- DL manuals

- AAON

- Heat Pump

- RN Series

- Installation operation & maintenance

AAON RN Series Installation operation & maintenance - Maintenance

78

Maintenance

(See back of the manual for maintenance

log)

At least once each year, a trained, qualified

service technician should check out the unit.

Fans, evaporator coils, and filters should be

inspected at least monthly.

Gas Heating

Make sure all gas supply lines have been

purged of air before turning on the electrical

power switch. Turn the gas valve to the on

position (see startup instructions). Turn the

main electrical power on and set the controls

to the heating mode of operation.

The combustion ventilation motor should

operate. The control will automatically

supply energy to the igniter and the gas

valve after the heating call is made.

The flame sensing probe detects the

presence of the flame. Should no flame be

detected in 10 seconds, the ignition system

will recycle. If no flame is detected after 3

tries, ignition system will lockout.

Remove the call for heating. The main gas

valves should be extinguished.

The supply fans are controlled by the

ignition system. In the fan “Auto” mode the

fan comes on 45 seconds after the flame is

proved and goes off 120 seconds after the

heating call is removed.

Furnace combustion ventilation air and flue

openings should be checked annually for

debris and obstructions. If vent extensions

are used they must meet category III

requirements.

This appliance contains a wire screen at the

vent outlet. Each heating season, prior to

placing the appliance in heat mode

maintenance check that no debris or foreign

matter has accumulated in the vent outlet. A

good practice is to check for debris each

time the air filters are changed.

In the event the vent outlet becomes blocked

do not attempt to start the appliance in heat

mode until the entire vent opening is

cleared.

In the event the unit shut down because the

vent was blocked a qualified technician or

service agency should monitor the unit prior

to re-starting.

The gas burner and heat exchanger should

never require cleaning. If cleaning is

necessary, this indicates faulty operation of

the unit. Cleaning should only be done by a

qualified service agency and only after

consultation

with

an

AAON

service

representative.

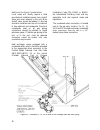

If induced draft blower/motor assembly has

to be replaced, care must be taken to provide

an airtight seal between the blower housing

and the burner box.

Once a year, before the unit is in

operation for the heating season, a

qualified service technician should

inspect all flue product carrying areas

of the furnace and main burners for

continued safe operation.

WARNING

LEAK CHECK GAS PIPE

The gas pipe in the unit should be

checked for leaks before startup.

Leak checking is the responsibility of

the

installing

contractor.

All

connections should be checked for

leaks

annually

after

installation.

Failure to leak check could result in

fire, explosion, or other hazardous

situations.

DANGER

Summary of RN Series

Page 1

Rn series horizontal packaged rooftop units, heat pumps, & outdoor air handling units installation, operation, & maintenance o do not store gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance o what to do if you smell gas do not try to light any appliance....

Page 3

3 table of contents safety .............................................................................................................................................. 8 rn series feature string nomenclature ........................................ Error! Bookmark not defined. General information ...

Page 4

4 adjusting refrigerant charge ................................................................................................... 68 checking liquid sub-cooling .............................................................................................. 68 checking evaporator superheat..............

Page 5

5 index of tables and figures tables: table 1 - electric and gas heating capacities ............................................................................. 28 table 2 - c cabinet unit clearances ............................................................................................ 29 tab...

Page 6

6 figures: figure 1 - lockable handle .......................................................................................................... 25 figure 2 - rn series c cabinet, ................................................................................................... 29 figure 3 - forkli...

Page 7: Aaon

7 aaon ® rn series horizontal configuration features and options introduction energy efficiency direct drive backward curved plenum supply fans variable capacity r-410a scroll compressors airside economizers factory installed aaonaire ® energy recovery wheels double wall rigid polyurethane foam pane...

Page 8: Safety

8 safety attention should be paid to the following statements: note - notes are intended to clarify the unit installation, operation, and maintenance. Caution - caution statements are given to prevent actions that may result in equipment damage, property damage, or personal injury. Warning - warning...

Page 9: Warning

9 fire, explosion or carbon monoxide poisoning hazard failure to replace proper controls could result in fire, explosion, or carbon monoxide poisoning. Failure to follow safety warnings exactly could result in serious injury, death or property damage. Do not store or use gasoline or other flammable ...

