- DL manuals

- Aastra

- PBX

- MX-ONE

- Installation Instructions Manual

Aastra MX-ONE Installation Instructions Manual

Summary of MX-ONE

Page 1

Installing mx-one installation instructions.

Page 2

Copyright © copyright aastra technologies limited, 2008. All rights reserved. Disclaimer no part of this document may be reproduced in any form without the written permission of the copyright owner. The contents of this document are subject to revision without notice due to continued progress in met...

Page 3

Contents contents 1 introduction 1 1.1 scope 1 1.2 target group 1 1.3 prerequisites 1 2 overview 3 2.1 battery string 6 2.2 ac/dc power unit 7 2.3 power calculations 8 2.4 dc/ac inverter 8 2.5 media gateway classic 8 2.6 fan unit 10 2.7 media gateway 10 2.8 servers 11 2.9 mx-one compact sm 12 2.10 t...

Page 4

Installing mx-one 4.8 installing media gateway classic 56 4.9 installing the fan unit 64 4.10 installing media gateway 69 4.11 installing servers 71 4.12 installing mx-one compact sm 74 4.13 installing a cabinet shelf 76 4.14 labeling 77 5 cabling 81 5.1 cable connectors 81 5.2 connector positions 8...

Page 5

Installing mx-one 9 installation test 141 9.1 basic installation test 141 9.2 installation test for mx-one telephony system 141 10 mounting side plates, doors, and back plate 143 10.1 installing panel 143 10.2 installing the side plates 144 10.3 installing the cabinet doors 147 10.4 installing the b...

Page 6

Installing mx-one 6/1531-asp 113 01 uen j2 2008-07-17.

Page 7

Introduction 1 introduction the mx-one ™ is a communication solution for mobile enterprises. Mx-one integrates voice and data communication in fixed and mobile networks for public as well as private service. The mx-one can be integrated into an existing local area network (lan) infrastructure. The m...

Page 8

Installing mx-one 1.3.2 electrical connections installation procedures involving connection of power cables and batteries must be performed according to local regulations. 1.3.3 safety all personnel involved in installation must read and understand the safety instructions prior to installation, see ...

Page 9

Overview 2 overview this section describes the hardware components in the mx-one, their functions, and technical details as dimensions and weights. The hardware components in the mx-one are mounted in two types of 19-inch cabinets: the byb 501 cabinet and the standard cabinet (locally sourced). This...

Page 10

Installing mx-one figure 1 mx-one cabinets 4 6/1531-asp 113 01 uen j2 2008-07-17.

Page 11

Overview table 1 size, weight, and voltage of mx-one hardware pos. Component product number width, height, and depth (mm) weight (kg) input voltage output voltage height (u) 3) height (m) 4) a byb 501 cabinet (including doors, side and back plates) 600 x 1,800 x 400 75 b standard cabinet locally sou...

Page 12

Installing mx-one table 1 size, weight, and voltage of mx-one hardware telephony server kdu 137 454/5 463 x 44 x 693 23 100 – 240 v ac 1 not for byb 501 mx-one availability kdu 137 454/6 463 x 44 x 693 23 100 – 240 v ac 1 not for byb 501 kdu 137 382/10 463 x 44 x 693 23 100 – 240 v ac 1 not for byb ...

Page 13

Overview figure 2 batteries (62 ah) and battery shelf for technical data about the batteries, table 1 on page 5 2.2 ac/dc power unit the ac/dc power unit converts the power input from the ac power supply network to dc output for the batteries and for the dc/dc converters in the subracks. Note: other...

Page 14

Installing mx-one figure 4 ac/dc power unit, 230v only for technical data about the ac/dc power unit, table 1 on page 5 2.3 power calculations for information about power calculations, see the environmental spec for mx-one site planning. 2.4 dc/ac inverter the dc/ac inverter converts the batteries d...

Page 15

Overview figure 5 media gateway classic the subracks consist of the following parts: a subrack a (upper subrack) b subrack b (lower subrack) c boards d dc/dc unit (board) e board cover (when needed) f cable chute g finger plate h front air plate 9 6/1531-asp 113 01 uen j2 2008-07-17.

Page 16

Installing mx-one i rear air plate j upper air plate k lower air plate for technical data about the media gateway classic, table 1 on page 5 2.6 fan unit the fan unit provides forced cooling of the media gateway classic boards in the subrack. Figure 6 fan unit for technical data about the fan unit, ...

Page 17

Overview figure 7 media gateway for technical data about the media gateway, table 1 on page 5 2.8 servers there are several types of servers used in the mx-one. The mx-one server for general lims and the standard server, to be used for high performance lims. The standard server is often used for lim...

Page 18

Installing mx-one figure 9 mx-one server for technical data about the servers, table 1 on page 5 the mx-one server consists of an embedded server unit (esu) built into a 1u high in the 19" building practice with internal cooling. Its mounting brackets can be turned to support either metric or 19-inc...

Page 19

Overview figure 10 mx-one compact sm for technical data about the mx-one compact sm, see table 1 on page 5 2.10 time slots and physical positions in lbp22 figure 11 time slots in lbp22 the lbp22 contains a total of 2 x 256 time slots, which is the maximum number of time slots that two dsu boards can...

Page 20

Installing mx-one 2.11 boards in media gateway classic for boards used in the exchange, table 2 on page 14 and table 3 on page 15 table 2 boards with front board product number building height time slots remarks alu2/11 rof 137 5373/11 20mm/8m 8 alarm unit for external alarms dc/dc rof 137 6303/1 40...

