- DL manuals

- ABB

- Monitor

- 9438

- User Manual

ABB 9438 User Manual - Ip66

3

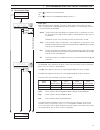

68

(2.68)

42

(1.65)

Fixing Centers

160 (6.3)

69 (2.72)

Fixing Centers

Allowance for

Cable Bends

200 (7.9)

61 (23/8) o.d.

Vertical Post

214

(8.43)

232

(9.13)

Three holes Ø6.3

suitable for M6

fasteners

Dimensions in mm (in)

250

(9.84)

Maximum distance

30 metres

C – Within Environmental Limits

55

C

Max.

–20

C

Min.

B – Within Temperature Limits

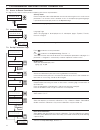

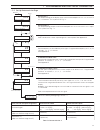

A – Maximum Distance of Instrument to Unit

Locate to suit

IP66

IP65

IP54

Environmental cover

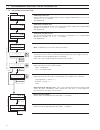

Dissolved Oxygen 9438

IP65

Liquid handling panel

Mark fixing centers

(see Fig. 2.3)

Drill suitable

holes

Fix instrument to wall using

suitable fixings

1

2

3

2.1.2

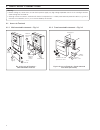

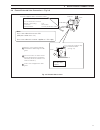

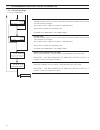

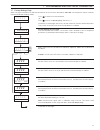

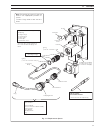

Dissolved Oxygen Flowcell – Fig 2.7

Allow sufficient clearance (200 mm all around) for easy removal

of the flowcell assembly for maintenance when not installed in

the optional enclosure – see Section 2.3.1 for overall dimensions

of units.

Note. To eliminate the risk of bubbles accumulating at the

sensor, and hence giving erroneous readings, the flowcell

assembly must be mounted vertically.

2.2

Mounting the Instrument

2.2.1

Wall-mounted Instrument – Figs 2.2 to 2.4

Fig. 2.1 Siting Requirements – Instrument/Sensor

Fig. 2.2 Overall Dimensions

Fig. 2.3 Wall Mounting

2

MECHANICAL INSTALLATION

2.1

Siting Requirements

2.1.1

Instruments – Fig. 2.1

Caution.

• Mount instruments in a location free from excessive

vibration.

• Mount away from harmful vapours and/or dripping fluids.

Information. It is preferable to mount the transmitter at eye

level thus allowing an unrestricted view of the front panel

displays and controls.

Summary of 9438

Page 1

Low and high level dissolved oxygen monitor 9438 user guide im/9438_6.

Page 2

Abb the company we are an established world force in the design and manufacture of instrumentation for industrial process control, flow measurement, gas and liquid analysis and environmental applications. As a part of abb, a world leader in process automation technology, we offer customers applicati...

Page 3

1 1 introduction ........................................................... 2 2 mechanical installation .................................... 3 2.1 siting requirements ............................................ 3 2.1.1 instruments ........................................... 3 2.1.2 dissolved oxyge...

Page 4

2 1 introduction model 9438 panel-mounted transmitter 9438 080 24 v dc p.S.U. (optional) dissolved oxygen 9438 sensor mounted in optional enclosure model 9438 wall-mounted transmitter 4600 abb 4600 abb d.O. g/kg 18 . 1 a1 a2 this manual describes how to install and operate the 9438 low level dissol...

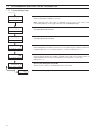

Page 5: Ip66

3 68 (2.68) 42 (1.65) fixing centers 160 (6.3) 69 (2.72) fixing centers allowance for cable bends 200 (7.9) 61 (23/8) o.D. Vertical post 214 (8.43) 232 (9.13) three holes Ø6.3 suitable for m6 fasteners dimensions in mm (in) 250 (9.84) maximum distance 30 metres c – within environmental limits 55 c ...

Page 6

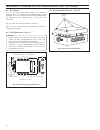

4 …2 mechanical installation position ‘u’ bolts on pipe position plates over ‘u’ bolts secure transmitter to mounting plate secure plates 1 2 3 4 191 (7.52) 12 (0.47) panel cut-out 96 (3.78) 96 (3.78) +0.8 –0 92 (3.62 ) +0.03 –0 +0.8 –0 92 (3.62 ) +0.03 –0 dimensions in mm (in) cut a hole in the pan...

