- DL manuals

- ABB

- Media Converter

- ACS 400

- User manual

ABB ACS 400 User manual

Summary of ACS 400

Page 1

Abb comp-ac user’s manual acs 400 ac drives for speed control of 3 to 50 hp (2.2 to 37 kw) ac induction motors.

Page 3

Acs 400 ac drives for speed control of ac induction motors user’s manual copyright 1999 abb drives & power products. All rights reserved. Acs400-us-04 3aua489002b5310 r0101 rev a effective: 2/1/99.

Page 5

Acs 400 user’s manual iii safety warning! Only a competent electrician should install the acs 400. Warning! Dangerous voltages are present when input power is connected. Wait at least 5 minutes after disconnecting the supply before removing the cover. Measure the voltage at dc terminals (u c+ , u c-...

Page 6

Iv acs 400 user’s manual.

Page 7

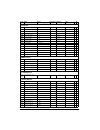

Acs 400 user’s manual v table of contents safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Iii installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 reference sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 8

Vi acs 400 user’s manual menu functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 led indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 resetting the drive from the control panel . . . . . . . . . . . . . . . . . 29 acs10...

Page 9

Acs 400 user’s manual vii group 22: accel/decel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 group 25: critical freq. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 group 26: motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 gr...

Page 10

Viii acs 400 user’s manual internal signal connections for the macros . . . . . . . . . . . . . . . . 117.

Page 11

Acs 400 user’s manual 1 installation study these installation instructions carefully before proceeding. Failure to observe the warnings and instructions may cause a malfunction or personal hazard. Preparation before installation to install the acs 400 you need the following: screwdrivers, wire strip...

Page 12

2 acs 400 user’s manual figure 1 step by step instructions for installing the acs 400. The references after each step refer to one or more of the reference sections on the following pages in this manual. 1 2 3 4 5 6 7 8 9 10 11 12 check the environment. Mount the acs 400 to the wall. Remove the cove...

Page 13

Acs 400 user’s manual 3 reference sections a installation environment stationary use • ambient temperature 32…104 °f (0...40 ° c) • max. Ambient temperature 122 °f (50 ° c) if p n and i 2 derated to 90% • installation altitude 0…3300 ft (1000 m) if p n and i 2 100% • installation altitude 3300…6600f...

Page 14

4 acs 400 user’s manual b dimensions (in/mm) units with ip 21/nema 1 enclosures figure 2 ip 21/nema 1 enclosures table 1 dimensions of units with ip 21/nema 1 enclosures dimension reference (in/mm) frame size, ip21/nema 1 (see paragraph s for frame size assignments of type codes) r1 r2 r3 r4 w 4.92/...

Page 15

Acs 400 user’s manual 5 units with ip 54/nema 12 enclosures the ip 54/nema 12 protection class has a different outer plastic cover. The ip 54/nema 12 enclosure uses the same internal plastic shell as the ip21 enclosure, but an internal fan is added to improve cooling. This structure increases the di...

Page 16

6 acs 400 user’s manual c mounting the acs 400 on a wall warning! Before installing the acs 400 ensure the input power supply to the drive is off. 1 the lid of the packing-box provides a wall mounting template. Remove the lid from the box. Figure 4 removing the wall mounting template. 2 the acs 400 ...

Page 17

Acs 400 user’s manual 7 d removing the cover 1 remove the control panel if needed. 2 lift the retaining lever and simultaneously pull the upper front cover slightly. 3 lift the other retaining lever e.G. With a screwdriver. 4 open the upper part of the front cover and remove it. 5 press the retainin...

Page 18

8 acs 400 user’s manual ip 54/nema 12 1 take the screws off. 2 remove the front cover. 3 remove panel if needed. Figure 10 opening type ip 54 / nema 12 drives..

Page 19

Acs 400 user’s manual 9 e terminal interface figure 11 terminal interface. F attaching a warning sticker the contents of the packing box include warning stickers in different languages. Attach a warning sticker in the language of your choice on the inside plastic shell as indicated above. Green led ...

Page 20

10 acs 400 user’s manual g type code and model designation the type code label is attached to the right side of the unit cover, on the heat sink. Figure 12 acs 400 type designation label. Figure 13 type code key. A serial number label is attached on upper part of the chokeplate between mounting hole...