Page 21

Overview board product number building height time slots remarks tlu76/13 rof 137 5338/13 20mm/8m 32 cas, e1 tlu76/14 rof 137 5338/14 20mm/8m 32 ss7, e1 tlu77/11 rof 137 5387/11 20mm/8m 23 isdn, t1 tlu77/12 rof 137 5387/12 20mm/8m 23 dpnss, t1 tlu77/13 rof 137 5387/13 20mm/8m 23 cas, ds1, t1 tlu79/1...

Page 22

Installing mx-one board product number building height time slots remarks tlu75 rof 137 5336/6 8m 8 analog trunk both-way tlu81 rof 137 5417/1 8m 8 analog trunk line tlu82 rof 137 5418/1 8m 8 analog tlu (loop start) tlu82 rof 137 5418/2 8m 8 analog tlu (ground start) tlu82 rof 137 5418/3 8m 8 analog...

Page 23

Overview 2.12 cables table 4 cables in mx-one type of cable product number description tsr 491 0306/20m alu2 – main distribution frame (mdf) tmu – mdf (for music-on-hold) tsr 910 1054/16m tsr 910 1054/32m elu31, elu33, elu34, tlu80, tlu83 – mdf tsr 491 414/32m elu26, tlu79 – mdf esu – corporate lan,...

Page 24

Installing mx-one type of cable product number description tsr 482 0211/20m rj45 – rj45 straight tsr 482 0211/200 compact sm front, lan a – lan 0 tsr 901 0452/3000 ip telephone – lan cable (100baset) network tsr 902 0240/7000 10baset – rj45 tsr 903 021/5000 tsr 903 021/12m ac/dc – dc/dc, general tsr...

Page 25

Overview the pbx operators room should be of standard office design, but the floor as in the exchange room should be covered by an antistatic carpet. 19 6/1531-asp 113 01 uen j2 2008-07-17.

Page 26

Installing mx-one 20 6/1531-asp 113 01 uen j2 2008-07-17.

Page 27

Installation preparation 3 installation preparation the site is prepared mostly during the site planning stage, as described in the environmental spec for mx-one site planning. Should these preparations not be complete, perform the following steps before starting the installation: 1. Mark where to p...

Page 28: Warning!

Installing mx-one tool product number dimensions used for esd wrist strap lyb 250 01/141 included in byb 501 cabinet frame esd wrist strap lyb 250 01/14 used in cabinets with connection point cable lug sng 804 23 warning! Drilling machines, soldering irons and so on, must be of double-insulated type...

Page 29

Installation preparation figure 13 esd-earth point cable lug sng 804 23 3.3 delivery documents verify that required documents are accessible: • delivery documents (shipping specification) • alex library for the mx-one • test checklist (supplied by the aastra partner) • acceptance form (supplied by t...

Page 30

Installing mx-one 3.4 unpacking to keep a tidy work environment it is recommended to unpack one piece of hardware at a time. Start unpacking the equipment in the following order: 1. Inspect the cases for any external damage. 2. Open the cases and the protecting plastic wrapping, and remove all packi...

Page 31

Hardware installation 4 hardware installation this section describes a full installation of hardware components in the byb 501 cabinet. The recommended installation order is from the bottom of the cabinet to the top. Depending on the configuration, some pieces of hardware can be pre-installed. There...

Page 32

Installing mx-one figure 14 workflow for the mx-one installation 4.2 mounting cabinets this section describes mounting of the cabinets. The instructions focus on the byb 501 cabinets. For installation of the standard server cabinet, see the manufacturer instructions. 26 6/1531-asp 113 01 uen j2 2008...

Page 33

Hardware installation after this installation phase, all cabinets are positioned, fastened, leveled, and anchored to the site floor. 4.2.1 unpacking when unpacking the cabinet, perform the following steps: 1. Open the cabinet case using the vikex opener. 2. Lift the cabinet using a cabinet hoist or ...

Page 34

Installing mx-one 1/byb 501 180 cabinet frame pos. Title/function product number quantity earthing plate sxa 123 0760/1 4 screw m 4x8 24/sbf 228 040/0080 8 push-button sky 117 01/4 2 screw 3.5x9.5 sbf 131 279/24 2 esd wriststrap lyb 250 01/141 1 label svb 129 16 1 marking label 2/svf 191 040/2 1 mar...

Page 35

Hardware installation 1. Level the cabinet by adjusting the feet (a) using the 24-mm u-ring wrench, page 28 2. Verify that the cabinet is leveled horizontally and vertically, using a water level. 3. Tighten the locking nuts (b) on all feet using the 24-mm u-ring wrench, page 28 4. Proceed to the nex...

Page 36

Installing mx-one figure 16 installing the tip protection note: the following procedure must be performed for the feet at the front and for the feet at the back: 1. Insert three spacers (b) in the holes in the yoke (a), page 30 2. Slide the yoke under the cabinet between the feet. 3. Move the yoke b...

Page 37

Hardware installation 4.2.6.1 installing the tip protection on a concrete floor figure 17 installing the expander screw note: the following procedure must be performed for the feet at the front and for the feet at the back: • insert two expander screws (c) through the yoke (a) and into the concrete,...

Page 38

Installing mx-one 4.2.6.2 installing the tip protection on a raised floor figure 18 installing the tip protection on a raised floor note: the following procedure must be performed for the feet at the front and for the feet at the back: 1. Insert two clamps (f) through the yoke (a) and the floor (x),...