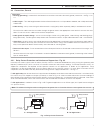

Page 7

5 2 mechanical installation dissolved oxygen 9438 Ø 8.5 for m8 fastener in four positions dimensions in mm. 25 25 25 160 mm space required below sensor panel, to allow for the opening of the optional environmental cover. 160 440 200 325 secure the enclosure to a vertical surface using the four fixin...

Page 8

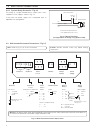

6 3 electrical connections 1 2 3 4 2 earth studs slide down pull out slightly. . . . . . And slide off remove protection cover slacken captive screws remove nuts and protection cover remove mains cover mains cover earth stud 1 2 warning. • before making any connections, ensure that the power supply,...

Page 9

7 3 electrical connections… nc c no external dc supply + – relay contacts load diode nc c no external ac supply l n relay contacts c r load a – ac applications b – dc applications 3.2 connections, general information. • earthing (grounding) – stud terminals are fitted to the transmitter case for bus...

Page 10

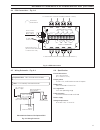

8 …3 electrical connections power supply retransmission relay 1 relay 2 serial power supply retrans. Relay 1 relay 2 1 2 3 4 5 6 7 + – n l serial (if fitted) 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 4 5 – – – – – – – – rx+ rx– tx+ tx– 0v retrans. Output relays 1 2 3 5 6 – – – – – nc c no c no relay 1 sol...

Page 11

9 3 electrical connections… + – normally closed common normally open common normally open neutral live earth tba relay 1 solenoid valve calibration relay 1 2 3 4 5 6 8 9 e n l 1 2 3 4 5 6 7 8 10 12 mains supply retransmission output 0v rx– rx+ tx– tx+ link green white –ve (black) +ve (red) tbb rs422...

Page 12

10 …3 electrical connections remove cover (see fig. 3.1) remove front panel screws remove front panel remove cap and screw slacken captive screws and remove protection cover 240 v ac 110 v ac 230 or 1 3 4 3 5 2 5 undo captive screw slide instrument out of case 240 v ac 110 v ac 230 or 3 4 1 2 3.5 se...

Page 13

11 3 electrical connections specification to bs 6500 cross sectional area = 0.5 mm 2 minimum current rating = 3 a construction = 16/0.2 mm nominal diameter = 5.4 mm (minimum 5.0 mm) remove cover to expose terminals and thread the cable through the cable gland. Connect the wires as shown. Ensure that...

Page 14

12 4 setting up 1 2 3 4 5 7 optional enclosure not shown for clarity slip the connector nut over the connector body and screw on to the oxygen sensor firmly. Insert the complete assembly into the flowcell ensuring that the o- ring is in place. Remove the top from the oxygen sensor container. Unscrew...

Page 15

13 4 setting up flow during normal operation solenoid operated valve – closed flow regulating valve sensor flow indicator drain sample in flow during calibration or thermal overload condition solenoid operated valve – open sample in drain line up the red spots and push the plug on firmly until the l...

Page 16

14 5 controls and displays 1 8 . 1 d.O. g/kg alarm leds upper display line lower display line membrane switches a – advancing to next page parameter 1 parameter 2 parameter 3 parameter 4 page 1 parameter 1 parameter 2 parameter 3 page 2 advance to next page for majority of parameters or b – moving ...

Page 17

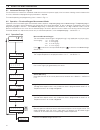

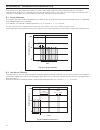

15 6 start up and operation operating parameters. A vailable only when 2 nd retransmission output is fitted. Secur e parameters. Li ne ar factory settings ––––– ua zero xxxx factory set code 0 0 0 0 0 electrical cal ––––– calibrate yes no ––––– ua span xxxx temp zero (1k0) xxxx temp span (1k5) xxxx ...

Page 18

16 …6 start up and operation d.O. g/kg temperature ( c) sensor cal. – – – – – 1 8 1 2 0 0 . High set g/kg 1 5 0 open valve no yes . ° . Sensor eff – – – – – low set g/kg 5 0 . – – – – – sensor o/p ( a) – – – – – 6.1 instrument start-up – fig. 6.1 ensure all electrical connections have been ...