Page 10: Caution

10 electric motor over-current protection and overload protection may be a function of the variable frequency drive to which the motors are wired. Never defeat the vfd motor overload feature. The overload ampere setting must not exceed 115% of the electric motor ’s fla rating as shown on the motor n...

Page 11: Warning

11 always use a pressure regulator, valves and gauges to control incoming pressures when pressure testing a system. Excessive pressure may cause line ruptures, equipment damage or an explosion which may result in injury or death. Warning to prevent damage to the unit, do not use acidic chemical coil...

Page 12: Warning

12 1. Startup and service must be performed by a factory trained service technician. 2. Use only with type of the gas approved for the furnace. Refer to the furnace rating plate. 3. The unit is for outdoor use only. See general information section for more information. 4. Provide adequate combustion...

Page 13

13 rn series feature string nomenclature g en mj rev s ize s eri es mnrev vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g -...

Page 14

14 rn series feature string nomenclature gen m jrev s ize s erie s m nrev vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g -...

Page 15

15 rn series feature string nomenclature gen m jrev s ize s erie s m nre v vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g ...

Page 16

16 rn series feature string nomenclature gen m jrev s ize s erie s m nrev vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g -...

Page 17

17 rn series feature string nomenclature gen m jrev s ize s erie s m nrev vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g -...

Page 18

18 rn series feature string nomenclature gen m jrev s ize s erie s m nrev vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g -...

Page 19

19 rn series feature string nomenclature gen m jrev s ize s erie s m nrev vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g -...

Page 20

20 rn series feature string nomenclature gen m jrev s ize s erie s m nrev vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g -...

Page 21

21 rn series feature string nomenclature gen m jrev s ize s erie s m nrev vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g -...

Page 22

22 rn series feature string nomenclature gen m jrev s ize s erie s m nrev vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g -...

Page 23

23 rn series feature string nomenclature gen m jrev s ize s erie s m nrev vlt a1 a2 a3 a4 a5 b1 b2 b3 b4 b5 1 2 3a 3b 3c 3d 4a 4b 4c 5a 5b 5c 5d 6a 6b 6c 6d 7 8 9a 9b 9c 9d 10a 10b rn a - 11 - c 0 - 3 - a a a 0 2 - b 0 1 b 0 : 0 1 - d q 0 j - e 0 0 - 0 0 0 0 - 0 0 0 0 - d a - a 0 a a - a 0 b 0 - g -...

Page 24: General Information

24 general information rn series packaged rooftop units, heat pumps and outdoor air handling units have been designed for outdoor installation only. Units are assembled, wired, charged and run tested at the factory. Startup and service must be performed by a factory trained service technician. Certi...

Page 25: Caution

25 installation of rn series units must conform to the icc standards of the international mechanical code, the international building code, and local building, plumbing and waste water codes. In the absence of local codes installation must conform to the current (united states) national fuel gas cod...

Page 26: Warning

26 the warranty card must be completed in full and returned to aaon not more than 3 months after unit is delivered. Storage if installation will not occur immediately following delivery, store equipment in a dry protected area away from construction traffic and in the proper orientation as marked on...

Page 27: Caution

27 concentration builds up, oil is washed out of the compressor, leaving it starved for lubrication. The compressor life will be seriously shorted by reduced lubrication and the pumping of excessive amounts of liquid oil and refrigerant. Note: low ambient operation air-cooled dx units without a low ...

Page 28: Installation

28 table 1 - electric and gas heating capacities model option b3 gas heat electric heat input capacity output capacity capacity mbh mbh kw (208v) kw (230v, 380v, 460v, 575v) 1 = heat 1 270.0 218.7 15.0 20 2 = heat 2 405.0 328.1 30.0 40 3 = heat 3 540.0 432.0 45.1 60 4 = heat 4 60.1 80 5 = heat 5 75....

Page 29: Warning

29 do not position flue opening to discharge into a fresh air intake of any other piece of equipment. Unit should also be installed so that the flow of combustion intake air is not obstructed from reaching the furnace. Vent opening must not be blocked by snow. A minimum 12” curb must be used or the ...

