- DL manuals

- ABB

- Measuring Instruments

- ACF-NT

- Operator's Manual

ABB ACF-NT Operator's Manual

Summary of ACF-NT

Page 1

Acf-nt, acf-nt v0309 multicomponent analyzer systems for emission and process monitoring operator’s manual 42/23572 en rev. 5.

Page 3: Contents

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 3 contents page foreword 4 important safety information 5 safety tips for handling electronic measurement devices 6 safety tips for handling the ftir spectrometer 7 safety tips for handling the voc analyzer 8 safety tips for handling harmful...

Page 4: Foreword

4 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 foreword the content of this manual this manual contains all the information you will need to safely and efficiently operate and maintain the analyzer system. This manual contains information on all the functional units in the analyzer sys...

Page 5: Important Safety Information

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 5 important safety information proper operation the analyzer system is designed for continuous measurement of concentrations of specific components in gases or vapor. Explosion protection the analyzer system must not be used to measure combu...

Page 6

6 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 safety tips for handling electronic measurement devices protective lead connection the protective lead should be attached to the protective lead connector before any other connection is made. Risks of a disconnected protective lead the ana...

Page 7

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 7 safety tips for handling the ftir spectrometer electrical safety the ftir spectrometer consists of an exposed metal chassis that is connected directly to earth via a power supply cord and is therefore classified as “safety class i” equipme...

Page 8

8 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 safety tips for handling the voc analyzer danger! Do not open any threaded connections in the voc analyzer gas paths. Doing so will damage gas path seal integrity. Combustion gas flowing out of the leak points thus formed in the internal g...

Page 9

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 9 special information about the system design for measurement of hf type designation acf-nt v0309 design of the analyzer system the analyzer system is equipped with a cooling unit which ensures the reliable operation of the analyzer in a tem...

Page 10: Chapter 1

10 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 chapter 1 startup restart initial startup of the analyzer system should be performed by trained personnel of the manufacturer or the supplier. Restart perform the following steps when restarting the analyzer system e.G. After maintenance ...

Page 11: Chapter 2

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 11 chapter 2 operation display/control unit figure 1 display/control unit status led’s numeric keypad softkeys cancel keys status led’s green led: the power supply is on. Yellow led: the “maintenance request” status signal is on. The measure...

Page 12: “Measured Values” Screen

12 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 “measured values” screen figure 2 “measured values” screen “measured values” screen values measured by the analyzer system, i.E. The ftir spectrometer, the o 2 ana- lyzer and the voc analyzer (fid) are displayed on pages 1 to 3 of the “me...

Page 13: “Control Panel” Screen

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 13 “control panel” screen figure 3 “control panel” screen indication the “control panel” screen offers controls for various functions of the analyzer system. Functions activated manually are indicated by means of a filled rectangle below the...

Page 14: “Control Panel” Screen,

14 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 “control panel” screen, continued maint. Mode maintenance control operate before starting and after finishing maintenance work (“maintenance key switch”) manual ref. Manual activation of reference spectrum recording, e. G. For restarts sh...

Page 15: “Diagnosis” Screen

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 15 “diagnosis” screen figure 4 “diagnosis” screen indication the indications in the “diagnosis” screen are used for service purposes. The upper four indications c/i % show the relation of the current spectral inten- sity to the initial one f...

Page 16: “Ranges” Screen

16 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 “ranges” screen figure 5 “ranges” screen indication the “ranges” screen displays the number of the activated measurement range (1 or 2) for measurement components with two measurement ranges. Note: mrf = measuring range feedback measuring...

Page 17: “Asp Module” Screen

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 17 “asp module” screen figure 6 “asp module” screen indication the “asp module” screen displays the values of the asp module temperature and pressure regulators. Parameter default t-co.D temperature controller sample conditioning block 180 °...

Page 18: “Multi-Fid” Screen

18 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 “multi-fid” screen figure 7 “multi-fid” screen indication the “multi-fid” screen displays the values of the voc analyzer temperature and pressure regulators. Parameter default t-co.D detector temperature (on “asp module” screen) 180 °c t-...

Page 19: “Flow” Screen

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 19 “flow” screen figure 8 “flow” screen indication the “flow” screen displays the various sample gas flow values: parameter default multi-fid 14 sample gas flow through the voc analyzer 60 l/h flow ges. Total sample gas flow 260 l/h asp modu...

Page 20: Changing The Password

20 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 changing the password step action input 1 select the change password menu item. Menu configure system change password 2 use the arrow keys to select the user group for which the password is to be changed (for example). Maintenance enter 3...

Page 21: Chapter 3

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 21 chapter 3 maintenance safety notes caution! Only persons familiar with the maintenance of comparable analyzer systems and certified as being capable of such work should work on the system. Caution! Observe the safety labels affixed to the...

Page 22: Visual Inspection

22 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 visual inspection figure 9 interior view catalyst power supply 24vdc, terminals ethernet hub ftir controller ftir spectrometer heated cell main switches circuit breaker, fuses temperature controller terminals terminals, rfi filter mcbs wi...

