- DL manuals

- AAF

- Ventilation Hood

- HermanNelson IM 725

- Installation Manual

AAF HermanNelson IM 725 Installation Manual

AAF

®

-HermanNelson

®

Classroom Unit Ventilators

©2002 AAF

®

-HermanNelson

®

Installation Manual

IM 725

Group:

Unit Ventilator

Part Number:

106506101

Date:

January 2002

Vertical Floor Models AVS, AVV, AVB, and AVR

Horizontal Ceiling Models AHF, AHB, AHV, and AHR

Before beginning installation, please read this publication in its entirety.

Develop a thorough understanding before starting the installation procedure.

This manual is to be used by the installer as a guide. Each installation is unique, only general topics are covered.

The order in which topics are covered may not be those required for the actual installation.

IMPORTANT!

Summary of HermanNelson IM 725

Page 1

Aaf ® -hermannelson ® classroom unit ventilators ©2002 aaf ® -hermannelson ® installation manual im 725 group: unit ventilator part number: 106506101 date: january 2002 vertical floor models avs, avv, avb, and avr horizontal ceiling models ahf, ahb, ahv, and ahr before beginning installation, please...

Page 2

2 im 725 (1-02) table of contents safety information and tools required ............................................................ 2 pre-installation considerations ......................................................................... 2 wall openings, louvers, and ventimatic shutter .............

Page 3

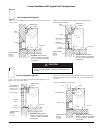

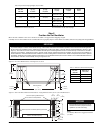

Im 725 (1-02) 3 figure 1 – typical classroom unit ventilator installation and louver details (see installation section for typical warnings and cautions) figure 2 – typical ventimatic ™ shutter assembly installation (see installation section for typical warnings and cautions) unit gasket pipe tunnel...

Page 4

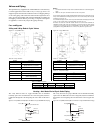

4 im 725 (1-02) figure 3 – horizontal and vertical blade louvers, without flange figure 4 – horizontal and vertical blade louvers, without flanges with grille or with flange without grille louver drain lip grille/louver with weep hole vertical blade louver horizontal blade louver flange flange outsi...

Page 5

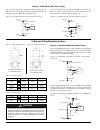

Im 725 (1-02) 5 figure 6 -16 5 ⁄ 8 " (422mm) deep unit with open pipe tunnel & high louver application with chased wall 1" (25mm) sealed cement mortar; pitch away from unit louver lintel (by others) floor line piping louver not less than 3" (76mm) not more than 21" (533mm) sealed cement mortar; pitc...

Page 6

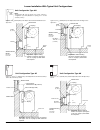

6 im 725 (1-02) figure 11 – the 21 7 / 8 ” (556mm) deep full adapter back unit with closed pipe tunnel, ducted with top intake figure 12 – 21 7 / 8 " (556mm) deep partial adapter back unit with open pipe tunnel intake louver not more than 12" unit configuration type ap unit configuration type ak fig...

Page 7

Im 725 (1-02) 7 installing louvers typical installation methods if the fresh air opening has not yet been made, see figures 5 through 12 for the recommended locations and the job-specific plans for the exact location. Follow local codes. Cut the wall opening so that it is slightly larger than the lo...

Page 8

8 im 725 (1-02) caulk (top and 2 sides) louvers drain holes (do not block) flange (4 sides) 1" minimum lintels (by others) bird screen sealed cement mortar pitched away from unit toward louver vertical or horizontal blade wall intake louver (flanged) (vertical blade shown) lintels (by others) louver...

Page 9

Im 725 (1-02) 9 plastic packaging is a suffocation hazard, dispose of properly. Keep away from children. Cleaning agents may cause serious damage to internal components, such as aluminum coils and electronic controls, etc. Do not operate unit ventilator while building maintenance cleaning agents are...

Page 10

10 im 725 (1-02) 1. Product category u = unit ventilator 2. Product identifier* avs = floor, face and bypass damper, heat/cool, heat only, cool only avv = floor, valve control, hydronic or electric heat/cool, heat only, cool only avr = floor, valve control, hydronic or electric reheat/dehumid avb = ...

Page 11

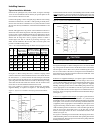

Im 725 (1-02) 11 models avs, avv, dimension "a" avr, avb inches (mm) s07 48" (1219) s10 60" (1524) s13 72" (1828) s15 84" (2133) models shipping weight approx. Shipping weight filter size unit length* number avs, avv, lbs. (kg) lbs. (kg) in. (mm) in. (mm) of fans avr, avb 16 5 / 8 "units 21 7 / 8 "u...