Page 30: Caution

30 be careful to install the provided neoprene isolator according to the following figure prior to setting the unit on the curb. All roofing work should be performed by competent roofing contractors to avoid any possible leakage. Caution where the supply or warm air duct passes through a combustible...

Page 31: Caution

31 forklifting the unit (11, 13 and 16-30 ton) 11, 13 and 16-30 ton units can be lifted using a forklift. 11-25 and 30 ton units must have forks 72” in length or the forks must have 72” fork extensions. 11, 13, and 16-30 ton units with energy recovery wheels cannot be lifted using a forklift. Standa...

Page 32

32 before lifting unit, be sure that all shipping material has been removed from unit. Secure hooks and cables at all lifting points / lugs provided on the unit. Hoist unit to a point directly above the curb and duct openings. Be sure that the gasket material has been applied to curb. Carefully lowe...

Page 33: Caution

33 duct connection there to be a minimum of a 12” straight duct off of the supply duct with no size reduction and then a limitation of no more than a 45 ⁰ transition for the next 24”, this is to insure proper performance of the heaters. Air quantity and temperature stagnation could still be effected...

Page 34

34 figure 6 - duct connection.

Page 35: Caution

35 outside air rain hood rain hood must be opened before startup of the unit. Fresh air intake adjustments should be made according to building ventilation of local code requirements. 11, 13 and 16-30 ton units remove the two screws at the bottom of the rain hood that secure it in the shipping posit...

Page 36: Warning

36 metal mesh filters (11, 13 and 16-30 ton) metal mesh outside air filters require installation of the filter rack on the intake of the rain hood. Clips which hold the metal mesh filters in the filter rack should face outward. Figure 9 - rain hood with metal mesh filter rack installation electrical...

Page 37: Caution

37 route power and control wiring, separately, through the utility entry in the base of the unit. Do not run power and control signal wires in the same conduit. The utility entry on 11, 13 and 16-30 ton units is located in the unit base in the front right hand corner of the unit (compressor compartm...

Page 38: Caution

38 three phase voltage imbalance will cause motor overheating and premature failure. The maximum allowable imbalance is 5%. Voltage imbalance is defined as 100 times the maximum deviation from the average voltage divided by the average voltage. Example: (218v+237v+235v)/3 = 230v, then 100*(230v-218v...

Page 39: Warning

39 table 3 - control wiring wire size (stranded) - copper conductors only total wire distance allowable 20 awg 200 ft 18 awg 350 ft 16 awg 500 ft 14 awg 750 ft 12 awg 1250 ft total wire distance allowable = (quantity of control wires) x (control wire distance) take the total wire distance allowable ...

Page 40

40 after verifying gas inlet pressure and manifold pressure the service technician must time the gas flow rate through the gas meter with a stopwatch to verify the gas input rate. Unit nameplate input rate value has been calculated at the altitude where the unit was shipped. Above 2,000 ft the input...

Page 41: Caution

41 piping sizing examples a 100 ft pipe run is needed for a 1080 mbh natural gas heater. The natural gas has a rating of 1000 btu/ft 3 and a specific gravity of 0.6 (obtain these values from the local gas supplier.) btu ft mbh 1000 1080 3 1080 ft 3 /hr from the natural gas maximum capacities table, ...

Page 42

42 additional gas piping considerations local codes will usually require a field provided and installed manual main shutoff valve and union external to the unit. Main shutoff valve should be labeled. A drip leg should be installed near the unit connection to trap sediment and condensate. Pipe joint ...

Page 43: Danger

43 leak testing all components of gas supply system, including manual shut off valves and the piping in the interior of the unit, should be leak tested with a soap solution before operating the appliance and at least on an annual basis thereafter. All gas fired heat exchangers are completely tested ...

Page 44: Caution

44 open loop applications this product contains one or more refrigerant-to-water heat exchangers made of 316 stainless steel. 316 stainless steel is subject to severe corrosion and failure when exposed to chlorides. Do not allow water containing any form of chlorides to enter this heat exchanger. Co...

