- DL manuals

- ABB

- Enclosure

- ACS550

- User Manual

ABB ACS550 User Manual

Summary of ACS550

Page 1

Acs550 user’s manual acs550-01 drives (0.75 … 132 kw) acs550-u1 drives (1 … 200 hp).

Page 2

Acs550 drive manuals general manuals acs550-01/u1 user's manual (0.75…132 kw) / (1 … 200 hp) 3afe64804588 (3aua0000001418) (english) acs550-02/u2 user's manual (160…355 kw) / (200…550 hp) 3afe64804626 (english) • safety • installation • start-up, control with i/o and id run • control panels • applic...

Page 3

Acs550-01/u1 drives 0.75…132 kw 1…200 hp user’s manual 3afe64804588 (3aua0000001418) rev f en effective: 16.04.2007 supersedes: 3afe64804588 rev d 24.06.2004 supersedes: 3aua0000001418 rev e 06.12.2004 © 2007 abb oy. All rights reserved..

Page 5: Safety

Acs550 user’s manual 5 safety safety use of warnings and notes there are two types of safety instructions throughout this manual: • notes draw attention to a particular condition or fact, or give information on a subject. • warnings caution you about conditions which can result in serious injury or ...

Page 6

6 acs550 user’s manual safety warning! If a drive whose internal emc filter is not disconnected is installed on an it system [an ungrounded power system or a high resistance-grounded (over 30 ohm) power system], the system will be connected to earth potential through the emc filter capacitors of the...

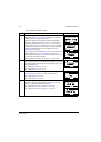

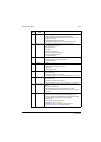

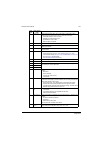

Page 7: Table Of Contents

Acs550 user’s manual 7 table of contents table of contents safety use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 table of contents installation installation flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 8

8 acs550 user’s manual table of contents feedback from the drive – efb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197 diagnostics – efb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198 modbus protocol technical data . . . . . . ...

Page 9

Acs550 user’s manual 9 table of contents index contact abb product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309 product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309 providing feedback...

Page 10

10 acs550 user’s manual table of contents.

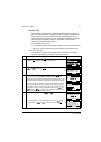

Page 11: Installation

Acs550 user’s manual 11 installation installation study these installation instructions carefully before proceeding. Failure to observe the warnings and instructions may cause a malfunction or personal hazard. Warning! Before you begin read chapter safety on page 5 . Note: the installation must alwa...

Page 12

12 acs550 user’s manual installation preparing for installation lifting the drive lift the drive only by the metal chassis. Unpacking the drive 1. Unpack the drive. 2. Check for any damage and notify the shipper immediately if damaged components are found. 3. Check the contents against the order and...

Page 13

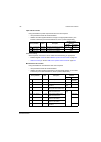

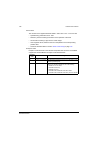

Acs550 user’s manual 13 installation type code use the following chart to interpret the type code found on both the type code and the serial number label. Ratings and frame size the chart in section ratings on page 259 lists technical specifications and identifies the drive’s frame size – significan...

Page 14

14 acs550 user’s manual installation motor compatibility the motor, drive and supply power must be compatible: tools required to install the acs550 you need the following: • screwdrivers (as appropriate for the mounting hardware used) • wire stripper • tape measure • drill • for installations involv...

Page 15

Acs550 user’s manual 15 installation confirm that the enclosure is appropriate, based on the site contamination level: • ip21 / ul type 1 enclosure: the site must be free of airborne dust, corrosive gases or liquids, and conductive contaminants such as dripping water, condensation, carbon dust and m...

Page 16

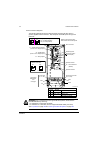

16 acs550 user’s manual installation installing the drive warning! Before installing the acs550, ensure the input power supply to the drive is off. Prepare the mounting location the acs550 should only be mounted where all of the requirements defined in section preparing for installation on page 12 a...

Page 17

Acs550 user’s manual 17 installation ip54 / ul type 12 1. If hood is present: remove screws (2) holding hood in place. 2. If hood is present: slide hood up and off of the cover. 3. Loosen the captive screws around the edge of the cover. 4. Remove the cover. Mount the drive ip21 / ul type 1 1. Positi...

Page 18

18 acs550 user’s manual installation wiring overview conduit/gland kit wiring drives with the ip21 / ul type 1 enclosure requires a conduit/gland kit with the following items: • conduit/gland box • five (5) cable clamps (acs550-01 only) • screws • cover. The kit is included with ip21 / ul type 1 enc...

Page 19

Acs550 user’s manual 19 installation • for frame size r6, see section power terminal considerations – r6 frame size on page 269 to install the appropriate cable lugs. • for drives using braking (optional), refer to the following, as appropriate: • when installing control wiring, refer to the followi...

Page 20

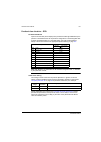

20 acs550 user’s manual installation power connection diagrams the following diagram shows the terminal layout for frame size r3, which, in general, applies to frame sizes r1 … r6, except for the r5/r6 power and ground terminals. Warning! For it systems and corner grounded tn systems, disconnect the...

Page 21

Acs550 user’s manual 21 installation the following diagram shows the power and ground terminal layout for frame sizes r5 and r6 warning! For it systems and corner grounded tn systems, disconnect the internal emc filter by removing screws f1 and f2. See it systems on page 268 and corner grounded tn s...

Page 22

22 acs550 user’s manual installation control terminals table the following provides information for connecting control wiring at x1 on the drive. X1 hardware description 1 scr terminal for signal cable screen. (connected internally to chassis ground.) 2 ai1 analog input channel 1, programmable. Defa...

Page 23

Acs550 user’s manual 23 installation note: terminals 3, 6 and 9 are at the same potential. Note: for safety reasons the fault relay signals a “fault” when the acs550 is powered down. Warning! All elv (extra low voltage) circuits connected to the drive must be used within a zone of equipotential bond...

Page 24

24 acs550 user’s manual installation install the wiring checking motor and motor cable insulation warning! Check the motor and motor cable insulation before connecting the drive to input power. For this test, make sure that motor cables are not connected to the drive. 1. Complete motor cable connect...

Page 25

Acs550 user’s manual 25 installation wiring ip21 / ul type 1 enclosure with cables 1. Open the appropriate knockouts in the conduit/gland box. (see section conduit/gland kit on page 18 .) 2. Install the cable clamps for the power/motor cables. 3. On the input power cable, strip the sheathing back fa...

Page 26

26 acs550 user’s manual installation wiring ip21 / ul type 1 enclosure with conduit 1. Open the appropriate knockouts in the conduit/gland box. (see section conduit/gland kit on page 18 .) 2. Install thin-wall conduit clamps (not supplied). 3. Install conduit/gland box. 4. Connect conduit runs to bo...

Page 27

Acs550 user’s manual 27 installation wiring ip54 / ul type 12 enclosure with cables 1. Cut the cable seals as needed for the power, motor and control cables. (the cable seals are cone-shaped, rubber seals on the bottom of the drive.) 2. On the input power cable, strip the sheathing back far enough t...

Page 28

28 acs550 user’s manual installation wiring ip54 / ul type 12 enclosure with conduit 1. Depends on frame size: • r1…r4: remove and discard the cable seals where conduit will be installed. (the cable seals are cone-shaped, rubber seals on the bottom of the drive.) • r5 and r6: use punch to create hol...

Page 29

Acs550 user’s manual 29 installation check installation before applying power, perform the following checks. Check installation environment conforms to the drive’s specifications for ambient conditions. The drive is mounted securely. Space around the drive meets the drive’s specifications for coolin...

Page 30

30 acs550 user’s manual installation reinstall the cover ip21 / ul type 1 1. Align the cover and slide it on. 2. Tighten the captive screw. 3. Reinstall the control panel. 4. Continue with start-up. See chapter start-up, control with i/o and id run on page 31 . Ip54 / ul type 12 1. Align the cover a...

Page 31

Acs550 user’s manual 31 start-up, control with i/o and id run start-up, control with i/o and id run the chapter instructs how to: • perform the start-up • start, stop, change the direction of rotation and adjust the speed of the motor through the i/o interface • perform an identification run for the...

Page 32

32 acs550 user’s manual start-up, control with i/o and id run check that the starting of the motor does not cause any danger. De-couple the driven machine if: • there is a risk of damage in case of incorrect direction of rotation, or • an id run needs to be performed during the drive start-up. Id ru...

Page 33

Acs550 user’s manual 33 start-up, control with i/o and id run select the application macro (parameter 9902 ). The general parameter setting procedure is given above. The default value 1 ( abb standard ) is suitable in most cases. Select the motor control mode (parameter 9904 ). 1 ( vector : speed ) ...

Page 34

34 acs550 user’s manual start-up, control with i/o and id run select the motor identification method (parameter 9910 ). The default value 0 ( off / idmagn ) using the identification magnetization is suitable for most applications. It is applied in this basic start-up procedure. Note however that thi...

