- DL manuals

- ABB

- DC Drives

- ACS580-07

- Hardware Manual

ABB ACS580-07 Hardware Manual

Summary of ACS580-07

Page 1

Abb general purpose drives hardware manual acs580-07.

Page 3: Hardware Manual

Hardware manual acs580-07 table of contents 1. Safety instructions 4. Mechanical installation 5. Guidelines for planning the electrical installation 9. Start-up © 2018 abb oy. All rights reserved. 3axd50000045815 rev c en effective: 2018-02-07.

Page 5: Table Of Contents

Table of contents 1 safety instructions 13 contents of this chapter ........................................................................... 13 use of warnings and notes ....................................................................... 14 general safety in installation, start-up and mainten...

Page 6

39 plinth height (options +c164 and +c179) .................................................. 39 empty cubicles (options +c196 to +c201) ................................................. 40 du/dt filter (option +e205) ..................................................................... 40 molded ca...

Page 7

63 power cable types for limited use ........................................................ 63 not allowed power cable types ........................................................... 63 motor cable shield .............................................................................. 64 selecting...

Page 8

89 connecting the safe torque off circuit ....................................................... 90 connecting external power supply wires for the cabinet heater (option +g300) ...... 90 setting the voltage range of the auxiliary control voltage transformer (t21) .............. 91 connecting a pc ....

Page 9

115 replacing the air filters (ip54 / ul type 12) ................................................... 115 inlet (door) filters (ip54 / ul type 12) ....................................................... 116 outlet (roof) filters (ip54 / ul type 12) ......................................................

Page 10

189 electrical power network specification .......................................................... 189 motor connection data ............................................................................ 189 control unit connection data .................................................................

Page 11

222 wiring ................................................................................................ 222 activation switch ................................................................................ 222 cable types and lengths ................................................................

Page 12

242 electrical installation ........................................................................... 242 necessary tools and instructions ......................................................... 242 terminal designations ...................................................................... 243 ...

Page 13: Safety Instructions

Safety instructions contents of this chapter this chapter contains the safety instructions which you must obey when you install, start up and do maintenance work on the drive. If you ignore the safety instructions, injury, death or damage can occur. Use of warnings and notes warnings tell you about ...

Page 14

General safety in installation, start-up and maintenance these instructions are for all personnel who do work on the drive. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. • keep the drive in its package until you install it. After unpacki...

Page 15

• frames r10 and r11: to prevent the drive module from falling, attach its top lifting lugs with chains to the cabinet lifting lug before you push the module into the cabinet and pull it from the cabinet. Push the module into the cabinet and pull it from the cabinet carefully preferably with help fr...

Page 16

• vacuum clean the area around the drive before the start-up to prevent the drive cooling fan from drawing the dust inside the drive. • make sure that there is sufficient cooling. See the technical data. • keep the cabinet doors closed when the drive is powered. With the doors open, a risk of a pote...

Page 17

• if you have a permanent magnet motor connected to the drive, disconnect the motor from the drive with a safety switch or by other means. • make sure that re-connection is not possible. Lock the disconnectors to open position and attach a warning notice to them. • disconnect any external power sour...

Page 18

Measuring points of frames r10 and r11 are shown below. You can also remove the metallic shield and measure through the holes in the clear plastic shroud behind it. L1 l2 l3 7. Install temporary grounding as required by the local regulations. 8. Ask the person in control of the electrical installati...

Page 19

Note: • the motor cable terminals of the drive are at a dangerous voltage when the input power is on, regardless of whether the motor is running or not. • when the input power is on, the drive dc bus is at a dangerous voltage. • external wiring can supply dangerous voltages to the relay outputs of t...

Page 20

Note: • you can use power cable shields as grounding conductors only when their conductivity is sufficient. • as the normal touch current of the drive is higher than 3.5 ma ac or 10 ma dc, you must use a fixed protective earth connection. See standard iec/en 61800-5-1, 4.3.5.5.2. Additional instruct...

Page 21: Contents Of This Chapter

Introduction to the manual contents of this chapter this chapter describes the manual. It contains a flowchart of steps in checking the delivery, installing and starting up the drive. The flowchart refers to chapters/sections in this manual and to other manuals. Target audience this manual is intend...

Page 22

Code name 3axd50000171835 emergency stop, stop category 0 (option +q963) without opening main contactor with safety relay for acs580-07, ach580-07 and acq580-07 drives user's manual 3axd50000030058 cptc-02 atex-certified thermistor protection module, ex ii (2) gd (+l537+q971) user's manual 3afe68615...

Page 23: Terms And Abbreviations

See task checking the insulation of the motor and motor cable (page 76) check the insulation of the supply cable, the motor and the motor cable. Connecting the power cables (page 74) , connecting the control cables (page 84) connect the power cables. Connect the control cables. Installation checklis...

Page 24

24.

Page 25: Description

Operation principle and hardware description contents of this chapter this chapter briefly describes the operation principle and construction of the drive. Product overview the acs580-07 is an air-cooled cabinet-installed drive for controlling asynchronous ac induction motors and permanent magnet mo...

Page 26

■ single-line circuit diagram of the drive r11 q1 q2 m 3 ~ t21 t1 r12 q1 q2 t21 t1 r8…r11 r6 r7 f22 f21 f22 r11 m 3 ~ r12 f21 in frames r6 and r7: switch fuse or molded case circuit breaker (option +f289). In frames r8 to r11: switch-disconnector or molded case circuit breaker (option +f289). Q1 lin...

Page 27

■ general information on the cabinet layout ip42 ul type 1 (option +b054) ip21 ■ cabinet layout – r6 and r7 (bottom entry and exit of cables) the cabinet layout of frame r7 with dut/dt filter (option +e205) is shown below. Degree of protection ip42 (option +b054). Frame r6 looks similar. Operation p...

Page 28

A b c 7 4 4 3 1 5 5 2 8 17 18 11 10 12 15 16 20 9 13 6 19 14 auxiliary voltage transformer t21 10 cabinet door closed a motor cable connection terminals 11 cabinet door open b note: for drives with no du/dt filter (option +e205), the motor cables are connected to the drive module terminals. Input ca...

Page 29

■ cabinet layout – r8 and r9 (bottom entry and exit of cables) the cabinet layout of frame r9 with du/dt filter (option +e205) is shown below. Degree of protection ip42 (option +b054). Frame r8 looks similar. 6 21 17 18 8 7 4 4 3 1 5 2 a b c 5 11 10 13 15 16 12 20 9 19 14 auxiliary voltage transform...

Page 30

■ mounting plate – r6 to r9 the components and terminals on the mounting plate of frames r6 to r9 are shown below. The layout of frames r6 and r7 is similar. External main contactor control x3 switch-disconnector and miniature circuit breaker for cabinet heater (option +g300) +g300 indication of mai...

Page 31

X251, x4, x6, x56, x53, x51, x55, x18 and x19: for internal use. Terminals for 1 2 3 4 pe x250 1 2 3 4 4 3 2 1 pe pe 1 2 3 4 5 6 - x289 1 2 3 4 5 6 6 5 4 3 2 1 auxiliary contacts of line contactor (option +f250) x250 auxiliary contacts of molded case circuit breaker (op- tion +f289) x289 push button...

Page 32

■ cabinet layout – r10 and r11 (bottom entry and exit of cables) 6 5 4 3 2 a b 1 7 11 14 8 9 12 10 10 13 main switch-disconnector 7 cabinet door closed a ac fuses 8 cabinet door open b line contactor (option +f250) 9 gratings for cooling air out 1 lifting lugs 10 operating switch 2 drive control uni...

