- DL manuals

- A & T International

- Receiver

- 1

- Service Manual

A & T International 1 Service Manual

HIGH-WALL AIR HANDLER (WCP)

CEILING-SUSPENDED AIR HANDLER

(CCP)

P/N# 240004373, Rev. B [07/15/2013]

An ISO 9001-2008 Certified Company

ECR International, Inc.

2201 Dwyer Avenue,

Utica NY 13501

web site: www.ecrinternational.com

CHILLED WATER

CEILING-SUSPENDED

AND HIGH-WALL

AIR HANDLERS

Installation, Operation and

Maintenance Manual

Summary of 1

Page 1

High-wall air handler (wcp) ceiling-suspended air handler (ccp) p/n# 240004373, rev. B [07/15/2013] an iso 9001-2008 certified company ecr international, inc. 2201 dwyer avenue, utica ny 13501 web site: www.Ecrinternational.Com chilled water ceiling-suspended and high-wall air handlers installation,...

Page 2

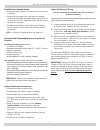

2 installer: (1) retain this manual and warranty for future reference. (2) before leaving the premises, review this manual to be sure the unit has been installed correctly and run the unit for one complete cycle to make sure it functions properly. Report shipping damage carrier examine exterior. Rem...

Page 3

3 important safety information warning • install or locate this unit only in accordance with instructions found in this manual. Use this unit only for its intended purpose as described in this manual. • connect emi air handler to properly grounded electrical supply. Do not fail to properly ground th...

Page 4

4 emi ductless split system air handler family consists of: wcp: two-pipe chilled water fan coil wall unit available in 12,000, 18,000, and 30,000 nominal btuh capacities (hot water coil not available). Ccp: two-pipe chilled water and optional hydronic heat fan coil ceiling units available in 12,000...

Page 5

5 high volt electrical wiring (see the appropriate air handler section for specific wiring information.) all wiring shall be in accordance with the national electric code (nec) and local building codes. 1. Inspect existing wiring for any deficiencies such as cut or frayed wires. Replace such wiring ...

Page 6

6 24v control transformer is located in air handler unit. This provides low volt control power to air handler . Depending on models selected, low volt interconnect control wiring may be effected. Note: all low volt interconnect wiring must be at least 18 awg. Cooling only units with or without heat ...

Page 7

7 wcp- to gain access to relay board, remove return air grill from front of unit. Remove any panels or covers to control section. The relay board is located in control box of unit. Set dipswitches (figure 3) according to table below(figure 4). Ccp- to gain access to relay board, remove return air gr...

Page 8

8 description • ccp is highly effective ceiling-suspended air handler for applications where fully exposed or partially recessed cabinetry can be used. • partially recessed mounting, units easily adapt to standard t-bar, drop-ceiling openings. • ccp is designed for residential and commercial applica...

Page 9

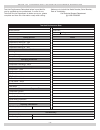

9 refer to common section of this manual for detailed instructions on: controls/components, electrical wiring, start-up, and more. Ccp physical dimensions and piping specifications model# width “a” width “b” width “c” width “d” width “e” drain hose ship- ping wt. Cw line size (supply & re- turn) 12 ...

Page 10

10 product description • wcp is chilled water air handler with contemporary design and attractive appearance to fit any décor. • offers high efficiency conditioning of small to mid-size commercial or residential spaces. • wcp is equipped with unit mounted infrared compatible controls; optional hand ...

Page 11

11 wcp/wcp physical dimensions model width “a” height “b” depth “c” width “d” width “e” width “f” width “g” width “h” width “i” shipping wt. 12 36½” 14½” 10¾” 22” 9” 24½” 8” 18” 16” 85 18 47½” 14½” 10¾” 32” 10” 34½” 8” 18” 27” 115 30 57½” 14½” 10¾” 42” 10” 44½” 8” 27” 28” 115 wcp dimensions and spec...

Page 12

12 wcp electrical specifications model # volts/hz/phase fan total amps min. Volt min. Ampacity (1) max fuse (1) fla hp 12 115/60/1 0.64 0.03 0.64 104 0.8 15 208/230/60/1 0.34 0.02 0.34 197 0.43 15 18 115/60/1 1.2 0.083 1.2 104 1.5 15 208/230/60/1 0.56 0.07 0.56 197 0.7 15 30 115/60/1 1.2 0.083 1.2 1...

Page 13

13 start up preparation see “common” section of this manual (on page 13-16) for control details. • confirm dip switch settings are correct for your unit (see page 6) • remove any tools or other obstructions • be sure the filter is in place • verify unit is level • separate any lines that contact eac...

Page 14

14 on/off switch on/off switch is used to turn equipment on or off. In off mode display will be blank and all led indicator lights will be dark. To turn unit on press on/off button once. Room temperature will be displayed and amber led indicators will show fan speed and mode selections (figure 5). F...

Page 15

15 dry mode operation dry mode removes humidity from air while maintaining specific setpoint temperature. This is done in cooling along with electric or hydronic heater. Dry mode will not maintain specific humidity level. Unit must be equipped with optional electric heat element or hydronic coil. Fo...

Page 16

16 choosing a thermostat emi offers several remote thermostats compatible with air handlers. Choose a thermostat that matches the equipment you have selected. For single stage cooling or heating choose single stage heat/cool thermostat. When selecting a thermostat other than those offered by emi, ch...

Page 17

17 test unit performance data sheet below is provided for use by qualified service professional. In order for our technical service department to better serve you, please complete and have this information ready when calling. Make sure to include the model number, serial number, date of installation...

Page 18

18 maintenance have service and annual maintenance performed by a qualified service agency. Emi units are designed and constructed for reliability and long life with minimal maintenance. To insure peak operating efficiency: 1. Clean air filters on monthly basis: filter is accessed by removing air in...

Page 19

19 power supply check • verify proper field voltage and breaker size with rating plate. • use voltmeter to verify incoming power supply agrees with rating plate. Incoming power should not exceed nameplate voltage. Incoming power should not be below minimum voltage stated on rating plate (197v for un...

Page 20

20 troubleshooting procedure - error codes error codes should one of two temperature sensors become disconnected or fail, error code will appear in display. Control will not operate properly until sensor is working. E1 – coil sensor malfunction or disconnected. Check location j1 on thermostat board....

Page 21

21 p/n 240000278 rev a (8/2012) limited warranty enviromaster international, llc (hereafter known as emi) offers to the original purchaser/owner that under normal use and maintenance for comfort cooling and conditioning applications, all emi products will be free from defects in material and workman...

Page 22

22 notes.

Page 23

23 notes.

Page 24

24 2201 dwyer avenue, utica ny 13501 1-800-228-9364 fax 1-800-232-9364.