Page 12

12 im 725 (1-02) step 3 make piping connections be sure the hot and chilled water supply and return system are thoroughly flushed and cleaned before connecting piping to the unit ventilator. In all systems be sure to install the control valve(s) on the correct unit ventilator. Indiscriminate mixing ...

Page 13

Im 725 (1-02) 13 in water systems after flushing piping adequately, so all debris is removed, fill the system. At initial operation, vent manually by unscrewing the vent plug one or two turns, figure 31. After venting, tighten the vent plug firmly. Unscrew the vent plug only one or two complete turn...

Page 14

14 im 725 (1-02) heating coils 00 = none cooling coils v = 2 row cw coil s = 3 row cw coil w = 4 row cw coil y = 5 row cw coil 5 = 2 row high capacity cw coil 6 = 3 row high capacity cw coil heating only figure 32 - hot water heating only unit (coils 65, 66, 67) cooling only unit series s07 s10 s13 ...

Page 15

Im 725 (1-02) 15 heat/cool see notes and tables 6 and 7 on page 14 table 8 - heat/cool position/combinations in air stream (one coil per position) note: x indicates available. Face and bypass valve first position in air stream second position in air stream avs avs elec. Avv avv elec. U d e f 00 x x ...

Page 16

16 im 725 (1-02) face and bypass valve first position in air stream second position in air stream avb avr avr elec. V s 5 6 65 66 67 68 69 78 79 x x w 7 65 66 x x g 65 66 67 68 69 78 79 x g 12 13 x v s w 5 6 7 12 13 x reheat table 9 - reheat coil position/combinations in air stream (one coil per pos...

Page 17

Im 725 (1-02) 17 valves and piping the optional factory-supplied aaf ® -hermannelson ® control valve(s) for water applications can be either 2-way or 3-way type, and is / are shipped separate from the unit ventilator itself so no shipping damage occurs to the piping of the connection stub from the w...

Page 18

18 im 725 (1-02) figure 59 - 2-way modulating, normally open, hot water or 2-pipe cw/hw valve piping 3 1 ⁄ 4 " (83mm) 6.9 max. (175mm) z y x optional factory-supplied 2-way modulating valve optional factory-supplied 3-way modulating valve 3 1 ⁄ 4 " (83mm) 6.9 max. (175mm) z y x connection c v x y z ...

Page 19

Im 725 (1-02) 19 in steam systems: the optional factory-supplied aaf ® -hermannelson ® modulating control valve for steam applications is the 2-way type. It is shipped separately from the unit ventilator to preclude shipping damage, yet provide the installer with maximum flexibility in making the fi...

Page 20

20 im 725 (1-02) typical hot water coil piping figure 65 - face and bypass with end-of-cycle valve (piping within unit end compartment) figure 66 - face and bypass with end-of-cycle valve (piping outside unit end compartment) figure 67 - 3-way modulating valve control (piping within unit end compart...

Page 21

Im 725 (1-02) 21 typical steam coil piping figure 69 - face and bypass with end-of-cycle valve - same end drain connection (piping within unit end compartment) figure 70 - face and bypass with end-of-cycle valve - same end drain connection (piping outside unit end compartment) figure 71 - 2-way modu...

Page 22

22 im 725 (1-02) direct-expansion r-22 (dx) piping dx coils have o.D. Sweat connections. Interconnecting tubing is field-supplied. See table 17, page 24 and job-specific drawings for correct tubing sizes. Wrap txv valve with a quenching cloth and remove bulb from suction line to avoid valve damage w...

Page 23

Im 725 (1-02) 23 figure 75 - typical piping and wiring for split system 2 wires (+) ground to open sight drain txv (thermal expansion valve) filter drier (field supplied) moisture indicator sight glass (field supplied) weatherproof fused disconnect per nec 2 wires (+) ground insulated suction line f...

Page 24

24 im 725 (1-02) hazardous voltage! Disconnect all electric power including remote disconnects before servicing. Failure to disconnect power before servicing can cause severe personal injury or death. Sight glass txv (thermal expansion valve) insulate bulb (reacts to refrigerant temperature and not ...

Page 25

Im 725 (1-02) 25 table 18 —saturated temperature - pressure chart (°f) r22-psig (°f) r22-psig (°f) r22-psig 32 57.5 44 74.5 80 143.6 33 58.8 45 76.0 85 155.7 34 60.1 46 77.6 90 168.4 35 61.5 47 79.2 95 181.8 36 62.8 48 80.8 100 195.8 37 64.2 49 82.4 105 210.8 38 65.6 50 84.0 110 226.4 39 67.1 55 92....

