- DL manuals

- ABB

- Media Converter

- ACS580-01 drives

- Hardware Manual

ABB ACS580-01 drives Hardware Manual

Summary of ACS580-01 drives

Page 1

Abb general purpose drives hardware manual acs580-01 drives (0.75 to 250 kw, 1.0 to 350 hp).

Page 2

List of related manuals drive manuals and guides code (english) acs580 standard control program firmware manual 3axd50000016097 acs580-01 (0.75 to 250 kw, 1.0 to 350 hp) hardware manual 3axd50000044794 acs580-01 quick installation and start-up guide for frames r1 to r5 3axd50000044838 acs580-01 quic...

Page 3: Hardware Manual

Hardware manual acs580-01 drives (0.75 to 250 kw, 1.0 to 350 hp) 3axd50000044794 rev a en effective: 2017-05-31 2017 abb oy. All rights reserved. 1. Safety instructions table of contents 4. Mechanical installation 6. Electrical installation.

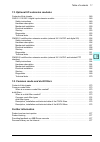

Page 5: Table of Contents

Table of contents 5 table of contents list of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1. Safety instructions contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

6 table of contents unpacking and examining delivery, frames r1 and r2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 frames r1 and r2 cable box (ip21, ul type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 unpacking and examining delivery, frames r3…r4 . . . . . ....

Page 7: 6. Electrical Installation

Table of contents 7 protecting the motor against thermal overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 protecting the drive against ground faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 residual current device compatibility ....

Page 8: 9. Technical Data

8 table of contents checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139 8. Maintenance and hardware diagnostics contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 9: 10. Dimension Drawings

Table of contents 9 losses, cooling data and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176 cooling air flow, heat dissipation and noise for stand-alone drives . . . . . . . . . . . . . . . . 176 cooling air flow and heat dissipation for flang...

Page 10: 11. Resistor Braking

10 table of contents frame r5, ip21 (ul type 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212 frame r5, ip55 (ul type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213 frame r6, ip21 (ul type 1)...

Page 11: Further Information

Table of contents 11 13. Optional i/o extension modules contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249 chdi-01 115/230 v digital input extension module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 12

12 table of contents.

Page 13: Safety Instructions

Safety instructions 13 1 safety instructions contents of this chapter this chapter contains the safety instructions which you must obey when you install and operate the drive and do maintenance on the drive. If you ignore the safety instructions, injury, death or damage can occur. Use of warnings an...

Page 14

14 safety instructions general safety in installation, start-up and maintenance these instructions are for all personnel that install the drive and do maintenance work on it. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • use safety sho...

Page 15

Safety instructions 15 • before you activate the automatic fault reset or automatic restart functions of the drive control program, make sure that no dangerous situations can occur. These functions reset the drive automatically and continue operation after a fault or supply break. If these functions...

Page 16

16 safety instructions electrical safety in installation, start-up and maintenance precautions before electrical work these warnings are for all personnel who do work on the drive, motor cable or motor. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment...

Page 17

Safety instructions 17 additional instructions and notes warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • if you install the drive on an it system (an ungrounded power system or a high- resistance-grounded [over 30 ohms] power system), di...

Page 18: Grounding

18 safety instructions warning! Use a grounding wrist band when you handle the printed circuit boards. Do not touch the boards unnecessarily. The boards contain components sensitive to electrostatic discharge. Grounding these instructions are for all personnel who are responsible for the electrical ...

Page 19

Safety instructions 19 additional instructions for permanent magnet motor drives safety in installation, start-up and maintenance these are additional warnings concerning permanent magnet motor drives. The other safety instructions in this chapter are also valid. Warning! Obey these instructions. If...

Page 20

20 safety instructions general safety in operation these instructions are for all personnel that operate the drive. Warning ! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • do not control the motor with the disconnector at the drive power supply...

Page 21: Introduction to The Manual

Introduction to the manual 21 2 introduction to the manual contents of this chapter the chapter describes applicability, target audience and purpose of this manual. It describes the contents of this manual and refers to a list of related manuals for more information. The chapter also contains a flow...

Page 22: Contents Of This Manual

22 introduction to the manual contents of this manual the manual consists of the following chapters: • safety instructions (page 13 ) gives safety instructions you must obey when installing, commissioning, operating and servicing the drive. • introduction to the manual (this chapter, page 21 ) descr...

Page 23: Related Documents

Introduction to the manual 23 related documents see list of related manuals on page 2 (inside of the front cover). Categorization by frame (size) the acs580-01 is manufactured in frames (frame sizes) r1…r9. Some instructions and other information which only concern certain frames are marked with the...

Page 24

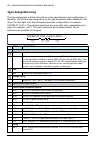

24 introduction to the manual quick installation and commissioning flowchart task see identify the frame of your drive: r1…r9. Operation principle and hardware description : type designation key on page 40 plan the installation: select the cables, etc. Check the ambient conditions, ratings and requi...

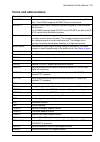

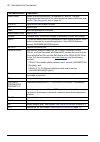

Page 25: Terms And Abbreviations

Introduction to the manual 25 terms and abbreviations term/abbreviation explanation acs-bp-s basic control panel, basic operator keypad for communication with the drive. The acs580 supports acs-bp-s basic control panel. Acs-ap-x assistant control panel, advanced operator keypad for communication wit...

Page 26

26 introduction to the manual frame (size) refers to drive physical size, for example r1 and r2. The type designation label attached to the drive shows the frame of the drive, see section type designation key on page 40 . Fsca-01 optional eia-485 adapter module i/o input/output igbt insulated gate b...

Page 27: Operation Principle and

Operation principle and hardware description 27 3 operation principle and hardware description contents of this chapter this chapter briefly describes the operation principle, layout, type designation label and type designation information. It also shows a general diagram of power connections and co...

Page 28: Operation Principle

28 operation principle and hardware description operation principle the acs580-01 is a drive for controlling asynchronous ac induction motors , permanent magnet motors and synchronous reluctance motors (synrm). The figure below shows the simplified main circuit diagram of the drive. 1 rectifier. Con...

Page 29: Layout

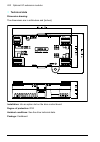

Operation principle and hardware description 29 layout frames r1…r2 the layout of a frame r1 drive is presented below. The main structure of frame r2 is similar to r1. Ip55 frames are also slightly different from ip21 frames, for example, ip21 front cover has two parts while ip55 front cover only ha...

Page 30

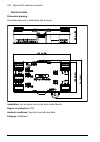

30 operation principle and hardware description frame r3 breakers input pe motor r- r+ udc+ l1 l2 l3 t1/u t2/v t3/w 1 mounting points (4 pieces) 2 cover 3 cover screw 4 control panel 5 control panel connection 6 cold configuration connection for cca-01 7 power ok and fault leds. See section leds on ...

Page 31

Operation principle and hardware description 31 frame r4 1 mounting points (4 pieces) 2 cover 3 cover screw 4 control panel 5 control panel connection 6 cold configuration connection for cca-01 7 power ok and fault leds. See section leds on page 156 . 8 i/o connections. See section external control ...

Page 32

32 operation principle and hardware description frame r5 1 mounting points (6 pieces: 2 at the top, 2 at the bottom of the main part of the frame, 2 at the top of the cable box) 2 cover 3 cable/conduit box 4 cover screws (2 pieces) 5 control panel 6 control panel connection 7 cold configuration conn...

Page 33

Operation principle and hardware description 33 frames r6…r9 the layout of a frame r6 drive is presented below. The constructions of frames r6…r9 differ to some extent. 1 mounting points (6 pieces: 2 at the top, 2 at the bottom of the main part of the frame, 2 at the top of the cable box) 2 cover 3 ...

Page 34

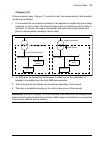

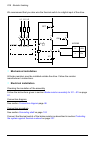

34 operation principle and hardware description overview of power and control connections the logical diagram below shows the power connections and control interfaces of the drive. 1 option slot 1 for optional fieldbus adapter modules 2 option slot 2 for optional i/o extension modules 3 panel port. ...

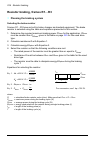

Page 35: …r5

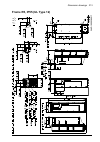

Operation principle and hardware description 35 external control connection terminals, frames r 1 …r5 the layout of the external control connection terminals of the r1 frame is shown below. Layout of the external control connection terminals is identical in frames r1…r5 but the location of the contr...

Page 36

36 operation principle and hardware description external control connection terminals, frames r6…r9 the layout of the external control connection terminals of frames r6…r9 is shown below. Warning! Do not connect the +24 v ac cable to the control board ground when the control board is powered using a...

Page 37: Control Panel

Operation principle and hardware description 37 control panel to remove the control panel, press the retaining clip at the top (1a) and pull it forward from the top edge (1b). To reinstall the control panel, put the bottom of the container in position (1a), press the retaining clip at the top (1b) a...