Page 19

17 6 start up and operation yes no abort for 2 secs calibrating air 8 7 9 . Sensor cal. – – – – – 0 0 0 0 0 cal. User code cal. Aborted – – – – – – – – – – sensor eff recovery period 5 2 0 . D.O. g/kg 1 8 . 1 calibrate yes no – – – – – – – – – – slow sensor cal. Or press to advance to next par...

Page 20

18 7 programming and electrical calibration security code 0 0 0 0 0 espanol – – – – – set up parameter – – – – – pressure mmhg 760 salinity ppt 0 temp. Units ( c) – – – – – disp. Units ug/kg ug/l ppb – – – – – autocal 4 weeks 1 week 1 day off – – – – – set up alarm – – – – – reset cal. No yes – – –...

Page 21

19 7 programming and electrical calibration… set up alarm – – – – – high spt ug/kg 1 5 0 . – – – – – – – – – – a1 action hi/lo high low a1 type status temp do off to alter sec. Code 7.4 set up alarm page press to advance to next parameter or press to advance to set up retrans page , section 7.5. Ala...

Page 22

20 …7 programming and electrical calibration high spt ug/kg 1 5 0 . Low spt ug/kg 5 0 . Alter sec. Code 0 0 0 0 0 alter cal. Code 0 0 0 0 0 set up retrans – – – – – ...Continued from a1 action high set point the high set point can be set to any value within the full measurement range, with the units...

Page 23

21 7 programming and electrical calibration… set up retrans – – – – – – – – – – set up retrans 1 – – – – – log bi-linear y e s linear rtx type 4-20 0-20 0-10 rtx. Log bi-linear linear – – – – – 2 0 0 . Rtx span mg/kg 2 0 . Rtx zero mg/kg 1 0 0 . Enter input % 5 0 0 . Enter output % diagnostics yes n...

Page 24

22 …7 programming and electrical calibration set up retrans 2 – – – – – cal. Time s 3 0 fail m.Time s 3 0 fail s.Time s 3 0 – – – – – log bi-linear linear rtx type 4-20 0-20 0-10 rtx. Log bi-linear linear – – – – – rtx o/p temp d.O. – – – – – temp d.O. 2 0 0 . Rtx span mg/kg o c 2 0 . Rtx zero mg/kg...

Page 25

23 7 programming and electrical calibration… y e s 1 0 0 . Enter input % 5 0 0 . Enter output % diagnostics yes no factory settings – – – – – bi-linear linear cal. Time s 3 0 fail m.Time s 3 0 fail s.Time s 3 0 test retrans. (%) 0 0 return to set up retrans no retrans 2 n o t n e m n g i s s a t u p...

Page 26

24 …7 programming and electrical calibration e p y t t n e m u r t s n i l a n i m r e t d e t n u o m ll a w 1 2 3 4 5 6 7 d e t n u o m l e n a p 2 1 1 1 0 1 9 8 7 6 t n e r r u c e v + t u p n i t n e r r u c e v – t u p n i t u p n i 0 0 0 1 t p o t k n i l ) 6 ( 7 l a n i m r e t t u p n i 0 0 ...

Page 27

25 7 programming and electrical calibration… factory settings – – – – – a zero (0 a) x x x x factory set code 0 0 0 0 0 electrical cal – – – – – calibrate yes no – – – – – a span (100 a) x x x x temp zero (1k0) x x x x yes no temp span (1k5) x x x x adjust rtx zero – – – – – 7.7 factory settings pag...

Page 28

26 …7 programming and electrical calibration adjust rtx span – – – – – cal time 1 (min) 2 cal time 2 (min) 30 alter fact. Code 0 0 0 0 0 d.O. g/kg 1 8 . 1 adjust rtx zero 2 – – – – – adjust rtx span 2 – – – – – …7.7 factory settings page adjust retransmission span set the milliammeter reading to 20...