Page 45: Warning

45 freezing water in the heat exchanger this product contains one or more refrigerant-to-water heat exchangers. A refrigerant-to-water heat exchanger contains refrigerant in one passage and water in another passage. Water is subject to freezing at 32°f. When water freezes in a heat exchanger signifi...

Page 46: Warning

46 table 9 - standard brazed plate heat exchanger water connections model (rn-) supply and return connection size 011, 013, 016, 018, 020 1 1/2” npt 025, 030 2” npt table 10 - smo 254 brazed plate heat exchanger water connections model (rn-) supply and return connection size 016, 018, 020, 025, 030 ...

Page 47: Caution

47 note: ball valves should be installed in the condenser water supply and return lines for unit isolation and water flow balancing. All manual flow valves should be of the ball valve design. Globe or gate valves should not be used due to high pressure drops and poor throttling characteristics. Pres...

Page 48: Caution

48 condensate drain piping 11, 13, 16-25 and 30 ton units are equipped with one condensate drain pan connection, on the right side of the unit, and are furnished with a p-trap for field installation. All drain connections must be used and individually trapped to ensure a minimum amount of condensate...

Page 49: Caution

49 draw-through coils figure 14 - draw-through drain trap the x dimension on the draw-through trap should be at least equal to the absolute value of the negative static pressure in the drain pan plus one inch. To calculate the static pressure at the drain pan add the pressure drops of all components...

Page 50: Warning

50 heating coils one or two row hot water and steam heating and preheating coils can be factory installed. All valve controls for heating operation are field supplied and field installed. Hot water and steam coil connections are spun copper tube. Water coils should not be subjected to entering air t...

Page 51

51 electric preheat figure 15 - preheat controller the electric preheat controller is factory installed within the preheat cabinet. The following details are for ehc1 version 1.10 of the preheat controller. Status display screens these screens are access by pressing either the left or right controll...

Page 52

52 6. Lltset - “low limit time” temperature (°f) setpoint. If this temperature is not reached at full output, relay will pull in. 7. Stage - current operating stage 1-6. 8. Stage - current operating stage 1-6. Mod - modulation rate % being applied to stage one heat strip scr. 9. Oat - outside air in...

Page 53

53 2. Belowllt - "below low limit time". Range = 10sec-1800sec, and the default is 10sec. If ‘lltset’ temperature is not reached within ‘belowllt’ after reaching full output, the status relay will operate. 3. Stages - number of stages. Range = 1-6, and the default is 1. The number of stages can be d...

Page 54

54 led flash alarm codes the flashing red led will be to the right of the screen. The number of blinks is described below. The lcd screen will also display the screens. 1 = lata probe open/short 2 = latb probe open/short 3 = oat sensor open/short 4 = leaving air temp over limit 5 = cooling down afte...

Page 55: Warning

55 if a safety is reached with the controller’s safety sensors then the electric preheat will be de-energized for a period of 2 minutes. Electric preheat will turn on stage one at 100% for 3 minutes to test if fault conditions still exist after the cool down period. The controller will repeat this a...

Page 56

56 normal maintenance requires periodic inspection of filters, the cassette wheel, drive belts, air seals, wheel drive motor, and its electrical connections. Wiring diagrams are provided with each motor. When wired according to wiring diagram, motor rotates clockwise when viewed from the shaft/pulle...

Page 57: Warning

57 airflow balancing and checking high performance systems commonly have complex air distribution and fan systems. Unqualified personnel should not attempt to adjust fan operation, or air circulation, as all systems have unique operations characteristics. Professional air balance specialists should ...

Page 58: Caution

58 adsorb and desorb moisture and also build up so as to reduce airflow. In a reasonably clean indoor environment such as a school or office building, measurable reductions of airflow or loss of sensible (temperature) effectiveness may not occur for several years. Measurable changes in latent energy...

Page 59

59 installation considerations energy recovery cassettes are incorporated within the design of packaged units, packaged air handlers and energy recovery ventilators. In each case, it is recommended that the following considerations be addressed: accessibility the cassette and all its operative parts...