Page 38: Type Designation Label

38 operation principle and hardware description control panel door mounting kits door mounting kits for the control panel are available. For more information see dpmp-01 mounting platform for control panels (3aua0000100140 [english]) or dpmp-02/03 mounting platform for control panels (3aua0000136205...

Page 39

Operation principle and hardware description 39 locations of the labels on the drive 1 2 3 1 2 3.

Page 40: Type Designation Key

40 operation principle and hardware description type designation key the type designation contains information on the specifications and configuration of the drive. You find the type designation on the type designation label attached to the drive. The first digits from the left express the basic con...

Page 41

Operation principle and hardware description 41 fieldbus adapters k454 fpba-01 profibus dp k457 fcan-01 canopen k451 fdna-01 devicenet™ k473 fena-11 ethernet (ethernet/ip™, modbus/tcp, profinet) k469 feca-01 ethercat k458 fsca-01 modbus/rtu k470 fepl-02 ethernet powerlink k462 fcna-01 controlnet™ k4...

Page 42

42 operation principle and hardware description.

Page 43: Mechanical Installation

Mechanical installation 43 4 mechanical installation contents of this chapter the chapter tells how to check the installation site, unpack, check the delivery and install the drive mechanically. Safety warning! Frames r5…r9: lift the drive with a lifting device. Use the lifting eyes of the drive. Do...

Page 44

44 mechanical installation checking the installation site the drive must be installed on the wall. There are three alternative ways to install it: • vertically alone. Do not install the drive upside down. Frame size vertical installation - free space above (a) below (b) 1) beside mm in mm in mm in r...

Page 45

Mechanical installation 45 • vertically side by side • horizontally alone, ip21 (ul type 1) only note 1: the vibration specification in section ambient conditions on page 192 may not be fulfilled. Note 2: in the horizontal mounting, the drive is not protected from dripping water. Frame size vertical...

Page 46: Required Tools

46 mechanical installation check the installation site according to the requirements below: • the installation site is sufficiently ventilated or cooled to transfer away the drive losses. See section losses, cooling data and noise on page 176 . • the operation conditions of the drive meet the specif...

Page 47

Mechanical installation 47 unpacking and examining delivery, frames r1 and r2 the figure below shows the layout of the transport package. Examine that all items are present and there are no signs of damage. Read the data on the type designation label of the drive to make sure that the drive is of th...

Page 48

48 mechanical installation to unpack: • cut the straps (7). • remove the upper tray (8a) and option tray (3). • remove the cardboard box (5). • remove the plastic bag (2). • lift the drive. Frames r1 and r2 cable box (ip21, ul type 1) this illustration shows the contents of the cable box package. Th...

Page 49

Mechanical installation 49 unpacking and examining delivery, frames r3…r4 the figure below shows the drive package with its contents. Examine that all items are present and there are no signs of damage. Read the data on the type designation label of the drive to make sure that the drive is of the co...

Page 50

50 mechanical installation unpacking and examining delivery, frame r5 the figure below shows the layout of the transport package. Examine that all items are present and there are no signs of damage. Read the data on the type designation label of the drive to make sure that the drive is of the correc...

Page 51

Mechanical installation 51 to unpack: • cut the straps (7). • remove the cardboard box (4) and option box (3). • remove the cover protecting film (6). • lift the drive. Frame r5 cable box (ip21, ul type 1) this illustration shows the contents of the cable box package. The package also includes an as...

Page 52

52 mechanical installation unpacking and examining delivery, frames r6…r9 the figure below shows the layout of the transport package. Examine that all items are present and there are no signs of damage. Read the data on the type designation label of the drive to make sure that the drive is of the co...

Page 53

Mechanical installation 53 to unpack: • cut the straps (4). • remove the cardboard box (3) and option tray (8). • remove the vci bag (5). • attach lifting hooks to the lifting eyes of the drive (see the figure on page 43 ). Lift the drive with a hoist. Frame r6 cable box (ip21, ul type 1) the figure...

Page 54

54 mechanical installation frame r7 cable box (ip21, ul type 1) the figure below shows the contents of the cable box package. The package also includes an assembly drawing which shows how to install cable box to the drive frame. 3aua0000111117.

Page 55

Mechanical installation 55 frame r8 cable box (ip21, ul type 1) the figure below shows the contents of the cable box package. The package also includes an assembly drawing which shows how to install the cable box to the drive frame. 3aua0000112174.

Page 56

56 mechanical installation frame r9 cable box (ip21, ul type 1) the figure below shows the contents of the cable box package. The package also includes an assembly drawing which shows how to install the cable box to the drive frame. 3aua0000112356.

Page 57: Installing The Drive

Mechanical installation 57 installing the drive installing the drive vertically, frames r1…r4 the figures show frame r3 as an example. 1. Mark the hole locations using the mounting template included in the package. Do not leave the mounting template under the drive. The drive dimensions and hole loc...

Page 58

58 mechanical installation 4. Position the drive onto the bolts on the wall. 5. Tighten the bolts in the wall securely. Install the cable box, frames r1…r2 6. Remove the screw (6a) and lift the cover off (6b) from the separate cable box. 7. Attach the cable box cover to the front cover. 8. Install t...

Page 59

Mechanical installation 59 installing the drive vertically, frame r5 1. Mark the hole locations using the mounting template included in the package. Do not leave the mounting template under the drive. The drive dimensions and hole locations are also shown in the drawings in chapter dimension drawing...

Page 60

60 mechanical installation ip21 (ul type 1) 4. Remove the front cover: remove the fastening screws (4a) and lift the cover from the bottom upwards (4b) and then to the top side (4c). 5. Attach the cable box to the drive frame. 6. Tighten the box screws. 7. Slide the box cover from the bottom (7a) an...

Page 61

Mechanical installation 61 ip21 (ul type 1), ip55 (ul type 12) 9. Position the drive onto the four bolts on the wall. Lift the drive with another person or with a lifting device as it is heavy. Tighten the bolts in the wall securely. 10. Tighten the two remaining bolts securely. 9 10 9a 9b 9b ×2 ×2.

Page 62

62 mechanical installation installing the drive vertically, frames r6…r9 1. Mark the hole locations for the six mounting holes using the mounting template included in the package. Do not leave the mounting template under the drive. The drive dimensions and hole locations are also shown in the drawin...

Page 63

Mechanical installation 63 ip21 (ul type 1) 6. Remove the front cover: remove the fastening screws (a), move the cover to the top side (b) and then up (c). 7. Attach the cable box to the drive frame. 8. Tighten the box screws: two at the top and four at the bottom. Ip55 (ul type 12) 9. Remove the fr...

Page 64: Flange Mounting

64 mechanical installation flange mounting instructions for flange mounting are delivered with the flange mounting kit: flange mounting kit quick installation guide for acx580-01 frames r0 to r5 (3axd50000036610 [english]) or flange mounting kit quick installation guide for acs880-01 and acx580-01 f...

Page 65: Planning The Electrical

Planning the electrical installation 65 5 planning the electrical installation contents of this chapter this chapter contains instructions for planning the electrical installation of the drive, for example, for checking the compatibility of the motor and drive, selecting cables, protections and cabl...

Page 66: European Union

66 planning the electrical installation european union to meet the european union directives, according to standard en 60204-1, safety of machinery , the disconnecting device must be one of the following types: • switch-disconnector of utilization category ac-23b (en 60947-3) • disconnector that has...

Page 67

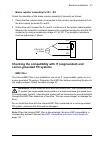

Planning the electrical installation 67 checking the compatibility of the motor and drive use an asynchronous ac induction motor , permanent magnet motor or synchronous reluctance motor with the drive. Several induction motors can be connected to the drive at a time but only one permanent magnet mot...

Page 68: Requirements Table

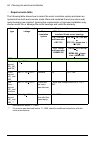

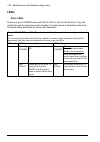

68 planning the electrical installation requirements table the following table shows how to select the motor insulation system and when an optional drive du/dt and common mode filters and insulated n-end (non-drive end) motor bearings are required. Ignoring the requirements or improper installation ...

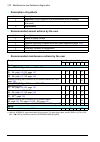

Page 69

Planning the electrical installation 69 the abbreviations used in the table are defined below. Additional requirements for the braking applications when the motor brakes the machinery, the intermediate circuit dc voltage of the drive increases, the effect being similar to increasing the motor supply...

Page 70

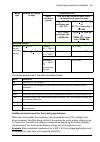

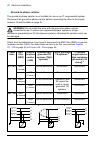

70 planning the electrical installation additional data for calculating the rise time and the peak line-to-line voltage if you need to calculate the actual peak voltage and voltage rise time considering the actual cable length, proceed as follows: • peak line-to line voltage: read the relative Û ll ...

Page 71

Planning the electrical installation 71 a drive with du/dt filter b drive without du/dt filter l motor cable length Û ll / u n relative peak line-to-line voltage (du/dt)/u n relative du/dt value note : Ûll and du/dt values are approximately 20% higher with resistor braking. Û ll / u n l (m) du/dt un...

