- DL manuals

- A.O. Smith

- Boiler

- XB-100

- Instruction Manual

A.O. Smith XB-100 Instruction Manual

XP BOILER

Instruction Manual

PRINTED IN THE U.S.A. 0711

320741-002

Thank you for buying this energy efficient boiler.

We appreciate your confidence in our products.

MODELS: XB/XW

1000, 1300, 1700

2000, 2600, 3400

SERIES 100/101

INSTALLATION - OPERATION -

MAINTENANCE - LIMITED WARRANTY

25589 Highway 1

McBee, SC 29101

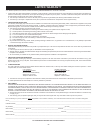

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do

not use any phone in your building.

Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot reach your gas supplier,

call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

•

•

•

•

Summary of XB-100

Page 1

Xp boiler instruction manual printed in the u.S.A. 0711 320741-002 thank you for buying this energy efficient boiler. We appreciate your confidence in our products. Models: xb/xw 1000, 1300, 1700 2000, 2600, 3400 series 100/101 installation - operation - maintenance - limited warranty 25589 highway ...

Page 2: Table of Contents

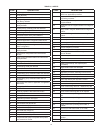

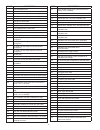

2 table of contents table of contents .......................................................................... 2 safe installation, use and service.......................................... 3 general safety................................................................................ 4 introduct...

Page 3: Approvals

3 the proper installation, use and servicing of this boiler is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your boiler to warn you and others of a potential injury hazard. Read and obey all safety...

Page 4: General Safety

4 grounding instructions this boiler must be grounded in accordance with the national electrical code, canadian electrical code and/or local codes. Boiler is polarity sensitive; correct wiring is imperative for proper operation. This boiler must be connected to a grounded metal, permanent wiring sys...

Page 5: Introduction

5 this instruction manual covers xp boiler models xb/xw 1000, 1300, 1700, 2000, 2600, 3400 - series 100/101. The instructions and illustrations contained in this instruction manual will provide you with troubleshooting procedures to diagnose and repair common problems and verify proper operation. Mo...

Page 6

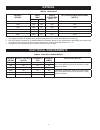

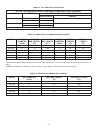

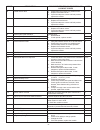

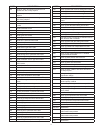

6 dimensions and capacity data table 1. Rough in dimensions (single) models xb/xw-1000 xb/xw-1300 xb/xw-1700 dimensions inches mm inches mm inches mm flue outlet diameter 6 152 8 152 8 203 air intake diameter 6 152 6 152 8 203 water inlet 2 inch npt 2 1/2 inch npt water outlet 2 inch npt 2 1/2 inch ...

Page 7

7 table 3. Rough in dimensions (double) models xb/xw-2000 xb/xw-2600 xb/xw-3400 dimensions inches mm inches mm inches mm flue outlet diameter 8 203 8 203 10 254 air intake diameter 8 203 8 203 10 254 water inlet 3 inch npt 4 inch npt water outlet 3 inch npt 4 inch npt gas inlet 2 inch npt 3 inch npt...

Page 8: Ratings

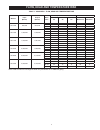

8 models (xb/xw) input mbh gross output mbh (note 1) net i=b=r ratings water mbh (note 2) max min 1000 920 100 856 744 1300 1300 130 1209 1051 1700 1700 170 1581 1375 2000 2000 100 1860 1617 2600 2600 130 2418 2103 3400 3400 212 3162 2750 ratings table 5. Ibr ratings notes: 1. The ratings are based ...

Page 9

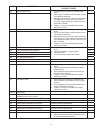

9 flow, head and temperature rise table 7. Xb models - flow, head and temperature rise models input (btu/hr) output (btu/hr) water flow temperature rise - Δt °f flow rate 20 30 40 maximum minimum xb-1000 920,000 855,600 gpm 86 56 43 86 43 lpm 325 211 162 325 162 Δp ft 26 12 7 26 7 Δp m 7.9 3.7 2.1 7...

