- DL manuals

- AAton

- Digital Camera

- XTRprod

- User Manual

AAton XTRprod User Manual

Summary of XTRprod

Page 1

X t r p r o d user’s guide september 2002.

Page 2

Aaton xtrprod user guide this manual was first written by peter abel abel cine tech 66 willow avenue staten island, ny 10305 usa aaton 2 rue de la paix bp 3002 38000 grenoble france +33 4 7642 9550 +33 4 7651 3491 fax e-mail: support@aaton.Com web: http://www.Aaton.Com (c) june 1997 aaton / grenoble...

Page 3: System Features and Controls

1 system features and controls front view 12 rear view 13 battery side 14 motor side 15 lcd control panel - quick reference 16 2 the camera body 2.1 lenses 20 arripl lens port 20 installing the lens 20 aaton lens port 21 2.2 viewing system 21 viewfinder options 21 attaching the extension finder 22 v...

Page 4

Installing the battery on the camera 33 battery charging 33 other power options 34 2.8 motor 35 camera speeds 35 using external speed devices 36 electronic inching 36 2.9 lightmeter 37 display 37 operation 38 using the lightmeter without running film 38 testing and adjusting the meter 38 turning the...

Page 5: The Magazine

The beamsplitter axis adjustment 48 the manual iris 48 battery life with ccd assists 49 installing the ccd heads 49 the vsa color ccd assist 52 menu operation 53 3 the magazine 3.1 concept 60 3.2 compatibility 60 dx magazines 60 super16 safe 60 3.3 pressure plate system 61 the picture plate 61 the c...

Page 6: Cleaning

4.4 shoulder operation 72 4.5 carrying handle 72 3/8 accessory screw 73 mounting from the carrying handle 73 tape measure stud 73 4.6 transport 73 4.7 extreme conditions 74 cold weather 75 warm weather 75 5 cleaning 5.1 lens 80 lens elements 80 lens exterior 80 mounting surface 80 5.2 body 80 exteri...

Page 7: Aatoncode

7 table of contents film processing 87 6.3 shooting super16 88 selecting a film stock 88 lenses 88 lighting 88 exposure 89 6.4 super16 field conversions 89 before you begin 90 procedure 90 7 aatoncode 7.1 concept 100 7.2 the internal clock 100 7.3 origincplus 101 7.4 initializing aatoncode in the ca...

Page 8

8.

Page 9

System features and controls 9 1.

Page 10

10 1.1 front view 1 friction adjusting ring adjusts the tension of the eyepiece swivel. 2 tape measure stud holds tape measure at film plane. 3 lateral lock knob locks the lateral position of the viewfinder. 4 beamsplitter access cap covers the port which accesses the beamsplitter adjustment screw. ...

Page 11

11 general overview 1.2 back view 11 magnetic drive provides magnetic magazine coupling. 12 mag release lever releases the magazine for removal. 13 amph9 accessory input provides +/-, hz, and camera run functions. 14 manual iris lever controls ccd iris operation. 15 lemo14 connects ccd head to the c...

Page 12

12 1.3 battery side 21 ccd control unit fastens to the body for ccd operation. 22 ccd on/off powers the ccd assist. Switch off to conserve battery life. 23 carrying handle includes tape measure stud, 3/8-16 accessory hole and adjusting tools. 24 diopter set ring adjusts the diopter setting of the vi...

Page 13

13 general overview 1.4 motor side 31 lcd control panel displays aatoncode, asa, speed, voltage, remaining footage. 32 carrying handle includes tape measure stud, 3/8-16 accessory hole and adjusting tools. 33 lemo5 aatoncode and smpte timecode communication. 34 lightmeter on/off activates the lightm...

Page 14

14 set show sync fps/ft ex/var time iso batt/iso mag elapse 1.5 lcd control panel - quick reference in show mode 24’ - 080 camera speed and remaining footage (default mode) iso = 100 film asa (1 x batt/iso) batt = 10’4 battery voltage (2 x batt/iso) ela = 042 elapsed footage during last take (2 x sp...

Page 15

15 general overview.

Page 17

The camera body 17 2.

Page 18: 2.1 Lenses

2.1 lenses the xtrprod’s flexible lens mounting system allows for the use of a wide variety of 16mm, 35mm and still-photographic lenses. 2.1.1 arripl lens port the arripl lens port is the standard mounting system delivered wi- th the xtrprod and allows the use of all 16 and 35mm arripl mounted motio...