Page 39

Hardware installation 4.2.7 installing the cabinet with earthquake bracing table 8 earthquake set, concrete floor 17/byb 501/1 (2 x sxk 118 0168/1) earthquake set, concrete floor pos. Title/function product number quantity a fixing iron sxa 123 0380/1 4 b bar sxa 123 0381/1 2 c coaster sxa 123 0382/...

Page 40

Installing mx-one • install the two fixing irons (a) between the feet of the cabinet with the bar (b), two screws (h), and two washers (g), figure 19 on page 33 . • align the holes in the fixing irons over the anchoring holes in the floor. • tighten the two screws (h) to a torque of 80 nm. 4.2.7.1 a...

Page 41

Hardware installation figure 21 securing the earthquake bracing note: the following procedure must be performed for the feet at the front and for the feet at the back: • place two expander screws (d) with insulation bushing (e) and washer (f) through the fixing irons and into the concrete floor, pag...

Page 42

Installing mx-one 4.2.8.1 fastening cabinets back-to-back table 9 mounting set, back-to-back 24/byb 501/2 mounting set, back-to-back, d=800 pos. Title/function product number quantity b screw 03/sba 121 060/0160 12 a guide pin2 sxa 123 0327/2 6 figure 22 fastening the cabinets back-to-back 1. Positi...

Page 43

Hardware installation 4.2.8.2 fastening cabinets side-by-side table 10 mounting set, side-by-side 14/byb 501, mounting set, side-by-side pos. Title/function product number quantity a plate sxa 123 0368/1 3 b screw m 6x10 24/sbf 228 060/0100 12 figure 23 fastening the cabinets side-by-side 1. Positio...

Page 44

Installing mx-one table 11 grounding material, basic ntm 503 46/122 earthing material, basic pos. Title/function product number quantity a earth bar snv 103 04 1 b earth clip 105 4546/1 5 c cable 50 mm 2 , isolated tfl 104 510/08 25 m table 12 earthing material, extra ntm 503 46/123 earthing materia...

Page 45

Hardware installation for an overview of grounding for the byb 501 cabinet, page 38 and page 39 table 13 cabinet earthing set 16/byb 501 cabinet earthing set pos. Title/function product number quantity a earthing cable sxk 118 0154/2 1 b screw m 8x25 78/sba 178 080/0250 2 c contact washer scl 100 16...

Page 46

Installing mx-one 4.3.1 mounting earthing bar table 14 material set for earthing bar 15/byb 501 material set for earthing pos. Title/function product number quantity b earthing bar sxa 210 033/1 2 a bar nut (not used in future cabinet) sxa 123 0687/2 4 c screw m8x16 (not used in future cabinet) 03/s...

Page 47

Hardware installation figure 26 mounting the earth bar 1. Slide the four bar nuts (a) into the slot at the top and bottom of each cabinet, page 41 . 2. Install the two earthing bars (b) with screws (c) using a wrench, page 41 . 3. Install the earth bars between each cabinet at the top and bottom. 4....

Page 48

Installing mx-one note: check that the mounting bars for the captive nuts are positioned at least 100 mm behind the door. Figure 27 mounting the captive nuts in the rack 4.5 installing batteries this section describes the installation of 31-ah and 62-ah batteries. Make sure to leave room in the cabi...

Page 49

Hardware installation ntm 144 266 material set for battery shelf in 19-inch cabinet or frame pos. Title/function product number quantity a captive nuts m6 sbm 173 060/03 4 c screws m6x16 78/sba 121 060/0160 4 figure 28 installing the battery shelf 1. Mount four captive nuts (a) ( section 4.4 on page...

Page 50

Installing mx-one table 16 material set for 48 v 31-ah bkb 201 003/1 material set for 48 v 31-ah battery pos. Title/function product number quantity a battery set bkc 508 03/1 4 mounting set for battery ntm 144 265 1 table 17 material set for 48 v 62-ah battery bkb 201 003/2 material set for 48 v 62...

Page 51: Warning!

Hardware installation figure 29 battery block spacer figure 30 installing the batteries warning! Before working on any equipment, be aware of the hazards involved with the electrical circuitry and be familiar with the standard practices for preventing accidents. 45 6/1531-asp 113 01 uen j2 2008-07-1...

Page 52

Installing mx-one to mount the batteries in the battery shelf, perform the following steps: 1. Mount the spacers (k) between the battery blocks (a), page 45 . 2. Place the safety strap through the slots in the battery shelf, page 47 . 3. Place the batteries on the shelf. Page 45 . Make sure the fron...

Page 53

Hardware installation figure 31 battery string safety strap figure 32 parallel connection of batteries warning label 4.6 installing ac/dc unit this section describes the installation of the ac/dc power unit in the cabinet. 47 6/1531-asp 113 01 uen j2 2008-07-17.

Page 54: Warning!

Installing mx-one warning! Before working on any equipment, be aware of the hazards involved with the electrical circuits and be familiar with the standard practices for preventing accidents. 4.6.1 installing the ac/dc unit shelves 115-230 v figure 33 installing ac/dc unit shelves 115-230 v first, i...

Page 55

Hardware installation figure 34 installing ac/dc unit 115-230 v 1. If not already done, mount four captive nuts (a) (see section 4.4 on page 41 ) according to the number positions shown, see figure 37. 2. Slide the ac/dc unit between the shelves until it reaches a fixed position, see figure 37. Some...

Page 56

Installing mx-one figure 35 energy hazard warning label when adding a rectifier module (bml 351 056) always start from the left most position in the subrack. Flip down the handle and pull out the dummy. Place the module into the correct mounting position and slide carefully the module until it conta...