Page 33

C 15 18 17 16 19 input cable connection terminals 17 cabinet door open, mounting plates and cabinet shrouds removed c drive module 18 power and control cable entries 15 auxiliary voltage transformer t21 19 motor cable connection terminals 16 mounting plate the components and terminals on the mountin...

Page 34

Indication of the status of the molded case circuit breaker (option +f289) x289 drive control unit a41 connection terminals for cabinet heater (option +g300) x300 emergency stop relay for options +q951 and +q963 a61 connection of external emergency stop button (options +q951 and q963) x951 switch-di...

Page 35

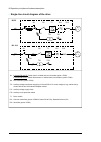

X251, x4, x6, x56, x53, x51, x55, x18 and x19: for internal use. ■ cooling air flow the figure below shows cooling air flow in frames r6 to r9 (side view) and in frames r10 and r11 (front view). R6…r9 r10, r11 ■ overview of power and control connections the diagram shows the power connections and co...

Page 36

L1 l2 l3 pe u2 v2 w2 m 3 ~ l1 l2 l3 pe . . . Slot 2 slot 1 .......... .......... .......... .......... .......... .......... 4 3 2 1 .. . 5 6 . . . 7 8 9 x12 option slot 1 for optional fieldbus adapter modules 1 option slot 2 for optional i/o extension modules 2 embedded fieldbus connector 3 panel p...

Page 37

■ door switches and lights 1 2 3 4 5 6 description label in local language label in english ready pilot light (option +g327) - ready 1 run pilot light (option+g328) - run 2 fault pilot light (option +g329) - fault 3 operating switch with option +f250 0 opens the main contactor (q2) and disables star...

Page 38

See the firmware manual or acx-ap-x assistant control panel user’s manual (3aua0000085685 [english]). 2 1 control by pc tools there is a usb connector on the front of the panel that can be used to connect a pc to the drive. When a pc is connected to the control panel, the control panel keypad is dis...

Page 39

The equipment is protected … ip code second numeral first numeral against dripping (vertically falling drops) against ingress of solid foreign objects >12.5 mm ip21 against dripping (15° tilting) water against ingress of solid foreign objects > 1 mm ip42 against splashing water dust-protected ip54 i...

Page 40

■ du/dt filter (option +e205) the du/dt filter protects the motor insulating system by reducing the voltage rise speed at the motor terminals. The filter also protects the motor bearings by reducing the bearing currents. More information on when the option is required: see section examining the comp...

Page 41: Type Designation Label

• stranded wire without ferrule 0.2 to 2.5 mm 2 (24 to 12 awg). Stripping length: 10 mm (0.5 in). Note: the option modules inserted in the slots of the control unit are not wired to the additional terminal block. The customer must connect the option module control wires directly to the modules. Type...

Page 42

Description code basic codes product series acs580 when no options are selected: cabinet-installed drive, ip21, main switch, ac fuses, acs-ap-s assistant control panel, for frames r6 to r9 emc filtering for first environment tn grounded systems (category c2), for frames r10 and r11 emc filtering for...

Page 43

Description code cabinet options cabinet heater (external supply). See cabinet heater with external supply (option +g300) (page 40) . G300 ready pilot light, white g327 run pilot light, green g328 fault pilot light, red g329 cabling top entry of cables. Additional channel: 125 mm (4.92 in) in cabine...

Page 44

Description code emergency stop of category 0 with opening the main contactor or breaker q951 emergency stop, category 0 without opening main contactor with safety relay q963 atex-certified safe disconnection function, ex ii (2) gd. Requires +l537 q971 printed documentation (manuals, dimensional dra...

Page 45: Mechanical Installation

Mechanical installation contents of this chapter this chapter describes the mechanical installation procedure of the drive. Examining the installation site examine the installation site: • the installation site is sufficiently ventilated or cooled to transfer away the drive losses. See the technical...

Page 46: Necessary Tools

Do not install the drive on an elevated platform or a recess. The module extraction/installation ramp included with the drive is only suitable for a height difference of 50 mm maximum (ie. The standard plinth height of the drive). Necessary tools the tools required for moving the unit to its final p...

Page 47

Vertical package: 1088 2321 a b 1 lifting the transport package with slings. A lifting points 1 lifting the transport package with forklift b mechanical installation 47.

Page 48

■ unpacking the transport package this drawing shows the layout of the horizontal transport package. 4 3 1 5 2 6 1 timber 5 bracket for attaching the drive to the wooden pallet 1 drive cabinet 6 cardboard packing hood 2 - - wooden pallet 3 unpack the horizontal transport package as follows: 1. Cut t...

Page 49

• drive cabinet • option modules (if ordered) installed onto the control unit at the factory • appropriate drive and option module manuals • delivery documents. Check that there are no signs of damage. Before attempting installation and operation, check the information on the type designation labels...

Page 50

Lift the cabinet to its position. Maximum allowed angle of the lifting slings is 20° (10° for frames r10 and r11, ip54). Max. 20 ° max. 1 0 ° r10, r11 ip54 ■ moving the cabinet after unpacking move drive cabinet carefully in the upright position. Avoid tilting. The center of gravity of the cabinet i...

Page 51

Final placement move the cabinet into its final position with an iron bar. Place a wooden piece at the bottom edge of the cabinet in order not to damage the cabinet frame with the iron bar. Attaching the cabinet to the floor and wall or roof ■ general rules • install the drive cabinet in an upright ...

Page 52

Note 1: make height adjustments before attaching the cabinet with metal shims between the cabinet bottom and the floor. Note 2: if you remove the lifting eyes, attach the bolts back to retain the degree of protection of the cabinet. ■ attaching methods attach the cabinet to the floor from the front ...

Page 53: Miscellaneous

Alternative 2 – using the holes inside the cabinet 1. Attach the cabinet to the floor through the bottom attaching holes with m10 to m12 (3/8” to 1/2”) bolts. The recommended maximum distance between the front edge attaching points is 800 mm (31.5”). 2. If the back attaching holes are not accessible...

Page 54

Connected improperly, the welding circuit can damage electronic circuits in the cabinet. Warning! Do not inhale the welding fumes. 54 mechanical installation.

Page 55: Installation

Guidelines for planning the electrical installation contents of this chapter this chapter contains instructions for planning the electrical installation of the drive. Some instructions are mandatory to follow in every installation, others provide useful information that only concerns certain applica...

Page 56

Examining the compatibility of the motor and drive use an asynchronous ac induction motors, permanent magnet synchronous motors, ac induction servomotors or abb synchronous reluctance motors (synrm motors) with the drive. Select the motor size and drive type from the rating tables on basis of the ac...

Page 57

This table shows the requirements when an abb motor is in use. Requirement for nominal ac supply voltage motor type abb du/dt and common mode filters, insulated n-end motor bearings motor insula- tion system p n ≥ 350 kw or frame size ≥ iec 400 100 kw ≤ p n kw or iec 315 ≤ frame size p n and frame s...

Page 58

This table shows the requirements when a non-abb motor is in use. Requirement for nominal ac supply voltage motor type abb du/dt and common mode filters, insulated n-end motor bearings motor insula- tion system p n ≥ 350 kw or frame size ≥ iec 400 100 kw ≤ p n kw or iec 315 ≤ frame size p n and fram...

Page 59

Availability of du/dt filter and common mode filter by drive type availability of common mode filter (cmf) availability of du/dt filter product type +e208 +e205 acs580-07 additional requirements for explosion-safe (ex) motors if you will use an explosion-safe (ex) motor, follow the rules in the requ...

Page 60

Requirement for nominal ac supply voltage abb du/dt and common mode filters, insulated n- end motor bearings motor insulation system 100 kw p n iec 315 iec 400 p n size 134 hp p n nema 500 nema 580 p n + n or cmf + n or cmf standard: Û ll = 1300 v u n ≤ 500 v + n + d u /d t + cmf + d u /d t + (n or ...