Page 10: Features And Components

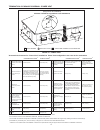

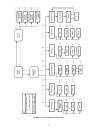

10 features and components figure 3. Single heat exchanger boiler components.

Page 11

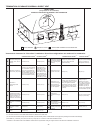

11 figure 4. Double heat exchanger boiler components.

Page 12

12 component description 1. Front access door: provides access to the gas train, burner controllers and the heat exchanger. 2. Air filter box: allows for the connection of the pvc air intake pipe to the boiler through a standard pvc adapter. It uses a filter to prevent dust and debris from entering ...

Page 13: Control Components

13 figure 7. Low/high gas pressure switch gas valve the gas valve is a normally closed servo regulated gas valve. The valve opens only when energized by the burner control and closes when the power is removed. The burner control supplies 24 volts to the gas valve during operation. Figure 8. Gas valv...

Page 14

14 flame sensor each burner is equipped with a flame sensor to detect the presence of the burner flames at high and low fire conditions. If no flame is sensed, the gas valve will close automatically. The voltage sensed by the flame sensor will also be displayed on the burner screen. Figure 10. Flame...

Page 15

15 general if the system is to be filled with water for testing or other purposes during cold weather and before actual operation, care must be taken to prevent freezing of water in the system. Failure to do so may cause the water in the system to freeze with resulting damage to the system. Damage d...

Page 16

16 circulating pump a circulating pump is used when a system requires a circulating loop or there is a storage tank used in conjunction with the boiler. Install in accordance with the current edition of the national electrical code, nfpa 70 or the canadian electrical code, csa c22.1. All bronze circ...

Page 17: Caution

17 a discharge pipe from the relief valve should terminate at an adequate floor drain. Do not thread, plug, or cap the end of drain line. The discharge pipe: • shall not be smaller in size than the outlet pipe size of the valve, or have any reducing couplings or other restrictions. • shall not be pl...

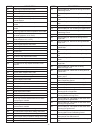

Page 18

18 table 8. Single unit installation, suggested gas pipe sizing. Maximum equivalent pipe length (in feet). Btu input 2” 2-1/2” 3” 4” nat pro nat pro nat pro nat pro 920,000 70 150 175 ----- ----- ----- ----- ----- 1,300,000 40 100 100 200 ----- ----- ----- ----- 1,700,000 20 60 70 150 200 ----- ----...

Page 19

19 • auto body shops • plastic manufacturing plants • furniture refinishing areas and establishments • new building construction • remodeling areas common household products, pool and laundry products may contain fluorine or chlorine compounds. When these chemicals come in contact with the boiler, t...

Page 20

20 table 10. Suggested pipe size for mul tiple gas appliances (na tural gas) nominal maximum capacity of pipe in btu/hr and kw for gas pressures of 14 in. W .C. (0.5 psi) or less and iron pipe a pressure drop of 0.5 in. W .C. (based on 0.60 specific gravity gas w/heating v alue of 1,000 btu’ s/ft3) ...

Page 21: General Requirements

21 general requirements required ability installation or service of this boiler requires ability equivalent to that of a licensed trades man in the field involved. Plumbing, air supply, venting, gas supply, and electrical work are re quired. Location when installing the boiler, consideration must be...

Page 22

22 leveling because this unit is a category iv appliance it produces some amounts of condensation. The unit has a condensation disposal system that requires this unit to be level to properly drain. Each unit should be checked to be certain that it is level prior to starting the unit. If the unit is ...

Page 23

23 confined space a confined space is one whose volume is less than 50 cubic feet per 1,000 btu/hr (4.8 cubic meters per kw) of the total input rating of all appliances installed in the space. Openings must be installed to provide fresh air for combustion, ventilation and dilution in confined spaces...

Page 24

24 the confined space shall be provided with two permanent vertical ducts, one commencing within 12 inches (300 mm) of the top and one commencing within 12 inches (300 mm) of the bottom of the enclosure. The vertical ducts shall communicate directly with the outdoors. See figure 20. Each duct openin...