Page 57

Hardware installation table 19 mounting set for ac/dc unit ntm 144 268 mounting set for ac/dc unit pos. Title/function product number quantity b1 shelf for ac/dc sxa 112 2340/1 2 b2 shelf for ac/dc sxa 112 2340/2 2 c screw m 6x16 78/sba 121 060/0160 12 a captive nut m6 sbm 173 060/03 12 figure 37 in...

Page 58

Installing mx-one 2. Mount four captive nuts in the cabinet to secure the ac/dc unit, page 52 . It will be difficult to mount these if the shelves have been installed. 3. Use the screws (c) supplied with the mounting set to fasten the shelves (b) to the captive nuts in the cabinet, page 51. Note: th...

Page 59

Hardware installation 4. Connection to the mains supply and protective earthing (d) in the building should be carried out by a service person. The manufacturers instructions manual must be followed. 5. Fasten the warning label, energy hazard (svb 131 75) below the circuit breakers on the front of th...

Page 60

Installing mx-one 4.7 installing the dc/ac inverter this section describes the installation of a dc/ac inverter in the cabinet. Note that aastra does not supply this unit. Therefore, the illustration below refers to an optional model that can be placed in the byb 501 cabinet. Use the following mount...

Page 61

Hardware installation figure 41 installing the dc/ac inverter 1. Mount four captive nuts (a) ( section 4.4 on page 41 ) according to the number positions shown, page 55 . 2. Use four screws (c) to fasten the dc/ac inverter to the captive nuts in the cabinet, page 55 . Note that the unit is supplied ...

Page 62

Installing mx-one note: make sure to leave a gap of at least 50 mm between the inverter and the underlying and overlying units, to allow proper ventilation. 4.8 installing media gateway classic this section describes the installation of the subracks containing the media gateway classic boards in the...

Page 63

Hardware installation table 22 mounting set for subrack b ntm 144 263 mounting set for subrack b pos. Title/function product number quantity h air plate, front (used in subrack a if the two subracks are mounted in one cabinet) sxa 112 2331/1 1 i air plate, rear (used in subrack a if the two subracks...

Page 64

Installing mx-one figure 42 mounting the lower air plate 1 place subrack b in an upside-down position on a steady surface. 2 insert the edge of the lower air plate (e) in the slot at the rear side of the subrack, page 58 . 3 lower the air plate to level it with the screw holes in the subrack, as dem...

Page 65

Hardware installation 4.8.2 installing subrack b figure 43 installing subrack b the lower air plate is only mounted in subrack b (lower subrack), section 4.8.1 on page 57 . In subrack a (upper subrack), front and rear air plates are installed instead. 1 mount four captive nuts (a) ( section 4.4 on p...

Page 66

Installing mx-one parts from this mounting set are used at a later installation stage, leave the remaining parts at hand. 4.8.3 mounting the front air plate in subrack a to prepare subrack a for installation in the cabinet, first mount front and rear air plates in the subrack as follows: figure 44 m...

Page 67

Hardware installation 4.8.4 mounting rear air plate in subrack a figure 45 mounting rear air plate in subrack a 1 turn subrack a back to an upright position. 2 loosen, but do not remove the screws (1, 3, 5, and 7) on the back panel of the subrack, so they stick out a few millimeters, page 61 note th...

Page 68

Installing mx-one figure 46 installing subrack a 1 mount four captive nuts (a) ( section 4.4 on page 41 ) according to the number positions shown, page 62 2 use the screws (c) to fasten the subrack a to the captive nuts in the cabinet. For the correct holes, page 62 make sure that no gap is left bet...

Page 69

Hardware installation 4.8.6 installing the board cover table 23 material set, cover for boards without fronts sxk 106 2046/1 material set, cover for boards without fronts pos. Title/function product number quantity a cover sxa 112 2334/1 1 bar (factory mounted) sxa 112 2338/1 1 rivet (factory mounte...

Page 70

Installing mx-one figure 47 installing the board cover note: the board cover must be installed to fulfill the emc requirement. 1 fasten the finger plate (b) using four screws (d), page 64 . 2 fasten the board cover (a) above the finger plate using four screws (d) on the top part, and the two screws ...

Page 71

Hardware installation the jumper on the control board inside the fan unit must be moved to the position for single feed if only one subrack is installed figure 48 on page 65 note: the factory setting is for dual feed. M0000457b conn 1 conn 2 mcu dual single figure 48 strapping the fan unit for singl...

Page 72

Installing mx-one figure 49 installing slides 66 6/1531-asp 113 01 uen j2 2008-07-17.

Page 73

Hardware installation figure 50 installing the fan unit • mount four captive nuts (a) ( section 4.4 on page 41 ) according to the number positions shown, page 66 and page 67 . • insert the two slides (d) with springs (e), page 66 and fasten them with the two screws (f). • slide the fan unit in posit...

Page 74

Installing mx-one to install the upper air plate, perform the following steps: figure 51 installing upper air plate • mount four captive nuts (a) ( section 4.4 on page 41 ) according to the number positions shown, page 68 . • fasten the air plate (b) to the four captive nuts in the cabinet using the...

Page 75

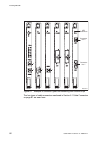

Hardware installation figure 52 a two lim-rack when installing a two-lim-equipped exchange cabinet (2 x subrack a+b) without internal power and batteries, two fan units with upper air plates (d) are mounted in the cabinet page 69 . 4.10 installing media gateway this section describes the installatio...