Page 19: 2.2 Viewing System

Is tight enough so that it cannot be inadvertantly unlocked. 2.1.3 aaton lens port the xtrprod can also be equipped with an aaton lens port. In or- der to install the aaton port, the arripl lens seat and locking ring must first be removed. Because the ffd of the aaton lens port is shorter than most ...

Page 20

The hyperlong finder can be used. Note that standard short eyepiece can be equipped with a heating system, as well as 250mm eyepiece extension in order to avoid any condensation on the eyepiece lens. Aaton can provide you a heating lens (neutral, + 3 or - 3 diopters) and the corresponding cable. 2.2...

Page 21

Clockwise; to decrease the tension, rotate the adjusting ring counter- clockwise. 2.2.4 adjusting the diopter before shooting, the diopter setting of the viewfinder should be ad- justed to the operator’s eye. To set the diopter (d) look through the viewfinder, rotate the diopter set ring until the e...

Page 22

Te 1/8 of a turn counterclockwise.On the hyperlong finder, rotate the knurled ring closest to the eyecup counter-clockwise to close the shutter. 2.2.6 adjusting the viewing horizon if the rotation of the image seen through the cameras viewfinder does not exactly match what is seen through the naked ...

Page 23

2.2.8 changing the viewing screen the viewing screen is designed to be easily removed by the user for the purposes of interchanging or for cleaning. To remove the screen, unscrew the black tool marked vw located in the hollow at the rear of the camera’s carrying handle. Remove the port cap. Clear th...

Page 24

Checking that the sharp focus of a lens matches the measured distan- ce on its barrel. If it does not, then you need to make an adjustment of the viewing screen focus. To proceed, you must first unscrew and remove the circular cap lo- cated on behind the camera body run/test switch.Inside the access...

Page 25: 2.3 Mirror Shutter

Running. The configuration of illuminated markings will differ slightly bet- ween screen types. Refer to the screen illustration on page 21 for a specific description of each screen type along with its corresponding aatonite markings. 2.3 mirror shutter 2.3.1 concept the reflex mirror shutter is des...

Page 26

Duce the shutter opening, turning clockwise will increase the ope- ning. When setting the opening to 172.8° or 144°, a shutter blade indica- ting these settings will be visible from behind the left edge of the mirror. Make sure the white line to the immediate right of the 172.8° and 144° markings me...

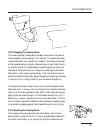

Page 27: Ment

The claw-side rail at the point of image exposure to assure maximum lateral stability. This unique, straight forward mechanism design results in horizon- tal and lateral film registration that is superior to all other 16mm ca- mera movements with an accuracy of 1/2000 of the image dimen- sions. 4.2 ...

Page 28

28 also mainly responsible for the sharpness of the images. Anyone who would like to change the ffd of his own camera should now do so by simply changing the spacer, and only with the spacer. He has not to polish any other surface, ot to insert anything else between the lens port and the film plane....

Page 29: 2.6 The Magazine

2.5.5 flange focal distances here are the flange focal distances for all the lens port available for the xtrprod. 2.6 the magazine the aaton magazine holds 400 ft (122m) of standard 16mm or su- per16 film. Shooting at 24 fps, a 400 ft roll will run for 10.5 mi- nutes; shooting 30 fps, the same roll ...

Page 30: 2.7 Power

30 2.6.2 removing the magazine to remove the magazine, situate yourself as before, towards the rear motor side of the camera. Grasp the magazine anywhere which is comfortable at its rear. Place your hand above the motor of the ca- mera and push the mag release lever towards the front of the camera w...

Page 31

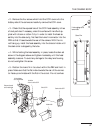

2.7.1 installing the battery on the camera the on-board battery fits below the ccd control unit on the batte- ry side of the camera body. In order to install, loosen the black knurled screw approximately four or five turns. Push the battery evenly onto the xlr4 connection on the body. When snug, tig...

Page 32: 2.8 Motor

Get into the habit of carrying a standard xlr4 powercable in your package in case an alternative power source is needed. Regarding ac power supplies, it is recommended that the unit you use be at least 4 amps and 25 watts. Before connecting any non- standard source, always make sure that the pin con...

