A.O. Smith NW 150 Instruction Manual

1

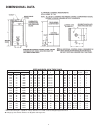

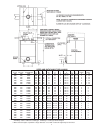

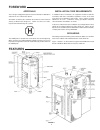

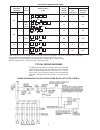

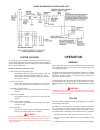

DURA-POWER MODELS NW 37- 670

COMMERCIAL ELECTRIC WATER BOILERS

•

Installation

•

Operation

•

Service

•

Maintenance

•

Limited Warranty

PLACE THESE INSTRUCTIONS ADJACENT TO THE BOILER AND NOTIFY OWNER TO KEEP FOR

FUTURE REFERENCE.BE SURE THAT THE WARRANTY INFORMATION

HAS BEEN FILLED IN ON COMPLETION OF INSTALLATION.

PRINTED IN U.S.A. 0004G 0900

PART NO. 60047-002 REV.2

FLOOD WARNING

IF THE BOILER SHOULD BECOME IMMERSED IN

WATER AT ANY TIME, THE BOILER SHOULD BE

EXAMINED BY A COMPETENT SERVICE PERSON

BEFORE IT IS RETURNED TO SERVICE.

A DIVISION OF A.O. SMITH CORPORATION

RENTON, WASHINGTON

www.hotwater.com

STANDARD

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTINS INFORMATION

RELATIVE TO YOUR SAFETY. PLEASE READ THOROUGHLY

BEFORE INSTALLING AND USING THE APPLIANCE.