Page 60: Caution

60 operation startup procedure 1. By hand, turn wheel clockwise (as viewed from the pulley side), to verify wheel turns freely through 360º rotation. 2. Before applying power to drive motor, confirm wheel segments are fully engaged in wheel frame and segment retainers are completely fastened. (see s...

Page 61

61 segment installation & replacement wheel segments are secured to the wheel frame by a segment retainer which pivots on the wheel rim and is held in place by a segment retaining catch. Segment retainer to install wheel segments follow steps one through five below. Reverse procedure for segment rem...

Page 62: Caution

62 hammer and drift (in drift pin hole) tap collar in the direction of wheel rotation to unlock collar. Remove collar. 3. Using socket wrench with extension, remove two nuts which secure bearing housing to the bearing support beam. Slide bearing from shaft. If not removable by hand, use bearing pull...

Page 63: Startup

63 startup (see back of the manual for startup form.) during startup, it is necessary to perform routine checks on the performance of the unit. This includes checking the air flow, air filters, condenser water flow, dampers, heaters, and refrigerant charge. Supply fans rn series units are equipped w...

Page 64

64 figure 16 - supply fan banding for single set screw applications, tighten the set screw to the required torque setting (table 16) using a calibrated torque wrench. For double set screw applications, tighten one set screw to half of the required torque setting (table 16) using a calibrated torque ...

Page 65

65 the gap tolerances that are allowed between the blower and the inlet cone for the plenum fan blowers are shown in figure 17. The inlet cone can be moved as necessary to center the cone in relation to the blower. The blower can be moved on the motor shaft to set the correct overlap. These toleranc...

Page 66

66 step 4: determine the bushing mount location the bushing mount is the center section of the hub through which the fan is mounted to the shaft, and typically contains either setscrews or a center-tapered hole where the bushing inserts. Location a is with the bushing mount on air inlet side of the ...

Page 67: Caution

67 step 7: determine the current blade pitch and the pin location for the new blades table 17 - pin location type bushing mount blade pitch angle 20° 25° 28° 30° 33° 35° 38° 40° 45° 50° 5z a - ret - ret ret ret hub hub hub hub b - hub - hub hub hub ret ret ret ret table 18 - pin groove location type...

Page 68: Caution

68 adjusting refrigerant charge adjusting the charge of a system in the field must be based on determination of liquid sub-cooling and evaporator superheat. On a system with a txv liquid sub-cooling is more representative of the charge than evaporator superheat but both measurements must be taken. B...

Page 69: Caution

69 table 19 - acceptable refrigeration circuit values air-cooled cond./ air-source heat pump sub-cooling 8-15°f / 2-4°f (hp)* sub-cooling with hot gas reheat 8-15°f /2-6°f (hp)* superheat 8-15°f water-cooled cond./water source heat pump sub-cooling 4-8°f superheat 8-15°f *in cooling mode operation a...

Page 70

70 table 20 - r-410a refrigerant temperature-pressure chart psig psig psig psig psig ( f) r- 410a ( f) r-410a ( f) r-410a ( f) r-410a ( f) r-410a 20 78.3 50 142.2 80 234.9 110 364.1 140 540.1 21 80.0 51 144.8 81 238.6 111 369.1 141 547.0 22 81.8 52 147.4 82 242.3 112 374.2 142 553.9 23 83.6 53 150.1...

Page 71

71 gas heater instructions figure 22 - gas heater instructions.

Page 72

72 condenser fan electronically commutated motor (ecm) startup the fan cycling option uses a fan cycle switch to switch between one of the discrete speed inputs (see table 21) on the motor thus cycling between two preset speeds based upon discharge pressure of the unit. By connecting 24vac to a sing...

Page 73

73 vfd controlled condenser fan startup with customer provided unit controls the vfd’s are factory provided and factory programmed. Vfd’s receives input from pressure transducers on each refrigerant circuit and vary the fan speed based on the pressure inputs to maintain a discharge (head) pressure. ...

Page 74

74 adjustable fan cycling switch procedure to adjust the fan cycle switch you will need a flathead screwdriver. Recommended settings the switch will come factory set to cut-in at 425psi (+/– 5psi) and a differential of 155psi (or open at 270psi (+/– 5psi)). Settings for cut in and differential press...