Page 33

Sible from the ex/var selector. The camera speed can also be adjusted while the camera is running in either sync or variable mode. For more information on these speed functions, refer to section lcd control panel and jog of this chapter. 2.8.2 using external speed devices the xtrprod can be driven e...

Page 34: 2.9 Lightmeter

Sory connectors, provide the capability of using a remote on/off with either a half-frame or full-frame inching function. 2.9 lightmeter the xtrprod is equipped with an internal lightmeter that is desi- gned to read the quantity of light reflected off the film itself. For ad- ded accuracy, the meter...

Page 35

Remember, the lightmeter is giving you an average reading of the entire frame. You may choose to vary the suggested exposure accor- ding to subject conditions. 2.9.3 using the lightmeter without running film it is also possible to use the lightmeter without actually running the camera. Set the iso s...

Page 36

Viewfinder by means of the four screws which mount it to the front housing. Locate the hole between the two viewfinder screwholes on the top motor side of the front housing. The white potentiometer will be visible within this hole. • 6 - with a small screwdriver, adjust the potentiometer slightly; 1...

Page 37

First press set, then go to the appropriate button. Information is changed by either toggling that button or by rotating the jog, de- pending on the parameter. Pressing set afterwards (or waiting for 7 seconds) will enter your selection. Capped text ( sync, ex/var, iso, mag) refers to those func- ti...

Page 38

Duction id, then the camera’s equipment #, in that order. 2.10.5 asa setting when using the internal lightmeter and/or aatoncode in the xtr- prod, the asa (iso) setting must be adjusted to the exposure index of the film stock being used. The iso selector on the lcd control panel provides settings be...

Page 39

39 the camera body lection of any .001 incremented crystal speed between 3.000 and 75.000 fps via the jog. To set the camera to be driven from an external source (such as film/video synchronizer or external speed control), press set, then ex/var twice. Et will be displayed, indicating that camera is...

Page 40

40 play will revert back to the default mode (speed and remaining foo- tage) after 10 seconds. 2.10.13 mag id the xtrprod will recall the footage according to the mag id, whi- ch distinguishes seven magazines (a through g). To check the id of a particular mag, as read from the control panel, press b...

Page 41: 2.11 Led Indicators

41 the camera body 2.11 led indicators the xtrprod utilizes led indicators in three locations to convey infor- mation: in the viewfinder and on both left and right outsides of the ca- mera body. 2.11.1 position and meaning of the diodes • two yellow diodes, placed on both right and left sides of the...

Page 42: 2.12 Ccd Assist

2.11.6 end-of-film warning sequence the lightmeter display features pre-end-of-film and end-of-film war- nings for the operator. Under normal operation, the lightmeter display will flash once for every foot or meter that is counted down. When the footage counter on the lcd control panel counts down ...

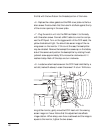

Page 43

Of the control unit to those connectors on the body and plug in the unit. Replace the two allen screws to fasten the control unit; a third screw of the same size should be screwed into the upper right side of the unit from the opposite direction. The control unit can remain permanently attached to t...

Page 44

One turn in the opposite direction to complete the adjustment. By backing the beamsplitter off its stop, fine centering of the ccd tar- get is maintained and the beamsplitter itself is less susceptive to resi- dual shocks caused by a drop or sudden jolt. Positioning the beamsplitter for video use - ...

Page 45

2.12.5 the manual iris the vas assist features an automatic gain. In certain situations, ho- wever, further light control may be desired (such as high contrast or strong back-light circumstances). In these instances, it is recommen- ded to employ the manual iris feature, which is located on the ccd ...

Page 46

The installation and removal of the vsa color head assembly is so- mewhat involved and considered a shop operation. Therefore, it is recommended that this procedure be performed by a qualified tech- nician. If you own a vsa, however, and feel that you would need to remove the assembly frequently, th...

Page 47

• 2 - remove the four screws which hold the ccd cover onto the battery side of the camera and carefully remove the ccd cover. • 3 - check that the exposed lens of the ccd head assembly is free of dust particles. If necessary, clean this surface with lens fluid ap- plied with a foam or cotton q-tip. ...

Page 48

This flat with the two flats on the threaded portion of the lemo. • 6 - replace the rubber gasket and the pbx cover plate via the four allen screws. Double-check that the lemo14 sits flush against the lip of the circular opening in the cover plate. • 7 - plug the control unit into the pbx and fasten...

