- DL manuals

- ABB

- DC Drives

- ACS320 series

- User Manual

ABB ACS320 series User Manual

Summary of ACS320 series

Page 1

Safety table of contents mechanical installation electrical installation start-up and control with i/o abb industry-specific drives short form user’s manual acs320 drives.

Page 2: List Of Related Manuals

List of related manuals you can find manuals and other product documents in pdf format on the internet. See section document library on the internet on the inside of the back cover. For manuals not available in the document library, contact your local abb representative. Purpose of the manual this s...

Page 3: Table of Contents

Table of contents 3 table of contents list of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 purpose of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4: Further Information

4 table of contents further information product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: 1. Safety

Safety 5 1. Safety safety in installation and maintenance these warnings are intended for all who work on the drive, motor cable or motor. Electrical safety warning! Ignoring the following instructions can cause physical injury or death, or damage to the equipment. • only qualified electricians are ...

Page 6: General Safety

6 safety note: • even when the motor is stopped, dangerous voltage is present at the power circuit terminals u1, v1, w1 and u2, v2, w2. • for more technical information, contact the factory or your local abb sales representative. General safety warning! If you ignore the safety instructions, injury ...

Page 7

Safety 7 note: • if an external source is selected for start command, and it is on, the drive starts immediately after an input voltage break or fault reset unless the drive is configured for 3-wire (a pulse) start/stop. • when the control location is not set to local (loc not shown on the display),...

Page 8

8 safety.

Page 9: 2. Hardware Description

Hardware description 9 2. Hardware description power connections and control interfaces rono ronc 3 9 di1 di2 di3 di4 di5 +24 v aux. Voltage output +24 v dc, max. 200 ma dosrc gnd dcom doout dognd digital/frequency output, pnp transistor type 30 v dc, max. 100 ma relay output 250 v ac / 30 v dc / 6 ...

Page 10: Type Designation Label

10 hardware description type designation label the type designation label is attached to the left side of the drive. An example label and explanation of the label contents are shown below. 1 type designation, see section type designation key on page 11 2 degree of protection by enclosure (ip and ul/...

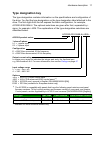

Page 11: Type Designation Key

Hardware description 11 type designation key the type designation contains information on the specifications and configuration of the drive. You find the type designation on the type designation label attached to the drive. The first digits from the left express the basic configuration, for example,...

Page 12

12 hardware description.

Page 13: 3. Mechanical Installation

Mechanical installation 13 3. Mechanical installation installing the instructions in this manual cover drives with the ip20 degree of protection. To comply with nema 1, use the mul1-r1, mul1-r3 or mul1-r4 option kit, which is delivered with multilingual installation instructions (3afe68642868, 3afe6...

Page 14

14 mechanical installation 3. Position the drive onto the screws on the wall. 4. Tighten the screws in the wall securely. On din rail • click the drive to the rail. • to detach the drive, press the release lever on top of the drive (1b). 3 4 1 1b.

Page 15: Fasten Clamping Plates

Mechanical installation 15 fasten clamping plates 1. Fasten the clamping plate to the plate at the bottom of the drive with the provided screws. 2. For frame sizes r0…r2, fasten the i/o clamping plate to the clamping plate with the provided screws. 1 2.

Page 16

16 mechanical installation.

Page 17: 4. Electrical Installation

Electrical installation 17 4. Electrical installation warning! Obey the safety instructions. See chapter safety on page 5 . If you ignore the safety instructions, injury or death can occur. If you are not a qualified electrician, do not do electrical work. Make sure that the drive is disconnected fr...

Page 18

18 electrical installation note: in frame size r4 the emc screw is located to the right of terminal w2. 1 emc var 1 emc.

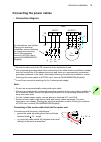

Page 19: Connecting The Power Cables

Electrical installation 19 connecting the power cables connection diagram u2 v2 w2 input 1) drive for alternatives, see chapter planning the electrical installation , section selecting the supply disconnecting device (disconnecting means) in acs320 user’s manual (3aua0000062599 [english]). Output u1...

Page 20: Connection Procedure

20 electrical installation connection procedure 1. Fasten the grounding conductor (pe) of the input power cable under the grounding clamp. Connect the phase conductors to the u1, v1 and w1 terminals. Use a tightening torque of 0.8 n·m (7 lbf·in) for frame sizes r0…r2, 1.7 n·m (15 lbf·in) for r3, and...

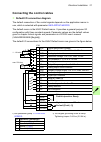

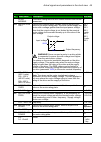

Page 21

Electrical installation 21 connecting the control cables default i/o connection diagram the default connection of the control signals depends on the application macro in use, which is selected with parameter 9902 applic macro . The default macro is the hvac default macro. It provides a general purpo...