Page 25: Venting

25 venting vent sizing, installation and termination should be in accordance with this installation manual. This boiler must be vented using pvc/cpvc or stainless steel materials. All electrical power and gas must be turned off prior to any installation of the venting system. Vent installation consi...

Page 26

26 vent and air pipe installation 1. Measure from the boiler level to vent. Refer to the table 14 on page 36 for the allowable lengths. 2. Prepare pipes to the required lengths and deburr the inside and outside of the pipe ends. Chamfer outside the pipe end to ensure even cement distribution when jo...

Page 27

27 (30.5 m). A maximum of three 90° elbows can be used. Minimum vertical vent is 7 equivalent feet (2.1 m) for direct vent installations. Standard minimum vertical vent length is 7 feet (2.1 m). See figure 25, figure 28 thru figure 30 for differences between standard and direct vent installations. 3...

Page 28

28 figure 25. Vertical venting figure 26. Horizontal venting models (xb/xw) vent kit numbers (rain cap) 1000 320884-000 1300 320884-001 1700 320884-001 2000 320884-001 2600 320884-001 3400 320884-002 models (xb/xw) vent kit numbers (tee) 1000 321765-000 1300 321765-001 1700 321765-001 2000 321765-00...

Page 29

29 figure 27. Direct vent horizontal figure 28. Direct vent vertical models (xb/xw) vent kit numbers (tee) air intake kit numbers (elbow) 1000 321765-000 321764-000 1300 321765-001 321764-000 1700 321765-001 321764-001 2000 321765-001 321764-001 2600 321765-001 321764-001 3400 321765-002 321764-002 ...

Page 30

30 figure 29. Direct vent, vertical vent horizontal intake figure 30. Direct vent, horizontal vent vertical intake models (xb/xw) vent kit numbers (rain cap) air intake kit numbers (elbow) 1000 320884-000 321764-000 1300 320884-001 321764-000 1700 320884-001 321764-001 2000 320884-001 321764-001 260...

Page 31

31 termination clearances sidewall power vent v x vent terminal air supply inlet area where terminal is not permitted v v a g v fixed closed fixed closed operable operable v c b b b b f b v v a j v h m x x v v k b e d l power vent (using room air for combustion) exterior clearances for sidewall vent...

Page 32

32 termination clearances sidewall direct vent figure 32. Direct vent vent terminal clearances for “direct vent” installations. Direct vent configurations use outdoor air for combustion. Canadian installations 1 us installations 2 canadian installations 1 us installations 2 a clearance above grade, ...

Page 33

33 for all side wall terminated, horizontally vented power vent, direct vent, and power direct vent gas fueled water heaters installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned or operated by the commonwealth and where the side ...

Page 34

34 direct vent: horizontal termination gas vent extending through an exterior wall must not terminate adjacent to a wall or below building extensions such as eaves, parapets, balconies, or decks. Failure to comply could result in severe personal injury, death, or substantial property damage. Install...

Page 35

35 direct venting: vertical termination installation must comply with local requirements and with the national fuel gas code, ansi z223.1 for u.S. Installations or csa b149.1 for canadian installations. Vent/air termination locations: follow these guidelines for locating the vent/air terminations: 1...

Page 36

36 all vent pipe materials and fittings must comply with the following: item material standards for installation in: united states canada vent pipe and fittings pvc schedule 40 ansi/astm d1785 cpvc and pvc venting must be ulc-s636 certified. Cpvc schedule 40/80 ansi/astm f441 pipe cement/primer pvc ...

Page 37: Condensate Disposal

37 condensate neutralizer the condensate drains from the boiler have ph levels between 4.3 and 5.0. The ph measurement of a fluid is an indicator of the acidity or alkalinity. Neutral fluids have ph of 7.0. Acid fluids have ph below 7. Some local codes may require the use of a condensate neutralizer...

Page 38: Gas Supply Connections

38 6. Use pipe sealing compound compatible with propane gases. Apply sparingly only to male threads of the pipe joints so that pipe dope does not block gas flow. Failure to apply pipe sealing compound as detailed in this manual can result in severe personal injury, death, or substantial property dam...