Page 49

• 9 - if the ccd image is centered in the monitor, your adjustment is complete. However, if the image is off to one side, the beamsplit- ter axis adjustment needs to be reset. Follow the directions under 14.4 the beamsplitter axis adjustment to recenter the image. After- wards, loosen the two screws...

Page 50

A telecine, no need also to have developped the rushes you won't use. 2.12.9 menu operation (v5.00) the control unit contains seven operator buttons: up, down, left, right arrows, menu on and exit keys. - press on to switch on the video assist - press menu to the have the menu displayed. - use arrow...

Page 51

You can increase or decrease the gain from -155 to + 100 use arrows to proceed. Date - date allows you to choose the position of the current date inser- tion inside the video image. Use arrows to proceed. Time - time allows you to choose the position of the current time inser- tion inside the video ...

Page 52

Technical - time code off/on allows you to choose to insert (on) or nor (off ) aatoncode information, which consists of time, date and equipment number id. - font allows you to choose the font you need for the characters to be inserted. Choose 1 for standard characters and 2 for bold charac- ters. -...

Page 53

53 the camera body.

Page 55

The magazine 55 3.

Page 56: 3.1 Concept

3.1 concept the aaton dx magazine incorporates many features which add to the camera system's ease-of-use, efficiency and reliability. The maga- zine's coaxial design allows for separate feed and take-up chambers, which ensures that the bulk of the loading process is performed in daylight. The dx ma...

Page 57: 3.3 Pressure Plate System

Sitive high speed stocks, as is the case with the ltr and some other manufacturers' magazines, has been known to cause grain fracturing and a resulting abnormal exposure of the film in that area.) 3.3 pressure plate system the dx magazine features two pressure plates which are located at the front o...

Page 58: 3.5 Loading

58 claw and functions to stabilize the film as the claw engages the film perf between exposures. Proper tension and functioning of the claw plate contribute to reliable transport and quiet operation. 3.4 mag identification system 3.4.1 mag id each dx magazine bears its own identification (id) determ...

Page 59

The straightforward design of the dx magazine allows for quick, easy loading and an absolute minimum amount of threading in the dark. The film does not need to be cut in preparation for loading. 3.5.1 feed side - in the changing bag • place the film can and the magazine, feed side up, in the changin...

Page 60

• remove the magazine from the changing bag. 3.5.2 take-up side - in daylight • unfasten the take-up door lock by rotating downward and open the door. • release the doors of the upper and lower pinch rollers by pressing the white buttons and gently pulling open. • pull the length of film from the sl...

Page 61

• hold the lower sprocket with your right thumb and rotate the ta- ke-up core counter-clockwise to remove any slack. • thread the film around the upper sprocket and adjust the loop until its taut length is 14 to 15 frames long outside of the nose. When the proper length is achieved, close the upper ...

Page 62

3.6 800 ft magazine though the 800 ft design and loading is very close to the 400 ft ma- gazine, the following points need to be respected. 3.6.1feed side, loading. The loading is very similar to the 400 ft. Do not forget to install the upper platter when the film stock is loaded. This platter allow...

Page 63

• mag identification system determined by the combination of magnets in receivers located abo- ve the drive wheel on the mag throat ( same combinations than the 400 ft magazine ). • footage a sensor coupled to an external display, allows to verify the remain footage in the magazine. The xp 5.13 soft...

Page 65

The aaton system 65 4.

Page 66: 4.1 Camera Configurations

4.1 camera configurations 4.1.1 15mm front rods the most versatile and popular configuration for accessorizing the xtrplus camera, the universal 15mm screw-in front rod system can instantly accept aaton, arri, chrosziel, petroff and other manufactu- rers' mattebox and follow focus systems. Utilizing...

Page 67: 4.2 Handgrip

Standard bridgeplates from aaton, arri and other manufacturers can be attached to the xtrprod by means of the 3/8-16 tripod recep- ticle on the underside of the camera. The sliding bridgeplate system is recommended when large 35mm lenses and accessories are to be used, when using a geared head or wh...

Page 68: 4.3 Tripod Use

Handgrip as a simple intervalometer. 4.2.3 handgrip adjustments the handgrip rotation should be adjusted for maximum handheld operating comfort. Loosen the t screw and rotate the handgrip at the star plate until a more comfortable position is found. If a more extreme repositioning is required, wheth...