Page 76

Installing mx-one table 25 mounting set for media gateway ntm 144 264 mounting set pos title/function product number quantity c screw m 6x16 78/sba 121 060/0160 4 a captive nut m6 sbm 173 060/03 4 to install the media gateway in the cabinet, perform the following steps: figure 53 installing media ga...

Page 77

Hardware installation 3 if necessary, install additional media gateways directly above the first one in the next available cabinet position. It is not needed to leave a gap between units. 4.11 installing servers the different servers, the mx-one telephony server, the mx-one availability, the mx-one ...

Page 78

Installing mx-one figure 54 installing mx-one server • mount four captive nuts (a) ( section 4.4 on page 41 ) according to the number positions shown, page 72 . • fasten the mx-one server to the four captive nuts in the cabinet, using the four screws (c), page 72 . • if necessary, install additional...

Page 79

Hardware installation pos. Title/function product number c usb interface adapter kdu 137 395 d patch cables rj45 - rj45 (included in kdu 137 390 and kdu 137 346) servers and esu boards are connected to the keyboard and monitor by using the usb interface adapter, figure 55 on page 74 note: a keyboard...

Page 80

Installing mx-one figure 55 connecting keyboard and monitor 4.12 installing mx-one compact sm this section describes the installation of mx-one compact sms in the byb 501 cabinet. 74 6/1531-asp 113 01 uen j2 2008-07-17.

Page 81

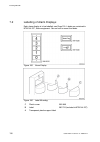

Hardware installation 4.12.1 install hw unit use the following mounting set to install the mx-one compact sm in the cabinet: table 28 mounting set for mx-one compact sm ntm 144 264 mounting set pos. Title/function product number quantity c screw m 6x16 78/sba 121 060/0160 4 a captive nut m6 sbm 173 ...

Page 82

Installing mx-one • fasten the compact sm to the four captive nuts in the cabinet, using the four screws (c), page 75 . • if necessary, and if there is space available, install additional compact sms directly above the first one in the next available cabinet position. No gap is needed between the un...

Page 83

Hardware installation figure 57 installing cabinet shelf • mount two captive nuts (a) ( section 4.4 on page 41 ) at the chosen position for the shelf. • fasten the two slides (g) to the two captive nuts in the cabinet using the two screws (c) and then loosen the screws. • loosen the four screws (f) ...

Page 84

Installing mx-one 4.14.1 lim labeling before cabling the cabinet it is necessary to label the lims using the labels provided in label sets svh 277 02/1 - /5, see table 30. The cabinet must be labeled with the number of lims that is installed in the cabinet. It is recommended to label the following i...

Page 85

Hardware installation figure 58 labeling of byb 501 4.14.2 circuit breakers for labeling of circuit breakers page 92 . 4.14.3 circuit breakers for the batteries for labeling of circuit breakers for the batteries page 92 . 4.14.4 cables for labelling of cables section 5.3.3 labeling of cables on page...

Page 86

Installing mx-one figure 59 warning label svb 131 75 4.14.6 warning label, parallel connection of batteries the warning label, parallel connection of batteries (svb 131 70) is for indoor use on aluminium, steel, or rigid plastic surface. It is made of self adhesive plastic material and not removable...

Page 87

Cabling 5 cabling cabling involves both internal and external connections onsite. External cabling is the routing of cables for grounding, to power equipment and other external devices. Internal cabling is the routing of cables within a cabinet or between cabinets. Use the fastener straps provided i...

Page 88

Installing mx-one m0000507b 1 1 1 1 led red/green connector no: 1 connector no: 2 1 2 figure 61 example of connector types and numbering from bottom to top the four types of cable connectors mentioned in section 5.1 cable connectors on page 81 are seen here. 82 6/1531-asp 113 01 uen j2 2008-07-17.

Page 89

Cabling figure 62 cable connectors the following boards have cable connectors: • alu2/11 • dc/dc • elu26/12, elu31/3, elu33, elu34/1, and elu34/2 • esu • ftu2/11 • iplu • lsu-e • spu4/11 • tlu76/11, tlu76/12, tlu76/13 and tlu76/14 • tlu77/11, tlu77/12, tlu77/13 • tlu79/11 • tlu80/11 • tlu83/1, tlu83...

Page 90

Installing mx-one 5.2.2 boards without cover the contact units in boards without cover are divided into upper and lower connector positions marked a (upper) and b (lower). Each connector position is divided into 1/4-sections, page 84 . Figure 63 board positions in boards without cover 84 6/1531-asp ...

Page 91

Cabling figure 64 side view, connectors the following board has this type of connectors: • tlu75 • tlu81 • tlu82 5.3 cable labeling 5.3.1 product labeling 5.3.1.1 previous type of labeling each cable has a product number as follows: figure 65 a = cable type b = cable length in mm 5.3.1.2 new type of...

Page 92

Installing mx-one b = cable length in m 5.3.2 label sets every lim has a label set with labels that are used to mark the cables in the lims. See page 86 table 31 product number lim number product number lim number svh 277 030/1 1 svh 277 030/5 6-10 svh 277 030/2 2 svh 277 030/6 11-20 svh 277 030/3 3...

Page 93

Cabling figure 67 labeling cables for a few examples for cable labeling, see page 88. 87 6/1531-asp 113 01 uen j2 2008-07-17.

Page 94

Installing mx-one figure 68 cable label examples 5.3.4 labelling of internal cables the internal cables connected to fixed positions in the exchange are already labelled at delivery. The label indicates the position of the cable’s own connector as well as that of the other end. For example: l1/81 (0...

Page 95: Warning!