Page 23: Seal Integrity Check

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 23 seal integrity check when is the seal integrity check needed? The seal integrity check must be performed regularly. The seal integrity check methods differ depending on whether a voc analyzer (multifid14) is installed in the analyzer syst...

Page 24: Wear Part Replacement

24 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 wear part replacement caution! Prior to performing any maintenance works on the analyzer system be sure to activate the maintenance control on the “control panel” screen (see page 14) thus setting the “maintenance mode” status signal. Als...

Page 25

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 25 replacing the filter element in the probe cleaning the filter element if the filter element is not permeable enough anymore, remove it so that you can remove the contamination mechanically. Replacing the filter stone if the filter stone i...

Page 26

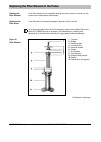

26 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 replacing the filter element in the probe, continued step action 1 turn the t-handle 1 of the filter removal device 1-3 in counter- clockwise direction. This pulls the filter element 8 via the detaching disk 3 out of the casing 10. 2 turn...

Page 27

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 27 replacing the filter element in the probe, continued step action either 5 clean the filter element 8. Replace seals 7 (o-rings from the accessory set). Re-lubrication is not necessary even after replacing o-rings 7. 6 it is not necessary ...

Page 28

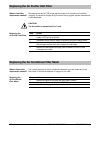

28 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 cleaning/replacing the sample gas filter in the sc block when is cleaning / replacement needed? Clean or replace the 1 μ stainless steel filter in the sample conditioning block (sc block) if it is contaminated and the sample gas flow is r...

Page 29

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 29 cleaning/replacing the sample gas filter in the sc block, continued step action remove the sample gas filter assembly from the sample conditioning block and disassemble it. 3 1 2 4 5 6 5 7 8 3 4 clean the sample gas filter 6 in an ultraso...

Page 30

30 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 replacing the air purifier inlet filter when is inlet filter replacement needed? Decreasing flow at the ftir purge gas flow meter is an indication of inlet filter clogging. A preventive change every 6 months during regular system maintena...

Page 31: Calibration

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 31 calibration ftir spectrometer zero spectrum the zero spectrum is recorded automatically twice a day. It is used for zero and sensitivity corrections. The zero spectrum is also named reference spectrum. Zero calibration is described in det...

Page 32: Calibration,

32 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 calibration, continued o 2 analyzer calibration the o 2 analyzer is automatically adjusted at the officially established maintenance interval (once per month). O 2 analyzer zero and span calibration is described in detail in the “oxygen a...

Page 33

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 33 ftir spectrometer zero calibration measuring principle the analyzer measures the intensity of infrared absorption of gases in the sample cell. Absorption is determined over a spectrum or band. Raw spectrum when analyzing a gas the analyze...

Page 34

34 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 ftir spectrometer zero calibration, continued manual reference spectrum recording sometimes it is necessary to record a new zero spectrum before or after certain maintenance works (e.G. Before a span check). The above-described sequence c...

Page 35: Ftir Spectrometer Span Check

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 35 ftir spectrometer span check correction factor span calibration establishes a correction factor for each component in order to assure the accuracy of the values displayed. This calibration is required since there can be slight deviations ...

Page 36: Oxygen Analyzer Calibration

36 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 oxygen analyzer calibration zero calibration for the zero calibration a test gas cylinder with 1 to 4 vol% oxygen in nitrogen is used. Span calibration for the span calibration air from the air purifier with a stable content of 20.96 vol%...

Page 37: Voc Analyzer Calibration

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 37 voc analyzer calibration zero calibration for the zero calibration either nitrogen from a cylinder or the zero gas for the oxygen analyzer is used. In the latter case a t-piece must be used to connect the test gas cylinder with the test g...

Page 38: Status Messages

38 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 status messages no. Message text f mr mm comments syst. Failure x measured value is invalid. Syst. Maint. Req. X measured value is valid. Syst. Maintenance x discard the measured value as a process measured value. Module failure error on ...

Page 39

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 39 taking the analyzer system out of service step action 1 stop the sample gas flow by switching the flow control to “zero gas probe” (see page 14). Voc analyzer (option): shut off the combustion gas supply. 2 purge the analyzer system with ...

Page 40: Appendix

40 operator’s manual acf-nt, acf-nt v0309 42/23-572 en rev. 5 appendix operating specifications ftir spectrometer 1) smallest meas. Range detection limit smallest meas. Range detection limit so 2 0–75 mg/m 3 0.27 mg/m 3 0–25 ppm 0.09 ppm no 0–200 mg/m 3 1.65 mg/m 3 0–150 ppm 1.24 ppm no 2 0–40 mg/m ...

Page 41: Index

42/23-572 en rev. 5 operator’s manual acf-nt, acf-nt v0309 41 index page air conditioner filter mesh replacing 30 air purifier inlet filter replacing 30 calibration 31 ftir spectrometer span check 35 ftir spectrometer zero calibration 33 oxygen analyzer 36 steam generator 35 test gases 31 toc analyz...

Page 42

Abb has sales & customer support expertise in over 100 countries worldwide. Www.Abb.Com the company’s policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice. Printed in the fed. Rep. Of germany (03.10) abb 2010 42/23572 e...