Page 39

39 pipe sizes for propane gas make sure to contact the gas supplier for pipe sizes, tanks, and 100% lockup gas pressure regulator. Purging gas line gas line purging is required with new piping or systems in which air has entered. Gas purging should be performed per nfpa 54 for us and can b149.1 for ...

Page 40

40 boiler start up and operations important only an a.O. Smith certified start-up agent must perform the initial firing of the boiler. At this time the user should not hesitate to ask the start-up agent any questions regarding the operation and maintenance of the unit. If you still have questions, p...

Page 41

41 table 18. Water hardness medium (0-12 grains per gallon) xw model no. ∆t ºf gpm ∆p feet 1000 25 76 17.5 1300 25 99 22 1700 25 129 23 2000 25 152 17.5 2600 25 198 22 3400 25 258 23 ∆t ºf = temperature rise ºf at the specified gpm. Gpm = flow rate in gallons per minute. ∆p = pressure loss through t...

Page 42

42 lighting and operating instructions.

Page 43

43 click on operation button, and under the modulation menu, set the required firing rate (high/low) by setting the rpm. On the firing rate page, set the firing rate rpm by selecting the manual in run check box. Adjustment there must be sufficient load to operate the boiler at high fire to perform t...

Page 44

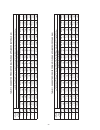

44 table 19. High fire rate table 20. Low fire rate high firing rate setting set the boiler to the high firing rate by setting the high firing rate rpm as described below. Check combustion readings using a combustion analyzer. If combustion readings are not in accordance with the chart below adjust ...

Page 45: Control System

45 3. Three pump outputs with 5 selectable operation modes. 4. 24vac: • output control of gas valve (pilot and main) and external ignition transformer. • digital inputs for room limit control, high limit control, gas pressure switch, low water cutoff. 5. External spark transformer. 6. Flame sensor. ...

Page 46

46 csd-1 acceptable. Meets csd-1 section cf-300 requirements as a primary safety control. Meets csd-1 section cw-400 requirements as a temperature operation control. Meets csd-1 section cw-400 requirements as a temperature high limit control when configured for use with 10 kohm ntc sensors. Federal ...

Page 47

47 general operational sequence initiate the r7910 enters the initiate sequence on initial power up or: • voltage fluctuations vary less than 20vac or greater than 30vac. • frequency fluctuations vary +/-5% (57 to 63 hz). • if demand, lci, or stat interrupt (open) during the prepurge period. • after...

Page 48

48 lead lag (ll) master general operation the xp boiler is a multiple burner application and it works on the basis of the lead lag operation. The xb boiler is factory configured for hydronic/central heating application, whereas the xw boiler is factory configured for domestic hot water application. ...

Page 49

49 for example: — if its add-stage action has been triggered, it will remain in this condition until either a stage has been added, or — the criteria for its being in an add-stage condition is no longer met; only then will it take another look around to see what state it should go to next. Definitio...

Page 50

50 10. Drill 1/4 in. Holes through the panel at the marked locations and secure the power supply with the two #6-32 screws and nuts provided. 11. Remove the 9-pin connector plug from the back of the oi display. 12. Wire the connector to the power supply and the rs-485 cables. 13. Ensure the 9-pin co...

Page 51

51 on system applications, each burner control system is represented on the home page by an icon and name. Pressing the icon allows the user to zoom in on that boiler and see its specific details. These details are provided on a new page, which can include additional buttons that display additional ...

Page 52

52 figure 53. S7999b display page flow.

Page 53

53 figure 54. Summary status page configure button pressing the configure button (bottom left) on the status page opens the configuration page. The s7999b configuration page does not have a “display setup” button. The configuration page allows the user to view and set parameters that define how the ...

Page 54

54 keyboard some pages request user entry of characters. When this type of input is required, a keyboard page appears, as shown in figure 58. The text box at the top of the screen displays the current (or default) setting of the user input. The user can add to this text, clear it, or change it. The ...