Page 35

Acs550 user’s manual 35 start-up, control with i/o and id run to change the direction of the motor rotation: • disconnect input power from the drive, and wait 5 minutes for the intermediate circuit capacitors to discharge. Measure the voltage between each input terminal (u1, v1 and w1) and earth wit...

Page 36

36 acs550 user’s manual start-up, control with i/o and id run how to perform the guided start-up to be able to perform the guided start-up, you need the assistant control panel. Before you start, ensure that you have the motor nameplate data on hand. Safety the start-up may only be carried out by a ...

Page 37

Acs550 user’s manual 37 start-up, control with i/o and id run after completing a set-up task, the start-up assistant suggests the next one. • press (when is highlighted) to continue with the suggested task. • press key to highlight and then press to move to the following task without doing the sugge...

Page 38

38 acs550 user’s manual start-up, control with i/o and id run how to control the drive through the i/o interface the table below instructs how to operate the drive through the digital and analog inputs when: • the motor start-up is performed, and • the default (standard) parameter settings are valid...

Page 39

Acs550 user’s manual 39 start-up, control with i/o and id run how to perform the id run the drive estimates motor characteristics automatically using identification magnetization when the drive is started for the first time and after any motor parameter ( group 99: start-up data ) is changed. This i...

Page 40

40 acs550 user’s manual start-up, control with i/o and id run id run with the assistant control panel change parameter 9910 id run to 1 ( on ). Save the new setting by pressing . If you want to monitor actual values during the id run, go to the output mode by pressing repeatedly until you get there....

Page 41: Control Panels

Acs550 user’s manual 41 control panels control panels about control panels use a control panel to control the drive, read status data and adjust parameters. The drive works with either of two different control panel types: • basic control panel – this panel (described in section basic control panel ...

Page 42

42 acs550 user’s manual control panels assistant control panel features the assistant control panel features: • alphanumeric control panel with an lcd display • language selection for the display • start-up assistant to ease drive commissioning • copy function – parameters can be copied to the contr...

Page 43

Acs550 user’s manual 43 control panels status line the top line of the lcd display shows the basic status information of the drive. Operation you operate the control panel with menus and keys. The keys include two context- sensitive soft keys, whose current function is indicated by the text shown in...

Page 44

44 acs550 user’s manual control panels initially, the panel is in the output mode, where you can start, stop, change the direction, switch between local and remote control, modify the reference value and monitor up to three actual values. To do other tasks, go first to the main menu and select the a...

Page 45

Acs550 user’s manual 45 control panels how to get help how to find out the panel version step action display 1. Press to read the context-sensitive help text for the item that is highlighted. If help text exists for the item, it is shown on the display. 2. If the whole text is not visible, scroll th...

Page 46

46 acs550 user’s manual control panels how to start, stop and switch between local and remote control you can start, stop and switch between local and remote control in any mode. To be able to start or stop the drive, the drive must be in local control. Step action display 1. • to switch between rem...

Page 47

Acs550 user’s manual 47 control panels output mode in the output mode, you can: • monitor actual values of up to three signals in group 01: operating data • change the direction of the motor rotation • set the speed, frequency or torque reference • adjust the display contrast • start, stop, change t...

Page 48

48 acs550 user’s manual control panels how to set the speed, frequency or torque reference how to adjust the display contrast step action display 1. If you are not in the output mode, press repeatedly until you get there. 2. If the drive is in remote control (rem shown on the status line), switch to...

Page 49

Acs550 user’s manual 49 control panels parameters mode in the parameters mode, you can: • view and change parameter values • start, stop, change the direction and switch between local and remote control. How to select a parameter and change its value step action display 1. Go to the main menu by pre...

Page 50

50 acs550 user’s manual control panels how to select the monitored signals step action display 1. You can select which signals are monitored in the output mode and how they are displayed with group 34: panel display parameters. See page 49 for detailed instructions on changing parameter values. By d...

Page 51

Acs550 user’s manual 51 control panels assistants mode when the drive is first powered up, the start-up assistant guides you through the setup of the basic parameters. The start-up assistant is divided into assistants, each of which guides you through the task of specifying a related parameter set, ...

Page 52

52 acs550 user’s manual control panels the table below lists the tasks of the assistants and the relevant drive parameters. Depending on the selection made in the application task (parameter 9902 applic macro), the start-up assistant decides, which consequent tasks it suggests. 5. • to accept the ne...

Page 53

Acs550 user’s manual 53 control panels selecting timed function status indicated through relay output ro 1401 selecting timed pid1 parameter set 1/2 control 4027 protections setting the current and torque limits 2003 , 2017 output signals selecting the signals indicated through relay output ro group...

Page 54

54 acs550 user’s manual control panels changed parameters mode in the changed parameters mode, you can: • view a list of all parameters that have been changed from the macro default values • change these parameters • start, stop, change the direction and switch between local and remote control. How ...

Page 55

Acs550 user’s manual 55 control panels fault logger mode in the fault logger mode, you can: • view the drive fault history of maximum ten faults (after a power off, only the three latest faults are kept in the memory) • see the details of the three latest faults (after a power off, the details of on...

Page 56

56 acs550 user’s manual control panels clock set mode in the clock set mode, you can: • show or hide the clock • change date and time display formats • set the date and time • enable or disable automatic clock transitions according to the daylight saving changes • start, stop, change the direction a...

Page 57

Acs550 user’s manual 57 control panels • to set the date, select set date on the menu and press . Specify the first part of the date (day or month depending on the selected date format) with keys and , and press . Repeat for the second part. After specifying the year, press . To cancel your changes,...

Page 58

58 acs550 user’s manual control panels parameter backup mode the parameter backup mode is used to export parameters from one drive to another or to make a backup of the drive parameters. Uploading to the panel stores all drive parameters, including up to two user sets, to the assistant control panel...

Page 59

Acs550 user’s manual 59 control panels how to upload and download parameters for the upload and download functions available, see above. Step action display 1. Go to the main menu by pressing if you are in the output mode, otherwise by pressing repeatedly until you get to the main menu. 2. Go to the...

Page 60

60 acs550 user’s manual control panels how to view information about the backup step action display 1. Go to the main menu by pressing if you are in the output mode, otherwise by pressing repeatedly until you get to the main menu. 2. Go to the par backup mode by selecting par backup on the menu with...

Page 61

Acs550 user’s manual 61 control panels i/o settings mode in the i/o settings mode, you can: • check the parameter settings related to any i/o terminal • edit the parameter setting. For example, if “1103: ref1” is listed under ain1 (analog input 1), that is, parameter 1103 ref 1 select has value ai 1...

Page 62

62 acs550 user’s manual control panels basic control panel features the basic control panel features: • numeric control panel with an lcd display • copy function – parameters can be copied to the control panel memory for later transfer to other drives or for backup of a particular system. Overview t...

Page 63

Acs550 user’s manual 63 control panels operation you operate the control panel with menus and keys. You select an option, e.G. Operation mode or parameter, by scrolling the and arrow keys until the option is visible in the display and then pressing the key. With the key, you return to the previous o...

Page 64

64 acs550 user’s manual control panels how to start, stop and switch between local and remote control you can start, stop and switch between local and remote control in any mode. To be able to start or stop the drive, the drive must be in local control. How to change the direction of the motor rotat...

Page 65

Acs550 user’s manual 65 control panels output mode in the output mode, you can: • monitor actual values of up to three group 01: operating data signals, one signal at a time • start, stop, change the direction and switch between local and remote control. You get to the output mode by pressing until ...

Page 66

66 acs550 user’s manual control panels reference mode in the reference mode, you can: • set the speed, frequency or torque reference • start, stop, change the direction and switch between local and remote control. How to set the speed, frequency or torque reference step action display 1. Go to the m...

Page 67

Acs550 user’s manual 67 control panels parameter mode in the parameter mode, you can: • view and change parameter values • select and modify the signals shown in the output mode • start, stop, change the direction and switch between local and remote control. How to select a parameter and change its ...

Page 68

68 acs550 user’s manual control panels how to select the monitored signals step action display 1. You can select which signals are monitored in the output mode and how they are displayed with group 34: panel display parameters. See page 49 for detailed instructions on changing parameter values. By d...

Page 69

Acs550 user’s manual 69 control panels copy mode the basic control panel can store a full set of drive parameters and up to two user sets of drive parameters to the control panel. The control panel memory is non- volatile. In the copy mode, you can: • copy all parameters from the drive to the contro...

Page 70

70 acs550 user’s manual control panels how to upload and download parameters for the upload and download functions available, see above. Basic control panel alarm codes in addition to the faults and alarms generated by the drive (see chapter diagnostics ), the basic control panel indicates control p...

Page 71: Application Macros

Acs550 user’s manual 71 application macros application macros macros change a group of parameters to new, predefined values. Use macros to minimize the need for manual editing of parameters. Selecting a macro sets all other parameters to their default values, except: • group 99: start-up data parame...