Page 21

Acs 400 user’s manual 11 h installation of acs 400 gland plates or conduit plates a package, containing three screws and two gland plates and/or one conduit plate, is included with the acs 400. Figure 15 gland plate for power cables (a) and for control cables (b). The conduit plate is a single piece...

Page 22

12 acs 400 user’s manual connect the gland plate for power cables with one screw. The threaded hole for the screw is located in the middle of the heat sink, at the bottom end (see figure 17, point marked with a) ip 21 / nema 1. Figure 17 installing the gland plate for power cables (a), type ip 21 / ...

Page 23

Acs 400 user’s manual 13 i cable connections follow local codes for cable size. To avoid electromagnetic interference, use separate conduits for input power wiring, motor wiring, control and communications wiring, and braking unit wiring. Keep these four classes of wiring separated in situations whe...

Page 24

14 acs 400 user’s manual j control terminals main i/o terminal x1 the analog input signal is selected with v/i jumper j1: ai open = v and ai connected = i. Digital input impedance 1.5 k Ω . Use multi-strand 0.5-1.5 mm 2 (20-16 awg) wire. Note! Di 4 is read only when powered-up (factory macro (0) and...

Page 25

Acs 400 user’s manual 15 note! Di 4 and 5 are electrically isolated from di1, 2, and 3. To utilize di4 and 5, a jumper must be connected. See section l for details. Note! Terminals 3, 6 and 8 are at the same potential. Rs485 terminal x3 k motor check for motor compatibility. The motor must be a thre...

Page 26

16 acs 400 user’s manual l connection examples rs485 multidrop application 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 0...20 ma scr ai1 agnd +10v ai2 agnd ao1 agnd +24v dcom1 di1 di2 di3 di4 di5 dcom2 ro1c ro1a ro1b ro2c ro2a ro2...

Page 27

Acs 400 user’s manual 17 m replacing the cover do not turn the power on before replacing the front cover. N applying power when power is applied to the acs 400, the green led comes on. Note! Before increasing motor speed, check that the motor is running in desired direction. O environmental informat...

Page 28

18 acs 400 user’s manual p protection features the acs 400 has a number of protective features: the acs 400 has the following led alarm and fault indicators: • for location of leds, see section e or if acs-pan-a control panel is connected, see the instructions on page 25. Note! Whenever the acs 400 ...

Page 29

Acs 400 user’s manual 19 q motor overload protection if the motor current i out exceeds nominal current i n of the motor for a prolonged period, the acs 400 automatically protects the motor from overheating by tripping. The trip time depends on the extent of the overload (i out / i n ), the output f...

Page 30

20 acs 400 user’s manual s specifications 200 v series 3~ input v 1 208v - 240v ±10 % 50/60 hz acs401- x006-1 x009-1 x011-1 x016-1 x020-1 x030-1 x041-1 frame size r1 r2 r3 r4 nominal ratings (see g) unit nominal motor p n normal duty hp 3.0 5.0 7.5 10 15 20 25 input current i 1nnd a 10.9 14.4 21.6 2...

Page 31

Acs 400 user’s manual 21 * power stages are designed for the continuous i 2nnd current. These values are valid when the altitude is less than 3300 ft (1000 m) asl. See r. ** low noise setting programmable with optional control panel. For ambient operating temperature 0...40 ° c, derate p n and i 2 t...

Page 32

22 acs 400 user’s manual *** follow local rules for cable size; see i. Shielded motor cable is recommended. **** fuse type: ul class cc or t. Use 60 ° c rated power cable (75 ° c if t amb above 45 ° c). T product conformity the acs 400 complies with european requirements: • low voltage directive 73/...

Page 33

Acs 400 user’s manual 23 u accessories acs 100-pan control panel for use with the acs 100 / acs 140 / acs 400. Acs-pan-a control panel for use with the acs 400. Acs 100-ext extension cable kit for use with the control panel. Acs400-if11-3 through acs400-if41-3 rfi input filters. Acs-brk- braking uni...

Page 34

24 acs 400 user’s manual.

Page 35

Acs 400 user’s guide 25 programming acs-pan-a control panel the acs-pan-a is an alphanumeric control panel with a backlit lcd display and multiple languages. The control panel can be connected to and detached from the drive at any time. The panel can be used to copy parameters to other acs 400 drive...

Page 36

26 acs 400 user’s manual output display when the control panel is powered up, it displays a selection of actual values, as in figure 19. Whenever the menu button is pressed and held, the control panel resumes this output display. Figure 19 output display variables. The frequency reference can be mod...

