- DL manuals

- Aarrow

- Stove

- Stratford Sf 50 Convector

- Installation & Operating Instructions Manual

Aarrow Stratford Sf 50 Convector Installation & Operating Instructions Manual

Summary of Stratford Sf 50 Convector

Page 1

Installation & operating instructions the stratford multifuel sf & si stoves stratford sf 50 convector please retain these instructions for future reference.

Page 2

2 congratulations on your choice of an aarrow stove. More than 20 years experience has been put into the development of our stratford multifuel to ensure ultimate performance and years of trouble free enjoyment. Every detail on the fire has been carefully engineered and designed which is why we are ...

Page 3: Stratford Sf & Si

3 the stratford sf & si installation and operating instructions contents operating instructions 1 introduction - the principle of the fire 5 2 checklist 6 a - stratford sf b - stratford si 3 fire bed 7 4 firebrick lining for sf only 8 5 throat inspection 9 6 the air system 10 a - interlock b - multi...

Page 4: Warning

4 warning to all solid fuel users petroleum coke some of whose brand names are "calco", "petrocoke" or "wonderco" must not be burned in this appliance to use this fuel will invalidate the appliance warranty if in doubt contact the solid fuel association telephone freephone 0800 600000 the use of spa...

Page 5: Operating Instructions For

5 operating instructions for the stratford multifuel sf & si. 1. Introduction - the principle of the fire your aarrow fire is built to the highest standard of craftsmanship using the best materials and the most modern equipment available. It is a highly efficient and sophisticated piece of machinery...

Page 6

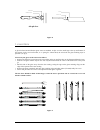

6 2. Check list inside the appliance you should find the following. Stratford sf 30 stratford sf 50 stratford sf 70 stratford sf 90 stratford si 40 stratford si 60 conv. Boil. Conv. Boil. Conv. Boil. Conv. Boil. Conv. Boil. Conv. Boil. Grate bars 7 7 9 9 11 11 11 11 7 7 11 11 fire bed surround 7 7 9...

Page 7

7 3. Fire bed grate the grates in the stratford sf & si multifuel units comprise a series of reciprocating cast iron bars seated on a pivoted "comb". All bars in the grate are identical, but every other bar is turned through 180 degrees, with the ends of the bars marked "h" sitting on the high secti...

Page 8

8 4. Refractory lining for s f convector models only warning: refractory linings are very fragile, handle with extreme care. Stratford sf multifuel convectors are lined with reflective panels, consisting of a combination of rectangular linings, which sit on the rear ledge, and side linings which sit...

Page 9

9 • remove front fuel retainer bars. • set the four linings on the side ledges on either side of the firebox. See fig 5. • set the three 197mm x 230mm rectangular linings on the upper surface of the grate bar channel at the rear of the firebox. • to keep the back linings in position, locate the stai...

Page 10

10 6. The air system flue outlet/hot plate only for sf the flue outlet is packed together with the firebrick lining and multi-purpose tool, inside the appliance. The hot plate comes fitted on the top of the fire. To fit flue outlet: • select the desired position (top or rear outlet) • smear a very t...

Page 11

11 disassemble air wash (see fig. 7) the air wash may be disassembled for cleaning or adjustment to achieve this the following procedure should be followed when the fire is cold and unlit. • support air wash cover with one hand • move cover up by smartly tapping the bottom with a hammer. • remove as...

Page 12

12 ash pit door figure 8 7. Glass/trim a gilt trim fitted around firedoor glass comes as standard. It clips on to the small lugs at the top and bottom of the aperture in the cast iron firedoor, as a "spring fit". When fitted, the trim locks the glass retaining clips in position. (see fig 9). If nece...

Page 13

13 8. Door adjustments the catch can be adjusted by sharply tapping the catch on the inside of the door as shown in fig 10. Once the appliance has been under fire for a period of time the fire door may appear to have moved out of alignment with relation to the door aperture or catch on the door inte...

Page 14

14 9. Spare parts list a - stratford sf description item part no sf30 sf50 sf70 sf90 ashpit door, complete with handle & seal 1 afs045 afs046 afs049 afs049 ashpit door handle 2 afs041 afs041 afs041 afs041 decorative trim (door surround) gold black 3 afs095 afs095a afs096 afs096a afs097 afs097a afs09...

Page 15

15 b -stratford si description item part no si40 si60 ashpit door, complete with handle & seal 1 afs045 afs046 ashpit door handle 2 afs041 afs041 decorative trim (door surround) gold black 3 afs095 afs095a afs096 afs096a fire door, complete with handle, glass, gaskets, clips & seal 4 afs200 afs201 h...