Page 72

72 acs550 user’s manual application macros abb standard macro this is the default macro. It provides a general purpose, 2-wire i/o configuration, with three (3) constant speeds. Parameter values are the default values defined in section complete parameter list on page 85 . Connection example: input ...

Page 73

Acs550 user’s manual 73 application macros 3-wire macro this macro is used when the drive is controlled using momentary push-buttons. It provides three (3) constant speeds. To enable, set the value of parameter 9902 to 2 (3- wire ). Note: when the stop input ( di 2) is deactivated (no input), the co...

Page 74

74 acs550 user’s manual application macros alternate macro this macro provides an i/o configuration adopted to a sequence of di control signals used when alternating the rotation direction of the motor. To enable, set the value of parameter 9902 to 3 ( alternate ). Connection example: input signals ...

Page 75

Acs550 user’s manual 75 application macros motor potentiometer macro this macro provides a cost-effective interface for plcs that vary the speed of the motor using only digital signals. To enable, set the value of parameter 9902 to 4 ( motor pot ). Connection example: input signals output signals ju...

Page 76

76 acs550 user’s manual application macros hand-auto macro this macro provides an i/o configuration that is typically used in hvac applications. To enable, set the value of parameter 9902 to 5 ( hand / auto ). Note: parameter 2108 start inhibit must remain in the default setting, 0 ( off ). Connecti...

Page 77

Acs550 user’s manual 77 application macros pid control macro this macro provides parameter settings for closed-loop control systems such as pressure control, flow control, etc. To enable, set the value of parameter 9902 to 6 ( pid control ). Note: parameter 2108 start inhibit must remain in the defa...

Page 78

78 acs550 user’s manual application macros pfc macro this macro provides parameter settings for pump and fan control (pfc) applications. To enable, set the value of parameter 9902 to 7 ( pfc control ). Note: parameter 2108 start inhibit must remain in the default setting, 0 ( off ). Connection examp...

Page 79

Acs550 user’s manual 79 application macros torque control macro this macro provides parameter settings for applications that require torque control of the motor. Control can also be switched to speed control. To enable, set the value of parameter 9902 to 8 ( torque ctrl ). Connection example: input ...

Page 80

80 acs550 user’s manual application macros connection example of a two-wire sensor many applications use process pi(d) and need a feedback signal from the process. The feedback signal is typically connected to analog input 2 (ai2). The macro wiring diagrams in this chapter show the connection when a...

Page 81

Acs550 user’s manual 81 application macros user parameter sets in addition to the standard application macros, it is possible to save two user parameter sets into the permanent memory and load them at a later time. A user parameter set consists of the user parameter settings, including group 99: sta...

Page 82

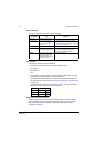

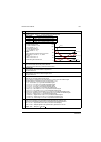

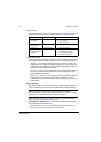

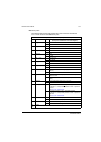

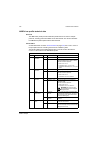

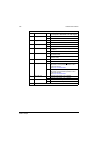

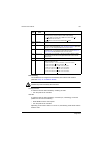

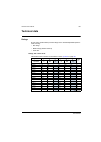

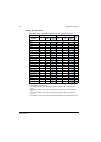

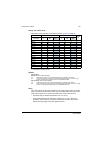

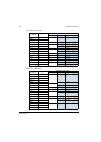

82 acs550 user’s manual application macros macro default values for parameters parameter default values are listed in section complete parameter list on page 85 . Changing from the default macro (abb standard), that is, editing the value of parameter 9902, changes the parameter default values as def...

Page 83

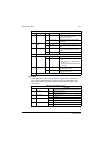

Acs550 user’s manual 83 application macros acs550-u1 parameter abb st andard 3-wire alternate motor potentiome ter hand-aut o pid contr ol pfc cont rol to rque control 9902 applic macro 1 2 3 4 5 6 7 8 9904 motor ctrl mode 3 1 1 1 1 1 3 2 1001 ext 1 commands 2 4 9 2 2 1 1 2 1002 ext 2 commands 0 0 0...

Page 84

84 acs550 user’s manual application macros.

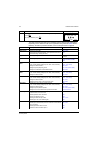

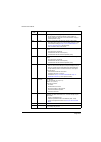

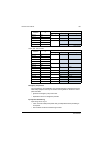

Page 85: Parameters

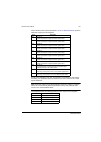

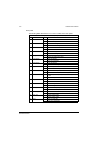

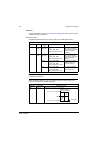

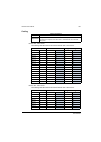

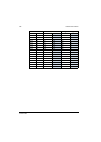

Acs550 user’s manual 85 parameters parameters complete parameter list the following table lists all parameters. Table header abbreviations are: • s = parameters can be modified only when the drive is stopped. • user = space to enter desired parameter values. Some values depend on the “construction” ...

Page 86

86 acs550 user’s manual parameters 0119 di 4-6 status 000…111 (0…7 decimal) 1 - 0120 ai 1 0.0…100.0% 0.1% - 0121 ai 2 0.0…100.0% 0.1% - 0122 ro 1-3 status 000…111 (0…7 decimal) 1 - 0123 ro 4-6 status 000…111 (0…7 decimal) 1 - 0124 ao 1 0.0…20.0 ma 0.1 ma - 0125 ao 2 0.0…20.0 ma 0.1 ma - 0126 pid 1 o...

Page 87

Acs550 user’s manual 87 parameters 0304 fb sts word 2 - 1 0 0305 fault word 1 - 1 0 0306 fault word 2 - 1 0 0307 fault word 3 - 1 0 0308 alarm word 1 - 1 0 0309 alarm word 2 - 1 0 group 04: fault history 0401 last fault fault codes (panel displays as text) 1 0 0402 fault time 1 date dd.Mm.Yy / power...

Page 88

88 acs550 user’s manual parameters 1206 const speed 5 0…30000 rpm / 0.0…500.0 hz 1 rpm / 0.1 hz 01: 1500 rpm / 25.0 hz u1: 1800 rpm / 30.0 hz 1207 const speed 6 0…30000 rpm / 0.0…500.0 hz 1 rpm / 0.1 hz 01: 2400 rpm / 40.0 hz u1: 2880 rpm / 48.0 hz 1208 const speed 7 0…30000 rpm / 0.0…500.0 hz 1 rpm...

Page 89

Acs550 user’s manual 89 parameters 1511 maximum ao 2 0.0…20.0 ma 0.1 ma 20.0 ma 1512 filter ao 2 0.0…10.0 s 0.1 s 0.1 s group 16: system controls 1601 run enable -6…7 1 0 ( not sel ) ! 1602 parameter lock 0 = locked , 1 = open , 2 = not saved 1 1 ( open ) 1603 pass code 0…65535 1 0 1604 fault reset ...

Page 90

90 acs550 user’s manual parameters group 22: accel/decel 2201 acc / dec 1/2 sel -6…7 1 5 ( di 5) 2202 acceler time 1 0.0…1800.0 s 0.1 s 5.0 s 2203 deceler time 1 0.0…1800.0 s 0.1 s 5.0 s 2204 ramp shape 1 0.0 = linear , 0.1…1000.0 s 0.1 s 0.0 s 2205 acceler time 2 0.0…1800.0 s 0.1 s 60.0 s 2206 dece...

Page 91

Acs550 user’s manual 91 parameters 2907 user mwh trig 0.0…6553.5 mwh, 0.0 disables 0.1 mwh 0.0 mwh 2908 user mwh act 0.0…6553.5 mwh 0.1 mwh 0.0 mwh group 30: fault functions 3001 ai min function 0…3 1 0 ( not sel ) 3002 panel comm err 1…3 1 1 ( fault ) 3003 external fault 1 -6…6 1 0 ( not sel ) 3004...

Page 92

92 acs550 user’s manual parameters group 33: information 3301 firmware 0000…ffff hex 1 firmware version 3302 loading package 0000…ffff hex 1 0 3303 test date yy.Ww 1 0 3304 drive rating - - - 3305 parameter table 0000…ffff hex 1 par. Table version group 34: panel display 3401 signal 1 param 100 = no...

Page 93

Acs550 user’s manual 93 parameters 3607 stop time 2 00:00:00…23:59:58 2 s 00:00:00 3608 start day 2 1…7 1 1 ( monday ) 3609 stop day 2 1…7 1 1 ( monday ) 3610 start time 3 00:00:00…23:59:58 2 s 00:00:00 3611 stop time 3 00:00:00…23:59:58 2 s 00:00:00 3612 start day 3 1…7 1 1 ( monday ) 3613 stop day...