Page 37

Acs 400 user’s guide 27 setting parameter value the parameter set mode is entered by pressing enter. In set mode, the value is underlined. The value is altered by using the up/down buttons. The modified value is stored by pressing enter. Modifications can be cancelled and set mode exited by pressing...

Page 38

28 acs 400 user’s manual menu functions use the up/down arrows to scroll through the menu for the desired menu function, then press and hold enter down until the display blinks to start the operation. Copy parameters from drive to panel (upload) note! The drive must be stopped and in local control. ...

Page 39

Acs 400 user’s guide 29 led indicators resetting the drive from the control panel when the red led of the acs-pan is on or blinking, a fault is active. To reset a fault when the red led is on, press the reset button. Caution! This may start the drive, when in remote control. To reset a fault when th...

Page 40

30 acs 400 user’s manual.

Page 41

Acs 400 user’s manual 31 acs100-pan control panel the control panel can be connected to and detached from the drive at any time. The acs100-pan panel cannot be used to copy parameters between two acs400 drives. Control modes the first time the drive is powered up, it is controlled from the control t...

Page 42

32 acs 400 user’s manual output display when power is applied to the control panel, it displays the actual output frequency. Whenever the menu button is pressed and held, the control panel resumes this output display. To toggle between output frequency and output current, press the up or down button...

Page 43

Acs 400 user’s manual 33 menu functions scroll through the parameter groups for the desired menu function. Press and hold enter until the display blinks to start the function. Note! The acs100-pan upload and download functions are not operational with acs 400. Relatively small permanent memory of th...

Page 44

34 acs 400 user’s manual.

Page 45

Acs 400 user’s manual 35 diagnostics the acs 400 alarms and faults are described in table 5 and table 6 respectively. The acs100-pan control panel displays only the alarm and fault codes. The alarm and fault messages are displayed only by the acs-pan-a control panel. Alarms al1-7 arise from button o...

Page 46

36 acs 400 user’s manual table 6 faults. Note! Faults (*) that are indicated by a red blinking led are reset by turning the power off and on. Other faults are reset from the control panel. See parameter 1604 fault reset sel . Code message description fl 1 overcurrent overcurrent: • possible mechanic...

Page 47

Acs 400 user’s guide 37 acs 400 basic parameters the acs 400 has a large number of parameters. Of these, only the basic parameters are initially visible. Setting up only a few basic parameters is sufficient for applications where the preprogrammed application macros of the acs 400 can provide all de...

Page 48

38 acs 400 user’s guide 9908 motor nom speed nominal motor speed from motor nameplate. Range 0 - 3600 rpm default: 1440 or 1720 rpm depending on application macro selected. á 9909 motor nom power nominal motor power from nameplate. Range: 1 - 100 kw (1.5 - 125 hp) default: 1 kw (1.5 hp) á 9910 motor...

Page 49

Acs 400 user’s guide 39 group 13 analog inputs 1301 minimum ai1 minimum value of ai1 in per cent. Defines relative analog input value where frequency reference reaches minimum value. Range: 0 - 100 % default value: 0 % group 15 analog output 1503 ao content max defines output frequency where analog ...

Page 50

40 acs 400 user’s guide s = parameters which can be modified only when the drive is stopped. Group 21 start/stop 2102 stop function conditions during motor stopping. 1 = coast motor coasts to stop. 2 = ramp ramp deceleration as defined by parameter 2203 deceler time 1 or 2205 deceler time 2. Default...

Page 51

Acs 400 user’s manual 41 application macros application macros are preprogrammed parameter sets. They minimize the number of different parameters to be set during start-up. Factory macro is the factory-set default macro. Note! The factory macro is intended for applications where there is no control ...

Page 52

42 acs 400 user’s manual application macro factory (0) this macro is intended for applications where there is no control panel available. It provides a general purpose i/o configuration that is typically used in europe. Note! The value of parameter 9902 is 0 ( factory ). Di4 is not connected. *note!...

Page 53

Acs 400 user’s manual 43 application macro factory (1) this macro is intended for applications where there is no control panel available. It provides a general purpose i/o configuration that is typically used in north america. Note! The value of parameter 9902 is 0 ( factory ). Di 4 is connected. *n...

Page 54

44 acs 400 user’s manual application macro abb standard this general purpose macro provides two more preset speeds compared to factory macro (0). Note! The value of parameter 9902 is 1 ( abb standard ). *constant speed selection: 0 = open, 1 = connected abb standard parameter values: input signals o...