Page 72: Selecting The Power Cables

72 planning the electrical installation selecting the power cables general rules select the input power and motor cables according to local regulations : • select a cable capable of carrying the drive nominal current. See section ratings (page 160 ) for the rated currents. • select a cable rated for...

Page 73: Typical Power Cable Sizes

Planning the electrical installation 73 typical power cable sizes the table below gives copper cable types with concentric copper shield for the drives with nominal current. The value separated by the plus sign means the diameter of the pe conductor. See also section terminal and lead-through data f...

Page 74: Motor Cable Shield

74 planning the electrical installation alternative power cable types the recommended and the not allowed power cable types to be used with the drive are presented below. Recommended power cable types power cable types for limited use not allowed power cable types motor cable shield if the motor cab...

Page 75: Additional Us Requirements

Planning the electrical installation 75 concentric layer of copper wires with an open helix of copper tape or copper wire. The better and tighter the shield, the lower the emission level and bearing currents. Additional us requirements use type mc continuous corrugated aluminum armor cable with symm...

Page 76: Shielding

76 planning the electrical installation shielded power cables are available from the following suppliers: • belden • lappkabel (Ölflex) • pirelli. Selecting the control cables shielding all control cables must be shielded. Use a double-shielded twisted pair cable (figure a below) for analog signals....

Page 77

Planning the electrical installation 77 the cable type tested and approved by the manufacturer is used in control panel option kits. Suitable cables are cat 5e unshielded or shielded twisted pair cables. Drive composer pc tool cable connect the drive composer pc tool to the drive through the usb por...

Page 78: Routing The Cables

78 planning the electrical installation routing the cables general rules route the motor cable away from other cable routes. Motor cables of several drives can be run in parallel installed next to each other. The motor cable, input power cable and control cables should be installed on separate trays...

Page 79: Motor Cable

Planning the electrical installation 79 separate control cable ducts lead 24 v and 230 v (120 v) control cables in separate ducts unless the 24 v cable is insulated for 230 v (120 v) or insulated with an insulation sleeving for 230 v (120 v). Continuous motor cable shield or enclosure for equipment ...

Page 80

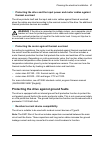

80 planning the electrical installation implementing thermal overload and short-circuit protection protecting the drive and input power cable in short-circuits protect the drive and input cable with fuses as follows: size the fuses at the distribution board according to instructions given in chapter...

Page 81: Thermal Overload

Planning the electrical installation 81 protecting the drive and the input power and motor cables against thermal overload the drive protects itself and the input and motor cables against thermal overload when the cables are sized according to the nominal current of the drive. No additional thermal ...

Page 82: Through)

82 planning the electrical installation implementing the emergency stop function for safety reasons, install the emergency stop devices at each operator control station and at other operating stations where emergency stop may be needed. Design the emergency stop according to relevant standards. Note...

Page 83

Planning the electrical installation 83 warning! When the vector control mode is in use, never open the output contactor while the drive controls the motor. The vector control operate extremely fast, much faster than it takes for the contactor to open its contacts. When the contactor starts opening ...

Page 84: Example Bypass Connection

84 planning the electrical installation example bypass connection an example bypass connection is shown below. Q1 main switch for the drive s11 drive main contactor on/off control q4 bypass circuit breaker s40 motor power supply selection (drive or direct-on-line) k1 drive main contactor s41 start w...

Page 85

Planning the electrical installation 85 switching the motor power supply from drive to direct-on-line 1. Stop the drive and the motor with the drive control panel (drive in local control mode) or with the external stop signal (drive in remote control mode). 2. Open the main contactor of the drive wi...

Page 86: Altitudes

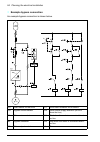

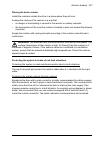

86 planning the electrical installation limiting relay output maximum voltages at high installation altitudes see sections isolation areas, r1…r5 on page 188 and isolation areas, r6…r9 on page 189 . 1 relay outputs 2 varistor 3 rc filter 4 diode 1 2 3 230 v ac + 24 v dc 4 230 v ac.

Page 87

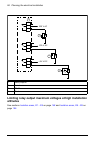

Planning the electrical installation 87 implementing a motor temperature sensor connection warning! Iec 60664 requires double or reinforced insulation between live parts and the surface of accessible parts of electrical equipment which are either non-conductive or conductive but not connected to the...

Page 88

88 planning the electrical installation the table shows what temperature sensor types you can connect to the drive i/o extension modules as well as the insulation requirement for the sensor. Extension module temperature sensor type type insulation ptc kty pt100, pt1000 cmod-02 reinforced insulation ...

Page 89: Electrical Installation

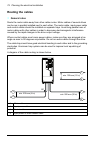

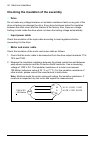

Electrical installation 89 6 electrical installation contents of this chapter the chapter describes how to check the insulation of the assembly and the compatibility with it (ungrounded) and corner-grounded tn systems. It then shows how to connect the power and control cables, install optional modul...

Page 90: Drive

90 electrical installation checking the insulation of the assembly drive do not make any voltage tolerance or insulation resistance tests on any part of the drive as testing can damage the drive. Every drive has been tested for insulation between the main circuit and the chassis at the factory. Also...

Page 91: Corner-Grounded Tn Systems

Electrical installation 91 brake resistor assembly for r1…r3 check the insulation of the brake resistor assembly (if present) as follows: 1. Check that the resistor cable is connected to the resistor, and disconnected from the drive output terminals r+ and r-. 2. At the drive end, connect the r+ and...

Page 92: Ground-to-Phase Varistor

92 electrical installation ground-to-phase varistor the ground-to-phase varistor is not suitable for use on an it (ungrounded) system. Disconnect the ground-to-phase varistor before connecting the drive to the supply network. Check the table on page 92 . Warning! Do not install the drive with the gr...

Page 93: Frames R1…r3

Electrical installation 93 frames r1…r3 to disconnect the internal emc filter or ground-to-phase varistor, if needed, do as follows: 1. Switch off the power from the drive. 2. Open the front cover, if not already opened, see page 97 . 3. To disconnect the internal emc filter, remove the emc screw (3...

Page 94: Frames R4…r9

94 electrical installation frames r4…r9 to disconnect the internal emc filter or ground-to-phase varistor, if needed, do as follows: 1. Switch off the power from the drive. 2. Open the cover, if not already opened. Frame r4: see page 97 , frame r5: see page 105 , frames r6…r9: see page 63 . 3. To di...

Page 95

Electrical installation 95 r6…r9 3 3 4.

Page 96: Connection Diagram

96 electrical installation connecting the power cables connection diagram 1 for alternatives, see section selecting the supply disconnecting device on page 65. 2 use a separate grounding pe cable (2a) or a cable with a separate pe conductor (2b) if the conductivity of the shield does not meet the re...

Page 97

Electrical installation 97 connection procedure, frames r1…r4 1. Remove the front cover: loosen the retaining screw with a screwdriver (1a) and lift the cover from the bottom outwards (1b) and then up (1c). Warning! If the drive will be connected on an it (ungrounded) system, make sure you have disc...

Page 98

98 electrical installation 3. Remove the rubber grommets from the cable entry if they point up. (the grommets may point up or down when you open the package, depending on the frame size.) r1…r3: the grommets point down and at this point you need to remove only the grommets for motor and input power ...

Page 99

Electrical installation 99 motor cable 4. Cut an adequate hole into the rubber grommet. Slide the grommet onto the cable. 5. Prepare the ends of the cable as illustrated in the figure. In frames r1 and r2 there are markings on the drive frame near the power cable terminals helping you to strip the w...

Page 100

100 electrical installation 7. Connect the motor cable: • ground the shield 360 degrees by tightening the clamp of the power cable grounding shelf onto the stripped part of the cable. (7a) • connect the twisted shield of the cable to the grounding terminal. (7b) • connect the phase conductors of the...

Page 101

Electrical installation 101 10. Slide the cable through the hole in the cable entry and attach the grommet to the hole. 11. Connect the input power cable: • ground the shield 360 degrees by tightening the clamp of the power cable grounding shelf onto the stripped part of the cable. (11a) • connect t...

Page 102

102 electrical installation grounding shelf 12. Frames r1…r2, r4: install the grounding shelf (included with the mounting screws in a plastic bag in the delivery). Brake resistor cable (if used) frames r1…r3 only 13. Repeat steps 4 … 6 for the brake resistor cable. Cut off one phase conductor. R4 r1...

Page 103

Electrical installation 103 14. Connect the cable as the motor cable in step 7 . Ground the shield 360 degrees (14a). Connect the twisted shield to the grounding terminal (14b) and the conductors to the r+ and r- terminals (14c) and tighten to the torque given below the figure. Finalization note: fr...