Page 22: Connection Procedure

22 electrical installation connection procedure 1. Remove the terminal cover by simultaneously pushing the recess and sliding the cover off the frame. 2. Digital signals : strip the outer insulation of the digital signal cable 360 degrees and ground the bare shield under the clamp. 3. Connect the co...

Page 23: Installation Checklist

Electrical installation 23 installation checklist check the mechanical and electrical installation of the drive before start-up. Go through the checklist below together with another person. Read chapter safety on page 5 before you work on the drive. Check mechanical installation the ambient operatin...

Page 24

24 electrical installation.

Page 25

Start-up and control with i/o 25 5. Start-up and control with i/o how to start up the drive warning! Only qualified electricians are allowed to start-up or operate the drive. Obey the safety instructions. See chapter safety on page 5 . Before adjusting the drive and putting it into service, make sur...

Page 26

26 start-up and control with i/o how to perform a manual start-up for the manual start-up, you can use the basic control panel or the advanced hvac control panel. The instructions below are valid for both control panels, but the displays shown are the basic control panel displays, unless the instruc...

Page 27

Start-up and control with i/o 27 • nominal motor voltage (parameter 9905 ) setting of parameter 9905 is shown below as an example of parameter setting with the basic control panel. You find more detailed instructions in chapter control panels, section basic control panel in acs320 user’s manual (3au...

Page 28

28 start-up and control with i/o direction of the motor rotation check the direction of the motor rotation. • if the drive is in remote control (rem shown on the left), switch to local control by pressing . • to go to the main menu, press if the bottom line shows output; otherwise press repeatedly u...

Page 29

Start-up and control with i/o 29 how to perform a guided start-up to be able to perform the guided start-up, you need the advanced hvac control panel. Before you start, make sure that you have the motor nameplate data on hand. Power-up apply input power. The control panel first asks if you want to u...

Page 30

30 start-up and control with i/o select the application macro according to which the control cables are connected. Continue with the application set-up. After completing a set-up task, the start-up assistant suggests the next one. • press (when is highlighted) to continue with the suggested task. • ...

Page 31

Start-up and control with i/o 31 final check after the whole set-up is completed, check that there are no faults or alarms shown on the display and the panel led is green and does not blink. The drive is now ready for use..

Page 32

32 start-up and control with i/o how to control the drive through the i/o interface the table below instructs how to operate the drive through the digital and analog inputs when: • the motor start-up is performed, and • the default (standard) parameter settings are valid. The below examples show the...

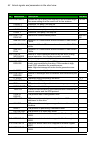

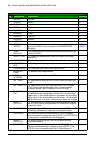

Page 33: 6. Actual Signals and

Actual signals and parameters in the short view 33 6. Actual signals and parameters in the short view note: when the control panel is in the short parameter view, that is when parameter 1611 parameter view is set to 2 ( short view ), the control panel only shows a subset of all signals and parameter...

Page 34

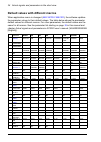

34 actual signals and parameters in the short view default values with different macros when application macro is changed ( 9902 applic macro ), the software updates the parameter values to their default values. The table below shows the parameter default values for different macros. For other param...

Page 35

Actual signals and parameters in the short view 35 3622 boost sel 0 = not sel 0 = not sel 0 = not sel 0 = not sel 0 = not sel 0 = not sel 0 = not sel 3 = di3 3626 timer 1 src 0 = not sel 0 = not sel 0 = not sel 0 = not sel 0 = not sel 0 = not sel 0 = not sel 23 = (p1+p2=p3+ b) 4001 gain 2.5 2.5 2.5 ...

Page 36

36 actual signals and parameters in the short view index name/ selection int timer cs floating pnt dual setppid dl sp pid cs e-bypass hand control e-clipse ac500 modbus 9902 applic macro 9 = int timer cs 10 = floating pnt 11 = dual setppid 12 = dl sp pid cs 13 = e- bypass 14 = hand control 15 = ecli...

Page 37

Actual signals and parameters in the short view 37 1) the default value depends on the drive type. E: 50 hz, u: 60 hz. 4010 setpoint sel 1 = ai1 0 = keypad 19 = internal 19 = internal 0 = keypad 1 = ai1 0 = keypad 0 = keypad 4011 internal setpnt 40.0% 40.0% 50.0% 50.0% 40.0% 40.0% 40.0% 40.0% 4027 p...

Page 38

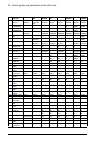

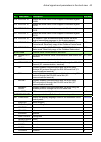

38 actual signals and parameters in the short view actual signals in the short parameter view actual signals in the short parameter view no. Name/value description fbeq 04 fault history fault history (read-only) 0401 last fault code of the latest fault. See chapter fault tracing in acs320 user’s man...

Page 39

Actual signals and parameters in the short view 39 parameters in the short parameter view parameters in the short parameter view no. Name/value description def/fbeq 11 reference select panel reference type, external control location selection and external reference sources and limits 1105 ref1 max d...