Page 55

55 note: when the installer proceeds with the safety parameter configuration, the control unlocks the safety parameters in this group and marks them unusable. Failure to complete the entire safety configuration procedure leaves the control in an un- runnable state (lockout 2). All safety configurati...

Page 56

56 fault/alarm handling each burner control reports to the oi display when a safety lockout or an alert occurs. Safety lockouts are indicated on each configuration page as an alarm bell symbol. At the status page (for s7999b), the history button turns red. If the s7999b is displaying the system stat...

Page 57

57 note: the system time can be set in the oi display to ensure that correct timestamps are given to the controls’ lockouts and alerts. Power interruptions will require the time to be reset as the display does not have a time backup means. The clear lockout button allows the user to acknowledge and ...

Page 58

58 operation button the operation button displays the burner control running operation, including setpoint and firing rate values. From this page the user can change setpoints, manually control the boiler’s firing rate, manually turn pumps on, view annunciation information, and switch between hydron...

Page 59

59 system configuration (s7999b oi display only) the oi display has some functions related to general configuration for the control in the end user installation. Pressing the display refresh button invokes a search procedure (see figure 74). A new r7910a hydronic control or r7911 steam control is id...

Page 60

60 configuration the burner control can be configured from the oi display. The control configuration is grouped into the functional groups as shown in table 23. Hydronic control system identification and access ch - central heat outdoor reset dhw - domestic hot water dhw storage dhw plate warm weath...

Page 61: Troubleshooting

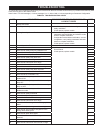

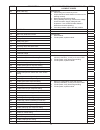

61 to support the recommended troubleshooting, the r7910 has an alert file. Review the alert history for possible trends that may have been occurring prior to the actual lockout. Note column: h= hold message; l=lockout message; h or l= either hold or lockout depending on parameter configuration. Cod...

Page 62

62 code description recommended troubleshooting of lockout codes note 30 internal fault: flame bias shorted to adjacent pin internal fault. 1. Reset module. 2. If fault repeats, replace module. H 31 internal fault: slo electronics unknown error h 32 - 46 internal fault: safety key 0 through 14 l sys...

Page 63

63 code description recommended troubleshooting of lockout codes note 67 ilk off 1. Check wiring and correct any possible shorts. 2. Check interlock (ilk) switches to assure proper function. 3. Verify voltage through the interlock string to the interlock input with a voltmeter. 4. If steps 1-3 are c...

Page 64

64 code description recommended troubleshooting of lockout codes note 94 header sensor fault 1. Check wiring and correct any possible errors. 2. Replace the header sensor. 3. If previous steps are correct and fault persists, replace the module. H 95 stack sensor fault 1. Check wiring and correct any...

Page 65

65 code description recommended troubleshooting of lockout codes note 124 high fire switch off 1. Check wiring and correct any potential wiring errors. 2. Check high fire switch to assure proper function (not welded or jumpered). 3. Manually drive the motor to the high fire position and adjust the h...

Page 66

66 code description recommended troubleshooting of lockout codes note 150 flame not detected oem specific 1. Sequence returns to standby and restarts sequence at the beginning of purge after the hf switch opens. If flame detected during safe start check up to flame establishing period. H 151 high fi...

Page 67

67 code description recommended troubleshooting of lockout codes note 164 block intake on oem specific 1. Check wiring and correct any errors. 2. Inspect the block intake switch to make sure it is working correctly. 3. Reset and sequence the module. 4. During standby and purge, measure the voltage a...

Page 68

68 code description recommended troubleshooting of lockout codes note 212 invalid preignition time setting 1. Return to configuration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace module. L 213 invalid ...

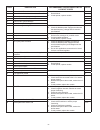

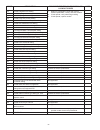

Page 69

69 code description 37 program module application parameter revision differs from application processor 38 program module safety parameter revision differs from safety processor 39 pcb incompatible with product contained in program module 40 parameter pcb in program module is too large for product 4...