Page 69: 4.5 Carrying Handle

Shoulder to tripod operating modes. 4.5 carrying handle the carrying handle of the xtrprod is reinforced to safely accommodate any carrying, operating or mounting situation. 4.5.1 3/8 accessory screw the handle features a 3/8-16 insert to receive accessories such as french flags and lightweight moni...

Page 70: 4.6 Transport

Which is positioned between the rods directly behind the 3/8 insert. To use this stud, pull it up and fasten the ring of a standard assis- tant's tape measure around it; the stud holds the tape measure zero point precisely at the film plane. 4.6 transport one often overlooked, yet vital factor in th...

Page 71: 4.7 Extreme Conditions

Facturers suggest a minimum of 1 1/2" padding between high preci- sion components such as the camera and lenses. 1" of padding is ac- ceptable, however, between some of the more rugged components, such as magazines and batteries. Manufacturers also suggest to allow 2" of padding between the componen...

Page 72

Temperatures at all times during a cold weather shoot. 7.2 warm weather to keep the temperature of the camera body down, avoid having the camera exposed to direct sunlight for long periods of time by using a barney, all-weather cover, or some form of shading, like an umbrella. Most importantly, keep...

Page 73

73 the aaton system.

Page 75

Cleaning 75 5.

Page 76: 5.1 Lens

5.1 lens 5.1.1 lens elements the front and rear surfaces of your lenses should be inspected regu- larly and always kept clean of dust particles, smudges, fingerprints, etc. First, blow off any large particles of debris using an air syringe. Lens elements should then be cleaned using lens cleaning fl...

Page 77: 5.3 Viewing System

Port ring completely free of dirt and debris. Clean this surface, as well as the threads of the lens lock ring using alcohol or a multi-pur- pose cleaner applied to a q-tip. 5.2.3 camera gate the gate should be cleaned of film particles by means of a pointed wooden or plastic orange stick. The tool ...

Page 78

Position, then removing the battery. Remove the viewing screen as described in section 2.8, changing the viewing screen in the came- ra body chapter of the manual. Clean both upper and lower surfaces of the screen and reinstall. 5.3.2 eyepiece clean the eye lens (a), which is the outermost element c...

Page 79: 5.4 Magazine

5.3.3 viewfinder with the eyepiece off, look into the remaining viewfinder and clean the exposed element of the pechan prism using canned air or an air syringe. If dirt particles are still present, remove the viewfinder as- sembly from the camera by removing the four allen screws that hold the base ...

Page 81

Super16 81 6.

Page 82: 6.1 Super16

6.1 super16 6.1.1 the format super16 is a means of utilizing the cost effectiveness of 16mm film for wide-screen applications. The 1.66 aspect of super16 uses 20% more of the film surface by extending the picture into an area other- wise reserved for soundtrack or a second set of perforations. This ...

Page 83

Film must be free from contact with transportation surfaces in all instances, whether it be in the camera, at the lab or on the telecine. The aaton xtr camera series, since its debut in 1984, has been built for safe and trouble-free super16 operation. On the other hand, equipment that has not been d...

Page 84: 6.3 Shooting Super16

6.2.3 ordering film when ordering raw stock from your distributor, make sure to speci- fy super16 or single perf film. In the us, where 16mm double perf film is manufactured as standard, it is recommended to check stock of super16 color negative 1-2 weeks prior to shooting. When orde- ring super16 b...

Page 85

Stops of 4 and above, when possible. 6.3.3 lighting it is recommended not to cut corners with your lighting package for the sake of the budget. Those scenes which rely in the speed of the lens to compensate for minimal lighting will produce more grain than scenes which are amply lit and use a less c...

Page 86

Simple steps. The following section offers detailed instructions on this procedure. • for easier identification, the super16 position of all adjustments will be marked with red dots, standard 16 position will be unmar- ked. • all references to alignment in these instructions are made looking at the ...

Page 87

By an individual who is somewhat mechanically inclined. 4.2 procedure • 1. Changing the viewing screen the xtrprod features an interchangeable viewing screen which al- lows the user to install a screen with the 16 or super16 aspect mar- kings of his choice. See section chnaging the viewing screen to...