Page 61

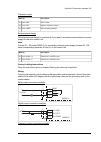

0.0 0.5 1.0 1.5 2.0 2.5 3.0 l (m) du/dt u n -------------(1/ p s) Û ll / u n a b Û ll / u n l (m) du/dt u n -------------(1/ p s) 1.0 1.0 5.0 4.0 3.0 2.0 100 200 300 150 250 350 50 0 100 200 300 150 250 350 50 0 drive with du/dt filter a drive without du/dt filter b motor cable length i relative pea...

Page 62

Use symmetrical shielded motor cable (see alternative power cable types (page 62) ). Ground motor cable shields 360° at both ends. Keep the motor cable and its pe pigtail (twisted shield) as short as possible to reduce high-frequency electromagnetic emissions. Note: when continuous metal conduit is ...

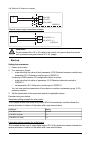

Page 63

Symmetrical shielded cable with three phase conductors and a concentric pe conductor as shield. A separate pe conductor is required if the shield does not meet the require- ments of iec 61800-5-1, see section motor cable shield (page 63) . Pe symmetrical shielded cable with three phase conductors an...

Page 64: Routing The Cables

Selecting the control cables ■ shielding all control cables must be shielded. Use a double-shielded twisted pair cable for analog signals. This type of cable is recommended for the pulse encoder signals also. Employ one individually shielded pair for each signal. Do not use common return for differe...

Page 65

1 2 4 2 5 3 5 90 ° min 300 mm (12 in.) min 500 mm (20 in.) min 200 mm (8 in.) drive 1 motor cable 2 input power cable 3 power cable 4 control cable 5 ■ separate control cable ducts lead 24 v and 230 v (120 v) control cables in separate ducts unless the 24 v cable is insulated for 230 v (120 v) or in...

Page 66

The drive is equipped with internal ac fuses as standard. In case of a short-circuit inside the drive, the ac fuses protect the drive, restrict drive damage, and prevent damage to adjoining equipment. ■ protecting the motor and motor cable in short-circuits the drive protects the motor cable and mot...

Page 67

Implementing the emergency stop function the drive can be equipped with emergency stop function of stop category 0. For safety reasons, install the emergency stop devices at each operator control station and at other operating stations where emergency stop can be needed. Note: pressing the stop key ...

Page 68: Motor

Supplying power for the auxiliary circuits the drive is equipped with an auxiliary control voltage transformer which supplies control voltage, for example, for the control devices and cabinet fan(s). Supply this option from an external power source: • +g300 cabinet heaters (230 or 115 v ac; external...

Page 69

Implementing a bypass connection if bypassing is required, employ mechanically or electrically interlocked contactors between the motor and the drive and between the motor and the power line. Make sure with interlocking that the contactors cannot be closed simultaneously. The installation must be cl...

Page 70

Implementing a motor temperature sensor connection warning! Iec 60664 requires double or reinforced insulation between live parts and the surface of accessible parts of electrical equipment which are either non-conductive or conductive but not connected to the protective earth. To connect a motor te...

Page 71: Electrical Installation

Electrical installation contents of this chapter this chapter gives instructions on the wiring the drive. Warnings warning! If you are not a qualified electrician do not do the installation work described in this chapter. Obey the instructions in chapter safety instructions . If you ignore them, inj...

Page 72

Layout of the cable entries (frames r6 to r9) the layout of the input and motor cable connection terminals of frame r9 without du/dt filter (option +e205) is shown below. The shrouds in front of the terminals are removed. The layout is similar for the other frame sizes. L1 l2 l3 1 1 u2 v2 w2 1 1 2 3...

Page 73

Layout of the cable entries (frames r10 and r11) the layout of the input and motor cable connection terminals of frame r10 is shown below. The shrouds in front of the terminals are removed. The layout is similar for frame r11. U2 v2 w2 5 4 l1 l2 l3 1 3 6 2 input power cable terminals l1, l2, l3 moto...

Page 74

Connecting the power cables ■ connection diagram 74 electrical installation.

Page 75

Pe acs580-07 u1 v1 w1 u2 v2 w2 3 7 6 5 l1 l2 l3 (pe) (pe) pe ~ ~ l1 l2 l3 t1/ t2/ t3/ 2 1b 1a l1/ l2/ l3/ 4 u1 v1 w1 u2 v2 w2 8 q2 m 3 ~ q1 *) **) use a separate grounding pe cable (1a) or a cable with a separate pe conductor (1b) if the conductivity of the shield does not meet the requirements for ...

Page 76

■ checking the insulation of the drive warning! Do not make any voltage withstand or insulation resistance tests on any part of the drive as testing can damage the drive. Every drive has been tested for insulation between the main circuit and the chassis at the factory. Also, there are voltage-limit...

Page 77

■ connection procedure (iec, frames r6 to r9) 1. Do the steps in section electrical safety precautions (page 16) before you start the work. 2. Open the cabinet door. 3. For drives without option +e205: to remove the mounting plate, undo the mounting screws and unplug the connectors on top of it: • a...

Page 78

5 7. Prepare the ends of the cables. Warning! Apply grease to stripped aluminum conductors before attaching them to non-coated aluminum cable lugs. Obey the grease manufacturer’s instructions. Aluminum-aluminum contact can cause oxidation in the contact surfaces. Pe pe 8. If fire insulation is used,...

Page 79

12. Seal the slot between the cable and mineral wool sheet (if used) with sealing compound (eg, csd-f, abb brand name dxxt-11, code 35080082). 13. Connect the twisted shields of the motor cables to the ground bar and the phase conductors to the u2, v2 and w2 terminals of the drive module. For drives...

Page 80

15. Tighten the power cable screws to the torque given in terminal and entry data for the power cables (page 160) . 16. Reinstall the shrouds and mounting plate. ■ connection procedure (iec, frames r10 and r11) 1. Do the steps in section electrical safety precautions (page 16) before you start the w...

Page 81

• with top entry (option +h351) and bottom exit: undo the mounting screws and pull the shroud out. Electrical installation 81.

Page 82

• with top entry and top exit (options +h351 and +h353): remove the shrouds and door fan (see replacing the door fan (frames r10 and r11) (page 119) ). Undo the mounting screws and pull the shrouds out. 4. Remove the door fan mounting plate. See section replacing the door fan (frames r10 and r11) (p...

Page 83

Warning! Apply grease to stripped aluminum conductors before attaching them to non-coated aluminum cable lugs. Obey the grease manufacturer’s instructions. Aluminum-aluminum contact can cause oxidation in the contact surfaces. Pe pe 7. If fire insulation is used, make an opening in the mineral wool ...

Page 84

11. Seal the slot between the cable and mineral wool sheet (if used) with sealing compound (eg, csd-f, abb brand name dxxt-11, code 35080082). 12. Connect the twisted shields of the motor cables to the ground bar and the phase conductors to the u2, v2 and w2 terminals of the drive module. 13. Connec...

Page 85

• connecting external wiring to the control unit or optional i/o terminal block (page 88) • connecting the emergency stop push buttons (options +q951 and +q963) (page 89) • connecting the safe torque off circuit (page 89) • connecting external power supply wires for the cabinet heater (option +g300)...

Page 86: •

• cover the turned shield and the stripped cable with copper foil to keep the shielding continuous. 98 electrical installation note 1 : keep the shields continuous as close to the connection terminals as possible. Secure the cables mechanically at the lead-through strain relief. Note 2: if the outer...

Page 87

■ routing the control cables inside the cabinet the route of the control cables is shown below in frame r9. The route is similar frames r6, r7 and r8. X504 (+l504) electrical installation 87.

