corrosion from potable water therein, th...