Page 104

104 electrical installation . 16. Secure the cables outside the unit mechanically. 17. Ground the motor cable shield at the motor end. For minimum radio frequency interference, ground the motor cable shield 360 degrees at the cable entry of the motor terminal box. 17 r4 17.

Page 105

Electrical installation 105 connection procedure, frame r5 ip21 (ul type 1) 1. Remove the module cover: loosen the retaining screws with a screwdriver (1a) and lift the cover from the bottom outwards (1b) and then up (1c). Remove the box cover: loosen the retaining screws with a screwdriver (1d) and...

Page 106

106 electrical installation 2. Attach the residual voltage warning sticker in the local language next to the control board. 3. Remove the shroud on the power cable terminals by releasing the clips with a screwdriver (3a) and pulling the shroud out (3b). 2 3b 3 3a 3a.

Page 107

Electrical installation 107 motor cable use symmetrical shielded cable for motor cabling. If the cable shield is the sole pe conductor for drive or motor, make sure that is has sufficient conductivity for the pe. 4. Cut an adequate hole into the rubber grommet. Slide the grommet onto the cable. 5. P...

Page 108

108 electrical installation 6. Slide the cable through the hole of the bottom plate and attach the grommet to the hole. 7. Connect the motor cable: • ground the shield 360 degrees by tightening the clamp of the power cable grounding shelf onto the stripped part of the cable (7a). • connect the twist...

Page 109

Electrical installation 109 input power cable 8. Repeat steps 4 … 6 for the input power cable. 9. Connect the input power cable. Tighten the screws to the torque given in the figure. 10. Install the cable box plate. Position the plate and tighten the screw. 8b 8a pe pe pe 9 9b 9c 9a 10a 10b 10 frame...

Page 110

110 electrical installation 11. Reinstall the shroud on the power terminals by putting the tabs at the top of the shroud in their counterparts on the drive frame and then pressing the shroud in place. Finalization 12. Secure the cables outside the unit mechanically. 13. Ground the motor cable shield...

Page 111

Electrical installation 111 connection procedure, frames r6…r9 warning! If the drive will be connected on an it (ungrounded) system, make sure you have disconnected the emc filter and ground-to-phase varistor. See page 91 . If the drive will be connected on a corner-grounded tn system, make sure you...

Page 112

112 electrical installation motor cable 6. Cut an adequate hole into the rubber grommet. Slide the grommet onto the cable. 7. Prepare the ends of the input power cable and motor cable as illustrated in the figure. If you use aluminum cables, put grease to the peeled aluminum cable before connecting ...

Page 113

Electrical installation 113 input power cable 10. Connect the input power cable as in step 9 . Use terminals l1, l2 and l3. Terminals t1/u, t2/v and t3/w • remove the nut that attaches the connector to its busbar. • put the conductor under the connector pressure plate and pre-tighten the conductor. ...

Page 114

114 electrical installation terminals l1, l2 and l3 • remove the combi screw that attaches the connector to its terminal post, and pull the connector off. • put the conductor under the connector pressure plate and pre-tighten the conductor. • put the connector back onto the terminal post. Start the ...

Page 115: Dc Connection

Electrical installation 115 13. Reinstall the shroud on the power terminals. 14. Secure the cables outside the unit mechanically. 15. Ground the motor cable shield at the motor end. For minimum radio frequency interference, ground the motor cable shield 360 degrees at the cable entry of the motor te...

Page 116

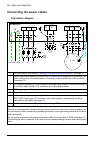

116 electrical installation connecting the control cables see section default i/o connection diagram (abb standard macro) on page 117 for the default i/o connections of the abb standard macro. For other macros, see acs580 firmware manual (3axd50000016097 [english]). Connect the cables as described u...

Page 117

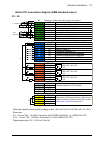

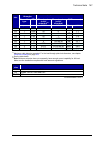

Electrical installation 117 default i/o connection diagram (abb standard macro) r1…r5 6) max. 500 ohm 1…10 kohm x1 reference voltage and analog inputs and outputs 1 scr signal cable shield (screen) 2 ai1 output frequency/speed reference : 0…10 v 1,3) 3 agnd analog input circuit common 4 +10v referen...

Page 118

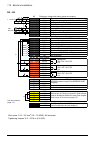

118 electrical installation r6…r9 max. 500 ohm 1…10 kohm xi reference voltage and analog inputs and outputs 1 scr signal cable shield (screen) 2 ai1 output frequency/speed reference : 0…10 v 1,3) 3 agnd analog input circuit common 4 +10v reference voltage 10 v dc 5 ai2 not configured 1) 6 agnd analo...

Page 119

Electrical installation 119 notes: 1) current [0(4)…20 ma, r in = 100 ohm] or voltage [ 0(2)…10 v, r in > 200 kohm]. Change of setting requires changing the corresponding parameter. 2) total load capacity of the auxiliary voltage output +24v (x2:10) is 6.0 w (250 ma / 24 v) minus the power taken by ...

Page 120

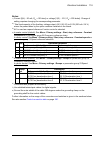

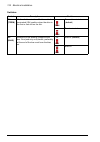

120 electrical installation switches switch description position s4 (term) modbus link termination. Must be set to the terminated (on) position when the drive is the first or last unit on the link. Bus not terminated ( default ) bus terminated s5 (bias) switches on the biasing voltages to the bus. O...

Page 121

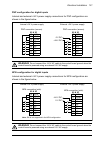

Electrical installation 121 pnp configuration for digital inputs internal and external +24 v power supply connections for pnp configuration are shown in the figure below. Warning! Do not connect the +24 v ac cable to the control board ground when the control board is powered using an external 24 v a...

Page 122

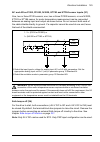

122 electrical installation connection for obtaining 0…10 v from analog output 2 (ao2) to obtain 0…10 v from analog output ao2, connect a 500 ohm resistor (or two 1 kohm resistors in parallel) between the analog output 2 ao2 and analog common ground agnd. Examples are shown in the figure below. X1 8...

Page 123

Electrical installation 123 connection examples of two-wire and three-wire sensors hand/auto, hand/pid, and pid macros (see acs580 firmware manual (3axd50000016097 [english])) use analog input 2 (ai2). The macro wiring diagrams on these pages use an externally powered sensor (connections not shown)....

Page 124

124 electrical installation di5 as frequency input for setting the parameters for the digital frequency input, see acs580 standard control program firmware manual (3axd50000016097 [english]). Di6 as ptc input if di6 is used as a ptc input, see acs580 standard control program firmware manual (3axd500...

Page 125

Electrical installation 125 ai1 and ai2 as pt100, pt1000, ni1000, kty83 and kty84 sensor inputs (x1) one, two or three pt100 sensors; one, two or three pt1000 sensors; or one ni1000, kty83 or kty84 sensor for motor temperature measurement can be connected between an analog input and output as shown ...

Page 126

126 electrical installation control cable connection procedure r1…r9 warning! Obey the instructions in chapter safety instructions on page 13 . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section precautions before electrical work ...

Page 127

Electrical installation 127 9. Route the cable as shown in the figures on pages 128 (r1…r2 and r3), 129 (r4), 130 (r5) or 131 (r6…r9). 10. Connect the conductors to the appropriate terminals of the control board and tighten to 0.5…0.6 n·m (0.4 lbf·ft). 11. Tie all control cables to the provided cabl...

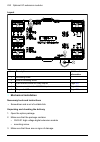

Page 128

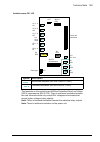

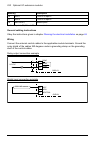

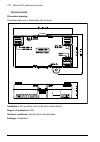

128 electrical installation pe breakers input pe motor r- r+ udc+ l1 l2 l3 t1/u t2/v t3/w r3 3 4 11 11 5 5 7 8 7 8 6 6 9 9 10 10 r 1 …r2: 0.5…0.6 n·m (0.4 lbf·ft) r3: 0.5…0.6 n·m (0.4 lbf·ft) 11 11 4 3 r1…r2.

Page 129

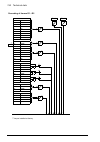

Electrical installation 129 r4 0.5...0.6 n·m (0.4 lbf·ft).

Page 130

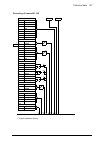

130 electrical installation r5 4 6 11 11 10 4 3 5 7 8 9 0.5...0.6 n·m (0.4 lbf·ft).

Page 131

Electrical installation 131 r6…r9 0.5...0.6 n·m (0.4 lbf·ft) 0.5...0.6 n·m (0.4 lbf·ft) m4×20 4 6 10 3 4 4 5 7 8 9 8 11 11.

Page 132: Installing Option Modules

132 electrical installation installing option modules note: in us deliveries, options are already installed at the factory. Note: if you will install the fpba - 01 module, see section fpba-01 profibus dp adapter module connectors on page 77 for suitable connector types. Mechanical installation of op...

Page 133

Electrical installation 133 r3…r5 r1…r2 3 2 3 4 6 6 7 7 4 5 5.