Cabling figure 69 labeling of cables for boards with cover for a board without a front the letter a or b indicates if the connector is to be placed to the upper or lower front connector. 5.4 connecting internal power cables for instructions on how to connect mains cable to the ac/dc unit, refer to m...

Page 96

Installing mx-one before battery conductors are connected, disconnected, or installed. Remove the conductor to the negative pole (a) or remove an interconnection bridge (b), page 90 figure 70 example of removing the negative battery conductor (a) and an interconnecting bridge (b) 90 6/1531-asp 113 0...

Page 97

Cabling figure 71 connecting the batteries in a 115-230 v system 91 6/1531-asp 113 01 uen j2 2008-07-17.

Page 98

Installing mx-one figure 72 connecting the batteries in a 230 v system general battery connection: 1 connect the cable lug (l) of the grey cable supplied with the batteries mounting set (bkb 201 003/1) to the red plus pole (d) of the rightmost battery block, see page 91 or page 92. 2 fasten the scre...

Page 99

Cabling 5 fasten the screw (b) to secure the cable lug and press down the cover (i) on the black minus pole (d). 6 connect the black negative (-48v) dc supply cable (m) to the appropriate negative dc distribution circuit breaker (y) by inserting the stripped end in the opening of the circuit breaker...

Page 100

Installing mx-one figure 73 service loop for the cables the service loops enable the unit to be fully or partly pulled out of the rack for service while maintaining its operation. When connecting cables in the ac/dc unit, always fasten nearby cables to each others using fastener straps included in t...

Page 101

Cabling figure 74 fastener straps figure 75 fastener straps note: do not cut the cables. The shortest length of the cables from the ac/dc unit to the dc/dc board must be 5 meters. Connect the output to the dc/dc boards in the media gateway classic using cable tsr 903 021/5000 or /12m, as follows:. N...

Page 102

Installing mx-one figure 76 ac/dc cabling to the subracks in 115-230v systems 96 6/1531-asp 113 01 uen j2 2008-07-17.

Page 103

Cabling figure 77 ac/dc cabling to the subracks in 230v systems • connect one cable tsr 903 021/5000 to fuse f1/out1, see figure 76 on page 96 or see figure 77 on page 97. Connect the negative (-48v) dc supply cable (d) to the appropriate negative dc distribution circuit breaker (y) by inserting the...

Page 104

Installing mx-one • connect the other end of cable tsr 903 021/5000 from fuse f2 to the dc/dc board (h) in subrack b. • use fuse f3 in the ac/dc unit to connect the ac/dc unit to the dc/ac inverter (if used). Note: for the uk market the cable tsr 490 0116 is used between ac/dc - dc/dc. Also note tha...

Page 105

Cabling figure 78 cabling to the fan unit 5.5 connecting cables some cables are pre-connected at delivery, depending on equipment configuration ordered. Use the figure and the table below to connect cables, or to verify that the cables are correctly connected. For cable connections to board position...

Page 106: Warning!

Installing mx-one warning! Always verify that the cable markings correspond before connecting cables. For a list of external cables, including source and destination for every cable, see page 102 . For a list of internal cables, including source and destination for every cable, see page 102 . Warnin...

Page 107

Cabling figure 79 cable connections configure example 101 6/1531-asp 113 01 uen j2 2008-07-17.

Page 108

Installing mx-one table 33 external cables cable name from position to remark tsr 482 0211/2400 esu 3 corporate lan tsr 482 0211/2400 iplu 2 corporate lan tsr 482 0211/20000 spu4 2 mdf tsr 491 0306/20m alu2 1 or 2 mdf tsr 491 0306/20m tmu 1 mdf tsr 910 1054/16m or /32m elu31/3 2 mdf tsr 910 1054/16m...

Page 109

Cabling cable name from position to position tsr 490 0116/5000, tsr 490 0116/12m (uk) ac/dc dc/dc 1 tsr 903 0113/1 (uk) battery ac/dc tfl 281 325/4000 battery battery tsr 491 406/120 lsu-e 1, 2 dsu 1 tsr 491 406/1050 lsu-e 3, 4 dsu 1 tsr 482 0206/1600 esu 4 lsu-e 5 5.6 connectors and leds on board f...

Page 110

Installing mx-one figure 80 tlu77, tmu, tlu76, elu33, elu34, and iplu board fronts 104 6/1531-asp 113 01 uen j2 2008-07-17.

Page 111

Cabling figure 81 esu front connectors and leds 105 6/1531-asp 113 01 uen j2 2008-07-17.

Page 112

Installing mx-one figure 82 dc/dc front connectors and leds 106 6/1531-asp 113 01 uen j2 2008-07-17.

Page 113

Cabling figure 83 alu2, elu31, spu4, tlu79, tlu80 and tlu83 fronts figure 84 tlu75 and tlu82 front connectors 107 6/1531-asp 113 01 uen j2 2008-07-17.

Page 114

Installing mx-one figure 85 tlu77 front connectors and leds 108 6/1531-asp 113 01 uen j2 2008-07-17.

Page 115

Cabling figure 86 tlu81 front connectors 5.7 dummy fronts this section describes the dummy fronts in 19" cabinets. Dummy fronts are installed at all empty positions in the 19" magazines. New boards can be installed at these positions. Remove the dummy front at the position were the new board is to b...

Page 116

Installing mx-one figure 87 dummy fronts 5.8 extension cable structure the twisted pair cable used in the mx-one is delivered with 32 pairs. The cable is structured with 8 pairs in a bundle, and each bundle is kept together with a bundle thread, page 111 . 110 6/1531-asp 113 01 uen j2 2008-07-17.

