1 printed in u.S.A. 0605 part no. 185171-001 keep this manual in the pocket on the heater for future reference whenever maintenance adjustment or service is required. Power vented gas models gpsh/gpcr with hot surface ignition thank you for buying this energy efficient water heater from a.O. Smith w...

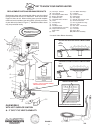

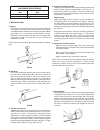

2 get to know your water heater (a) vent pipe - exhaust (b) vent terminal (c) vent adapter-rubber boot (d) blower assembly (e) cold water inlet (f) inlet water shut-off valve (g) union (h) inlet dip tube (j) anode** (k) hot water outlet (l) oulet receptacle (115 vac) (m) temperature-pressure relief ...

3 then call your gas supplier or service agent. Keep area clear until a service call has been made. At times you may not be able to smell an lp gas leak. One cause is odor fade, which is a loss of the chemical odorant that gives lp gas its distinctive smell. Another cause can be your physical condit...

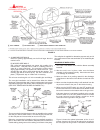

4 air requirements dilution air temperature must be 100°f or less. In calculating the free area of a vent opening, the blocking effect of screens, louvers and grills should be considered. Screens shall not be of a mesh smaller than 1/4 inch square. If the free area is not known, the current edition ...

5 caution in cold climates provide protection against freeze-up. The heater should be located in an area where leakage of the tank or connections will not result in damage to the area adjacent to the heater or to lower floors of the structure. When such locations cannot be avoided, a suitable drain ...

6 to prevent damage, care must be taken not to apply too much torque when attaching gas supply pipe to gas valve inlet. The thermostat inlet has a pad for use with back up wrench. Apply joint compounds (pipe dope) sparingly and only to the male threads of pipe joints. Do not apply compound to the fi...

7 3. A) masonry side walls chisel an opening approximately one half inch larger than the marked circle. B) wooden side walls drill a pilot hole approximately one quarter inch outside of the marked circle. This pilot hole is used as a starting point for a saws-all or sabre saw blade. Cut around the m...

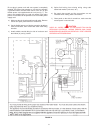

8 figure 6 d.) splice field wiring into existing wiring using code authorized method (wire nuts, etc.). E.) be certain that neutral and line connections are not reversed when making these connections. F.) close panel on the side of control box, make sure that access panel is secured shut. Caution la...

9 installation of vent system caution for installation of a new vent system, follow the guidelines in the manual. For pre-existing vent systems, inspect the vent for blockage or any signs of damage. Check to see if the vent pipe is properly pitched and its joints secured. Follow the venting specific...

10 vertical vent through roof this unit is approved for venting through the roof with the type vent terminal that is included with the unit. A proper flashing or “boot” should be used to seal the pipe where it exits the roof. The total vent system should not exceed that which is specified in the tab...

11 recommended brush* size for primer and cement applications nominal pipe size brush width (ips) (ins.) 2 1-1/2 3 1-1/2 - 2-1/2 *use only natural bristle 3. Making the joint a. Cutting pipe must be squarely cut to allow for the proper interfacing of the pipe end and the fitting socket bottom. This ...

12 g. Cleanup and joint movement remove all excess cement from around the pipe and fitting with a dry cotton rag. This must be done while the cement is still soft. The joint should not be disturbed immediately after the cementing procedure, and sufficient time should be allowed for proper curing of ...

13 for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the b...

14 temperature regulation warning this water heater is equipped with an adjustable thermostat to control water temperature. Hot water temperatures required for automatic dishwasher and laundry use can cause painful scalding with possible serious and permanent injury. The temperature at which injury ...

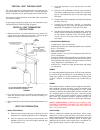

15 water heating ignition sequence (make sure gas and electric power are connected properly) 1) the ignition control module is powered and monitors the system, waiting for a call for heat from the thermostat. 2) the thermostat calls for heat by reading a resistance value within a given range directl...

16 venting system have venting system checked every six months for obstructions and/or deterioration in vent piping. Blower assembly maintenance caution the air flow restrictor screen on the inlet side of the blower unit should be checked periodically for any accumulation of dust and lint. Any build...

17 trouble shooting please check guidelines below. For your safety, water heater service should be performed only by a qualified service technician. Read the general safety information section first. Problem solution an open earth ground circuit to the 1. Check that the earth ground connection is ig...

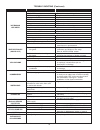

18 trouble shooting (continued) problem cause solution 1) blower will not run. A) “on/off” control switch turned off. Turn switch to the “on” position. B) blower unplugged. Plug blower back into 115 vac. Outlet. C) no power at outlet. Repair service to outlet. D) thermostat defective. Replace thermo...

19 this warranty is applicable to the original owner only. If the glass lined tank in this water heater shall prove upon examination by a. O. Smith corporation (the warrantor) to have leaked during the warranty period in normal residential use, due to natural corrosion from potable water therein, th...

20 5621 w. 115th street, alsip, il 60803 phone: 1-800-433-2545 fax: 1-800-433-2515 www.Hotwater.Com e-mail: parts@hotwater.Com replacement parts.