Page 88

The aperture opening (indicated below in grey). Regardless of the screen or format, the entire full frame indicated on all screens, should be centered to the entire aperture opening of the camera gate. The tolerance for this alignment is approximately the thickness of a line of the screen. If the vi...

Page 89

If the port cap is on, remove it. Notice that there are six slotted screws which lock the lens port ring to the lens holder, each with an unoccupied hole alongside it. Also note that one of each pair of holes will be marked with a red dot indicating super16 positioning. Remove the six screws and car...

Page 90

Shift the lens port by refastening the lens port ring utilizing the se- cond set of screw holes on both the lens port ring and the lens hol- der. The clockwise-side holes on both are for standard 16 positio- ning, the counter-clockwise holes are for super16. Carefully replace the lens port ring and ...

Page 91

Make sure that the right edge of the centering rod is flush against the right edge of the aperture opening. For super16 centering, make sure the super16 end of the centering rod fits evenly through the aperture opening. When the centering rod is aligned accordingly, firmly secure the screws of the l...

Page 92

Position the camera body underneath the paper target with the lens port facing up towards the target. Use a block of wood or a spacer of sorts to position the camera so that the lens port is approximately parallel to the ceiling. Select the zoom lens that will be used most frequently with the ca- me...

Page 93

93 super16.

Page 95

Aatoncode 95 7.

Page 96: 7.1 Concept

7.1 concept aatoncode, aaton's proprietary in-camera timecode system, is re- corded in the xtrprod on the edge of the film between the perfora- tions in both matrix and man-readable form. As recorded in the ca- mera, aatoncode contains a six digit production id, a smpte- compatible real time address...

Page 97: 7.3 Origincplus

97 aaton code me) for 8 hours. After 8 hours of keeping time, the yellow diode on the base of the xtrprod will flash once every four seconds, indica- ting that accurate time is no longer guaranteed. In order for the internal clock to operate, the camera must be powe- red before initialization. The c...

Page 98

Prod camera. The preferred method is by means of the origincplus, which inputs timecode in ascii form. It is also possible for the camera to receive information in smpte form directly from a smpte timeco- de device such as an tc audio recorder. Both methods are detailed be- low. 7.4.1 using the orig...

Page 99: Aatoncode

Ra base will blink to indicate running timecode. Also, the control pa- nel of the xtrprod will display hours/minutes/seconds when the button marked time is selected. Toggling this button will also dis- play year/month/day, then the production id, then the equipment #. • make sure to adjust the asa s...

Page 100: 7.6 Gmt1

Tion to act as a visual reference and for quick drift monitoring. Once ti- mecode has been initialized into the camera(s) and sound recorder, accu- rate time will be individually maintained in each machine for six hours. It is suggested, however, that new timecode be re-initialized after four hours ...

Page 101

Fically designed for cinema, which means with no integrated timeco- de, aaton needed to modify its origincplus: now, origincplus is able to serve as a smpte generator, which you can connect to any sound recorder. But origincplus may be too big and too powerful for such an usa- ge. So aaton decided t...

Page 102

Of the normal gate cleaning procedure, clean this area with a q-tip and lens cleaning fluid to assure that no dust particles cover the led array. The seven diodes will illuminate in test position whether or not ti- mecode is running in the camera. 8.7.2 setting the asa when changing magazines, make ...

Page 103

103 aaton code.

Page 105

Technical specifications 105 8.

Page 106: Technical Specifications

106 technical specifications weight 6kg / 13 lbs with 400 ft load and 12v on-board battery. Power 10-14 v, 600 ma, with film à 25°c / 77°f. Temperature range -20°c / +4°f to +40°c / +104°f. Noise level 20 db -1/+2. Speeds preset speeds of 6, 12, 18, 20, 23.98, 24, 25, 29.97, 30, 36, 40, 48, 60 and 7...

Page 107

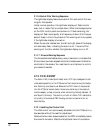

107 technical specifications 8.2 connector - pin attributions t ype fonctions diagram localisation pin attributions lemo2 on/off/test between the 1 ground two motors. 2 start looking down. Lemo5 timecode under 1 ground interface jog wheel. 2 smpte in 3 ascii in/out 4 et 5l not used lemo6 power zoom ...

Page 108: Available Viewing Screens

108 available viewing screens.

Page 109

109 technical specifications.