Page 55

Acs 400 user’s manual 45 application macro 3-wire this macro is intended for those applications where the drive is controlled using momentary push- buttons. It gives two more preset speeds compared to factory macro (1) by using di4 and di5. Note! The default frequency is 60 hz. Note! The value of pa...

Page 56

46 acs 400 user’s manual application macro alternate this macro offers an i/o configuration that uses a sequence of di control signals to alternate the direction of drive rotation. Note! The value of parameter 9902 is 3 ( alternate ). *constant speed selection: 0 = open, 1 = connected application ma...

Page 57

Acs 400 user’s manual 47 application macro motor potentiometer this macro provides a cost-effective interface for plcs that vary the speed of the drive using only digital signals. Note! The value of parameter 9902 is 4 ( motor pot ). *note! • if both di 3 and di 4 are active or inactive, reference i...

Page 58

48 acs 400 user’s manual application macro hand - auto this macro offers an i/o configuration that is typically used for fan or pump applications. Note! The value of parameter 9902 is 5 ( hand / auto ). Note! Parameter 2107 (start inhibit) must be disabled (off) to permit simultaneous closure of di3...

Page 59

Acs 400 user’s manual 49 application macro pid control this macro is intended for use with different closed-loop control systems such as pressure and flow control. The value of parameter 9902 is 6 ( pid ctrl ). Note! ** constant speed is not used while in pid control (pid). Pid control parameters (g...

Page 60

50 acs 400 user’s manual application macro premagnetize this macro is intended for those applications where the drive must start very quickly. Building up the flux in the motor always takes time. Using the premagnetize macro will minimize this delay. The value of parameter 9902 is 7 ( premagn ). *co...

Page 61

Acs 400 user’s manual 51 acs 400 complete parameter list initially, only the basic parameters (shaded grey in table 7) are visible. See “selecting full parameter set” on page 28 for menu function to select full parameter set. S = parameters can be modified only when the drive is stopped. M = default...

Page 62

52 acs 400 user’s manual 0128 last fault 0 - 26 1 0 0129 previous fault 0 - 26 1 0 0130 oldest fault 0 - 26 1 0 0131 serial link data 1 0 - 255 1 0132 serial link data 2 0 - 255 1 0133 serial link data 3 0 - 255 1 0134 process var 1 0 - 65535 or -32768 - 32767 1 0135 process var 2 0 - 65535 or -3276...

Page 63

Acs 400 user’s manual 53 1306 filter ai 2 0 - 10 s 0.1 s 0.1 s group 14 relay outputs 1401 relay output 1 0 - 27 1 3 ( fault (-1)) 1402 relay output 2 0 - 27 1 2 ( run ) 1403 relay 1 on delay 0 - 3600 s 0.1 s; 1 s 0 s 1404 relay 1 off delay 0 - 3600 s 0.1 s; 1 s 0 s 1405 relay 2 on delay 0 - 3600 s ...

Page 64

54 acs 400 user’s manual group 22 accel/decel 2201 acc / dec 1/2 sel 0 - 5 1 * á á 2202 acceler time 1 0.1 - 1800 s 0.1; 1 s 5 s 2203 deceler time 1 0.1 - 1800 s 0.1; 1 s 5 s 2204 acceler time 2 0.1 - 1800 s 0.1; 1 s 60 s 2205 deceler time 2 0.1 - 1800 s 0.1; 1 s 60 s 2206 ramp shape 0 - 3 1 0 ( lin...

Page 65

Acs 400 user’s manual 55 group 31 automatic reset 3101 nr of trials 0 - 5 1 0 3102 trial time 1.0 - 180.0 s 0.1 s 30 s 3103 delay time 0.0 - 3.0 s 0.1 s 0 s 3104 ar overcurrent 0 - 1 1 0 ( disable ) 3105 ar overvoltage 0 - 1 1 0 ( disable ) 3106 ar undervoltage 0 - 1 1 0 ( disable ) 3107 ar ai min 0...

Page 66

56 acs 400 user’s manual group 40 pid-control 4001 pid gain 0.1 - 100 0.1 1.0 4002 pid integ time 0.1 - 320 s 0.1 s 60 s 4003 pid deriv time 0 - 10 s 0.1 s 0 s 4004 pid deriv filter 0 - 10 s 0.1 s 1 s 4005 error value inv 0 - 1 1 0 ( no ) 4006 actual val sel 1 - 9 1 1 ( act 1) á 4007 act 1 input sel...