Page 88

The route of the control cables for frames r10 and r11 is shown below. X504 (+l504) ■ connecting external wiring to the control unit or optional i/o terminal block note: keep any signal wire pairs twisted as close to the terminals as possible. Twisting the wire with its return wire reduces disturban...

Page 89

Leave the other ends of the control cable shields unconnected or ground them indirectly via a high-frequency capacitor with a few nanofarads, eg, 3.3 nf / 630 v. The shield can also be grounded directly at both ends if they are in the same ground line with no significant voltage drop between the end...

Page 90: Transformer (T21)

* remove bridges 1–2 and 3–4 if there is an external safe torque off function 1* 2* 3* 4* 5 x969 sto out1 sto in1 sto in2 sto out2 sto internal sto out1 sto in1 sto in2 sto out2 internal connections customer connections ■ connecting external power supply wires for the cabinet heater (option +g300) c...

Page 91: Connecting A Pc

Connecting a pc a pc (with eg. The drive composer pc tool) can be connected to the drive as follows: 1. Connect a control panel to the drive either by using an ethernet (eg. Cat5e) networking cable, or by inserting the panel into the panel holder. Warning! Do not connect the pc directly to the contr...

Page 92

2. Tighten the mounting screw (chassis) to 0.8 n·m. The screw tightens the connections and grounds the module. It is necessary for fulfilling the emc requirements and for correct operation of the module. ■ wiring the optional modules see the appropriate optional module manual or for i/o options chap...

Page 93: Control Unit

Control unit contents of this chapter this chapter contains the default i/o connection diagram, descriptions of the terminals and technical data for the drive control unit (ccu-24) layout the layout of the external control connection terminals on the drive module control unit is shown below. 7 contr...

Page 94

Slot 1 option slot 1 (fieldbus adapter modules) analog in/out analog input 1 1...3 current/voltage selection switch for analog input 1 ai1 analog input 2 4...6 current/voltage selection switch for analog input 2 ai2 analog outputs 7...9 current/voltage selection switch for analog output 1 ao1 auxili...

Page 95

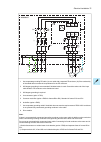

Default i/o connection diagram the default i/o connections of the abb standard macro are shown below. Max. 500 ohm 1…10 kohm xi reference voltage and analog inputs and outputs 1 scr signal cable shield (screen) 2 ai1 output frequency reference : 0…10 v 1) 3 agnd analog input circuit common 4 +10v re...

Page 96

2. Total load capacity of the auxiliary voltage output +24v (x2:10) is 6.0 w (250 ma / 24 v) minus the power taken by the option modules installed on the board. 3. In scalar control (default): see menu - primary settings - start, stop, reference - constant frequencies or parameter group 28 frequency...

Page 97

Pnp connection (source) x50 3 :1 x504:18 +24 v dc 0 v dc pnp connection (source) 10 +24v 11 dgnd 12 dcom 13 di1 14 di2 15 di3 16 di4 17 di5 18 di6 x504:18 x50 3 :1 10 +24v 11 dgnd 12 dcom 13 di1 14 di2 15 di3 16 di4 17 di5 18 di6 internal +24 v power supply external +24 v power supply power supply c...

Page 98

Internal +24 v power supply external +24 v power supply npn connection (sink) 10 +24v 11 dgnd 12 dcom 13 di1 14 di2 15 di3 16 di4 17 di5 18 di6 npn connection (sink) 10 +24v 11 dgnd 12 dcom 13 di1 14 di2 15 di3 16 di4 17 di5 18 di6 0 v dc +24 v dc x4 x 4 changing internal overtemperature supervision...

Page 99

External +24 v power supply internal +24 v power supply pnp connection (source) pnp connection (source) x2 & x3 10 +24v 11 dgnd 12 dcom 13 di1 14 di2 15 di3 16 di4 17 di5 18 di6 +24 v dc 0 v dc x2 & x3 10 +24v 11 dgnd 12 dcom 13 di1 14 di2 15 di3 16 di4 17 di5 18 di6 warning! Do not connect the +24 ...

Page 100

X1 8 ao2 analog output 2. Default output 0…20 ma. 9 agnd analog common ground. Internally connected to chassis through a 2 mohm resistor. 500 ohm x1 8 ao2 analog output 2. Default output 0…20 ma. 9 agnd analog common ground. Internally connected to chassis through a 2 mohm resistor. 1 kohm 1 kohm 0…...

Page 101

"0" > kohm "1" i max = 5 ma ptc 18 10 t ■ ai1 and ai2 as pt100, pt1000, ni1000, kty83 and kty84 sensor inputs (x1) one, two or three pt100 sensors; one, two or three pt1000 sensors; or one ni1000, kty83 or kty84 sensor for motor temperature measurement can be connected between an analog input and ou...

Page 102: Technical Data

Remove the jumpers before connecting an external safe torque off circuitry to the drive. See also chapter safe torque off function (page 221) . Note: only 24 v dc can be used for sto. Only pnp input configuration can be used. Technical data maximum power: 36 w, 1.50 a at 24 v ac/dc ±10% as standard ...

Page 103

Current/voltage output mode for ao1 selected with a dip switch, see connec- tion for obtaining 0…10 v from analog output 2 (ao2) (page 99) . Current output: 0…20 ma, r load : voltage input: 0…10 v, r load : > 100 kohm (ao1 only) terminal size: 0.14…2.5 mm 2 analog outputs ao1 and ao2 (term. 7 and 8)...

Page 104

The terminals on the control board fulfill the protective extra low voltage (pelv) requirements (en 50178): there is reinforced insulation between the user terminals which only accept elv voltages and terminals that accept higher voltages (relay outputs). Note: there is functional insulation also be...

Page 105

Ground isolation diagram x1 1 scr 2 ai1 3 agnd 4 +10v 5 ai2 6 agnd 7 ao1 8 ao2 9 agnd x2 & x3 10 +24v 11 dgnd 12 dcom 13 di1 14 di2 15 di3 16 di4 17 di5 18 di6 x6, x7, x8 19 ro1c 20 ro1a 21 ro1b 22 ro2c 23 ro2a 24 ro2b 25 ro3c 26 ro3a 27 ro3b x5 29 b+ 30 a- 31 dgnd x4 34 out1 35 out2 36 sgnd 37 in1 ...

Page 106

106.

Page 107: Installation Checklist

Installation checklist contents of this chapter this chapter contains a list for checking the mechanical and electrical installation of the drive. Checklist check the mechanical and electrical installation of the drive before start-up. Go through the checklist together with another person. Warning! ...

Page 108

Check that … there is an adequately sized protective earth (ground) conductor between the motor and the drive, and the conductor has been connected to appropriate terminal, and the terminal have been tightened. (pull on the conductors to check.). Proper grounding has also been measured according to ...

Page 109: Start-Up

Start-up contents of this chapter this chapter contains the start-up procedure of the drive. The default device designations (if any) are given in brackets after the name, for example "main switch-disconnector (q1)". The same device designations are also used in the circuit diagrams, typically. Star...

Page 110

Action drives with main contactor (q2, option +f250): close the main contactor by turning the operating switch on the cabinet door from off into on position. Perform the first start of the drive and motor. Stop the motor and drive. Drives with a fieldbus adapter module (optional): set the fieldbus p...

Page 111: Fault Tracing

Fault tracing contents of this chapter this chapter describes the fault tracing possibilities of the drive. Warning and fault messages see the firmware manual for the descriptions, causes and remedies of the drive control program warning and fault messages. 10 fault tracing 111.

Page 112

112.

Page 113: Maintenance

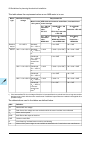

Maintenance contents of this chapter this chapter contains preventive maintenance instructions. Maintenance intervals the table below shows the maintenance tasks which can be done by the end user. The complete maintenance schedule is available on the internet ( www.Abb.Com/drivesservices ).For more ...