Page 117

Cabling figure 88 cable structure the cables connected to the extension and trunk boards are connected on the other end to external telephone lines through the main distribution frames (mdf). The following tables specify the color coding of the 32 pair cable used for elu33, elu34, and other boards, ...

Page 118

Installing mx-one 5.8.1 elu33, elu34, elu31/3, tlu80 table 36 color coding in 32 pair cable for elu33, elu34, elu31/3 and tlu80/11 pair core color bundle connector pair core color bundle connector a white d18 a white d9 1 b blue c18 21 b blue c9 a white a17 a white a8 2 b orange b17 22 b orange b8 a...

Page 119

Cabling table 36 color coding in 32 pair cable for elu33, elu34, elu31/3 and tlu80/11 pair core color bundle connector pair core color bundle connector a yellow d10 a yellow a1 18 b green c10 38 b green b1 19 a yellow a9 39 a yellow d1 b brown b9 b brown c1 5.8.2 tlu83 the tlu83 board uses the same ...

Page 120

Installing mx-one table 37 color coding in 32 pair cable for tlu83 (tsr 910 1054/16m or 32m) pair/ tl ind core color bundle connector pair/ tl ind core color bundle connector a black d14 a black a4 11/ 0 b blue c14 31/ nc b blue b4 a black d13 a black d4 12/ 1 b orange c13 32/ nc b orange c4 a black...

Page 121

Cabling pair core color connector description a white 1 rx (link a line a) 2 b orange 2 rx (link a line b) a white 3 3 b green 6 a white 7 4 b brown 8 5.8.4 elu26, tlu79 table 39 color coding in cable for elu26 and tlu79 (tsr 491 414) pair core color connector a white c6 1 b blue d6 a white a6 2 b o...

Page 122

Installing mx-one 116 6/1531-asp 113 01 uen j2 2008-07-17.

Page 123

Connection of external cables 6 connection of external cables 6.1 general cabling to the mdf uses prefabricated cables. Twisted, shielded, pair-cables are to be used for cabling between the pbx and mdf or pbx and pbx (lim - lim). For more information about cables see page 17, see section 5.8 extensi...

Page 124

Installing mx-one tlu76 260 m if using a 120 ohm twisted pair cable without repeater tlu77 260 m if using a 120 ohm twisted pair cable without repeater tlu79 see page 125. Tlu80 7000 m if using a twisted pair cable with wire diameter 0.4 mm. 11000 m if using a twisted pair cable with wire diameter 0...

Page 125

Connection of external cables 6.4 digital extensions as an example, digital system telephones may have the type designations dbc 2xx connected to elu33. Only one system telephone per line can be connected, no parallel telephone or extra bell. Note: the line must not have any irrelevant open cable en...

Page 126

Installing mx-one 6.4.2 isdn extensions with elu26 the isdn-terminals are connected to the elu26 board in the pbx through the mdf. Figure 92 example with an isdn-terminal, 4-wire connection 6.4.3 door signal a door signal (call in progress) can be connected to the system telephone. The digital syste...

Page 127

Connection of external cables figure 93 example of door signal with system telephone dbc 225 1 wall terminal box rnv 114 or nef 181 2 buffer amplifier 3 door signal lamp 4 power supply unit if using system telephones dbc 22x, an optional unit can be connected with outlets for door signal and extra b...

Page 128

Installing mx-one figure 94 elu31/3 - mdf - rfp 6.6 analog external lines analog external lines are connected to analog tlu boards,tlu75, tlu82, tlu81, tlu83/1 or tlu83/2. 6.6.1 tlu75 or tlu82 figure 95 tlu75 or tlu82 - mdf (8 pairs) 122 6/1531-asp 113 01 uen j2 2008-07-17.

Page 129

Connection of external cables 6.6.2 tlu81 figure 96 tlu81 - mdf 6.6.3 tlu83 figure 97 tlu83 - mdf 123 6/1531-asp 113 01 uen j2 2008-07-17.

Page 130

Installing mx-one 6.7 digital external lines 6.7.1 tlu77 figure 98 tlu77, 120ohm pair cable 6.7.2 isdn 6.7.2.1 isdn with tlu76/11, -12, -13, -14, - 30b+d table 40 color coding in cable for tlu76 (tsr 482 0211/2400 or 20m) pair core color connector description a white 4 tx (link a line a) 1 b blue 5 ...

Page 131

Connection of external cables 6.7.2.2 digital external lines with tlu79 and an nt1-box, network terminal-box figure 100 2-wire isdn with tlu79 and an nt1-box (8 pairs) note: make sure that each individual’s receive (rx) and transmit (tx) are properly connected between the tlu79 board and the nt1-box...

Page 132

Installing mx-one how to carry out the cross-connection, see page 126 . These extensions must not be equipped with digital system telephones. If the public exchange is not capable of receiving dtmf-signals, then the extension must be equipped with a rotary dial telephone or a telephone for 10 pps (p...

Page 133

Connection of external cables figure 103 daughter boards on tlu75 6.9.2 call metering tlu83/2 the tlu83/2 is needed as this board contains the call metering hardware. The metering frequency, of 12 khz or 16 khz, is set when the board is activated. 6.10 private trunk lines (tie lines) the tie lines c...

Page 134

Installing mx-one 128 6/1531-asp 113 01 uen j2 2008-07-17.

Page 135

Alarms 7 alarms alarms can be connected to an alu2 board. The alu2 board can receive up to eight different alarm signals and send out up to seven control signals. If more in or out signals are required, the number of alu2 boards can be increased. Alarm indications are normally transferred to the pbx...