Page 67

Acs 400 user’s manual 57 group 99: start-up data note! Start-up data parameters are used for setting up the acs 400. Figure 20 output voltage as a function of output frequency. Code description 9901 language language selection for acs-pan-a control panel. Note! The acs-100 pan does not support langu...

Page 68

58 acs 400 user’s manual group 01: operating data this group contains drive operating data, including actual signals and fault memories. Actual signal values are measured or calculated by the drive and they cannot be set by the user. Fault memories can be cleared by the user from the control panel. ...

Page 69

Acs 400 user’s manual 59 0118 ai1 relative value of analog input 1 displayed in %. 0119 ai2 relative value of analog input 2 displayed in %. 0121 di5 & relays status of digital input 5 and relay outputs. 1 indicates that the relay is energized and 0 indicates that the relay is de-energized. 0122 ao ...

Page 70

60 acs 400 user’s manual group 10: command inputs start, stop and direction commands can be given from the control panel or from two external locations ( ext 1, ext 2). The selection between the two external locations is made with parameter 1102 ext 1/ ext 2 sel . For more information on control loc...

Page 71

Acs 400 user’s manual 61 1002 ext2 commands defines the connections and the source of start, stop and direction commands for external control location 2 ( ext 2). Refer to parameter 1001 ext 1 commands above. 1003 direction 1 = forward 2 = reverse 3 = request rotation direction lock. This parameter ...

Page 72

62 acs 400 user’s manual group 11: reference select reference commands can be given from the control panel or from two external locations. The selection between the two external locations is made with parameter 1102 ext 1/ ext 2 sel . For more information on control locations, refer to “appendix”, s...

Page 73

Acs 400 user’s manual 63 1103 ext ref1 select this parameter selects the signal source of external reference 1. 0 = keypad reference is given from the control panel. 1 = ai 1 reference is given through analog input 1. 2 = ai 2 reference is given through analog input 2. 3 = ai1/ joyst ; 4 = ai2/ joys...

Page 74

64 acs 400 user’s manual 1104 ext ref1 min sets the minimum frequency reference for external reference 1 in hz. When analog input signal is at minimum, external reference 1 equals to ext ref 1 min . See figure 22 on page 65. 1105 ext ref1 max sets the maximum frequency reference for external referen...

Page 75

Acs 400 user’s manual 65 figure 22 setting ext ref minimum and ext ref maximum . The range of the analog input signal is set by parameters 1301 and 1302 or parameters 1304 and 1305, depending on the analog input used. Example: for 4 to 20 ma input, set 1301 = 20% and 1302 = 100%. Ext ref analog inpu...

Page 76

66 acs 400 user’s manual group 12: constant speeds the acs 400 has 7 programmable constant speeds, ranging from 0 to 250 hz. Negative speed values cannot be given for constant speeds. Constant speed selections are ignored if the drive is in local mode or if the process pid reference is followed (see...

Page 77

Acs 400 user’s manual 67 group 13: analog inputs code description 1301 minimum ai1 relative minimum value of ai1 (%). Value corresponds to minimum reference set by parameter 1104 ext ref 1 min or 1107 ext ref 2 min . See figure 22 on page 65. 1302 maximum ai1 maximum value of ai1 (%). Value correspo...

Page 78

68 acs 400 user’s manual group 14: relay outputs code description 1401 relay output 1 relay output 1 content. Selects which information is indicated with relay output 1. 0 = not sel relay is not used and is de-energized. 1 = ready the acs 400 is ready to function. The relay is energized unless no ru...

Page 79

Acs 400 user’s manual 69 21 = acs overload relay is energized when acs 400 overload alarm or fault exists. 22 = undervoltage relay is energized when undervoltage alarm or fault exists. 23 = ai1 loss relay is energized when ai1 signal is lost. 24 = ai2 loss relay is energized when ai2 signal is lost....

Page 80

70 acs 400 user’s manual group 15: analog output analog output is used to output the value of any parameter of the operating data group (group 1) as a current signal. Output current minimum and maximum values are configurable, as are the allowed minimum and maximum values for the observed parameter....

Page 81

Acs 400 user’s manual 71 group 16: system controls code description 1601 run enable selects the source of the run enable signal. 0 = not sel the acs 400 is ready to start without an external run enable signal. 1...5 = di1 ... Di5 to activate the run enable signal, the selected digital input must be ...