Page 94

94 acs550 user’s manual parameters 4009 100% value unit and scale defined by par. 4006 and 4007 - 100.0% 4010 set point sel 0…2, 8…17, 19…20 1 1 ( ai 1) ! 4011 internal setpnt unit and scale defined by par. 4006 and 4007 - 40.0% 4012 setpoint min -500.0…500.0% 0.1% 0.0% 4013 setpoint max -500.0…500....

Page 95

Acs550 user’s manual 95 parameters 4122 sleep selection -6…7 1 0 ( not sel ) 4123 pid sleep level 0…30000 rpm / 0.0…500.0 hz 1 rpm / 0.1 hz 0 rpm / 0.0 hz 4124 pid sleep delay 0.0…3600.0 s 0.1 s 60.0 s 4125 wake - up dev unit and scale defined by par. 4106 and 4107 - 0.0% 4126 wake - up delay 0.00…6...

Page 96

96 acs550 user’s manual parameters 5127 fba par refresh 0 = done , 1 = refresh 1 0 ( done ) ! 5128 file cpi fw rev 0…0xffff (hex) 1 0 5129 file config id 0…0xffff (hex) 1 0 5130 file config rev 0…0xffff (hex) 1 0 5131 fba status 0…6 1 0 ( idle ) 5132 fba cpi fw rev 0…0xffff (hex) 1 0 5133 fba appl f...

Page 97

Acs550 user’s manual 97 parameters 8109 start freq 1 0.0…500.0 hz 0.1 hz 01: 50.0 hz / u1: 0.0 hz 8110 start freq 2 0.0…500.0 hz 0.1 hz 01: 50.0 hz / u1: 0.0 hz 8111 start freq 3 0.0…500.0 hz 0.1 hz 01: 50.0 hz / u1: 0.0 hz 8112 low freq 1 0.0…500.0 hz 0.1 hz 01: 25.0 hz / u1: 30.0 hz 8113 low freq ...

Page 98

98 acs550 user’s manual parameters complete parameter descriptions this section describes the actual signals and parameters for acs550. Group 99: start-up data this group defines special start-up data required to: • set up the drive • enter motor information. Code description 9901 language selects t...

Page 99

Acs550 user’s manual 99 parameters 9906 motor nom curr defines the nominal motor current. • must equal the value on the motor rating plate. • range allowed: 0.2…2.0 · i 2hd (where i 2hd is drive current). 9907 motor nom freq defines the nominal motor frequency. • range: 10…500 hz (typically 50 or 60...

Page 100

100 acs550 user’s manual parameters group 01: operating data this group contains drive operating data, including actual signals. The drive sets the values for actual signals, based on measurements or calculations. You cannot set these values. Code description 0101 speed & dir the calculated signed s...

Page 101

Acs550 user’s manual 101 parameters 0118 di 1-3 status status of the three digital inputs. • status is displayed as a binary number. • 1 indicates that the input is activated. • 0 indicates that the input is deactivated. 0119 di 4-6 status status of the three digital inputs. • see parameter 0118 di ...

Page 102

102 acs550 user’s manual parameters 0136 comm value 2 free data location that can be written from serial link. 0137 process var 1 process variable 1 • defined by parameters in group 34: panel display . 0138 process var 2 process variable 2 • defined by parameters in group 34: panel display . 0139 pr...

Page 103

Acs550 user’s manual 103 parameters 0151 input kwh (r) calculated actual intake energy in kwh. 0152 input mwh calculated actual intake energy in mwh. 0158 pid comm value 1 data received from fieldbus for pid control (pid1 and pid2). 0159 pid comm value 2 data received from fieldbus for pid control (...

Page 104

104 acs550 user’s manual parameters group 03: fb actual signals this group monitors fieldbus communications. Code description 0301 fb cmd word 1 read-only copy of the fieldbus command word 1. • the fieldbus command is the principal means for controlling the drive from a fieldbus controller. The comm...

Page 105

Acs550 user’s manual 105 parameters 0305 fault word 1 read-only copy of the fault word 1. • when a fault is active, the corresponding bit for the active fault is set in the fault words. • each fault has a dedicated bit allocated within fault words. • see section fault listing on page 244 for a descr...

Page 106

106 acs550 user’s manual parameters group 04: fault history this group stores a recent history of the faults reported by the drive. Code description 0401 last fault 0 – clear the fault history (on panel = no record). N – fault code of the last recorded fault. The fault code is displayed as a name. S...

Page 107

Acs550 user’s manual 107 parameters group 10: start/stop/dir this group: • defines external sources ( ext 1 and ext 2) for commands that enable start, stop and direction changes • locks direction or enables direction control. To select between the two external locations use the next group (parameter...

Page 108

108 acs550 user’s manual parameters 11 = timed func 1. – assigns start/stop control to timed function 1 (timed function activated = start ; timed function de-activated = stop ). See group 36: timed functions . 12…14 = timed func 2…4 – assigns start/stop control to timed function 2…4. See timed func ...

Page 109

Acs550 user’s manual 109 parameters group 11: reference select this group defines: • how the drive selects between command sources • characteristics and sources for ref 1 and ref 2. Code description 1101 keypad ref sel selects the reference controlled in local control mode. 1 = ref 1(hz/rpm) – refer...

Page 110

110 acs550 user’s manual parameters 5 = di 3 u ,4 d ( r ) – defines digital inputs as the speed reference source (motor potentiometer control). • digital input di 3 increases the speed (the u stands for “up”). • digital input di 4 decreases the speed (the d stands for “down”). • a stop command reset...

Page 111

Acs550 user’s manual 111 parameters 1104 ref1 min sets the minimum for external reference 1. • the minimum analog input signal (as a percent of the full signal in volts or amperes) corresponds to ref 1 min in hz/rpm. • parameter 1301 minimum ai 1 or 1304 minimum ai 2 sets the minimum analog input si...

Page 112

112 acs550 user’s manual parameters group 12: constant speeds this group defines a set of constant speeds. In general: • you can program up to 7 constant speeds, ranging from 0 … 500 hz or 0 … 30000 rpm. • values must be positive (no negative speed values for constant speeds). • constant speed selec...

Page 113

Acs550 user’s manual 113 parameters 13 = di 3,4,5 – selects one of seven constant speeds (1…7) using di 3, di 4 and di 5. • see above ( di 1,2,3) for code. 14 = di 4,5,6 – selects one of seven constant speeds (1…7) using di 4, di 5 and di 6. • see above ( di 1,2,3) for code. 15…18 = timed func 1…4 –...

Page 114

114 acs550 user’s manual parameters 1209 timed mode sel defines timed function activated, constant speed mode. Timed function can be used to change between external reference and a maximum of three constant speeds, or to change between a maximum of 4 selectable speeds, i.E. Constant speeds 1, 2, 3 a...

Page 115

Acs550 user’s manual 115 parameters group 13: analog inputs this group defines the limits and the filtering for analog inputs. Code description 1301 minimum ai1 defines the minimum value of the analog input. • define value as a percent of the full analog signal range. See example below. • the minimu...

Page 116

116 acs550 user’s manual parameters group 14: relay outputs this group defines the condition that activates each of the relay outputs. Code description 1401 relay output 1 defines the event or condition that activates relay 1 – what relay output 1 means. 0 = not sel – relay is not used and is de-ene...

Page 117

Acs550 user’s manual 117 parameters 35 = comm – energize relay based on input from fieldbus communication. • fieldbus writes binary code in parameter 0134 that can energize relay 1…relay 6 according to the following: • 0 = de-energize relay, 1 = energize relay. 36 = comm (-1) – energize relay based ...

Page 118

118 acs550 user’s manual parameters 1409 ro 3 off delay switch-off delay for relay 3. • see ro 1 off delay . 1410 … 1412 relay output 4…6 defines the event or condition that activates relay 4…6 – what relay output 4…6 means. • see 1401 relay output 1. 1413 ro 4 on delay defines the switch-on delay f...

Page 119

Acs550 user’s manual 119 parameters group 15: analog outputs this group defines the drive’s analog (current signal) outputs. The drive’s analog outputs can be: • any parameter in group 01: operating data • limited to programmable minimum and maximum values of output current • scaled (and/or inverted...

Page 120

120 acs550 user’s manual parameters 1511 maximum ao2 sets the maximum output current. See maximum ao 1 above. 1512 filter ao2 defines the filter time constant for ao 2. See filter ao 1 above. Code description.

Page 121

Acs550 user’s manual 121 parameters group 16: system controls this group defines a variety of system level locks, resets and enables. Code description 1601 run enable selects the source of the run enable signal. 0 = not sel – allows the drive to start without an external run enable signal. 1 = di 1 ...

Page 122

122 acs550 user’s manual parameters 1605 user par set chg defines control for changing the user parameter set. • see parameter 9902 applic macro . • the drive must be stopped to change user parameter sets. • during a change, the drive will not start. Note: always save the user parameter set after ch...

Page 123

Acs550 user’s manual 123 parameters 1608 start enable 1 selects the source of the start enable 1 signal. Note: start enable functionality differs from the run enable functionality. 0 = not sel – allows the drive to start without an external start enable signal. 1 = di 1 – defines digital input di1 a...