Page 134: Wiring The Modules

134 electrical installation wiring the modules see the appropriate option module manual for specific installation and wiring instructions. R6…r9 3 4 5 6 7.

Page 135: Reinstalling Covers

Electrical installation 135 reinstalling covers reinstalling cover, frames r1…r4 1. Reinstall the cover: put the tabs on the cover top in their counterparts on the housing (1a) and the press the cover (1b). 2. Tighten the retaining screw at the bottom with a screwdriver. 1b 2 x 2 2 1a 1b ip21 (ul ty...

Page 136

136 electrical installation reinstalling covers, frame r5 ip21 (ul type 1) 1. Reinstall the box cover: slide the cover upwards (1a) and tighten the retaining screws (1b). 2. Reinstall the module cover: press the cover at the bottom (2a) and tighten the retaining screws (2b). Ip55 (ul type 12) 1. Rei...

Page 137

Electrical installation 137 reinstalling side plates and covers, frames r6…r9 ip21 (ul type 1) 1. Reinstall the side plates of the cable box. Tighten the retaining screws with a screwdriver. 2. Slide the cover of the cable box on the module from below until the cover snaps into place. 3. Reinstall t...

Page 138: Connecting A Pc

138 electrical installation connecting a pc to be able to connect a pc to the drive, you need an assistant control panel (acs- ap-i, acs-ap-s or acs-ap-w). It is also possible to use cca-01 configuration adapter. Connect a pc to the drive with a usb data cable (usb type a usb type mini-b) as follows...

Page 139: Installation Checklist

Installation checklist 139 7 installation checklist contents of this chapter this chapter contains an installation checklist which you must complete before you start up the drive. Warnings warning! Obey the instructions in chapter safety instructions on page 13 . If you ignore them, injury or death,...

Page 140

140 installation checklist if the drive has not been powered (either in storage or unused) over one year: the electrolytic dc capacitors in the dc link of the drive have been reformed. See section replacing the auxiliary cooling fan, ip55 (ul type 12) frames r1…r2 on page 150 . There is an adequatel...

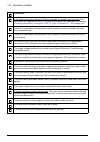

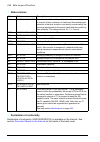

Page 141: Maintenance and Hardware

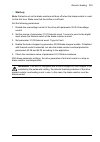

Maintenance and hardware diagnostics 141 8 maintenance and hardware diagnostics contents of this chapter the chapter contains preventive maintenance instructions and led indicator descriptions. Maintenance intervals the table below shows the maintenance tasks which can be done by the end user. The c...

Page 142: Description Of Symbols

142 maintenance and hardware diagnostics description of symbols recommended annual actions by the user recommended maintenance actions by the user action description i inspection (visual inspection and maintenance action if needed) p performance of on/off-site work (commissioning, tests, measurement...

Page 143: Heatsink

Maintenance and hardware diagnostics 143 heatsink the drive heatsink fins pick up dust from the cooling air. The drive can run into overtemperature warnings and faults if the heatsink is not clean. When necessary, clean the heatsink as follows. Warning! Obey the instructions in chapter safety instru...

Page 144: Fans

144 maintenance and hardware diagnostics fans see section maintenance intervals on page 141 for the fan replacement interval in average operation conditions. In a speed-controlled fan, the speed of the fan matches the cooling needs. This increases the life span of the fan. Main fans are speed contro...

Page 145: Type 12) Frames R1…r4

Maintenance and hardware diagnostics 145 replacing the main cooling fan, ip21 and ip55 (ul type 1 and ul type 12) frames r1…r4 warning! Obey the instructions in chapter safety instructions on page 13 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Stop ...

Page 146

146 maintenance and hardware diagnostics r4 2. Lever the fan assembly off the drive frame with for example a screwdriver (2a) and pull out the fan assembly (2b). 3. Install the fan assembly in reverse order. R4 2a.

Page 147: Type 12) Frames R5…r8

Maintenance and hardware diagnostics 147 replacing the main cooling fan, ip21 and ip55 (ul type 1 and ul type 12) frames r5…r8 warning! Obey the instructions in chapter safety instructions on page 13 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Stop ...

Page 148: Type 12) Frame R9

148 maintenance and hardware diagnostics replacing the main cooling fans, ip21 and ip55 (ul type 1 and ul type 12) frame r9 warning! Obey the instructions in chapter safety instructions on page 13 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Stop the...

Page 149: Type 12) Frames R5…r9

Maintenance and hardware diagnostics 149 replacing the auxiliary cooling fan, ip21 and ip55 (ul type 1 and ul type 12) frames r5…r9 warning! Obey the instructions in chapter safety instructions on page 13 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. ...

Page 150: R1…r2

150 maintenance and hardware diagnostics replacing the auxiliary cooling fan, ip55 (ul type 12) frames r1…r2 warning! Obey the instructions in chapter safety instructions on page 13 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Stop the drive and disc...

Page 151

Maintenance and hardware diagnostics 151 replacing the auxiliary cooling fan, ip55 (ul type 12) frame r3 warning! Obey the instructions in chapter safety instructions on page 13 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Stop the drive and disconne...

Page 152

152 maintenance and hardware diagnostics replacing the auxiliary cooling fan, ip55 (ul type 12) frame r4 warning! Obey the instructions in chapter safety instructions on page 13 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Stop the drive and disconne...

Page 153: Frames R8…r9

Maintenance and hardware diagnostics 153 replacing the second auxiliary cooling fan, ip55 (ul type 12) frames r8…r9 warning! Obey the instructions in chapter safety instructions on page 13 . Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Stop the drive a...

Page 154: Capacitors

154 maintenance and hardware diagnostics capacitors the drive intermediate dc circuit employs several electrolytic capacitors. Their lifespan depends on the operating time of the drive, loading and ambient temperature. Capacitor life can be prolonged by lowering the ambient temperature. Capacitor fa...

Page 155: Control Panel

Maintenance and hardware diagnostics 155 control panel cleaning the control panel use a soft damp cloth to clean the control panel. Avoid harsh cleaners which could scratch the display window. Replacing the battery in the control panel a battery is used in all control panels, except the basic contro...

Page 156: Leds

156 maintenance and hardware diagnostics leds drive leds there is a green power and a red fault led on the front of the drive. They are visible through the panel cover but invisible if a control panel is attached to the drive. The table below describes the drive led indications. Drive leds power and...

Page 157: Control Panel Leds

Maintenance and hardware diagnostics 157 control panel leds the assistant control panel has one led. The table below describes the control panel led indications. For more information see a cs-ap-x assistant control panels user’s manual (3aua0000085685 [english]). Control panel led, at the left edge ...

Page 158

158 maintenance and hardware diagnostics.

Page 159: Technical Data

Technical data 159 9 technical data contents of this chapter the chapter contains the technical specifications of the drive, for example ratings, sizes and technical requirements as well as provisions for fulfilling the requirements for ce, ul and other approval marks..

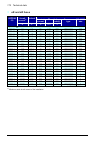

Page 160: Ratings

160 technical data ratings iec ratings see definitions and notes on page 161 . Type acs580 -01- input rating max. Current output ratings max. Losses frame size nominal use light-duty use heavy-duty use i 1 i max i n p n i ld p ld i hd p hd a a a kw a kw a kw w 3-phase u n = 400 v (380…415 v) 02a7-4 ...

Page 161: Nema Ratings

Technical data 161 nema ratings definitions type acs580 -01- input rating max. Current output ratings max. Losses air flow frame size north american type nominal use heavy-duty use i 1 i max i ld p ld i hd p hd acs580 -01- a a a hp a hp w ft 3 /min 3-phase u n = 480 v (440…480 v) 02a7-4 2.1 2.9 2.1 ...

Page 162: Sizing

162 technical data sizing drive sizing is based on the rated motor current and power. To achieve the rated motor power given in the table, the rated current of the drive must be higher than or equal to the rated motor current. Also the rated power of the drive must be higher than or equal to the rat...

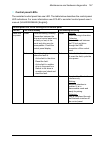

Page 163: Derating

Technical data 163 derating the load capacity ( i n , i ld , i hd ; note that i max is not derated) decreases in certain situations. In such situations, where full motor power is required, oversize the drive so that the derated value provides sufficient capacity. Note: the drivesize dimensioning pc ...

Page 164

164 technical data ambient temperature derating, ip21 (ul type 1) in the temperature range +40…50 °c (+104…122 °f), the rated output current is derated by 1% for every added 1 °c (1.8 °f). The output current can be calculated by multiplying the current given in the rating table by the derating facto...

Page 165

Technical data 165 (1.8 °f). The output current can be calculated by multiplying the current given in the rating table by the derating factor (k): 0.90 k 0.80 0.75 0.85 0.95 t +40 °c +104 °f +50 °c +122 °f +45 °c +113 °f -15 °c -59 °f … 0.825 1.00

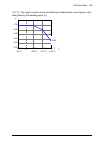

Page 166: Altitude Derating

166 technical data altitude derating in altitudes 1000…4000 m (3300…13120 ft) above sea level, the derating is 1% for every 100 m (330 ft). The output current is calculated by multiplying the current given in the rating table by the derating factor k, which for x meters (1000 m altitude and ambient ...