Page 82

72 acs 400 user’s manual group 20: limits code description 2003 max current maximum output current. The maximum output current that the acs 400 will supply to the motor. The default value is 1.5 * i n . 2005 overvolt ctrl dc overvoltage controller enable. Fast braking of a high inertia load causes t...

Page 83

Acs 400 user’s manual 73 group 21: start/stop the acs 400 supports several start and stop modes, including flying start and torque boost at start. Dc current can be injected either before the start command ( premagn sel = di 1... Di 5) or right after the start command ( premagn sel = const ). Dc hol...

Page 84

74 acs 400 user’s manual group 22: accel/decel two acceleration/deceleration ramp pairs can be used. If both ramp pairs are used, selection can be made between these while running through a digital input. The s curve of the ramps is adjustable. Figure 26 definition of acceleration/deceleration ramp ...

Page 85

Acs 400 user’s manual 75 group 25: critical freq in some mechanical systems, certain speed ranges can cause resonance problems. With this parameter group, it is possible to set up to two different speed ranges that the acs 400 will skip over. Example: a fan system vibrates badly from 18 hz to 23 hz ...

Page 86

76 acs 400 user’s manual group 26: motor control figure 28 operation of ir compensation code description 2603 ir compensation ir compensation voltage at 0 hz. Note! Ir compensation should be kept as low as possible to prevent overheating. Refer to table 10. Table 10 typical ir compensation values. 2...

Page 87

Acs 400 user’s manual 77 group 30: fault functions the acs 400 can be configured to respond to certain abnormal external conditions: analog input fault, external fault signal and panel loss. In these cases, the drive can either continue operation at current speed or at a set constant speed while sho...

Page 88

78 acs 400 user’s manual 3004 mot therm prot motor overtemperature function. This parameter defines the operation of the motor thermal protection function which protects the motor from overheating. 0 = not sel 1 = fault displays a warning indication at 95 % of the nominal value. Displays a fault ind...

Page 89

Acs 400 user’s manual 79 3007 zero speed load this parameter defines the maximum allowable current at zero speed relative to 9906 motor nom curr . Refer to figure 30. 3008 break point break point of motor load curve. Refer to figure 30 for an example of a motor load curve. See figure 32. 3009 stall ...

Page 90

80 acs 400 user’s manual figure 32 thermal protection trip times when parameters 3005 mot therm time , 3006 mot load curve and 3007 zero speed load have default values. Figure 33 underload curve types. T m nominal torque of the motor, ƒ n nominal frequency of the motor. 3015 underload curve this par...

Page 91

Acs 400 user’s manual 81 group 31: automatic reset the automatic reset system can be used for resetting overcurrent, overvoltage, undervoltage and analog input loss faults automatically. Number of allowed automatic reset operations within a certain time is selectable. Warning! If parameter 3107 ar a...

Page 92

82 acs 400 user’s manual group 32: supervision parameters of this group are used together with relay output parameters 1401 relay output 1 and 1402 relay output 2. Any two parameters within the operating data group (group 1) can be supervised. Relays can be configured to be energized when the values...

Page 93

Acs 400 user’s manual 83 group 33: information code description 3301 sw version software version. 3302 test date displays the test date of the acs 400 (yy.Ww)..

Page 94

84 acs 400 user’s manual group 34: process variables parameters within this group can be used to create custom process variables. Values of process variables can be seen in parameters 0134 process var 1 and 0135 process var 2 and optionally in the acs-pan output display. Value is calculated by takin...

Page 95

Acs 400 user’s manual 85 example: assume that a two pole motor is directly connected to a roll of 0.1 m diameter and the line speed is to be displayed in m/s. The following settings are then needed: 3401 display sel = 2 ( process var ) 3402 p var 1 sel = 0103 ( output freq ) 3406 p var 1 unit = 19(m...

Page 96

86 acs 400 user’s manual group 40: pid control the pid control macro allows the acs 400 to take a reference signal (setpoint) and an actual signal (feedback), and automatically adjust the speed of the drive to match the actual signal to the reference. The control signal block diagram is show in figu...

Page 97

Acs 400 user’s manual 87 4006 actual val sel pid controller feedback (actual) signal selection. Feedback signal can be a combination of two actual values act 1 and act 2. Source for actual value 1 is selected by parameter 4007 and source for actual value 2 is selected by parameter 4008. 1 = act 1 ac...