Page 124

124 acs550 user’s manual parameters 1609 start enable 2 selects the source of the start enable 2 signal. Note: start enable functionality differs from the run enable functionality. 0 = not sel – allows the drive to start without an external start enable signal. 1 = di 1 – defines digital input di1 a...

Page 125

Acs550 user’s manual 125 parameters group 20: limits this group defines minimum and maximum limits to follow in driving the motor – speed, frequency, current, torque, etc. Code description 2001 minimum speed defines the minimum speed (rpm) allowed. • a positive (or zero) minimum speed value defines ...

Page 126

126 acs550 user’s manual parameters 2007 minimum freq defines the minimum limit for the drive output frequency. • a positive or zero minimum frequency value defines two ranges, one positive and one negative. • a negative minimum frequency value defines one speed range. See the figure. Note: keep min...

Page 127

Acs550 user’s manual 127 parameters 2017 max torque 1 sets the first maximum limit for torque (%). Value is a percent of the motor nominal torque. 2018 max torque 2 sets the second maximum limit for torque (%). Value is a percent of the motor nominal torque. Code description.

Page 128

128 acs550 user’s manual parameters group 21: start/stop this group defines how the motor starts and stops. The acs550 supports several start and stop modes. Code description 2101 start function selects the motor start method. The valid options depend on the value of parameter 9904 motor ctrl mode ....

Page 129

Acs550 user’s manual 129 parameters 2105 dc hold speed sets the speed for dc hold. Requires that parameter 2104 dc hold ctl = 1 ( dc hold ). 2106 dc curr ref defines the dc current control reference as a percentage of parameter 9906 motor nom curr . 2107 dc brake time defines the dc brake time after...

Page 130

130 acs550 user’s manual parameters 2112 zero speed delay defines the delay for the zero speed delay function. If parameter value is set to zero, the zero speed delay function is disabled. The function is useful in applications where a smooth and quick restarting is essential. During the delay the d...

Page 131

Acs550 user’s manual 131 parameters group 22: accel/decel this group defines ramps that control the rate of acceleration and deceleration. You define these ramps as a pair, one for acceleration and one for deceleration. You can define two pairs of ramps and use a digital input to select one or the o...

Page 132

132 acs550 user’s manual parameters 2208 emerg dec time sets the deceleration time for maximum frequency to zero for an emergency. • see parameter 2109 emerg stop sel . • ramp is linear. 2209 ramp input 0 defines control for forcing the ramp input to 0. 0 = not sel – not selected. 1 = di 1 – defines...

Page 133

Acs550 user’s manual 133 parameters group 23: speed control this group defines variables used for speed control operation. Code description 2301 prop gain sets the relative gain for the speed controller. • larger values may cause speed oscillation. • the figure shows the speed controller output afte...

Page 134

134 acs550 user’s manual parameters 2304 acc compensation sets the derivation time for acceleration compensation. • adding a derivative of the reference to the output of the speed controller compensates for inertia during acceleration. • 2303 derivation time describes the principle of derivative act...

Page 135

Acs550 user’s manual 135 parameters group 24: torque control this group defines variables used for torque control operation. Code description 2401 torq ramp up defines the torque reference ramp up time – the minimum time for the reference to increase from zero to the nominal motor torque. 2402 torq ...

Page 136

136 acs550 user’s manual parameters group 25: critical speeds this group defines up to three critical speeds or ranges of speeds that are to be avoided due, for example, to mechanical resonance problems at certain speeds. Code description 2501 crit speed sel sets the critical speeds function on or o...

Page 137

Acs550 user’s manual 137 parameters group 26: motor control this group defines variables used for motor control. Code description 2601 flux opt enable changes the magnitude of the flux depending on the actual load. Flux optimization can reduce the total energy consumption and noise, and it should be...

Page 138

138 acs550 user’s manual parameters 2606 switching freq sets the switching frequency for the drive. Also see parameter 2607 switch freq ctrl and section switching frequency derating on page 262 . • higher switching frequencies mean less noise. • the 1, 4 and 8 khz switching frequencies are available...

Page 139

Acs550 user’s manual 139 parameters group 29: maintenance trig this group contains usage levels and trigger points. When usage reaches the set trigger point, a notice displayed on the control panel signals that maintenance is due. Code description 2901 cooling fan trig sets the trigger point for the...

Page 140

140 acs550 user’s manual parameters group 30: fault functions this group defines situations that the drive should recognize as potential faults and defines how the drive should respond if the fault is detected. Code description 3001 ai defines the drive response if the analog input ( ai ) signal dro...

Page 141

Acs550 user’s manual 141 parameters 3007 mot load curve sets the maximum allowable operating load of the motor. • when set to 100%, the maximum allowable load is equal to the value of parameter 9906 motor nom curr . • adjust the load curve level if the ambient temperature differs from nominal. 3008 ...

Page 142

142 acs550 user’s manual parameters 3018 comm fault func defines the drive response if the fieldbus communication is lost. 0 = not sel – no response. 1 = fault – displays a fault (28, serial 1 err ) and the drive coasts to stop. 2 = const sp 7 – displays an alarm (2005, i / o comm ) and sets speed u...

Page 143

Acs550 user’s manual 143 parameters group 31: automatic reset this group defines conditions for automatic resets. An automatic reset occurs after a particular fault is detected. The drive holds for a set delay time, then automatically restarts. You can limit the number of resets in a specified time ...

Page 144

144 acs550 user’s manual parameters group 32: supervision this group defines supervision for up to three signals from group 01: operating data . Supervision monitors a specified parameter and energizes a relay output if the parameter passes a defined limit. Use group 14: relay outputs to define the ...

Page 145

Acs550 user’s manual 145 parameters 3207 superv 3 param selects the third supervised parameter. See 3201 superv 1 param above. 3208 superv 3 lim lo sets the low limit for the third supervised parameter. See 3207 superv 3 param above. 3209 superv 3 lim hi sets the high limit for the third supervised ...

Page 146

146 acs550 user’s manual parameters group 33: information this group provides access to information about the drive’s current programs: versions and test date. Code description 3301 firmware contains the version of the drive’s firmware. 3302 loading package contains the version of the loading packag...

Page 147

Acs550 user’s manual 147 parameters group 34: panel display this group defines the content for control panel display (middle area), when the control panel is in the output mode. Code description 3401 signal1 param selects the first parameter (by number) displayed on the control panel. • definitions ...

Page 148

148 acs550 user’s manual parameters 3405 output1 unit selects the units used with the first display parameter. Note: parameter is not effective if parameter 3404 output 1 dsp form = 9 ( direct ). 3406 output1 min sets the minimum value displayed for the first display parameter. Note: parameter is no...

Page 149

Acs550 user’s manual 149 parameters 3421 output3 max sets the maximum value displayed for the third display parameter. See parameter 3407. Code description.

Page 150

150 acs550 user’s manual parameters group 35: motor temp meas this group defines the detection and reporting for a particular potential fault – motor overheating, as detected by a temperature sensor. Typical connections are defined below. Warning! Iec 60664 requires double or reinforced insulation b...

Page 151

Acs550 user’s manual 151 parameters for other faults, or for anticipating motor overheating using a model, see group 30: fault functions . Code description 3501 sensor type identifies the type of motor temperature sensor used, pt100 (°c), ptc (ohm) or thermistor. See parameters 1501 ao 1 content sel...

Page 152

152 acs550 user’s manual parameters group 36: timed functions this group defines the timed functions. The timed functions include: • four daily start and stop times • four weekly start, stop and boost times • four timers for collecting selected periods together. A timer can be connected to multiple ...

Page 153

Acs550 user’s manual 153 parameters code description 3601 timers enable selects the source for the timer enable signal. 0 = not sel – timed functions are disabled. 1 = di 1 – defines digital input di 1 as the timed function enable signal. • the digital input must be activated to enable the timed fun...

Page 154

154 acs550 user’s manual parameters 3612 start day 3 defines timer 3 weekly start day. • see parameter 3604. 3613 stop day 3 defines timer 3 weekly stop day. • see parameter 3605. 3614 start time 4 defines timer 4 daily start time. • see parameter 3602. 3615 stop time 4 defines timer 4 daily stop ti...

Page 155

Acs550 user’s manual 155 parameters 21 = t 1+ t 3+ b – booster and time periods 1 and 3 selected in the timer. 22 = t 2+ t 3+ b – booster and time periods 2 and 3 selected in the timer. 23 = t 1+ t 2+ t 3+ b – booster and time periods 1, 2 and 3 selected in the timer. 24 = t 4+ b – booster and time ...

Page 156

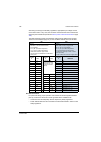

156 acs550 user’s manual parameters group 37: user load curve this group defines supervision of user adjustable load curves (motor torque as a function of frequency). The curve is defined by five points. Code description 3701 user load c mode supervision mode for the user adjustable load curves. Thi...