Page 114

■ recommended annual maintenance actions by the user. Target action ip42 air inlet and outlet meshes on the cabinet doors i ip54 air filters on the cabinet doors r quality of supply voltage p spare parts i capacitor reforming, spare modules and spare capacitors p tightness of terminals i dustiness, ...

Page 115: Filtered)

3. Check the air inlet and outlet meshes/filters of the cabinet. Clean when necessary. For ip42 (ul type 1 filtered) drives: see section cleaning the air inlet (door) meshes (ip42 / ul type 1 filtered) below. For ip54 (ul type 12) drives: see section cleaning the air inlet (door) meshes (ip42 / ul t...

Page 116: Heatsink

3 ■ outlet (roof) filters (ip54 / ul type 12) 1. Remove the front and back gratings of the fan cubicle by lifting them upwards 2. Remove the air filter mat. 3. Place the new filter mat in the grating. 4. Reinstall the grating in reverse order. Heatsink the drive module heatsink fins pick up dust fro...

Page 117: Fans

2. Remove the drive module from the cabinet. See section replacing the drive module (frames r6 to r9) (page 126) 3. Undo the attaching screws of the handle plate of the drive module. 4. Remove the handle plate. 5. Vacuum the interior of the heatsink from the opening. 6. Blow clean compressed air (no...

Page 118

3 4 4 ■ replacing the cabinet fan (frames r6 to r9) applicability: for drives without any of these options +f250, +l537, +b055, +q951, +q963, +q971 and +g300 warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. ...

Page 119

4 2 3 3 ■ replacing the door fan (frames r10 and r11) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety precautions (page 16) before you start the ...

Page 120

120 maintenance.

Page 121

■ replacing the cabinet fan (frames r10 and r11, ip54) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety precautions (page 16) before you start the...

Page 122

A 4 3 b 6 ■ replacing the drive module main fans (frames r6 to r8) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety precautions (page 16) before y...

Page 123

10. Install the new fan in reverse order. 11. Reset the fan on-time counter in parameter group 5 of the drive control program. 9 6 5 7 ■ replacing the drive module main fans (frame r9) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to t...

Page 124

■ replacing the drive module main fans (frames r10 and r11) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety precautions (page 16) before you star...

Page 125

■ replacing the auxiliary cooling fan of the drive module (frames r6 to r9) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1. Stop the drive and do the steps in section electrical safety precautions (page 16)...

Page 126

4 3 replacing the drive module (frames r6 to r9) this replacing procedure requires: preferably two persons, a set of screw drivers with extension bar and a torque wrench, chains for securing the module during the installation. The drawings below show a cabinet of frame size r7. The procedure is the ...

Page 127

3b 3a torx m6x16 tap screw m6x16 t30 (hex) 3d 3e 3c 3e torx m6x16 torx m6x16 4. Unplug the wires connected to the mounting plate connectors (if present). 5. Remove the mounting plate (four screws). 6. Remove the shroud (two screws). 7. Remove the shroud on the power cable connection terminals. Maint...

Page 128

5 6 4 6 5 5 5 7 8. Disconnect the option modules from the control unit. 9. For drives with additional i/o terminal block (option +l504), disconnect the upper terminals and remove any fastening. Move the wires aside before you lift the module out. Note: mark the wires for reconnection! 128 maintenanc...

Page 129

10. For drives without additional i/o terminal block (option +l504), disconnect the customer-installed wires from the control unit. Note: mark the wires for reconnection! 11. For drives with line contactor (option +f250), disconnect the input power cables from the output of the contactor. 12. Discon...

Page 130

13. Secure the drive module with chains from the lifting eyes. 14. Undo the mounting screws of the flange. 15. Slide the drive module forwards along the sliding bars. 16. Lift the module out of the cabinet with a lifting device. 130 maintenance.

Page 131

14 13 15 16 17. Remove the flange. Maintenance 131.

Page 132

M6 nut, 6 n·m m6×10 t30, 6 n·m combiscrew m6×25 t25 m6 nut, 6 n·m 18. Install the new module in reverse order. 132 maintenance.

Page 133

Replacing the drive module (frames r10 and r11) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. This replacing procedure requires: preferably two persons, installation ramp, a set of screw drivers and a torque...

Page 134

3 4 5 134 maintenance.

Page 135

6 maintenance 135.

Page 136

7. Disconnect the drive module input busbars with a torque wrench withn an extension bar of 500 mm (20 in). Combi screw m12, 70 n·m (52 lbf·ft). 8. Disconnect the drive module output busbars. M12, 70 n·m (52 lbf·ft). 7 8 136 maintenance.

Page 137

9. Remove the shroud. Undo the screws that attach the drive module to the cabinet at the top and behind the front support legs. Maintenance 137.

Page 138

10. Attach the extraction ramp to the cabinet base with two screws. 11. Attach the drive module lifting lugs to the cabinet lifting lug with chains. 12. Pull the drive module carefully out of the cabinet preferably with help from another person. 138 maintenance.

Page 139

13. Install the new module in reverse order. 13 12 11 replacing the drive module (frames r10 and r11, ip54) warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. This replacing procedure requires: preferably two per...

Page 140

4 5 3 140 maintenance.

Page 141

6 maintenance 141.

Page 142

7. Disconnect the drive module input busbars with a torque wrench withn an extension bar of 500 mm (20 in). Combi screw m12, 70 n·m (52 lbf·ft). 8. Disconnect the drive module output busbars. M12, 70 n·m (52 lbf·ft). 7 8 142 maintenance.

Page 143

9. Remove the shroud. Undo the screws that attach the drive module to the cabinet at the top and behind the front support legs. Maintenance 143.

Page 144

10. Attach the extraction ramp to the cabinet base with two screws. 11. Attach the drive module lifting lugs to the cabinet lifting lug with chains. 12. Pull the drive module carefully out of the cabinet preferably with help from another person. 144 maintenance.

Page 145: Capacitors

13. Install the new module in reverse order. 13 12 11 capacitors the dc circuit of the power modules of the drive contain several electrolytic capacitors. Their lifespan depends on the operating time of the drive, loading and ambient temperature. Capacitor life can be prolonged by lowering the ambie...

Page 146: Control Panel

4. Replace the fuses with the fuse handle which is in the cabinet. 5. Reinstall the shrouding removed earlier and close the cabinet door. ■ replacing ac fuses warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. 1....

Page 147

■ replacing the battery in the assistant control panel a battery is only used in assistant control panels that have the clock function. The battery keeps the clock operating during power interruptions. The expected life for the battery is greater than ten years. Note: the battery is not required for...

Page 148

148.

Page 149: Technical Data

Technical data contents of this chapter this chapter contains the technical specifications of the drive, for example, the ratings, sizes and technical requirements, provisions for fulfilling the requirements for ce and other markings. Ratings the nominal ratings for the drives with 50 hz and 60 hz s...

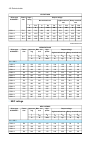

Page 150

Iec ratings output ratings input rating frame size drive type acs580-07- heavy-overload use light-overload use no-overload use p hd i hd p ld i ld p n s n i 2 i max i 1 kw a kw a kw kva a a a 250 477 355 634 355 450 650 730 650 r10 0650a-4 315 566 400 715 400 502 725 1020 725 r11 0725a-4 355 625 450...

Page 151: Output Derating

Nec ratings output ratings app. Power max. Cur- rent input rat- ing frame size drive type acs580-07- heavy-overload use light-overload use p hd i hd p ld i ld s n i max i 1 hp a hp a kva a a 150 240* 200 260 203 418 260 r8 0260a-4 250 302 300 361 251 542 361 r9 0361a-4 300 361** 350 414 298 542 414 ...

