- DL manuals

- ABB

- Industrial Equipment

- ACS880-14

- Firmware Instructions

ABB ACS880-14 Firmware Instructions

Summary of ACS880-14

Page 1

Abb industrial drives firmware manual acs880 esp control program (option +n5600).

Page 2

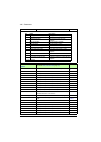

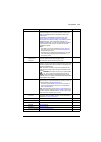

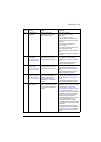

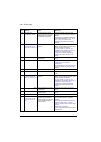

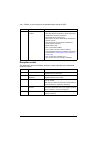

List of related manuals you can find manuals and other product documents in pdf format on the internet. See section document library on the internet on the inside of the back cover. For manuals not available in the document library, contact your local abb representative. *lists of hyperlinks to prod...

Page 3: Firmware Manual

Firmware manual acs880 esp control program (option +n5600) 3axd50000041193 rev a en effective: 2017-06-30 2017 abb oy. All rights reserved. Table of contents.

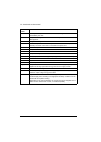

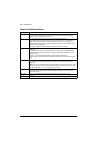

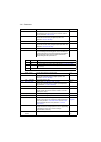

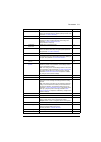

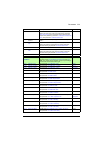

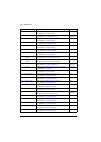

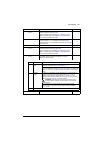

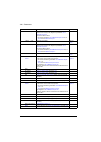

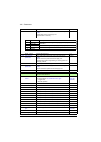

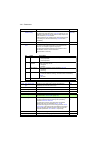

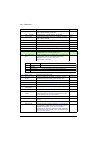

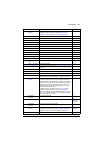

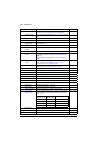

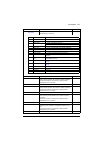

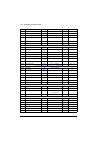

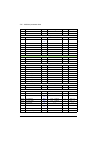

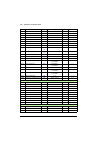

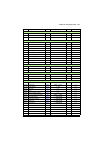

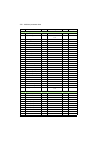

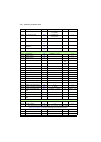

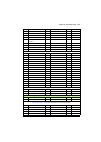

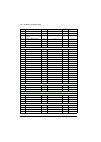

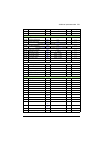

Page 5: Table of Contents

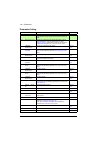

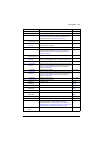

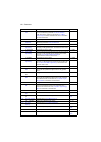

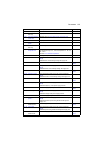

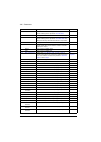

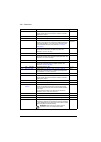

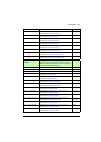

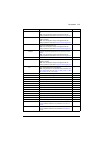

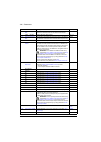

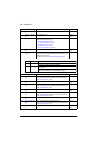

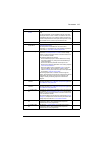

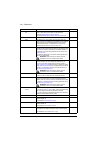

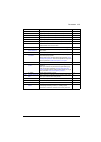

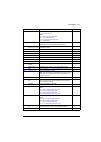

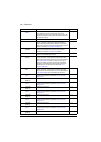

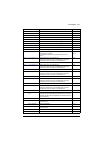

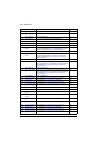

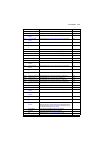

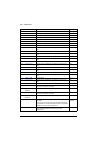

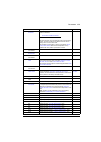

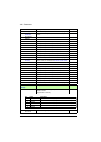

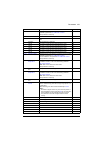

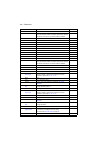

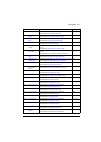

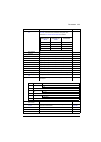

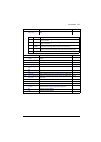

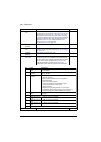

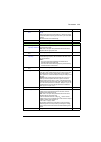

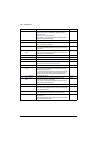

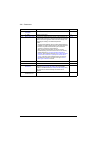

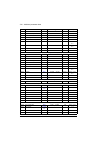

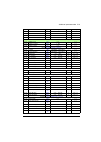

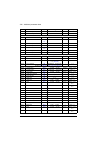

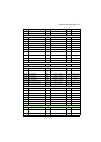

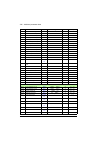

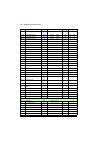

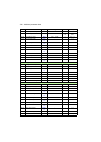

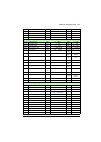

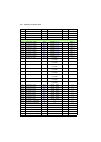

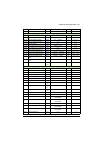

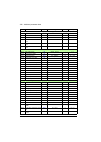

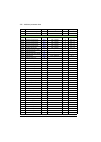

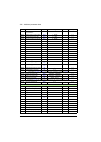

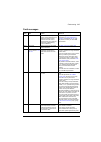

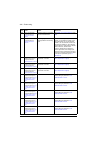

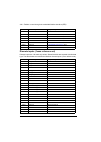

Table of contents 5 table of contents list of related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1. Introduction to the manual what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

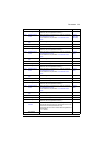

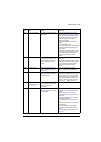

6 table of contents kick-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 current pulse-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 esp productio...