Page 136

Installing mx-one 7.2 labelling of alarm displays each alarm display is to be labelled, see page 130. Labels are contained in ntm 144 237, alarm equipment. See on how to mount the labels. Figure 105 alarm display figure 106 label mounting c plastic cover 355 848 b label 383 720 (included in ntm 144 ...

Page 137

Alarms 7.3 service signals to pbx operator console the exchange is equipped with a signalling channel which interconnects the exchange room to the pbx operator console. The signal lights the service indication. A toggle switch (with adjacent lamp display) in the exchange room is used for operating t...

Page 138

Installing mx-one 7.4 fan unit alarm connect the fan alarm using cable tsr 482 0211/20m to the mdf, see page 132. And connect the alu2 board to the mdf according to the cabling list for the site. For an example of connection to the alu2 board, see page 132. Figure 108 mdf alarms for the fan unit the...

Page 139

Alarms the red led is normally dark. The led is lit for a- and b- alarm conditions. The led is dark for alarm condition: the (absolute) supply voltage is below 15 v. Table 41 fan unit alarms fan alarm_a is active when one or more of the conditions is/are: -48v is too low (towards 0 v) or the tempera...

Page 140

Installing mx-one figure 109 alarm ports on the 115-230 v cherokee power system the ports where the connections are made can be seen in figure 110 on page 135. 134 6/1531-asp 113 01 uen j2 2008-07-17.

Page 141

Alarms figure 110 ports 115-230 v cherokee power system the left side of figure 110 on page 135 just shows how the alarm contacts, on the right, are numbered. There are two sets of relay contacts, x8 and x9. Each column, like 1, 2, 3, shows the contact positions of one relay. From figure 109 on page...

Page 142

Installing mx-one figure 111 mdf alarms for ac/dc unit 115-230v cherokee power system the cherokee alarm conditions are seen in table 42 on page 136. Table 42 alarms from ac/dc unit 115-230v cherokee power system block 1 alarms urgent alarm relay 1 alarm if: more than one rectifier are faulty or if ...

Page 143

Alarms block 4 alarms not activated alarm relay 4 not activated and no need to connect to mdf. For example, to detect urgent alarms relay 1 is used. It is located on the fourth column from the left of the x8 (or x9) control ports. The contacts are marked 10, 11, and 12, where 10 is the common port a...

Page 144

Installing mx-one table 43 alarms from ac/dc unit 230v power one system block 1 alarms (j9) low system voltage high system voltage load or battery disconnected distribution fuse failure battery fuse failure battery fuse disconnected urgent module failure partial load disconnected block 2 alarms (j8)...

Page 145

Software installation and configuration 8 software installation and configuration for software installation and configuration of mx-one telephony system, see the installation instructions for installing and configuring mx-one telephony system. For software installation and configuration of mx-one me...

Page 146

Installing mx-one 140 6/1531-asp 113 01 uen j2 2008-07-17.

Page 147

Installation test 9 installation test this section describes installation test at the end of the installation procedure. 9.1 basic installation test this section specifies basic check for correct installation of hardware components, mechanics, and cables. 1 make sure all internal, external, power an...

Page 148

Installing mx-one 142 6/1531-asp 113 01 uen j2 2008-07-17.

Page 149

Mounting side plates, doors, and back plate 10 mounting side plates, doors, and back plate use the material sets described in the tables to install side plates, doors, and back plate for the byb 501 cabinet. Start installation of cabinet side plates, doors, and back plates with installation of panel...

Page 150

Installing mx-one figure 113 installing the panel • install the lower panel (b) to the cabinet using two screws (e), page 144 . • install the upper panel (a) to the cabinet using two screws (e), page 144 . The doors from this mounting set are used at a later installation stage, leave the remaining p...

Page 151

Mounting side plates, doors, and back plate figure 114 installing the side plates the following procedure is done on one single cabinet or on the first and last cabinet in a row. 1 install three screws (i) and three spacers (h) to support the side plate at the top, the middle, and the bottom on each...

Page 152

Installing mx-one 10.2.1 installing the side plates in back-to-back cabinets table 46 side plate, extra, back-to-back 22/byb 501 180 side plate, extra, back to back pos. Title/function product number quantity k side plate sxk 118 0442/2 2 l earthing cable sxk 118 0439/2 4 figure 115 installing the s...

Page 153

Mounting side plates, doors, and back plate 10.3 installing the cabinet doors table 47 door set with lock 10/byb 501 180/1 door set with lock pos. Title/function product number quantity a panel (upper) 1 sxk 118 0185/1 1 b panel (lower) 1 sxk 118 0446/1 1 c door (right) sxk 118 0445/1 1 d door (left...

Page 154

Installing mx-one 3 tighten the screw (t) in the upper position, page 147 . 4 install the door (c) in the same way. 5 connect the earthing cables (s) from the doors to the cable lugs (y) at the top and bottom, page 147 . 10.4 installing the back plate table 48 back plate 23/byb 501 180 back plate, c...

Page 155

Mounting side plates, doors, and back plate 2 connect the two earthing cables (l) from the back plate to the cable lugs in the upper front of the cabinet, page 148 . 149 6/1531-asp 113 01 uen j2 2008-07-17.

Page 156

Installing mx-one 150 6/1531-asp 113 01 uen j2 2008-07-17.

Page 157

Concluding routines 11 concluding routines before leaving the installation site, complete the following steps: • clean up the site and remove objects like wrapping paper and cable pieces. • dispose of waste material according to local regulations. • print one copy of the safety document, and place i...