Page 167

Technical data 167 the altitude derating can be reduced if the temperature is below +40 °c, for example, if the temperature is 30 °c, the derating factor is 1 - 1.5% · 10 = 0.85. You can reduce the output current by 35% instead of 40% at 4000 meter above the see level. Note: check the supply network...

Page 168: Fuses (Iec)

168 technical data fuses (iec) gg as well as ur or ar fuses for protection against short-circuit in the input power cable or drive are listed below. Either fuse type can be used for frames r1…r9 if it operates rapidly enough. The operating time depends on the supply network impedance and the cross-s...

Page 169: Gg Fuses

Technical data 169 gg fuses check on the fuse time-current curve to ensure the operating time of the fuse is below 0.5 seconds. Obey the local regulations. Type acs580 -01- min. Short- circuit current 1) input current gg (iec 60269) north american type acs580 -01- nominal current i 2 t voltage ratin...

Page 170: Ur And Ar Fuses

170 technical data ur and ar fuses type acs580 -01- min. Short- circuit current 1) input current ur or ar nominal current i 2 t voltage rating bussmann type iec 60269 size a a a a 2 s v 3-phase u n = 400 or 480 v (380…415 v, 440…480 v) 02a7-4 65 2.6 25 130 690 170m1561 000 03a4-4 65 3.3 25 130 690 1...

Page 171: Fuses (Ul)

Technical data 171 fuses (ul) ul class t fuses for branch circuit protection per nec are listed below. Fast acting class t or faster fuses are recommended in the usa. Check on the fuse time- current curve to ensure the operating time of the fuse is below 0.5 seconds. Obey the local regulations. Note...

Page 172: Circuit Breakers

172 technical data circuit breakers the table below lists mcb and mccb circuit breakers that can be used with the drive. Not allowed for us installation. Type acs580 -01- mcbs and mccbs abb type max. Short- circuit tmax frame xt / t class tmax rating electronic release sace ordering code for breaker...

Page 173

Technical data 173 dimensions, weights and free space requirements frame size dimensions and weights dimensions and weights ip21 ul type 1 h1 h2 h3 h4 w d weight h1 h2 h3 h4 w d weight mm mm mm mm mm mm kg in in in in in in lb r1 332 301 355 332 125 223 4.8 13.08 11.85 13.96 13.08 4.92 8.78 10.59 r2...

Page 174

174 technical data frame size dimensions and weights ip55 ul type 12 h3 h4 w d weight h3 h4 w d weight hh hw mm mm mm mm kg in in in in lb in in r1 387 332 125 233 5.1 15.23 13.08 4.92 9.17 11.25 2.56 5.09 r2 481 432 125 239 6.7 18.93 17.02 4.92 9.41 14.80 2.56 5.10 r3 456 490 203 237 13.0 17.94 19....

Page 175

Technical data 175 see the figures in section checking the installation site on page 44 . Frame size free space, ip21 (ul type 1) and ip55 (ul type 12) vertical mounting stand alone vertical mounting side by side above below beside above below between mm in mm in mm in mm in mm in mm in r1 200 7.87 ...

Page 176

176 technical data losses, cooling data and noise the air flow direction is from bottom to top. Cooling air flow, heat dissipation and noise for stand-alone drives the table below specifies the heat dissipation in the main circuit at nominal load and in the control circuit with minimum load (i/o, op...

Page 177: +C135)

Technical data 177 cooling air flow and heat dissipation for flange mounting (option +c135) type acs580 -01- heat dissipation (option +135) air flow (option +135) frame size heatsink front heatsink front w w m 3 /h ft 3 /min m 3 /h ft 3 /min 3-phase u n = 400 or 480 v (380…415 v, 440…480 v) 145a-4 1...

Page 178: Iec

178 technical data terminal and lead-through data for the power cables iec input, motor, resistor and dc cable lead-throughs, maximum wire sizes (per phase) and terminal screw sizes and tightening torques ( t ) are given below. Frame size cable lead- throughs l1, l2, l3, t1/u, t2/v, t3/w terminals g...

Page 179

Technical data 179 frame size cable lead- throughs r+, r-, udc+ and udc- terminals per cable type Ø 1) min wire size (solid/ stranded) 3) max wire size (solid/ stranded) t (wire screw) pcs mm mm 2 mm 2 m… n·m r1 1 23 0.20/0.25 6/4 2) 1.2…1.5 r2 1 23 0.5/0.5 16/16 2) 1.2…1.5 r3 1 23 0.5/0.5 35/25 2) ...

Page 180

180 technical data us input, motor, resistor and dc cable lead-throughs, maximum wire sizes (per phase) and terminal screw sizes and tightening torques ( t ) are given below. Frame size cable lead- throughs l1, l2, l3, t1/u, t2/v, t3/w terminals grounding terminals per cable type Ø 1) min wire size1...

Page 181

Technical data 181 frame size cable lead- throughs r+, r-, udc+ and udc- terminals per cable type Ø 1) min wire size (solid/ stranded) 3) max wire size (solid/ stranded) t (wire screw) pcs in awg awg m… lbf·ft r1 1 0.906 24 10 2) 0.4 r2 1 0.906 20 6 2) 1.1 r3 1 0.906 20 2 2) 3.3 r4 1 1.54 50 1 2) 3....

Page 182: Iec

182 technical data terminal and lead-through data for the control cables iec control cable lead-throughs, wire sizes and tightening torques ( t ) are given below. Us control cable lead-throughs, wire sizes and tightening torques ( t ) are given below. Frame size cable lead- throughs control cable en...

Page 183: Motor Connection Data

Technical data 183 electrical power network specification voltage ( u 1 ) input voltage range 3~ 380…480 v ac. This is indicated in the type designation label as typical input voltage levels 3~ 400/480 v ac. Network type public low voltage networks. Tn (grounded), it (ungrounded) and corner-grounded...

Page 184

184 technical data maximum recommended motor cable length operational functionality and motor cable length the drive is designed to operate with optimum performance with the following maximum motor cable lengths. Note: conducted and radiated emissions of these motor cable lengths do not comply with ...

Page 185

Technical data 185 emc compatibility and motor cable length to comply with the european emc directive (standard en 61800-3), use the following maximum motor cable lengths at 4 khz switching frequency. See the table below. Note 1: radiated and conducted emissions are according to category c2 with a i...

Page 186: Control Connection Data

186 technical data control connection data external power supply maximum power: frames r1…r5: 25 w, 1.04 a at 24 v ac/dc ±10% with an option module frames r6…r9: 36 w, 1.50 a at 24 v ac/dc ±10% as standard supplied from an external power supply through option module cmod-01 or cmod-02 with frames r1...

Page 187

Technical data 187 relay outputs ro1…ro3 (term. 19…27) 250 v ac / 30 v dc, 2 a terminal size: frames r1…r5: 0.14…1.5 mm 2 frames r6…r9: 0.14…2.5 mm 2 see sections isolation areas, r1…r5 on page 188 and isolation areas, r6…r9 on page 189 . Analog inputs ai1 and ai2 (term. 2 and 5) current/voltage inp...

Page 188

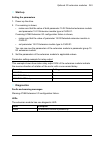

188 technical data isolation areas, r1…r5 x6 ro3 x7 ro2 x8 ro1 symbol description reinforced insulation (iec/en 61800-5-1:2007) functional insulation (iec/en 61800-5-1:2007) below altitudes 4000 m (6562 ft): the terminals on the control board fulfill the protective extra low voltage (pelv) requireme...

Page 189

Technical data 189 isolation areas, r6…r9 symbol description reinforced insulation (iec/en 61800-5-1:2007) functional insulation (iec/en 61800-5-1:2007) the terminals on the control board fulfill the protective extra low voltage (pelv) requirements (en 50178): there is reinforced insulation between ...

Page 190

190 technical data grounding of frames r1…r5 x1 1 scr 2 ai1 3 agnd 4 +10v 5 ai2 6 agnd 7 ao1 8 ao2 9 agnd x2 & x3 10 +24v 11 dgnd 12 dcom 13 di1 14 di2 15 di3 16 di4 17 di5 18 di6 x6, x7, x8 19 ro1c 20 ro1a 21 ro1b 22 ro2c 23 ro2a 24 ro2b 25 ro3c 26 ro3a 27 ro3b x5 29 b+ 30 a- 31 dgnd x4 34 out1 35 ...

Page 191

Technical data 191 grounding of frames r6…r9 x1 1 scr 2 ai1 3 agnd 4 +10v 5 ai2 6 agnd 7 ao1 8 ao2 9 agnd x2 & x3 10 +24v 11 dgnd 12 dcom 13 di1 14 di2 15 di3 16 di4 17 di5 18 di6 x6, x7, x8 19 ro1c 20 ro1a 21 ro1b 22 ro2c 23 ro2a 24 ro2b 25 ro3c 26 ro3a 27 ro3b x5 29 b+ 30 a- 31 dgnd x4 34 out1 35 ...