Page 98

88 acs 400 user’s manual 4009 act1 minimum minimum value for actual value 1 ( act 1). Refer to figure 38 and to group 13 parameters for analog input minimum and maximum settings. 4010 act1 maximum maximum value for actual value 1 ( act 1). Refer to figure 38 and to group 13 parameters for analog inp...

Page 99

Acs 400 user’s manual 89 note! The proportional gain and integration time values are used to adjust the responsiveness of the system. A low value for proportional gain and a high value for integral time ensures stable operation, but provides sluggish response. Too large of a proportional gain value ...

Page 100

90 acs 400 user’s manual group 50: communication parameters of this group define some general communication settings. Parameters 5001-5002 are used only if ddcs option card is installed. Code description 5001 ddcs bit rate ddcs link baud rate in mbits/s. 5002 ddcs node nr ddcs link node number. 5003...

Page 101

Acs 400 user’s manual 91 group 51: ext comm module parameters of this group need to be adjusted when a ddcs option module is installed. Refer to option module documentation for more information regarding these parameters. Code description 5101 fieldbuspar 1 parameter 1 of communication module in ddc...

Page 102

92 acs 400 user’s manual group 52: standard modbus the acs 400 can be connected to a modbus fieldbus system. Parameters of this group are used to set up station number, communication speed and parity. Parameters 5206 - 5215 are diagnostic counters that can be used to debug the fieldbus system. Refer...

Page 103

Acs 400 user’s manual 93 5211 crc errors this diagnostic counter increases by one every time when a message with a crc error is received. • ambient noise levels may be too high. • crc calculation is not performed correctly. 5212 busy errors in modbus network, only one device can transmit at any give...

Page 104

94 acs 400 user’s manual.

Page 105

Acs 400 user’s manual 95 standard serial communication overview the acs 400 can be connected to an external control system using the standard modbus fieldbus connection. The acs 400 can receive all of its control information either from the modbus fieldbus, or the control can be distributed between ...

Page 106

96 acs 400 user’s manual figure 41 structure of a fieldbus system. Fieldbus fieldbus master (plc) control w o rd (cw ) re fe renc es (ref) s tatus w o rd (s w ) a c tual v alues ( a ct) data flow par a meter r /w requests.

Page 107

Acs 400 user’s manual 97 grounding and termination rs485 bus the rs485 network should not be directly grounded at any point. All the devices on the network should be well grounded using their corresponding grounding terminals. As always, the grounding wires should not form any closed loops, and all ...

Page 108

98 acs 400 user’s manual activating modbus protocol the factory setting for channel 1 is not enabled. To enable standard modbus protocol for channel 1, set parameter 5005 protocol sel to 2 ( std modbus ). After this parameter change, the acs400 is ready to communicate via channel 1 using the default...

Page 109

Acs 400 user’s manual 99 communication settings communication settings define the communication speed, parity checking, number of stop bits and fault functions. These settings for channel 1 are defined using parameters in groups 50 communication and 52 standard modbus. Default communication settings...

Page 110

100 acs 400 user’s manual control locations the acs 400 drive can receive control information from multiple sources, including digital i/o, analog i/o, keypad, and modbus fieldbus. To control the acs 400 via the serial communication channel 1 (modbus fieldbus), it must be programmed to accept contro...

Page 111

Acs 400 user’s manual 101 1106 ext ref 2 select keypad ai 1 ... Comm comm + ai 1 comm * ai 1 comm , comm + ai 1 or comm * ai 1 fieldbus reference 2 is used when ext2 is selected as control location. See section references below for information on the alternative settings. Group 16 system controls 16...

Page 112

102 acs 400 user’s manual output signal source selection it is possible to control both the relay outputs 1 and 2, as well as the analog output from the serial communication channel 1. Relay outputs can be controlled in the following way: step 1: configure the acs 400 to supervise the value of any o...

Page 113

Acs 400 user’s manual 103 table 16 analog output control. 3206 superv 2 lim hi 0 - 255 e.G. 100 upper supervision limit for supervised parameter 2. Code parameter name alternative settings setting for standard modbus function/information group 01 operating data 0133 ser link data 3 0 - 255 - control...

Page 114

104 acs 400 user’s manual diagnostic counters diagnostic counters can be used for debugging the modbus system. Counters will roll over from 65535 to 0. The counter values are stored to permanent memory when power is disconnected. Counters can be reset from the control panel by pressing the up and do...