Page 152

T 1.00 0.90 +40 °c +104 °f +50 °c +122 °f k 0.80 for example: derated current temperature i hd i ld 40 ºc (104 ºf) 0.95 · i d 0.95 · i ld 45 ºc (113 ºf) 0.90 · i hd 0.90 · i ld 50 ºc (122 ºf) drive types acs580-0414a-4 and acs580-0430a-4 in the temperature range +35…50 °c (+95…122 °f), the rated out...

Page 153

If ambient temperature is below +40 °c (+104 .°f), the derating can be reduced by 1.5% for every 1 °c reduction in temperature. Curves with derating factors from 1.00 to 0.80 are shown below. For a more accurate derating, use the drivesize pc tool. A few altitude derating curves are shown below. Ins...

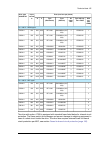

Page 154: Fuses (Iec)

Changing the value of parameter 97.01 switching frequency reference does not require derating. Fuses (iec) the standard drive is equipped with ar fuses listed below. Ultrarapid (ar) fuses (one fuse per phase) input cur- rent (a) drive type acs580-07- size type (mersen) type (buss- mann) v a 2 s (a) ...

Page 155

Fuse (one fuse per phase) input current a drive type acs580-07- size (op- tion +f289) type with op- tion +f289 ul class / size type (mersen) type (bussmann) v a u n = 480 v - nema types 1 170m3416 j b235889a (hsj 250) dfj-250 600 250 124 0145a-4 1 170m3416 j c235890a (hsj 300) dfj-300 600 300 156 01...

Page 156

Fuse (one fuse per phase) with option +f289 input current a drive type acs580-07- size type manufacturer a u n = 480 v 1 170m3416 bussmann 250 124 0145a-4 1 170m3416 bussmann 250 156 0169a-4 1 170m4410 bussmann 315 180 0206a-4 2 170m5408 bussmann 400 240 0246a-4 2 170m5410 bussmann 500 260 0293a-4 3...

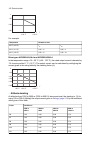

Page 157: Dimensions And Weights

Nec type fuse (one fuse per phase) input current a drive type acs580-07- ul class type manufacturer v a l a4by800 ferraz 600 800 705 0725a-4 l a4by900 ferraz 600 900 807 0820a-4 l a4by1000 ferraz 600 1000 807 0880a-4 note 1 : see also implementing the emergency stop function (page 67) . Note 2 : fus...

Page 158: Typical Power Cable Sizes

R6, r7: 400 mm (15.75”) in) r8, r9: 500 mm (19.68 in) r10. R11: 800 mm (31.50 in) maximum allowed plinth height for the extraction/installation ramp the maximum plinth height for the extraction/installation ramp delivered with the drive is 50 mm (1.97 in). Typical power cable sizes the table below g...

Page 159

Us 2) iec 1) frame size drive type acs580-07- cu cable type al cable type cu cable type awg/kcmil per phase mm 2 mm 2 2x2/0 2x(3x95) 2x(3x70) r8 0240a-4 2x3/0 2x(3x120) 2x(3x95) r8 0260a-4 2x250 mcm 2x(3x185) 2x(3x120) r9 0361a-4 2x300 mcm 2x(3x240) 2x(3x150) r9 0414a-4 1. The cable sizing is based ...

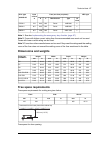

Page 160

Terminal and entry data for the power cables there are two (in frames r6 to r9) or four (in frames r10 and r11) 60 mm (2.36 in) diameter holes in the entry plate for the input power cables and two (in frames r6 to r9) or four (in frames r10 and r11) 60 mm (2.36 in) diameter holes for the motor cable...

Page 161

Pe (grounding) t1/u2, t2/v2, t3/w2 l1, l2, l3 frame size tighten- ing torque lbf·ft bolt size tighten- ing torque lbf·ft max. Wire size awg min. Wire size 1) awg tighten- ing torque lbf·ft bolt size max. Wire size awg 29.5 m10 (3/8") 22.1 3×300 mcm 3 22.1 m10 (3/8") 3×300 mcm r6 29.5 m10 (3/8") 22.1...

Page 162: Connection Drawings

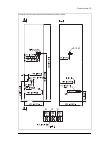

Connection drawings frame r6: input and motor cable terminal dimensions (bottom entry and exit, switch fuse os250) det a 162 technical data.

Page 163

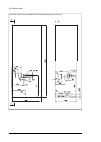

Frame r6: input and motor cable terminal dimensions (bottom entry and exit, switch fuse os400) det a technical data 163.

Page 164

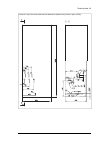

Frame r6: input and motor cable terminal dimensions (option +f289) det a 164 technical data.

Page 165

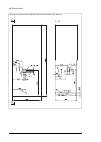

Frames r6 and r7: input and motor cable terminal dimensions (bottom entry and exit, switch fuse os250, du/dt filter [option +e205]) technical data 165.

Page 166

Frames r6 and r7: input and motor cable terminal dimensions (bottom entry and exit, switch fuse os400, du/dt filter [option +e205]) 166 technical data.

Page 167

Frames r6 and r7: input and motor cable terminal dimensions (bottom entry and exit, options +f289 and +e205) technical data 167.

Page 168

Frame r7: input and motor cable terminal dimensions (bottom entry and exit, switch fuse os250) det a 168 technical data.

Page 169

Frame r7: input and motor cable terminal dimensions (bottom entry and exit, switch fuse os400) det a technical data 169.

Page 170

Frame r7: input and motor cable terminal dimensions (bottom entry and exit, option +f289) 170 technical data.

Page 171

Frames r6 and r7: input and motor cable terminal dimensions (top entry and exit, options +h351 and +h353) technical data 171.

Page 172

Frame r8: input and motor cable terminal dimensions (bottom entry and exit, switch-disconnector ot400) det a 172 technical data.

Page 173

Frame r8: input and motor cable terminal dimensions (bottom entry and exit, switch-disconnector ot400, du/dt filter [option +e205]) technical data 173.

Page 174

Frame r8: input and motor cable terminal dimensions (bottom entry and exit, option +f289) 174 technical data.

Page 175

Frame r9: input and motor cable terminal dimensions (bottom entry and exit, switch-disconnector ot630) det a technical data 175.

Page 176

Frame r9: input and motor cable terminal dimensions (bottom entry and exit, switch-disconnector ot630, du/dt filter [option +e205]) 176 technical data.

Page 177

Frames r8 and r9: input and motor cable terminal dimensions (top entry and exit, options +h351 and +h353) technical data 177.

Page 178

Frames r8 and r9: input and motor cable terminal dimensions (bottom entry and exit, options +f289 and +e205) 178 technical data.

Page 179

Frame r9: input and motor cable terminal dimensions (option +f289) technical data 179.

Page 180

Frame r10: input and motor cable terminal dimensions (bottom entry and exit) 180 technical data.

Page 181

Frame r10: input and motor cable terminal dimensions (bottom entry and exit, option +e205) technical data 181.

Page 182

Frame r10: input and motor cable terminal dimensions (top entry and exit) 182 technical data.

Page 183

Frame r10: input and motor cable terminal dimensions (top entry and exit, option +f289) technical data 183.

Page 184

Frame r11: input and motor cable terminal dimensions (bottom entry and exit) 184 technical data.

Page 185

Frame r11: input and motor cable terminal dimensions (bottom entry and exit, option +e205) technical data 185.

Page 186

Frame r11: input and motor cable terminal dimensions (top entry and exit) 186 technical data.