Page 16

16 10. Accessories stands elegant stands are available for the stratford sf only. These increase the height of the appliance and rear flue outlet by approximately 125mm (6''). Check current brochure for details. Traceries for added decorative effect, beautiful door traceries (arches, dawn & sunburst...

Page 17

17 technical data the stratford sf range stratford sf 30 stratford sf 50 stratford sf 70 stratford sf 90 conv. Boiler conv. Boiler conv. Boiler conv. Boiler room heater only min/max output (kw) 2 - 8 n/a 3 - 11 n/a 4 - 19 n/a 5 - 26 n/a boiler type 30 boiler type 50 boiler type 70/90 boiler type 70/...

Page 18

18 recommended fuels are as fellows: the hetas ltd, "three tick" appliance approval only covers the use of the following fuels in this appliance; phurnacite, phurnacite plus, centurion, maxibrite, extracite, pureheat, blazebrite, taybrite, sunbrite (doubles/singles), anthracite and welsh dry steam c...

Page 19

19 lighting the fire solid fuel burning • on multifuel fires with variable grate setting facility set the grate to the "coal" burning position. • ensure that ash pan is in position and the fire door closed. • set the air wash to one quarter open position. • set the primary inlet to the fully open po...

Page 20

20 in the morning • open air control fully until the embers begin to glow brightly. • lightly de-ash. • place smaller pieces of fuel on the fire up to the top of the fuel retainer bars. • when the fire is well established de-ash and empty the ash pan. Note: the exact setting of the controls will var...

Page 21

21 for stratford si • engage the operating tool on the comb extention. • move up and down vigorously the riddling lever (ash will fall into the ash pan beneath the grate). • when de-ashing is complete re-set grate to previous position. • empty ash pan the ash pan should be emptied at least twice a d...

Page 22

22 aarrow fires are designed so that the flue can be swept through the appliance once the throat plate has been removed. Access for cleaning should also be incorporated in the chimney (i.E. A soot door). Door glass the door glass should remain clear during normal daytime burning. However under certa...

Page 23

23 installation instructions for the stratford sf & si multifuel 17. General during installation ensure that adequate precautions are taken to avoid unnecessary risk to yourself or any householder. In particular the danger from asbestos dust and the caustic nature of the fire cement should be avoide...

Page 24

24 21. Air for combustion there must always be a permanent means of providing air for combustion into the room in which the fire is installed. A permanent vent with a total free area of at least 550 2 mm for every kw rated output above 5kw should be connected directly to the outside air or to an adj...

Page 25

25 when a flue lining is fitted (to stainless steel or pumice chimney systems) it should be supported independently to the appliance, i.E. With clips, brackets, flue lintels, etc. Not simply resting on top of the appliance. It should be possible to remove the fire for major maintenance work. Note: i...

Page 26

26 b - the stratford si take out the removable items from the appliance (see section 18 handling). Plug boiler connections, which are not required. Checking the thermostat. The thermostat is fitted within the outer casing on the left hand side of the unit's front. To remove the side panel loosen the...

Page 27

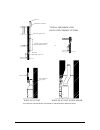

27 minimum 6" dia. Soot door asbestos rope packing minimum 150mm (6") brick up aperture fill void rear flue outlet all installations must conform to the building regulations reinstate brickwork around pipes using lime mortar, and make good. Fill the space around the appliance level with the top unit...

Page 28

28 register plate top flue outlet insulated chimney system soot door horizontal 150mm (6") between support brackets 2.4 metres (8' 0") maximum or maximum 50mm (2") gap to wall 600mm (24") minimum typical prefabricated rain cap non-combustible all installations must conform to the building regulation...

Page 29

29 typical installations for integral boiler central heating and domestic hot water, system using three boiler tappings. Typical installations for integral boiler central heating and domestic hot water, system using four boiler tappings. Note: diagrammatic representation only. Design and calculation...

Page 30

30 26. Water connections heating systems the size of the heating system, which can be run, will depend on the output rating of the appliance. It will be necessary to work out heat loss calculations for the system envisaged in order to establish the kw/hr rating. An appliance that will meet this figu...

Page 31

31 a check list (pre-lighting checks) appears in the operating instructions, but in addition to this the installer should: • operate the heating system and set the pump head. • balance the radiators. • re-vent and ensure no air locks. • check the circulation round the primary system and the heat lea...

Page 32

32 28. Guarantee once again we would like to thank you very much for buying a stratford fire. When you buy an aarrow fire, you are not only buying a first class appliance - you are buying a commitment from us to look after you and your appliance for as long as you want. Your aarrow fire carries a de...

Page 33

33 30. Service record date of visit company name of engineer telephone work carried out parts replaced stamp or signature should you have any questions about your fire that are not covered in this manual please contact our technical department on 01308 427234 please keep all repair receipts safely p...

Page 34

34 manufactured by july 2001.