Page 75

75 to lower the pressure set point for the cut in gauge, turn the adjustable screw clockwise. To raise the pressure set point for the cut in gauge, turn the adjustable screw counter clockwise. To raise the pressure set point for the differential gauge, turn the adjustable screw clockwise. To lower t...

Page 76: Operation

76 operation unit operations should be controlled with thermostat, or unit controller, never at the main power supply, except for servicing, emergency, or complete shutdown of the unit. Thermostat operation heating thermostat system switch - "heat" thermostat fan switch - "auto" or "on" thermostat t...

Page 77: Warning

77 packaged dx cooling operation and control when a call for cooling (g and y1, y2, etc.) is made the supply blower motors and compressors will energize. Note: when using field controls any variable capacity compressors should run at 100% for 1 minute when starting. Gas heater operation when heat (g...

Page 78: Maintenance

78 maintenance (see back of the manual for maintenance log) at least once each year, a trained, qualified service technician should check out the unit. Fans, evaporator coils, and filters should be inspected at least monthly. Gas heating make sure all gas supply lines have been purged of air before ...

Page 79: Warning

79 gas heat exchanger removal removal disconnect all wiring on the heat exchanger. Disconnect flex gas lines and pull out of the way. Remove screws around the perimeter of the heat exchanger face plate that connect it to the unit. Only the outermost screws should be removed. Pull the heat exchanger ...

Page 80: Warning

80 removal take off the fan grill by removing the screws that attach it to the orifice. The condenser fan motor wires can then be accessed and disconnected. Remove the screws that attach the orifice to the condenser assembly. The screws are located on the top of the orifice around the perimeter, and...

Page 81: Warning

81 evaporator coil (6-25 and 30 ton) removal evacuate refrigerant from the systems. Remove the txv bulbs from the suction lines. Disconnect the suction and liquid line copper connections to the evaporator coil. Figure 25 - evaporator coil access remove the screws attaching the filter rack to the eva...

Page 82: Warning

82 brazed plate heat exchanger cleaning because of a normally high degree of turbulence in brazed plate heat exchangers, for many applications the heat exchanger channels are self cleaning. For applications that are not self cleaning (i.E. Hard water at high temperatures, etc.) or applications where...

Page 83: Caution

83 for routine quarterly cleaning, first clean the coil with the below approved coil cleaner. After cleaning the coils with the approved cleaning agent, use the approved chloride remover to remove soluble salts and revitalize the unit. Recommended coil cleaner the following cleaning agent, assuming ...

Page 84: Warning

84 documented routine cleaning of microchannel coils with factory provided e- coating is required to maintain coating warranty coverage. Use the e-coated coil cleaning section for details on cleaning e- coated coils. Field applied coil coatings are not recommended with microchannel coils. Allowed ch...

Page 85: Warning

85 generally the best and broadest based procedure is #1. The grease cutting effect of the simple green is good for restaurant applications. Other coil cleaners there are many cleaners on the market for condenser coils. Before using any cleaner that is not covered in this section you must get writte...

Page 86

86 remove the wire connections from auxiliary limit switch (if applicable) which is mounted in the brace at the fan opening. Remove the brace located at the fan opening. Remove the six bolts that connect the motor mount to the blower frame. Two bolts are on the angle on the back of the motor mount b...

Page 87

87 once the line voltages recover, the dpm will re-energize the output relay after the restart time delay. All settings and the last 4 faults are retained, even if there is a complete loss of power. Dpm setup procedure with the supply voltage active to the module, you can setup all of the dpm’s sett...

Page 88

88 screens manufacturer’s screen r-k electronics dpm v0.0.00 average voltage screen vavg imb hz 460 0 60 off default – the default screen shows the real time voltage detected in each of the 3 phases: a-b b-c c-a 460 459 461 on voltage selection screen (vertical format) default = 460v, 3Ø 200, 1Ø; 20...

Page 89: Warning

89 variable capacity compressor controller units with variable capacity scroll compressors may include the following compressor controller. The following is an explanation of the terminals and troubleshooting alert flash codes of the controller. For more information on the compressor controller, see...