Page 187

Frame r11: input and motor cable terminal dimensions (top entry and exit, option +f289) technical data 187.

Page 188

Terminal and connection data for auxiliary control circuits maximum acceptable voltage and current values and wire sizes in terminal blocks are given below. Maximum acceptable voltage and current values and wire sizes terminal block 230v ac / 24v dc, 2a x250 • solid wire 0,14...4 mm2 (28...12 awg) •...

Page 189: Motor Connection Data

Electrical power network specification acs580-07-xxxxx-4 drives: 380…480 vac 3-phase ±10%. This is indicated in the type designation label as typical input voltage levels 3~400/480 v ac. Voltage (u 1 ) tn (grounded) and it (ungrounded) systems network type maximum allowable prospective short-circuit...

Page 190: Protection Classes

Protection classes ip21 (standard), ip42 (optional), ip54 (optional) degrees of protection (iec/en 60529) ul type 1 (standard), ul type 1 (option +b054), ul type 12 (option +b055). For indoor use only. Enclosure types (ul50) iii, except for auxiliary power connections (fan, control, heating, lightin...

Page 191: Ambient Conditions

Ambient conditions environmental limits for the drive are given below. The drive is to be used in a heated, indoor, controlled environment. Transportation storage operation in the protective package in the protective package installed for stationary use - - 0 to 2000 m (6561 ft) above sea level. For...

Page 192: Materials

Auxiliary circuit power consumption 100 w cabinet heater (option +g300) materials hot-dip zinc coated 1.5 mm thick steel sheet (thickness of coating approximately 20 micrometers). Polyester thermosetting powder coating (thickness approximately 80 micrometers) on visible surfaces, color ral 7035 and ...

Page 193: Applicable Standards

The main parts of the drive can be recycled to preserve natural resources and energy. Product parts and materials should be dismantled and separated. Disposal generally all metals, such as steel, aluminum, copper and its alloys, and precious metals can be recycled as material. Plastics, rubber, card...

Page 194

■ compliance with the european low voltage directive the compliance with the european low voltage directive has been verified according to standard en 61800-5-1. ■ compliance with the european emc directive the emc directive defines the requirements for immunity and emissions of electrical equipment...

Page 195

Declaration of conformity technical data 195.

Page 196

196 technical data.

Page 197

■ compliance with the en 61800-3:2004 definitions emc stands for e lectro m agnetic c ompatibility. It is the ability of electrical/electronic equipment to operate without problems within an electromagnetic environment. Likewise, the equipment must not disturb or interfere with any other product or ...

Page 198: Ul Marking

If in doubt, the supply transformer with static screening between the primary and secondary windings can be used. 1 2 3 4 5 6 7 8 9 4 6 equipment 6 medium voltage network 1 supply transformer 7 neighboring network 2 static screen 8 point of measurement 3 drive 9 low voltage 4 equipment (victim) 5 2....

Page 199: Rcm Marking

In this chapter. The ampere rating is based on tests done according to the appropriate ul standard. • the cables located within the motor circuit must be rated for at least 75 °c (167 °f) in ul-compliant installations. • the input cable must be protected with fuses. Suitable iec and ul classified fu...

Page 200: Disclaimers

Disclaimers ■ generic disclaimer the manufacturer shall have no obligation with respect to any product which (i) has been improperly repaired or altered; (ii) has been subjected to misuse, negligence or accident; (iii) has been used in a manner contrary to the manufacturer’s instructions; or (iv) ha...

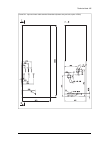

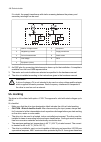

Page 201: Dimension Drawings

Dimension drawings example dimension drawings are shown below. 13 dimension drawings 201.

Page 202

Frames r6 and r7 (ip21, ul type 1) 202 dimension drawings.

Page 203

Frames r6 and r7 (+b054: ip42, ul type 1) dimension drawings 203.

Page 204

Frames r6 and r7 (+b055: ip54, ul type 12) 204 dimension drawings.

Page 205

Frames r6 and r7 (+h351 and +h353: top entry and exit) dimension drawings 205.

Page 206: Frames R6 And R7 (+F289)

Frames r6 and r7 (+f289) 206 dimension drawings.

Page 207

Frames r6 and r7 (+f289, +h351, +h353) dimension drawings 207.

Page 208: Frames R8 And R9 (Ip21)

Frames r8 and r9 (ip21) 208 dimension drawings.

Page 209

Frames r8 and r9 (+b054: ip42, ul type 1) dimension drawings 209.

Page 210

Frames r8 and r9 (+b055: ip54, ul type 12) 210 dimension drawings.

Page 211

Frames r8 and r9 (+h351 and +h353: top entry and exit) dimension drawings 211.

Page 212: Frames R8 And R9 (+F289)

Frames r8 and r9 (+f289) 212 dimension drawings.

Page 213

Frames r8 and r9 (+f289, +h351, +h353) dimension drawings 213.

Page 214

Frames r10 and r11 (ip21) 214 dimension drawings.

Page 215

Frames r10 and r11 (+b054: ip42, ul type 1) dimension drawings 215.

Page 216

Frames r10 and r11 (+b055: ip54, ul type 12) 216 dimension drawings.

Page 217

Frames r10 and r11 (+f289) t dimension drawings 217.

Page 218

Frames r10 and r11 (+h351, +h353) 218 dimension drawings.

Page 219

Frames r10 and r11 (+b054: ip42, ul type 1, +h351, +h353) t dimension drawings 219.

Page 220: +H353)

Frames r10 and r11 (+b055: ip54, ul type 12, +h351, +h353) t 220 dimension drawings.

Page 221: Safe Torque Off Function

Safe torque off function contents of this chapter this chapter describes the safe torque off function of the drive and gives instructions for its use. Description the safe torque off function can be used, for example, to construct safety or supervision circuits that stop the drive in case of danger ...

Page 222: Wiring

Name standard functional safety of electrical/electronic/programmable electronic safety-re- lated systems – part 1: general requirements iec 61508-1:2010 functional safety of electrical/electronic/programmable electronic safety-re- lated systems – part 2: requirements for electrical/electronic/progr...

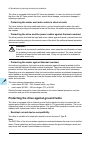

Page 223

Maximum cable lengths: • 300 m (984 ft) between activation switch (k) and drive control unit • 60 m (200 ft) between multiple drives • 60 m (200 ft) between external power supply and first drive. Note that the voltage at the inx terminals of each drive must be at least 13 v dc to be interpreted as “...

Page 224

Single-channel connection + 24 v dc control unit + 24 v dc sto drive control logic udc+ udc– a t1/u, t2/v, t3/w k out2 out1 in1 in2 sgnd 34 35 36 37 38 224 safe torque off function.

Page 225

■ single drive (external +24 v dc power supply) + 24 v dc control unit + 24 v dc sto drive control logic udc+ udc– a t1/u, t2/v, t3/w out2 out1 in1 in2 sgnd 34 35 36 37 38 + 24 v dc - k ■ wiring examples an example of a safe torque off wiring with internal +24 v dc power supply is shown below. 24 14...

Page 226

24 14 23 13 y1 a2 y2 a1 31 32 safety relay safe plc out gnd 34 37 35 38 drive 36 sgnd in1 in2 out1 out2 k +24 v dc external power supply - + 226 safe torque off function.

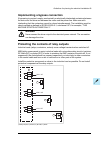

Page 227

■ multiple drives (internal power supply) drive drive drive sto control unit control unit control unit k sto out2 out1 + 24 v dc in1 in2 sgnd + 24 v dc 34 35 36 37 38 sto out2 out1 + 24 v dc in1 in2 sgnd + 24 v dc 34 35 36 37 38 out2 out1 + 24 v dc in1 in2 sgnd + 24 v dc 34 35 36 37 38 safe torque o...