Page 157

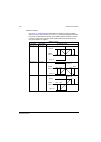

Acs550 user’s manual 157 parameters correspondence with the obsolete underload supervision the now obsolete parameter 3015 underload curve provided five selectable curves shown in the figure. The parameter characteristics were as described below. • if the load drops below the set curve for longer th...

Page 158

158 acs550 user’s manual parameters obs. Par. New parameters 3015 under load curve 3704 load freq 1 (hz) 3705 load torq low 1 (%) 3707 load freq 2 (hz) 3708 load torq low 2 (%) 3710 load freq 3 (hz) 3711 load torq low 3 (%) 3713 load freq 4 (hz) 3714 load torq low 4 (%) 3716 load freq 5 (hz) 3717 lo...

Page 159

Acs550 user’s manual 159 parameters group 40: process pid set 1 this group defines a set of parameters used with the process pid (pid1) controller. Typically only parameters in this group are needed. Pid controller – basic set-up in pid control mode, the drive compares a reference signal (setpoint) ...

Page 160

160 acs550 user’s manual parameters pid controller – advanced the acs550 has two separate pid controllers: • process pid (pid1) and • external pid (pid2) process pid (pid1) has 2 separate sets of parameters: • process pid (pid1) set1, defined in group 40: process pid set 1 and • process pid (pid1) s...

Page 161

Acs550 user’s manual 161 parameters 4002 integration time defines the pid controller’s integration time. Integration time is, by definition, the time required to increase the output by the error value: • error value is constant and 100%. • gain = 1. • integration time of 1 second denotes that a 100%...

Page 162

162 acs550 user’s manual parameters 4008 0% value defines (together with the next parameter) the scaling applied to the pid controller’s actual values (pid1 parameters 0128, 0130 and 0132). • units and scale are defined by parameters 4006 and 4007. 4009 100% value defines (together with the previous...

Page 163

Acs550 user’s manual 163 parameters analog input reference correction parameter values 9, 10 and 14…17 use the formula in the following table. Where: • c = main reference value ( = comm for values 9, 10 and = ai 1 for values 14…17) • b = correcting reference ( = ai 1 for values 9, 10 and = ai 2 for ...

Page 164

164 acs550 user’s manual parameters 4016 act1 input defines the source for actual value 1 ( act 1). See also parameter 4018 act 1 minimum . 1 = ai 1 – uses analog input 1 for act 1. 2 = ai 2 – uses analog input 2 for act 1. 3 = current – uses current for act 1. 4 = torque – uses torque for act 1. 5 ...

Page 165

Acs550 user’s manual 165 parameters 4023 pid sleep level sets the motor speed / frequency that enables the pid sleep function – a motor speed / frequency below this level, for at least the time period 4024 pid sleep delay enables the pid sleep function (stopping the drive). • requires 4022 = 7 ( int...

Page 166

166 acs550 user’s manual parameters 4027 pid 1 param set process pid (pid1) has two separate sets of parameters, pid set 1 and pid set 2. • pid set 1 uses parameters 4001…4026. • pid set 2 uses parameters 4101…4126. Pid 1 param set defines which set is selected. 0 = set 1 – pid set 1 (parameters 400...

Page 167

Acs550 user’s manual 167 parameters group 41: process pid set 2 parameters of this group belong to pid parameter set 2. The operation of parameters 4101…4126 is analogous with set 1 parameters 4001…4026. Pid parameter set 2 can be selected by parameter 4027 pid 1 param set . Code description 4101 … ...

Page 168

168 acs550 user’s manual parameters group 42: ext / trim pid this group defines the parameters used for the second pid controller (pid2), which is used for the external / trimming pid. The operation of parameters 4201 … 4221 is analogous with process pid set 1 (pid1) parameters 4001…4021. Code descr...

Page 169

Acs550 user’s manual 169 parameters 4232 correction src defines the trimming reference for the correction source. 1 = pid 2 ref – uses appropriate ref max (s witch a or b): • 1105 ref 1 max when ref 1 is active (a). • 1108 ref 2 max when ref 2 is active (b). 2 = pid 2 output – uses the absolute maxi...

Page 170

170 acs550 user’s manual parameters group 50: encoder this group defines the setup for encoder use: • sets the number of encoder pulses per shaft revolution. • enables the encoder operation. • defines how mechanical angle and revolution data is reset. See also user’s manual for pulse encoder interfa...

Page 171

Acs550 user’s manual 171 parameters group 51: ext comm module this group defines set-up variables for a fieldbus adapter (fba) communication module. For more information on these parameters, refer to the user’s manual supplied with the fba module. Code description 5101 fba type displays the type of ...

Page 172

172 acs550 user’s manual parameters group 52: panel comm this group defines the communication settings for the control panel port on the drive. Normally, when using the supplied control panel, there is no need to change settings in this group. In this group, parameter modifications take effect on th...

Page 173

Acs550 user’s manual 173 parameters group 53: efb protocol this group defines set-up variables used for an embedded fieldbus (efb) communication protocol. The standard efb protocol in the acs550 is modbus. See chapter embedded fieldbus page 189 . Code description 5301 efb protocol id contains the id...

Page 174

174 acs550 user’s manual parameters 5311 efb par 11 specifies the parameter mapped to modbus register 40006. 5312 efb par 12 specifies the parameter mapped to modbus register 40007. 5313 efb par 13 specifies the parameter mapped to modbus register 40008. 5314 efb par 14 specifies the parameter mappe...

Page 175

Acs550 user’s manual 175 parameters group 81: pfc control this group defines a pump-fan control (pfc) mode of operation. The major features of pfc control are: • the acs550 controls the motor of pump no. 1, varying the motor speed to control the pump capacity. This motor is the speed regulated motor...

Page 176

176 acs550 user’s manual parameters 8104 reference step 2 sets a percentage value that is added to the process reference. • applies only when at least two auxiliary (constant speed) motors are running. • see parameter 8103 reference step 1. 8105 reference step 3 sets a percentage value that is added...

Page 177

Acs550 user’s manual 177 parameters 8112 low freq 1 sets the frequency limit used to stop the first auxiliary motor. The first auxiliary motor stops if: • only one (the first) auxiliary motor is running. • acs550 output frequency drops below the limit: 8112 - 1. • output frequency stays below the re...

Page 178

178 acs550 user’s manual parameters 8117 nr of aux mot sets the number of auxiliary motors. • each auxiliary motor requires a relay output, which the drive uses to send start/stop signals. • the autochange function, if used, requires an additional relay output for the speed regulated motor. • the fo...

Page 179

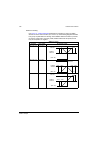

Acs550 user’s manual 179 parameters • the table below shows the acs550 pfc motor assignments for some typical settings in the relay output parameters (1401…1403 and 1410…1412), where the settings are either =31 ( pfc ), or =x (anything but 31), and where the autochange function is disabled (8118 aut...

Page 180

180 acs550 user’s manual parameters 8119 autochng level sets an upper limit, as a percent of output capacity, for the autochange logic. When the output from the pid/pfc control block exceeds this limit, autochange is prevented. For example, use this parameter to deny autochange when the pump-fan sys...

Page 181

Acs550 user’s manual 181 parameters 8120 interlocks defines operation of the interlock function. When the interlock function is enabled: • an interlock is active when its command signal is absent. • an interlock is inactive when its command signal is present. • the acs550 will not start if a start c...

Page 182

182 acs550 user’s manual parameters 2 = di 2 – enables the interlock function and assigns a digital input (starting with di 2) to the interlock signal for each pfc relay. These assignments are defined in the following table and depend on: • the number of pfc relays [number of parameters 1401…1403 an...

Page 183

Acs550 user’s manual 183 parameters 3 = di 3 – enables the interlocks function and assigns a digital input (starting with di 3) to the interlock signal for each pfc relay. These assignments are defined in the following table and depend on: • the number of pfc relays [number of parameters 1401…1403 a...

Page 184

184 acs550 user’s manual parameters 5 = di 5 – enables the interlock function and assigns a digital input (starting with di 5) to the interlock signal for each pfc relay. These assignments are defined in the following table and depend on: • the number of pfc relays [number of parameters 1401…1403 an...

Page 185

Acs550 user’s manual 185 parameters 8121 reg bypass ctrl selects regulator by-pass control. When enabled, regulator by-pass control provides a simple control mechanism without a pid regulator. • use regulator by-pass control only in special applications. 0 = no – disables regulator by-pass control. ...

Page 186

186 acs550 user’s manual parameters 8124 acc in aux stop sets the pfc acceleration time for a zero-to-maximum frequency ramp. This pfc acceleration ramp: • applies to the speed regulated motor, when an auxiliary motor is switched off. • replaces the acceleration ramp defined in group 22: accel/decel...

Page 187

Acs550 user’s manual 187 parameters group 98: options this group configures for options, in particular, enabling serial communication with the drive. Code description 9802 comm prot sel selects the communication protocol. 0 = not sel – no communication protocol selected. 1 = std modbus – the drive c...