Page 192: Efficiency

192 technical data auxiliary circuit power consumption maximum external power supply: frames r1…r5: 25 w, 1.04 a at 24 v ac/dc (with option modules cmod-01, cmod-02) frames r6…r9: 36 w, 1.50 a at 24 v ac/dc (as standard, terminals 40…41) efficiency approximately 98% at nominal power level degree of ...

Page 193

Technical data 193 relative humidity 5 to 95% max. 95% max. 95% no condensation allowed. Maximum allowed relative humidity is 60% in the presence of corrosive gases. Contamination levels (iec 60721-3-x) iec 60721-3-3: 2002: classification of environmental conditions - part 3-3: classification of gro...

Page 194: Materials

194 technical data shock/drop (ista) not allowed r1…r4 (ista 1a): drop, 6 faces, 3 edges and 1 corner r5…r9 (ista 3e): shock, incline impact: 1.1 m/s (3.61 ft/s) shock, rotational edge drop: 200 mm (7.9 in) 1) for neutral-grounded tn and tt systems and non-corner grounded it systems. See also sectio...

Page 195

Technical data 195 en 60204-1:2006 + ac:2010 safety of machinery. Electrical equipment of machines. Part 1: general requirements . Provisions for compliance: the final assembler of the machine is responsible for installing - emergency-stop device - supply disconnecting device. Iec/en 60529:1992 + a2...

Page 196: Ce Marking

196 technical data ce marking a ce mark is attached to the drive to verify that the drive follows the provisions of the european low voltage, emc and rohs directives.The ce marking also verifies that the drive, in regard to its safety functions (such as safe torque off), conforms with the machinery ...

Page 197: Definitions

Technical data 197 compliance with the en 61800-3:2004 + a1:2012 definitions emc stands for e lectro m agnetic c ompatibility. It is the ability of electrical/electronic equipment to operate without problems within an electromagnetic environment. Likewise, the equipment must not disturb or interfere...

Page 198: Category C2

198 technical data category c2 the emission limits are complied with the following provisions: 1. The motor and control cables are selected as specified in this manual. 2. The drive is installed according to the instructions given in this manual. 3. For the maximum motor cable length with 4 khz swit...

Page 199: Category C4

Technical data 199 category c4 if the provisions under category c3 cannot be met, the requirements of the standard can be met as follows: 1. It is ensured that no excessive emission is propagated to neighboring low-voltage networks. In some cases, the inherent suppression in transformers and cables ...

Page 200: Ul Marking

200 technical data ul marking the drive is culus listed. Ul checklist • make sure that the drive type designation label includes the culus listed marking. • caution - risk of electric shock . After disconnecting the input power, always wait for 5 minutes to let the intermediate circuit capacitors di...

Page 201: China Rohs Marking

Technical data 201 china rohs marking the people’s republic of china electronic industry standard (sj/t 11364-2014) specifies the marking requirements for hazardous substances in electronic and electrical products. The green mark is attached to the drive to verify that it does not contain toxic and ...

Page 202

202 technical data or any other network (as the case may be). Customer shall establish and maintain any appropriate measures (such as but not limited to the installation of firewalls, application of authentication measures, encryption of data, installation of anti-virus programs, etc) to protect the...

Page 203: Dimension Drawings

Dimension drawings 203 10 dimension drawings contents of this chapter this chapter shows the dimension drawings of the acs580-01. The dimensions are given in millimeters and [inches]..

Page 204: Frame R1, Ip21 (Ul Type 1)

204 dimension drawings frame r1, ip21 (ul type 1) 3a x d 10 00 06 01 65 2.

Page 205

Dimension drawings 205 frame r1, ip55 (ul type 12) 3a x d 100 00 60 16 99.

Page 206: Frame R2, Ip21 (Ul Type 1)

206 dimension drawings frame r2, ip21 (ul type 1) 3a x d 10 00 06 02 39 8.

Page 207

Dimension drawings 207 frame r2, ip55 (ul type 12) 3a x d 10 00 06 02 40 1.

Page 208: Frame R3, Ip21 (Ul Type 1)

208 dimension drawings frame r3, ip21 (ul type 1) 3a x d 10 00 06 02 46 6.

Page 209

Dimension drawings 209 frame r3, ip55 (ul type 12) 3a x d 10 00 06 02 51 9.

Page 210: Frame R4, Ip21 (Ul Type 1)

210 dimension drawings frame r4, ip21 (ul type 1) 3a x d 10 00 03 32 43 0

Page 211

Dimension drawings 211 frame r4, ip55 (ul type 12) 3a x d 10 0004 27 93 3.

Page 212: Frame R5, Ip21 (Ul Type 1)

212 dimension drawings frame r5, ip21 (ul type 1) 3a x d 10 00 04 12 280

Page 213

Dimension drawings 213 frame r5, ip55 (ul type 12) 3a x d 10 00 03 86 01 7.

Page 214: Frame R6, Ip21 (Ul Type 1)

214 dimension drawings frame r6, ip21 (ul type 1) 3a x d 10 00 02 58 70 5.

Page 215

Dimension drawings 215 frame r6, ip55 (ul type 12) 3 a x d 10 00 03 30 66 7.

Page 216: Frame R7, Ip21 (Ul Type 1)

216 dimension drawings frame r7, ip21 (ul type 1) 3a x d 10 00 02 58 99 5.

Page 217

Dimension drawings 217 frame r7, ip55 (ul type 12) 3a x d 10 00 03 30 93 2.

Page 218: Frame R8, Ip21 (Ul Type 1)

218 dimension drawings frame r8, ip21 (ul type 1) 3a x d 10 00 02 87 67 0

Page 219

Dimension drawings 219 frame r8, ip55 (ul type 12) 3a x d 10 00 03 32 44 6.

Page 220: Frame R9, Ip21 (Ul Type 1)

220 dimension drawings frame r9, ip21 (ul type 1) 3a x d 10 00 02 87 42 8.

Page 221

Dimension drawings 221 frame r9, ip55 (ul type 12) 3a x d 10 00 03 34 31 0

Page 222

222 dimension drawings.

Page 223: Resistor Braking

Resistor braking 223 11 resistor braking contents of this chapter the chapter describes how to select the brake resistor and cables, protect the system, connect the brake resistor and enable resistor braking. Operation principle and hardware description the brake chopper handles the energy generated...

Page 224

224 resistor braking resistor braking, frames r1…r3 planning the braking system selecting the brake resistor frames r1…r3 have an built-in brake chopper as standard equipment. The brake resistor is selected using the table and equations presented in this section. 1. Determine the required maximum br...

Page 225

Resistor braking 225 the table shows reference resistor types for the maximum braking power. Warning! Do not use a brake resistor with a resistance below the minimum value specified for the particular drive. The drive and the internal chopper are not able to handle the overcurrent caused by the low ...

Page 226

226 resistor braking selecting and routing the brake resistor cables use a shielded cable with the conductor size specified in section terminal and lead- through data for the power cables on page 178 . Minimizing electromagnetic interference follow these rules in order to minimize electromagnetic in...

Page 227

Resistor braking 227 placing the brake resistor install the resistors outside the drive in a place where they will cool. Arrange the cooling of the resistor in a way that: • no danger of overheating is caused to the resistor or nearby materials • the temperature of the room the resistor is located i...

Page 228: Mechanical Installation

228 resistor braking we recommend that you also wire the thermal switch to a digital input of the drive. Mechanical installation all brake resistors must be installed outside the drive. Follow the resistor manufacturer’s instructions. Electrical installation checking the insulation of the assembly f...

Page 229: Start-Up

Resistor braking 229 start-up note: protective oil on the brake resistors will burn off when the brake resistor is used for the first time. Make sure that the airflow is sufficient. Set the following parameters: 1. Disable the overvoltage control of the drive with parameter 30.30 overvoltage control...

Page 230

230 resistor braking resistor braking, frames r4…r9 planning the braking system frames r4…r9 need external brake choppers and resistors. The table below lists suitable choppers and resistors. For more information, see nbra-6xx braking choppers installation and start-up guide (3afy58920541 [english])...

Page 231: Safe Torque Off Function

Safe torque off function 231 12 safe torque off function contents of this chapter this chapter describes the safe torque off (sto) function of the drive and gives instructions for its use. Description the safe torque off function can be used, for example, to construct safety or supervision circuits ...

Page 232

232 safe torque off function the safe torque off function of the drive complies with these standards: the function also corresponds to prevention of unexpected start-up as specified by en 1037:1995 + a1:2008 and uncontrolled stop (stop category 0) as specified in en/iec 60204-1:2016. Compliance with...