Page 40

40 actual signals and parameters in the short view 14 relay outputs status information indicated through relay output, and relay operating delays. For more information, see chapter actual signals and parameters in acs320 user’s manual (3aua0000062599 [english]). 1401 relay output 1 selects a drive s...

Page 41

Actual signals and parameters in the short view 41 22 accel/decel acceleration and deceleration times 2202 acceler time 1 defines the acceleration time 1, i.E., the time required for the speed to change from zero to the speed defined by parameter 2008 maximum freq . • if the speed reference increase...

Page 42

42 actual signals and parameters in the short view 5304 efb parity defines the use of parity and stop bit(s) and the data length. The same setting must be used in all on-line stations. 8 none 1 8 none 1 8 data bits, no parity, one stop bit. 0 8 none 2 8 data bits, no parity two stop bits. 1 8 even 1...

Page 43

Actual signals and parameters in the short view 43 5314 efb par 14 selects an actual value to be mapped to modbus register 40009. 0 5315 efb par 15 selects an actual value to be mapped to modbus register 40010. 0 5316 efb par 16 selects an actual value to be mapped to modbus register 40011. 0 5317 e...

Page 44

44 actual signals and parameters in the short view russki russian 11 polski polish 12 tÜrkÇe turkish 13 czech czech 14 magyar hungarian 15 ellinika greek 16 chinese chinese 17 korean korean 18 japanese japanese 19 9902 applic macro selects the application macro. See chapter application macros in acs...

Page 45

Actual signals and parameters in the short view 45 ac500 modbus this macro configures the drive communication and control parameters. 21 9905 motor nom volt defines the nominal motor voltage. Must be equal to the value on the motor rating plate. The drive cannot supply the motor with a voltage great...

Page 46

46 actual signals and parameters in the short view.

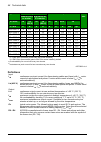

Page 47: 7. Technical Data

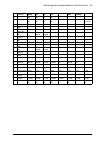

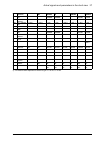

Technical data 47 7. Technical data ratings note : when choke is not used, input current is effected by supply network and impedance. Use the table in fuses and alternate short-circuit protection (page 50 ) to correctly size the input cabling as well as input fuses or mmp for branch circuit protecti...

Page 48: Definitions

48 technical data definitions 03x-04a1-4 7.6 6.3 3.8 3.2 3.7 4.1 7.2 1.5 2.0 r1 03x-05a6-4 10.6 8.8 5.3 4.4 5.1 5.6 9.8 2.2 3.0 r1 03x-07a3-4 12.8 10.7 6.8 5.7 6.6 7.3 12.8 3.0 3.0 r1 03x-08a8-4 15.0 12.5 8.6 7.2 8.0 8.8 15.4 4.0 5.0 r1 03x-12a5-4 20.7 17.2 12.3 10.3 11.4 12.5 21.9 5.5 7.5 r3 03x-15...

Page 49: Sizing

Technical data 49 sizing drive sizing is based on the rated motor current and power. To achieve the rated motor power given in the table, the rated current of the drive must be higher than or equal to the rated motor current. The rated power of the drive must also be higher than or equal to compared...

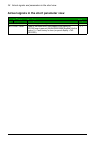

Page 50: Fuses

50 technical data fuses and alternate short-circuit protection fuses the rated fuse currents given in the table are the maximums for the mentioned fuse types. If smaller fuse ratings are used, check that the fuse rms current rating is larger than the rated i 1n current given in the ratings table on ...

Page 51: Fuses And Mmps

Technical data 51 fuses and mmps type fuses mmps acs320- gg ul class t or cc (600 v) frame i 1n mmp type e min. Encl. Vol. 4) x = e/u 1) a min a 2) max a a dm 3 in 3 1-phase u n = 200…240 v (200, 208, 220, 230, 240 v) 01x-02a4-2 10 6 10 r0 6.1 ms132-6.3 & s1-m3-25 18.9 1152 01x-04a7-2 16 10 20 r1 11...

Page 52

52 technical data 03x-15a6-4 35 15 35 r3 18.0 ms165-20 3) - - 03x-23a1-4 50 20 50 r3 26.0 ms165-32 3) - - 03x-31a0-4 80 25 80 r4 43.0 ms165-54 3) - - 03x-38a0-4 100 30 100 r4 51.0 ms165-65 3) - - 03x-44a0-4 100 35 100 r4 56.0 ms165-65 3) - - 00578903.Xls.J 1) e = emc filter connected (metal emc filt...

Page 53: Ul Marking

Technical data 53 ul marking see the type designation label for the valid markings of your drive. The ul mark is attached to the drive to verify that it meets ul requirements. Ul checklist see the instructions for electrical installation in the sections in this manual or in the acs320 user’s manual ...

Page 54

54 technical data.

Page 55

Technical data 55.

Page 56

56 technical data.

Page 57

Further information product and service inquiries address any inquiries about the product to your local abb representative, quoting the type designation and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to www.Abb.Com/searchcha...