Page 115

Acs 400 user’s manual 105 communication this chapter describes the modbus communication for the acs 400 drive. Introduction to modbus modbus is a serial, asynchronous protocol. The modbus protocol does not specify the physical interface. Typical physical interface is rs485. Modbus is designed for in...

Page 116

106 acs 400 user’s manual register mapping the drive parameters are mapped to the 4xxxx area so that: • 40001 – 40099 are reserved for drive control registers • 40101 – 40199 is reserved for the actual values (parameter group 1) • 40201 – 40299 is reserved for parameter group 2 • 40301 – 40399 is re...

Page 117

Acs 400 user’s manual 107 exception codes the acs 400 supports the standard modbus exception codes. These are shown in table 19. Table 19 exception codes. Function codes the acs 400 supports the modbus function codes given in table 20. If any other function codes are used acs 400 returns an exceptio...

Page 118

108 acs 400 user’s manual the control word holding register: 40001 the control word is the principal means for controlling acs 400 from a fieldbus system. It is sent by the fieldbus master station to the drive. Acs 400 switches between its states according to the bit-coded instructions on the contro...

Page 119

Acs 400 user’s manual 109 references references are 16-bit words containing a sign bit and a 15-bit integer. A negative reference (indicating reversed direction of rotation) is formed by calculating the two’s complement from the corresponding positive reference. Reference 1 holding register: 40002 r...

Page 120

110 acs 400 user’s manual the status word holding register: 40004 the status word is a read-only word containing information of the acs 400 status. The contents of status word is presented in the following table. The text in italics refers to the states in figure 43. Table 22 the status word. Bit va...

Page 121

Acs 400 user’s manual 111 actual values actual values are read-only values containing information on the operation of the drive. Actual values are 16-bit words containing sign bit and a 15-bit integer. A negative value is given as two’s complement of the corresponding positive value. Actual value 1 ...

Page 122

112 acs 400 user’s manual figure 43 the state machine for evaluation of start and stop signals. Power off power on (cw bit0=0) (sw bit6=1) ( sw bit0=0 ) from any state f=0 / i=0 off1 (cw bit0=0) a c d (cw bit3=0) (sw bit2=0) (sw bit0=1) (cw xxxx xxxx xxxx x111) (sw bit1=1) (cw bit3=1 and (cw bit5=0)...

Page 123

Acs 400 user’s manual 113 fault and alarm status the acs 400 provides fault and alarm status words that are accessible only from the serial communication link (not from the control panel). These status words are located in place of parameter group 3 (modbus holding registers 40301- 40309). These reg...

Page 124

114 acs 400 user’s manual table 26 alarm word 1 bit descriptions. Bit # alarm word 1 0 overcurrent controller alarm 1 overvoltage controller alarm 2 undervoltage controller alarm 3 direction lock alarm 4 serial communication loss 5 modbus exception generated locally 6 analog input 1 loss 7 analog in...

Page 125

115 appendix local control vs. Remote control the acs 400 can be controlled from two remote control locations or from the control panel. Figure 44 below shows the acs 400 control locations. The selection between local control (loc) and remote control (rem) can be done by pushing the menu and enter b...

Page 126

116 remote control when the acs 400 is in remote control (rem), the commands are given primarily through digital and analog inputs, although commands can be given also through the control panel or serial communication. Parameter 1102 ext 1/ ext 2 select selects between the two external control locat...

Page 127

117 internal signal connections for the macros figure 46 the control signal connections of the abb standard, alternate and premagnetize macros. Control terminals analog inputs ai1, ai2 ext ref 2 select 1106 ext ref 1 select 1103 ext 1/ ext 2 select 1102 const sp select 1201 ai1 ext 1 ext 2 keypad ai...

Page 128

118 figure 47 the control signal connections of the pid control macro. Control terminals analog inputs ext ref 2 select 1106 ext ref 1 select 1103 ext 1/ ext 2 sel 1102 const speed sel 1201 ai1 ext 1 ext 2 keypad ai1 remote keypad local remote local const. Speeds min freq max freq crit. Sp. Acc/dec ...

Page 129

Acs4 00-us-0 4 3 a u a 489 002 b53 10 r 0 101 r e v a ef fec tiv e: 2/1 /99 abb drives & power products 16250 w. Glendale drive new berlin, wi 53151 telephone (414) 785-8378 (800) 243-4384 fax (414) 780-5135.