Page 70

70 code description 114 mix modulation range (max minus min) was too small ( modulation operation faults 115 fan was limited to its minimum duty cycle 116 manual rate was > ch max modulation rate 117 manual rate was > dhw max modulation rate 118 manual rate was 119 manual rate in standby was > absol...

Page 71

71 code description 191 lead lag base load common setting was invalid 192 lead lag dhw demand switch setting was 193 lead lag mix demand switch setting was invalid 194 lead lag modulation sensor setting was invalid 195 lead lag backup modulation sensor setting was invalid 196 lead lag slave mode set...

Page 72

72 code description 274 abnormal recycle: demand off during pilot flame establishing period 275 abnormal recycle: lci off during drive to purge rate 276 abnormal recycle: lci off during measured purge time 277 abnormal recycle: lci off during drive to lightoff rate 278 abnormal recycle: lci off duri...

Page 73

73 code description 341 abnormal recycle: hardware slo electronics 342 abnormal recycle: hardware processor clock 343 abnormal recycle: hardware ac phase 344 abnormal recycle: hardware a2d mismatch 345 abnormal recycle: hardware vsnsr a2d 346 abnormal recycle: hardware 28v a2d 347 abnormal recycle: ...

Page 74

74 code description 482 internal error: safety key bit 4 was incorrect 483 internal error: safety key bit 5 was incorrect 484 internal error: safety key bit 6 was incorrect 485 internal error: safety key bit 7 was incorrect 486 internal error: safety key bit 8 was incorrect 487 internal error: safet...

Page 75

75 code description 571 heat exchanger high limit response was invalid 572 heat exchanger high limit was exceeded 573 heat exchanger high limit wasn't allowed due to stack limit setting 574 heat exchanger high limit wasn't allowed due to stack connector setting 575 heat exchanger high limit delay wa...

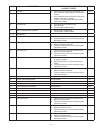

Page 76: Maintenance Procedures

76 inspect boiler area 1. Verify that boiler area is free of any combustible materials, gasoline and other flammable vapors and liquids. 2. Verify that air intake area is free of any of the contaminants. If any of these are present in the boiler intake air vicinity, they must be removed. If they can...

Page 77

77 5. Loosen the seven bolts on the blower adapter at the base and move the burner ground wire (green) aside. 6. Lift the blower adapter and remove the manifold assembly up from the 6 studs located on the cover plate and remove the burner gasket. 7. Remove any loose foreign material such as dust or ...

Page 78

78 1. Turn off the electrical power, and manual gas shut-off. • allow boiler parts to cool before disassembly. 2. Remove the vent pipe. • check parts and chimney for obstructions and clean as necessary. 3. Remove burner from boiler and other metal parts as required to clean as necessary. • refer to ...

Page 79

79 handling ceramic fiber materials removal of combustion chamber lining: the combustion chamber insulation in this boiler contains ceramic fiber material. Ceramic fibers can be converted to cristobalite in very high temperature applications. The international agency for research on cancer (iarc) ha...

Page 80: Piping Diagrams

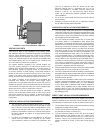

80 piping diagrams figure 78. Primar y/secondar y piping system notes: 1. Preferred piping diagram. 2. The temperature and pressure relief valve setting shall not exceed pressure rating of any component in the system. 3. Service valves are shown for servicing unit. However , local codes shall govern...

Page 81

81 aos storage tank hot water to fixtures finished floor expansion tank alternate connection cold water supply system return notes: 1. Preferred piping diagram. 2. The temperature and pressure relief valve setting shall not exc eed pressure rating of any component in the system. 3. Service valves ar...

Page 82: Limited Warranty

82 limited warranty a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this boiler: 1. If within ten years after initial installation of the boiler, a heat exchanger or gas burner should prove upon examination by the warrantor to be defective in material o...

Page 83

83 25589 highway 1, mcbee, sc 29101 technical support: 800-527-1953 • parts: 800-433-2545 • fax: 800-644-9306 www.Hotwater.Com.