Page 188

188 acs550 user’s manual parameters.

Page 189: Embedded Fieldbus

Acs550 user’s manual 189 embedded fieldbus embedded fieldbus overview the acs550 can be set up to accept control from an external system using standard serial communication protocols. When using serial communication, the acs550 can either: • receive all of its control information from the fieldbus, ...

Page 190

190 acs550 user’s manual embedded fieldbus – actual value 3 – actual value 4 – actual value 5 – actual value 6 – actual value 7 – actual value 8 the content of these words is defined by profiles. For details on the profiles used, sees section abb control profiles technical data on page 209 . Note: t...

Page 191

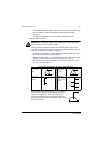

Acs550 user’s manual 191 embedded fieldbus • to reduce noise on the network, terminate the rs485 network using 120 Ω resistors at both ends of the network. Use the dip switch to connect or disconnect the termination resistors. See following diagram and table. • connect the shield at each end of the ...

Page 192

192 acs550 user’s manual embedded fieldbus serial communication configuration setting 9802 automatically sets the appropriate default values in parameters that define the communication process. These parameters and descriptions are defined below. In particular, note that the station id may require a...

Page 193

Acs550 user’s manual 193 embedded fieldbus activate drive control functions – efb controlling the drive fieldbus control of various drive functions requires configuration to: • tell the drive to accept fieldbus control of the function • define as a fieldbus input, any drive data required for control...

Page 194

194 acs550 user’s manual embedded fieldbus input reference select using the fieldbus to provide input references to the drive requires: • drive parameter values set as defined below • fieldbus controller supplied reference word(s) in the appropriate location. (the location is defined by the protocol...

Page 195

Acs550 user’s manual 195 embedded fieldbus relay output control using the fieldbus for relay output control requires: • drive parameter values set as defined below • fieldbus controller supplied, binary coded, relay command(s) in the appropriate location. (the location is defined by the protocol ref...

Page 196

196 acs550 user’s manual embedded fieldbus pid control setpoint source using the following settings to select the fieldbus as the setpoint source for pid loops: communication fault when using fieldbus control, specify the drive’s action if serial communication is lost. Drive parameter value descript...

Page 197

Acs550 user’s manual 197 embedded fieldbus feedback from the drive – efb pre-defined feedback inputs to the controller (drive outputs) have pre-defined meanings established by the protocol. This feedback does not require drive configuration. The following table lists a sample of feedback data. For a...

Page 198

198 acs550 user’s manual embedded fieldbus for example: diagnostics – efb fault queue for drive diagnostics for general acs550 diagnostics information, see chapter diagnostics on page 243 . The three most recent acs550 faults are reported to the fieldbus as defined below. Serial communication diagno...

Page 199

Acs550 user’s manual 199 embedded fieldbus diagnostic situations the sub-sections below describe various diagnostic situations – the problem symptoms and corrective actions. Normal operation during normal network operation, 5306…5309 parameter values act as follows at each drive: • 5306 efb ok messa...

Page 200

200 acs550 user’s manual embedded fieldbus fault 28 – serial 1 err if the drive’s control panel shows fault code 28, serial 1 err , check for either of the following: • the master system is down. To correct, resolve problem with master system. • the communication connection is bad. To correct, check...

Page 201

Acs550 user’s manual 201 embedded fieldbus modbus protocol technical data overview the modbus® protocol was introduced by modicon, inc. For use in control environments featuring modicon programmable controllers. Due to its ease of use and implementation, this common plc language was quickly adopted ...

Page 202

202 acs550 user’s manual embedded fieldbus mapping summary the following table summarizes the mapping between the acs550 (parameters and i/0) and modbus reference space. For details, see modbus addressing below. Communication profiles when communicating by modbus, the acs550 supports multiple profil...

Page 203

Acs550 user’s manual 203 embedded fieldbus • relay output states, numbered sequentially beginning with coil 00033. The following table summarizes the 0xxxx reference set: for the 0xxxx registers: • status is always readable. • forcing is allowed by user configuration of the drive for fieldbus contro...

Page 204

204 acs550 user’s manual embedded fieldbus the acs550 supports the following modbus function codes for coils: 1xxxx mapping – modbus discrete inputs. The drive maps the following information to the 1xxxx modbus set called modbus discrete inputs: • bit-wise map of the status word (selected using para...

Page 205

Acs550 user’s manual 205 embedded fieldbus for the 1xxxx registers: • additional discrete inputs are added sequentially. The acs550 supports the following modbus function codes for discrete inputs: 3xxxx mapping – modbus inputs. The drive maps the following information to the 3xxxx modbus addresses ...

Page 206

206 acs550 user’s manual embedded fieldbus the following table summarizes the 4xxxx drive control registers 40001…40099 (for 4xxxx registers above 40099, see the drive parameter list, e.G. 40102 is parameter 0102): modbus register access remarks 4 0001 control word r/w maps directly to the profile‘ ...

Page 207

Acs550 user’s manual 207 embedded fieldbus for the modbus protocol, drive parameters in group 53: efb protocol report the parameter mapping to 4xxxx registers. Except where restricted by the drive, all parameters are available for both reading and writing. The parameter writes are verified for the c...

Page 208

208 acs550 user’s manual embedded fieldbus actual values the contents of the register addresses 40005…40012 are actual values and are: • specified using parameters 5310…5317 • read-only values containing information on the operation of the drive • 16-bit words containing a sign bit and a 15-bit inte...

Page 209

Acs550 user’s manual 209 embedded fieldbus abb control profiles technical data overview abb drives profile the abb drives profile provides a standard profile that can be used on multiple protocols, including modbus and the protocols available on the fba module. Two implementations of the abb drives ...

Page 210

210 acs550 user’s manual embedded fieldbus abb drives profile the following table and the state diagram later in this sub-section describe the control word content for the abb drives profile. Abb drives profile control word (see parameter 5319) bit name value commanded state comments 0 off1 control ...

Page 211

Acs550 user’s manual 211 embedded fieldbus dcu profile the following tables describe the control word content for the dcu profile. 7 reset 0=>1 reset fault reset if an active fault exists (enter switch - on inhibited ). Effective if 1604 = comm . 0 operating continue normal operation 8…9 unused 10 u...

Page 212

212 acs550 user’s manual embedded fieldbus status word the contents of the status word is status information, sent by the drive to the master station. 8 stpmode_em 1 emergency ramp stop mode 0 (no op) 9 stpmode_c 1 coast stop mode 0 (no op) 10 ramp_2 1 ramp pair 2 0 ramp pair 1 11 ramp_out_0 1 ramp ...

Page 213

Acs550 user’s manual 213 embedded fieldbus abb drives profile the following table and the state diagram later in this sub-section describe the status word content for the abb drives profile. Abb drives profile (efb) status word (see parameter 5320) bit name value description (correspond to states/bo...

Page 214

214 acs550 user’s manual embedded fieldbus dcu profile the following tables describe the status word content for the dcu profile. Dcu profile status word (see parameter 0303) bit name value status 0 ready 1 drive is ready to receive start command. 0 drive is not ready. 1 enabled 1 external run enabl...

Page 215

Acs550 user’s manual 215 embedded fieldbus dcu profile status word (see parameter 0304) bit name value status 16 alarm 1 an alarm is on. 0 no alarms are on. 17 req_maint 1 a maintenance request is pending. 0 no maintenance request is pending. 18 dirlock 1 direction lock is on. (direction change is l...

Page 216

216 acs550 user’s manual embedded fieldbus state diagram abb drives profile to illustrate the operation of the state diagram, the following example ( abb drv lim implementation of the abb drives profile) uses the control word to start the drive: • first, the requirements for using the control word m...

Page 217

Acs550 user’s manual 217 embedded fieldbus the state diagram below describes the start-stop function of control word (cw) and status word (sw) bits for the abb drives profile. (cw xxxx x1xx xxxx x110) mains off power on (cw bit0=0) (sw bit6=1) (sw bit0=0) from any state n(f)=0 / i=0 off1 (cw bit0=0)...

Page 218

218 acs550 user’s manual embedded fieldbus reference scaling abb drives and dcu profiles the following table describes reference scaling for the abb drives and dcu profiles. Note: the setting of parameter 1104 ref 1 min and 1107 ref 2 min has no effect on the scaling of references. When parameter 11...

Page 219

Acs550 user’s manual 219 embedded fieldbus ref1 comm * ai 1 comm (%) · ( ai (%) / 0.5 · ref 1 max (%)) ref2 comm + ai 1 comm (%) + ( ai (%) - 0.5 · ref 2 max (%)) ref2 comm * ai 1 comm (%) · ( ai (%) / 0.5 · ref 2 max (%)) abb drives and dcu profiles reference value setting ai reference scaling 0% 5...