Page 26

26 im 725 (1-02) table 20 - floor av electrical data/motor data and unit amp unit cfm l/s motor unit current # series (nom.) hp watts 115v 208v 230v 265v s07 750 354 1/4 164 1.8 1.0 0.9 0.8 s10 1000 472 1/4 244 3.1 1.7 1.5 1.3 s13 1250 590 1/4 306 3.5 1.9 1.8 1.5 s15 1500 708 1/4 334 3.7 2.0 1.8 1.6...

Page 27

Im 725 (1-02) 27 figure 85 - typical electrical locations, vertical floor models avs, avv, avb, avr, front view, access panels removed unit mounted microtech ™ direct digital controls (ddc) components this drawing shows the location of the standard and optional aaf ® -hermannelson ® microtech ™ cont...

Page 28

28 im 725 (1-02) exhaust fan interlock master/slave wiring pneumatic day/night changeover control ventilation lockout control network wiring day/night changeover control (stand-alone units only) remote condensing unit control wiring microtech ™ or controls by others (stand-alone units only) (stand-a...

Page 29

Im 725 (1-02) 29 typical wall mounted room air sensor figure 90 - wall sensor with tenant override, setpoint adjustment, communications port, and thermometer (shown) or without thermometer installation 1. Installer must be qualified, experienced technician. 2. Disconnect power supply before installa...

Page 30

30 im 725 (1-02) remove debris, heavy dust and dirt or any obstruction from the area in front of the return air intake grille at the floor,(approximately 3' - see shaded area) as this will affect unit performance. If a draftstop system has been installed be sure that all draftstop intake grilles are...

Page 31

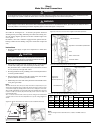

Im 725 (1-02) 31 tools required a forklift or other lifting device to install this product (see figure 97). Install this product in accordance with good engineering practices and workmanship, following these general instructions, plus the job- specific aaf ® -hermannelson ® submittal drawings provid...

Page 32

32 im 725 (1-02) 1. Product category u = unit ventilator 2. Product identifier* ahf = ceiling, face & bypass ahv = ceiling, valve control ahr= ceiling, valve control with reheat. Ahb = ceiling, face & bypass with reheat. * end panels ship installed 3. Design series 4 = d design 4. Nominal capacity s...

Page 33

Im 725 (1-02) 33 see table 21 for dimension “a” typical ceiling ah unit air arrangements discharge air arrangements 30 1 ⁄ 2 ˝ (750 to 1500 cfm) discharge air arrangement 40˝ (750 to 2000 cfm) discharge air arrangements 36˝ (750 to 2000 cfm) figure 99 - arrangement aj front discharge with duct colla...

Page 34

34 im 725 (1-02) inlet air arrangements typical ceiling ah unit air arrangements (continued) outdoor air return air 5 1 ⁄ 4 "(133mm) x a 3 ⁄ 4 " (19mm) 1 1 ⁄ 2 " (38mm) outdoor air return air 1 " (25mm) figure 104 - arrangement 26 return air bottom grille/outdoor air top duct collar figure 105 - arr...

Page 35

Im 725 (1-02) 35 duct design for noise control proper acoustics is often a design requirement for schools. Most of the problems that are associated with hvac generated sound can be avoided by properly selecting and locating the components of the system. There are some general do’s and don’ts: the fo...

Page 36

36 im 725 (1-02) figure 113 - install ah ceiling unit flange the following general suggestions are offered only to stress their importance; however, there are additional important factors that must be considered. Assistance in the design of ductwork can be found in the ashrae handbook and smacna pub...

Page 37

Im 725 (1-02) 37 figure 115 - fully recessed unit safety chains filters see page 25 for information. Model ah filter is removed by opening the hinged access door, removing the sealing plate and then replacing the filter, reinstalling the sealing plate and securing the access door, (see figure 115). ...

Page 38

38 im 725 (1-02) notes: 1. The auxiliary contact of the remote speed switch is closed at “hi” and “lo” positions and open at “off” position. 2. Refer to detailed wiring diagram furnished with unit for internal connections. 3. Mount remote speed switch in ul listed outlet box. Class 1 wiring (both fi...

Page 39

Im 725 (1-02) 39 remove front access panels. Rotate fans manually, all parts should be aligned properly and move freely. Also, inspect fans for obstructions. Installing unit ventilator end panels: align each end panel with the top and front edges of the ceiling unit ventilator. Attach each end panel...

Page 40

©2002 mcquay international • www.Mcquay.Com • 800-432-1342 im 725 (1/02) ® the information in this bulletin supersedes and replaces previous [catalogs][bulletins] with regard to aaf ® -hermannelson ® unit ventilator products. Illustrations cover the general appearance of aaf-hermannelson unit ventil...