Page 29

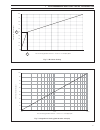

27 7 programming and electrical calibration dissolved oxygen measurement – shown as % of display span % retransmission output 0 10 20 30 40 50 60 70 80 90 100 0 10 20 30 40 50 60 70 80 90 100 a b dissolved oxygen measurement – shown as % of display span % retransmission output 1% 100% 10% 0 10 20 30...

Page 30

28 8.1 introduction no routine maintenance is required for this instrument other than periodic calibration – see section 6.2.2. However, if following a calibration the sensor output shows one flashing bar, the sensor capsule has therefore become exhausted and needs replacing immediately. If the outp...

Page 31

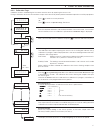

29 9 simple fault finding e g a s s e m c i t s o n g a i d 1 a m r a l a s u t a t s e s u a c e l b i s s o p y d e m e r d e l n o i t c a n o i t c a y a l e r ) e f a s l i a f ( y a l p s i d g n i h s a l f f f o d e z i g r e n e g n i r u s a e m e h t f o e d i s t u o s i g n i d a e r g ...

Page 32

30 …9 simple fault finding e r u t a r e p m e t ( ) c e c n a t s i s e r t u p n i ( ) 0 0 . 0 0 0 1 0 1 0 . 9 3 0 1 0 2 3 . 9 7 0 1 0 3 7 . 6 1 1 1 0 4 4 . 5 5 1 1 0 5 0 . 4 9 1 1 0 6 4 . 2 3 2 1 0 7 7 . 0 7 2 1 0 8 9 . 8 0 3 1 0 9 0 . 7 4 3 1 0 0 1 0 . 5 8 3 1 5 . 0 3 1 0 . 0 0 5 1 9.2 low se...

Page 33

31 10 specification system measuring ranges programmable within the ranges 0 to 20.0 µg kg –1 and 0 to 20 mg kg –1 scaling µg kg –1 , mg kg –1 or ppb, ppm accuracy ±5% of reading or ±1 µg kg –1 , whichever is the greater response time 90% of a step change in 1 minute resolution 0.1 µg kg –1 stabilit...

Page 34

32 …10 specification 11 spares specification – transmitter transmitter display measured value 5-digit x 7-segment back-lit l.C.D. Information 16-character, single line, dot matrix, back-lit l.C.D. Insulation, contacts to earth 2 kv r.M.S. Set point and relay no. Of set points one set point adjustmen...

Page 35

33 11 spares replacement seals pack (9437016) comprising: 2 x large o-rings 2 x small o-rings 2 x nylon seals 2 x end caps* 1 x protective cover *the end cap is used to blank off this connector when the plug is not fitted. End cap o-ring protective cover flowcell connector body o-ring ( 3 / 4 in. I....

Page 36

34 appendix a – 9438 080 24 v dc power supply unit (optional) 23 all dimensions in mm note. Make allowance for cable bends 160 63 ctrs fixing 98 145 ctrs 136 62 m6 stud for earth bonding fixing screws m4 slacken captive screws a.1 description the 24 v dc switch mode power supply unit is capable of p...

Page 37

35 appendix a – 9438 080 24 v dc power supply unit (optional) pre-wired to terminal block 110/115 v ac 230/240 v ac mains cable in to earth terminal in lid to 4641/4646 transmitter solenoid valve relay (maximum: 4) to solenoid valve on flowcell assembly (maximum: 4 valves) earth bonding stud. (enclo...

Page 38

36 appendix b – calibration diagnostics cal pulse expose to air recovery period time output curr ent (%) 50 100 0 mark (30 s to 5 min) expose to air output curr ent (%) 50 100 space (30 s to 5 min) 0 time fig. B.1 during calibration fig. B.2 low sensor efficiency the transmitter can be configured to...

Page 39

Products & customer support products automation systems • for the following industries: – chemical & pharmaceutical – food & beverage – manufacturing – metals and minerals – oil, gas & petrochemical – pulp and paper drives and motors • ac and dc drives, ac and dc machines, ac motors to 1kv • drive s...

Page 40

Im/9438 issue 6 the company’s policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice. Printed in uk (05.05) © abb 2005 abb limited oldends lane, stonehouse gloucestershire gl10 3ta uk tel: +44 (0)1453 826 661 fax: +44 (0)14...