Page 220

220 acs550 user’s manual embedded fieldbus reference handling use group 10: start/stop/dir parameters to configure for control of rotation direction for each control location ( ext 1 and ext 2). The following diagrams illustrate how group 10 parameters and the sign of the fieldbus reference interact...

Page 221: Fieldbus Adapter

Acs550 user’s manual 221 fieldbus adapter fieldbus adapter overview the acs550 can be set up to accept control from an external system using standard serial communication protocols. When using serial communication, the acs550 can either: • receive all of its control information from the fieldbus, or...

Page 222

222 acs550 user’s manual fieldbus adapter control interface in general, the basic control interface between the fieldbus system and the drive consists of: • output words: – control word – reference (speed or frequency) – others: the drive supports a maximum of 15 output words. Protocols limits may f...

Page 223

Acs550 user’s manual 223 fieldbus adapter – parameter 9802 comm prot sel = 4 ( ext fba ). – the external plug-in fieldbus adapter is configured to use the drive profile mode or drive profile objects. The content of the control word depends on the protocol/profile used. See the user’s manual provided...

Page 224

224 acs550 user’s manual fieldbus adapter mechanical and electrical installation – fba warning! Connections should be made only while the drive is disconnected from the power source. Overview the fba (fieldbus adapter) is a plug-in module that fits in the drive’s expansion slot 2. The module is held...

Page 225

Acs550 user’s manual 225 fieldbus adapter communication set-up – fba serial communication selection to activate the serial communication, use parameter 9802 comm prot sel . Set 9802 = 4 ( ext fba ). Serial communication configuration setting 9802, together with mounting a particular fba module, auto...

Page 226

226 acs550 user’s manual fieldbus adapter input reference select using the fieldbus to provide input reference to the drive requires: • drive parameter value set as defined below • fieldbus controller supplied reference word(s) in the appropriate location. (the location is defined by the protocol re...

Page 227

Acs550 user’s manual 227 fieldbus adapter relay output control using the fieldbus for relay output control requires: • drive parameter values set as defined below • fieldbus controller supplied, binary coded, relay command(s) in the appropriate location. (the location is defined by the protocol refe...

Page 228

228 acs550 user’s manual fieldbus adapter pid control setpoint source using the following settings to select the fieldbus as the setpoint source for pid loops: communication fault when using fieldbus control, specify the drive’s action if serial communication is lost. Feedback from the drive – fba i...

Page 229

Acs550 user’s manual 229 fieldbus adapter diagnostics – fba fault handling the acs550 provides fault information as follows: • the control panel display shows a fault code and text. See chapter diagnostics on page 243 for a complete description. • parameters 0401 last fault , 0412 previous fault 1 a...

Page 230

230 acs550 user’s manual fieldbus adapter 27 config file 630fh 28 serial 1 err 7510h 29 efb con file 6306h 30 force trip ff90h 31 efb 1 ff92h 32 efb 2 ff93h 33 efb 3 ff94h 34 motor phase ff56h 35 outp wiring ff95h 36 incompatible sw 630fh 37 cb overtemp 4110h 38 user load curve ff6bh 101 serf corrup...

Page 231

Acs550 user’s manual 231 fieldbus adapter serial communication diagnostics besides the drive fault codes, the fba module has diagnostic tools. Refer to the user’s manual supplied with the fba module..

Page 232

232 acs550 user’s manual fieldbus adapter abb drives profile technical data overview the abb drives profile provides a standard profile that can be used on multiple protocols, including protocols available on the fba module. This section describes the abb drives profile implemented for fba modules. ...

Page 233

Acs550 user’s manual 233 fieldbus adapter status word as described earlier in section control interface on page 222 , the contents of the status word is status information, sent by the drive to the master station. The following table and the state diagram later in this sub-section describe the statu...

Page 234

234 acs550 user’s manual fieldbus adapter 4 off_2_sta 1 off 2 inactive 0 of f 2 active 5 off_3_sta 1 off 3 inactive 0 of f 3 active 6 swc_on_inhib 1 switch - on inhibit active 0 switch - on inhibit not active 7 alarm 1 alarm (see section alarm listing on page 250 for details on alarms.) 0 no alarm 8...

Page 235

Acs550 user’s manual 235 fieldbus adapter the state diagram below describes the start-stop function of control word (cw) and status word (sw) bits. (cw xxxx x1xx xxxx x110) mains off power on (cw bit0=0) (sw bit6=1) (sw bit0=0) from any state n(f)=0 / i=0 off1 (cw bit0=0) a c d (cw bit3=0) (sw bit2=...

Page 236

236 acs550 user’s manual fieldbus adapter reference as described earlier in section control interface on page 222 , the reference word is a speed or frequency reference. Reference scaling the following table describes reference scaling for the abb drives profile. Note: the setting of parameter 1104 ...

Page 237

Acs550 user’s manual 237 fieldbus adapter ref1 comm * ai 1 comm (%) · ( ai (%) / 0.5 · ref 1 max (%)) ref2 comm + ai 1 comm (%) + ( ai (%) - 0.5 · ref 2 max (%)) ref2 comm * ai 1 comm (%) · ( ai (%) / 0.5 · ref 2 max (%)) abb drives profile (fba) reference value setting ai reference scaling 0% 50% 2...

Page 238

238 acs550 user’s manual fieldbus adapter reference handling use group 10: start/stop/dir parameters to configure for control of rotation direction for each control location ( ext 1 and ext 2). The following diagrams illustrate how group 10 parameters and the sign of the fieldbus reference interact ...

Page 239

Acs550 user’s manual 239 fieldbus adapter actual value as described earlier in section control interface on page 222 , actual values are words containing drive values. Actual value scaling the scaling of the integers sent to the fieldbus as actual values depends on the resolution of the selected dri...

Page 240

240 acs550 user’s manual fieldbus adapter generic profile technical data overview the generic profile aims to fulfill the industry-standard drive profile for each protocol (e.G. Profidrive for profibus, ac/dc drive for devicenet). Control word as described earlier in section control interface on pag...

Page 241

Acs550 user’s manual 241 fieldbus adapter actual value scaling for actual values, scale the feedback integer using the parameter’s resolution. (see section complete parameter list on page 85 for parameter resolutions.) for example: where parameters are in percent, the complete parameter list section...

Page 242

242 acs550 user’s manual fieldbus adapter.

Page 243: Diagnostics

Acs550 user’s manual 243 diagnostics diagnostics warning! Do not attempt any measurement, parts replacement or other service procedure not described in this manual. Such action will void the warranty, may endanger correct operation and increase downtime and expense. Warning! All electrical installat...

Page 244

244 acs550 user’s manual diagnostics the message reappears after a few seconds if the control panel is not touched and the fault is still active. Flashing green – alarms for less severe errors, called alarms, the diagnostic display is advisory. For these situations, the drive is simply reporting tha...

Page 245

Acs550 user’s manual 245 diagnostics 2 dc overvolt intermediate circuit dc voltage is excessive. Check for and correct: • static or transient overvoltages in the input power supply. • insufficient deceleration time (parameters 2203 deceler time 1 and 2206 deceler time 2). • undersized brake chopper ...

Page 246

246 acs550 user’s manual diagnostics 11 id run fail the motor id run was not completed successfully. Check for and correct: • motor connections. • motor parameters 9905…9909. 12 motor stall motor or process stall. Motor is operating in the stall region. Check for and correct: • excessive load. • ins...

Page 247

Acs550 user’s manual 247 diagnostics 24 overspeed motor speed is greater than 120% of the larger (in magnitude) of 2001 minimum speed or 2002 maximum speed . Check for and correct: • parameter settings for 2001 and 2002. • adequacy of motor braking torque. • applicability of torque control. • brake ...

Page 248

248 acs550 user’s manual diagnostics faults that indicate conflicts in the parameter settings are listed below. 101… 199 system error error internal to the drive. Contact your local abb representative and report the error number. 201… 299 system error error in the system. Contact your local abb repr...

Page 249

Acs550 user’s manual 249 diagnostics fault resetting the acs550 can be configured to automatically reset certain faults. Refer to parameter group 31: automatic reset . Warning! If an external source for start command is selected and it is active, the acs550 may start immediately after fault reset. F...

Page 250

250 acs550 user’s manual diagnostics • digital input • serial communication. When the fault has been corrected, the motor can be started. History for reference, the last three fault codes are stored into parameters 0401, 0412, 0413. For the most recent fault (identified by parameter 0401), the drive...

Page 251

Acs550 user’s manual 251 diagnostics 2004 dir lock the change in direction being attempted is not allowed. Either: • do not attempt to change the direction of motor rotation, or • change parameter 1003 direction to allow direction change (if reverse operation is safe). 2005 io comm fieldbus communic...

Page 252

252 acs550 user’s manual diagnostics 2013 (note 1) autoreset this alarm warns that the drive is about to perform an automatic fault reset, which may start the motor. • to control automatic reset, use group 31: automatic reset . 2014 (note 1) autochange this alarm warns that the pfc autochange functi...

Page 253