Page 228: Operation Principle

■ multiple drives (external power supply) drive drive drive sto control unit control unit control unit sto out2 out1 + 24 v dc in1 in2 sgnd + 24 v dc 34 35 36 37 38 sto out2 out1 + 24 v dc in1 in2 sgnd + 24 v dc 34 35 36 37 38 24 v dc – + k out2 out1 + 24 v dc in1 in2 sgnd + 24 v dc 34 35 36 37 38 o...

Page 229

5. Motor coasts to stop (if running). The drive cannot restart while the activation switch or safety relay contacts are open. After the contacts close, a new start command is required to start the drive. Start-up including acceptance test to ensure safe operation of the safe torque off function, val...

Page 230: Use

Action test the operation of the sto function when the motor is stopped. • give a stop command for the drive (if running) and wait until the motor shaft is at a standstill. Make sure that the drive operates as follows: • open the sto circuit. The drive generates an indication if one is defined for ‘...

Page 231: Maintenance

The drive or the motor can only be carried out after isolating the drive system from the main supply. Warning! (with permanent magnet or synchronous reluctance [synrm] motors only) in case of a multiple igbt power semiconductor failure, the drive system can produce an alignment torque which maximall...

Page 232: Fault Tracing

■ competence the maintenance and proof test activities of the safety function must be carried out by a competent person with adequate expertise and knowledge of the safety function as well as functional safety, as required by iec 61508-1 clause 6. Fault tracing the indications given during the norma...

Page 233

A fault exclusion on the failure mode "short circuit on printed circuit board" has been made (en 13849-2, table d.5). The analysis is based on an assumption that one failure occurs at one time. No accumulated failures have been analyzed. • sto reaction time (shortest detectable break): 1 ms • sto re...

Page 234

234.

Page 235: Contents Of This Chapter

Optional i/o extension modules contents of this chapter this chapter describes how to install and start up the optional chdi-01, cmod-01 and cmod-02 multifunction extension modules. The chapter also contains diagnostics and technical data. Chdi-01 115/230 v digital input extension module ■ hardware ...

Page 236

Layout 1 2 3 3 4 4 5 4 - grounding screw 1 - hole for mounting screw 2 terminal designations (page 237) 3-pin terminal blocks for relay outputs 3 terminal designations (page 237) 3-pin terminal block for 115/230 v inputs 4 leds (page 239) diagnostic led 5 ■ mechanical installation necessary tools an...

Page 237

■ electrical installation warning! Obey the instructions in chapter safety instructions . If you ignore them, injury or death, or damage to the equipment can occur. If you are not a qualified electrician, do not do electrical work. Make sure that the drive is disconnected from the input power during...

Page 238

General cabling instructions obey the instructions given in chapter planning the electrical installation . Wiring connect the external control cables to the applicable module terminals. Ground the outer shield of the cables 360 degrees under a grounding clamp on the grounding shelf of the control ca...

Page 239

■ diagnostics faults and warning messages warning a7ab extension i/o configuration failure. Leds the extension module has one diagnostic led. Description color the extension module is powered up. Green ■ technical data dimension drawing: the dimensions are in millimeters and [inches]. Installation: ...

Page 240

Package: cardboard isolation areas: hdi chdi-01 ro5 ro4 hdi hdi 1 reinforced insulation (iec 61800-5-1:2007) functional insulation (iec 61800-5-1:2007) relay outputs (50…52, 53…55): • wire size max. 1.5 mm2 • minimum contact rating: 12 v / 10 ma • maximum contact rating: 250 v ac / 30 v dc / 2 a • m...

Page 241

Cmod-01 multifunction extension module (external 24 v ac/dc and digital i/o) ■ hardware description product overview the cmod-01 multifunction extension module (external 24 v ac/dc and digital i/o) expands the outputs of the drive control unit. It has two relay outputs and one transistor output, whi...

Page 242

Terminal designations (page 242) 3-pin terminal block for transistor output 4 terminal designations (page 242) 2-pin terminal block for external power supply 5 leds (page 245) diagnostic led 6 ■ mechanical installation necessary tools and instructions • screwdriver and a set of suitable bits. Unpack...

Page 243

Transistor output description marking source input do1 src 42 digital or frequency output do1 out 43 ground (earth) potential do1 sgnd 44 external power supply the external power supply is needed only if you want to connect an external back-up power supply for the drive control unit. Note: frames r1...

Page 244

42 43 44 1) cmod-01 do1 src do1 out do1 sgnd external power supply connection example 40 41 1) + - cmod-01 24v ac/dc + in 24v ac/dc - in warning! Do not connect the +24 v ac cable to the control unit ground when the control unit is powered using an external 24 v ac supply. ■ start-up setting the par...

Page 245

Setting parameter digital output 15.22 do1 configuration reverse 15.23 do1 source 1 s 15.24 do1 on delay 1 s 15.25 do1 off delay parameter setting example for frequency output this example shows how to make digital output do1 of the extension module indicate the motor speed 0... 1500 rpm with a freq...

Page 246

Installation: into an option slot on the drive control unit degree of protection: ip20 ambient conditions: see the drive technical data. Package: cardboard isolation areas: 246 optional i/o extension modules.

Page 247

Do1 cmod-01 ro5 ro4 24 v in 1 reinforced insulation (iec 61800-5-1:2007) functional insulation (iec 61800-5-1:2007) relay outputs (50…52, 53…55): • wire size max. 1.5 mm 2 • minimum contact rating: 12 v / 10 ma • maximum contact rating: 250 v ac / 30 v dc / 2 a • maximum breaking capacity: 1500 va6 ...

Page 248

Cmod-02 multifunction extension module (external 24 v ac/dc and isolated ptc interface) ■ hardware description product overview the cmod-02 multifunction extension module (external 24 v ac/dc and isolated ptc interface) has a motor thermistor connection for supervising the motor temperature and one ...

Page 249

Mechanical installation (page 249) grounding screw 1 mechanical installation (page 249) hole for mounting screw 2 terminal designations (page 249) 2-pin terminal block for motor thermistor connection 3 terminal designations (page 249) 2-pin terminal block for relay output 4 terminal designations (pa...

Page 250

Relay output description marking common, c ro ptc c 62 normally open, no ro ptc b 63 external power supply the external power supply is needed only if you want to connect an external back-up power supply for the drive control unit. Note: frames r1…r5 need cmod-01 for connecting external power supply...

Page 251

62 63 cmod-02 ccu 34 35 x4 36 37 38 out1 out2 sgnd in1 in2 ro ptc c ro ptc b power supply connection example 40 41 1) + - 24v ac/dc + in 24v ac/dc - in cmod-02 warning! Do not connect the +24 v ac cable to the control unit ground when the control unit is powered using an external 24 v ac supply. ■ s...

Page 252

Description color the extension module is powered up. Green ■ technical data dimension drawing: the dimensions are in millimeters and [inches]. Installation: into an option slot on the drive control unit degree of protection: ip20 ambient conditions: see the drive technical data. Package: cardboard ...

Page 253

Cmod-02 ptc in ro ptc 24 v in 1 reinforced insulation (iec 61800-5-1:2007) functional insulation (iec 61800-5-1:2007) motor thermistor connection (60…61): • wire size max. 1.5 mm 2 • supported standards: din 44081 and din 44082 • number of ptc thermistor relays: 1 or 3…6 in series • triggering thres...

Page 255

Further information product and service inquiries address any inquiries about the product to your local abb representative, quoting the type designation and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to www.Abb.Com/searchcha...

Page 256

Contact us www.Abb.Com/drives 3axd50000045815 rev c (en) effective 2018-02-07 3axd50000045815c.