Page 90: Warning

90 figure 29 - compressor controller flash code details filter replacement monthly air filter inspection is required to maintain optimum unit efficiency. It is strongly recommended that filter media be replaced monthly. Filters are located upstream of the evaporator coil in the filter and economizer...

Page 91

91 filter information (rab = return air bypass, pe = power exhaust, pr = power return) table 23 - rn series 11, 13, 16-25 and 30 ton pre filters feature 9a quantity / size type 0 no pre filters b,c,d 6 / 20” x 25” x 2” pleated, 30% eff, merv 8 feature 19 quantity / size type b 3 / 20” x 25” x 1” met...

Page 92

92 figure 30 - rn series 11, 13, 16-25 and 30 ton units ton standard filter layouts all dimensions are in inches and are height x length. Layouts are viewed from the upstream side of the cooling coil. Replacement parts parts for aaon equipment may be obtained from your local aaon representative. Ref...

Page 93

93 appendix a - heat exchanger corrosion resistance corrosion resistance of copper and stainless steel in brazed plate heat exchangers - points to measure and check in a water analysis the resistance guide provides the corrosion resistance of stainless steel type aisi 316 and pure copper (99.9%) in ...

Page 94

94 water containing concentration (mg/l or ppm) time limits - analyze before aisi 316 smo 254 copper alloy nickel alloy total hardness (°dh) 4.0-8.5 no limit + + + + nitrate (no 3 ) no limit + + + + > 100 + + 0 + iron (fe) no limit + + + + > 0.2 + + 0 + aluminum (al) no limit + + + + > 0.2 + + 0 + m...

Page 95

95 appendix b - thermistor temperature vs. Resistance values deg c deg f resistance (kohms) -40 -40 2889.6 -35 -31 2087.22 -30 -22 1522.20 -25 -13 1121.44 -20 -4 834.72 -15 5 627.28 -10 14 475.74 -5 23 363.99 0 32 280.82 5 41 218.41 10 50 171.17 15 59 135.14 20 68 107.44 25 77 86.00 30 86 69.28 35 9...

Page 96: Rn Series Startup Form

96 rn series startup form date:______________ job name:_____________________________________________________________________ address:______________________________________________________________________ ______________________________________________________________________________ model number:____...

Page 97

97 energy recovery wheel assembly wheel(s) spin freely check rotation fla____________ number hp l1 l2 l3 1 2 power return/exhaust assembly alignment check rotation nameplate amps________ number hp l1 l2 l3 1 2 outside air/economizer dampers operation check damper actuator type: economizer changeover...

Page 98

98 refrigeration system 1 – cooling mode pressure saturated temperature line temperature sub-cooling superheat discharge n/a n/a suction n/a liquid n/a refrigeration system 2 – cooling mode pressure saturated temperature line temperature sub-cooling superheat discharge n/a n/a suction n/a liquid n/a...

Page 99

99 refrigeration system 4 – heating mode (heat pump only) pressure saturated temperature line temperature sub-cooling superheat discharge n/a n/a suction n/a liquid n/a air-cooled condenser alignment check rotation nameplate amps________ number hp l1 l2 l3 1 2 3 4 5 6 water/glycol system 1. Has the ...

Page 100: Maintenance Log

100 electric preheating limit lockout aux. Limit lockout outside air temperature setpoint ________°f preheat leaving air temperature setpoint ________°f stage amps stage amps 1 5 2 6 3 7 4 8 maintenance log this log must be kept with the unit. It is the responsibility of the owner and/or maintenance...

Page 101: Literature Change History

Literature change history april 2016 added adjustable fan cycling switch procedure section. July 2016 updated neoprene statements and e-coated cleaning section. Updated table 19 - acceptable refrigeration circuit values. January 2017 updated feature string nomenclature for newly added features: feat...

Page 104

Copyright © aaon, all rights reserved throughout the world. Aaon ® and aaonaire ® are registered trademarks of aaon, inc., tulsa, ok. Aaon 2425 south yukon ave. Tulsa, ok 74107-2728 www.Aaon.Com rn series horizontal installation, operation & maintenance v76270 · rev. A · 170727 factory technical sup...