Page 233: Connection Principle

Safe torque off function 233 connection principle connection with internal +24 v dc power supply out2 out1 + 24 v dc in1 in2 t1/u, t2/v, t3/w control board sgnd + 24 v dc sto udc+ udc- a drive 34 35 36 37 38 control logic k.

Page 234

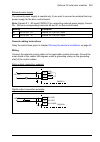

234 safe torque off function connection with internal +24 v dc power supply, single line out2 out1 in1 in2 t1/u, t2/v, t3/w control board sgnd sto udc+ udc- a drive 34 35 36 37 38 control logic k + 24 v dc + 24 v dc notes: • both sto inputs (in1, in2) must be connected to the activation switch. Othe...

Page 235: Wiring Examples

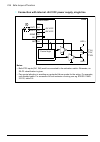

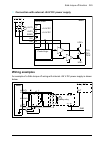

Safe torque off function 235 connection with external +24 v dc power supply wiring examples an example of a safe torque off wiring with internal +24 v dc power supply is shown below. + out2 out1 in1 in2 t1/u, t2/v, t3/w control board sgnd 24 v dc sto udc+ udc- a drive 34 35 36 37 38 control logic + ...

Page 236: Activation Switch

236 safe torque off function an example of a safe torque off wiring with external +24 v dc power supply is shown below. For information on the specifications of the sto input, see chapter control connection data (page 186 ). Activation switch in the wiring diagram above (page 235 ), the activation s...

Page 237: Operation Principle

Safe torque off function 237 grounding of protective shields • ground the shield in the cabling between the activation switch and the control board at the control board. • ground the shield in the cabling between two control boards at one control board only. Operation principle 1. The safe torque of...

Page 238: Acceptance Test Reports

238 safe torque off function functional safety, as required by iec 61508-1 clause 6. The test procedures and report must be documented and signed by this person. Acceptance test reports signed acceptance test reports must be stored in the logbook of the machine. The report shall include documentatio...

Page 239: Acceptance Test Procedure

Safe torque off function 239 acceptance test procedure after wiring the safe torque off function, validate its operation as follows. If a cptc-02 module is installed, see cptc-02 atex-certified thermistor protection module, ex ii (2) gd (+l537+q971) user's manual (3axd50000030058 [english]). Action ...

Page 240: Use

240 safe torque off function use 1. Open the activation switch, or activate the safety functionality that is wired to the sto connection. 2. Sto inputs on the drive control board de-energize, and the drive control board cuts off the control voltage from the output igbts. 3. The control program gener...

Page 241

Safe torque off function 241 warning! With permanent magnet motors or synchronous reluctance [synrm] motors only: in case of a multiple igbt power semiconductor failure, the drive system can produce an alignment torque which maximally rotates the motor shaft by 180/ p degrees (with permanent magnet ...

Page 242: Maintenance

242 safe torque off function maintenance after the operation of the circuit is validated at start-up, the sto function shall be maintained by periodic proof testing. In high demand mode of operation, the maximum proof test interval is 20 years. In low demand mode of operation, the maximum proof test...

Page 243

Safe torque off function 243 see the drive firmware manual for the indications generated by the drive, and for details on directing fault and warning indications to an output on the control board for external diagnostics. Any failures of the safe torque off function must be reported to abb..

Page 244: Safety Data

244 safe torque off function safety data the safety data for the safe torque off function is given below. Note: the safety data is calculated for redundant use, and does not apply if both sto channels are not used. • the following temperature profile is used in safety value calculations: • 670 on/of...

Page 245

Safe torque off function 245 • the sto is a type a safety component as defined in iec 61508-2. • relevant failure modes: • the sto trips spuriously (safe failure) • the sto does not activate when requested a fault exclusion on the failure mode “short circuit on printed circuit board” has been made (...

Page 246: Abbreviations

246 safe torque off function abbreviations declaration of conformity declaration of conformity (3axd10000302783) is available on the internet. See section document library on the internet on the inside of the back cover. Abbr. Reference description cat. En iso 13849-1:2015 classification of the safe...

Page 247: Certificate

Safe torque off function 247 certificate tÜv certificate (3axd10000302787) is available on the internet. See section document library on the internet on the inside of the back cover..

Page 248

248 safe torque off function.

Page 249: Optional I/o Extension

Optional i/o extension modules 249 13 optional i/o extension modules contents of this chapter this chapter describes how to install and start up the optional chdi-01, cmod-01 and cmod-02 multifunction extension modules. The chapter also contains diagnostics and technical data. Chdi-01 115/230 v digi...

Page 250: Mechanical Installation

250 optional i/o extension modules layout mechanical installation necessary tools and instructions • screwdriver and a set of suitable bits. Unpacking and checking the delivery 1. Open the option package. 2. Make sure that the package contains: • chdi-01 high voltage digital extension module • mount...

Page 251: Electrical Installation

Optional i/o extension modules 251 installing the module see chapter installing option modules on page 132 . Electrical installation warnings warning! Obey the instructions in chapter safety instructions on page 13 . If you ignore them, injury or death, or damage to the equipment can occur. If you a...

Page 252

252 optional i/o extension modules general cabling instructions obey the instructions given in chapter planning the electrical installation on page 65 . Wiring connect the external control cables to the applicable module terminals. Ground the outer shield of the cables 360 degrees under a grounding ...

Page 253: Start-Up

Optional i/o extension modules 253 start-up setting the parameters 1. Power up the drive. 2. If no warning is shown, • make sure that the value of both parameter 15.02 detected extension module and parameter 15.01 extension module type is chdi-01. If warning a7ab extension i/o configuration failure ...

Page 254: Technical Data

254 optional i/o extension modules technical data dimension drawing: the dimensions are in millimeters and [inches]. Installation: into an option slot on the drive control board degree of protection: ip20 ambient conditions: see the drive technical data. Package: cardboard.

Page 255

Optional i/o extension modules 255 isolation areas: relay outputs (50…52, 53…55): • wire size max. 1.5 mm 2 • minimum contact rating: 12 v / 10 ma • maximum contact rating: 250 v ac / 30 v dc / 2 a • maximum breaking capacity: 1500 va 115/230 v inputs (70…78): • wire size max. 1.5 mm 2 • input volta...

Page 256: Safety Instructions

256 optional i/o extension modules cmod-01 multifunction extension module (external 24 v ac/dc and digital i/o) safety instructions warning! Obey the safety instructions for the drive. If you ignore the safety instructions, injury or death can occur. Hardware description product overview the cmod-01...

Page 257: Mechanical Installation

Optional i/o extension modules 257 layout mechanical installation necessary tools and instructions • screwdriver and a set of suitable bits. Unpacking and checking the delivery 1. Open the option package. 2. Make sure that the package contains: • cmod-01 multifunction extension module • mounting scr...

Page 258: Electrical Installation

258 optional i/o extension modules installing the module see chapter installing option modules on page 132 . Electrical installation warnings warning! Obey the instructions in chapter safety instructions on page 13 . If you ignore them, injury or death, or damage to the equipment can occur. If you a...

Page 259

Optional i/o extension modules 259 external power supply the external power supply is needed only if you want to connect an external back-up power supply for the drive control board. Note: frames r1…r5 need cmod-01 for connecting external power supply, frames r6…r9 have corresponding terminals 40 an...

Page 260: Start-Up

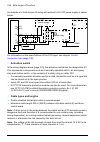

260 optional i/o extension modules frequency output connection example external power supply connection example warning! Do not connect the +24 v ac cable to the control board ground when the control board is powered using an external 24 v ac supply. Start-up setting the parameters 1. Power up the d...

Page 261: Diagnostics

Optional i/o extension modules 261 examples are given below. Parameter setting example for relay output this example shows how make relay output ro4 of the extension module indicate the reverse direction of rotation of the motor with a one-second delay. Parameter setting example for digital output t...

Page 262: Technical Data

262 optional i/o extension modules technical data dimension drawing: the dimensions are in millimeters and [inches]. Installation: into an option slot on the drive control board degree of protection: ip20 ambient conditions: see the drive technical data. Package: cardboard.

Page 263

Optional i/o extension modules 263 isolation areas: relay outputs (50…52, 53…55): • wire size max. 1.5 mm 2 • minimum contact rating: 12 v / 10 ma • maximum contact rating: 250 v ac / 30 v dc / 2 a • maximum breaking capacity: 1500 va6 transistor output (42…44): • wire size max. 1.5 mm 2 • type: tra...

Page 264: Safety Instructions

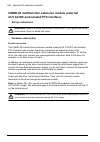

264 optional i/o extension modules cmod-02 multifunction extension module (external 24 v ac/dc and isolated ptc interface) safety instructions warning! Obey the safety instructions for the drive. If you ignore the safety instructions, injury or death can occur. Hardware description product overview ...

Page 265: Mechanical Installation

Optional i/o extension modules 265 layout mechanical installation necessary tools and instructions • screwdriver and a set of suitable bits item description additional information 1 grounding screw page 265 2 hole for mounting screw page 265 3 2-pin terminal block for motor thermistor connection pag...

Page 266: Electrical Installation