Page 7

Table of contents 7 overvoltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112 undervoltage control (power loss ride-through) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112 voltage control and trip limits . . ....

Page 8

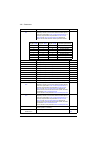

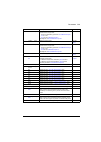

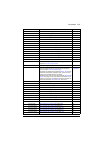

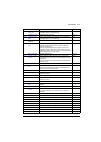

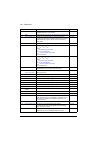

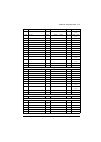

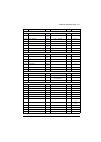

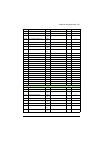

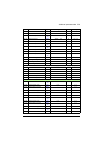

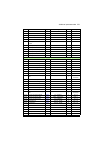

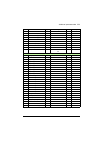

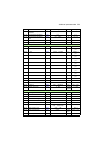

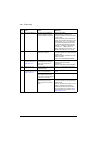

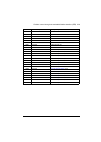

8 table of contents 8. Parameters what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147 terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148 summa...

Page 9

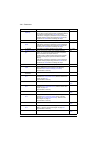

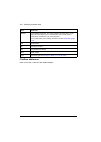

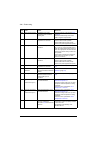

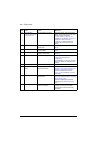

Table of contents 9 58 embedded fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385 60 ddcs communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393 61 d2d and ddcs transmit data . ....

Page 10

10 table of contents connecting the fieldbus to the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608 setting up the embedded fieldbus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 609 setting the drive control param...

Page 11

Table of contents 11 torque limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 654 torque controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 655 fre...

Page 12

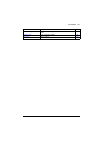

12 table of contents.

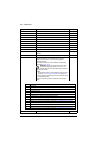

Page 13: Introduction to The Manual

Introduction to the manual 13 1 introduction to the manual what this chapter contains this chapter describes the contents of the manual. It also contains information on the compatibility, safety and intended audience. Applicability this manual applies to the acs880 esp control program (option +n5600...

Page 14

14 introduction to the manual licensing the esp control program (+n5600), version aeslx 1.00 or later comes with a license key on the zmu-02 memory unit. The program activates only after recognizing the key and correspondingly registers itself with the esp software. You can see the license informati...

Page 15

Introduction to the manual 15 contents of the manual this manual contains the following chapters: • using the control panel provides basic instructions for the use of the control panel. • control locations and operating modes describes the control locations and operating modes of the drive. • quick ...

Page 16

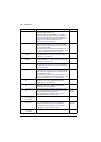

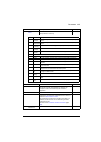

16 introduction to the manual terms and abbreviations term/abbre- viation definition ac 800m type of programmable controller manufactured by abb. Acs800 a product family of abb drives acs-ap-i types of control panel used with acs880 drives acs-ap-w ai analog input; interface for analog input signals...

Page 17

Introduction to the manual 17 fen-21 optional resolver interface module fen-31 optional htl encoder interface module fena-11 optional ethernet/ip, modbus/tcp and profinet io adapter fena-21 optional dual-port ethernet/ip, modbus/tcp and profinet io adapter fepl-02 optional powerlink adapter fio-01 o...

Page 18

18 introduction to the manual parameter user-adjustable operation instruction to the drive, or signal measured or calculated by the drive pid controller proportional–integral–derivative controller. Drive speed control is based on pid algorithm. Plc programmable logic controller power unit contains t...

Page 19

Introduction to the manual 19 cybersecurity disclaimer this product is designed to be connected to and to communicate information and data via a network interface. It is customer's sole responsibility to provide and continuously ensure a secure connection between the product and customer network or ...

Page 20

20 introduction to the manual.

Page 21: Using The Control Panel

Using the control panel 21 2 using the control panel refer to acx-ap-x assistant control panels user’s manual (3aua0000085685 [english])..

Page 22

22 using the control panel.

Page 23: Control Locations And

Control locations and operating modes 23 3 control locations and operating modes what this chapter contains this chapter describes the control locations and operating modes supported by the control program..

Page 24

24 control locations and operating modes local control vs. External control the acs880 has two main control locations: external and local. The control location is selected with the loc/rem key on the control panel or in the pc tool. Local control the control commands are given from the control panel...

Page 25

Control locations and operating modes 25 external control when the drive is in external control, control commands are given through • the i/o terminals (digital and analog inputs), or optional i/o extension modules • the embedded fieldbus interface or an optional fieldbus adapter module • the extern...

Page 26

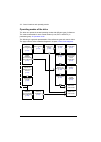

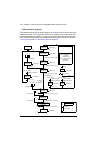

26 control locations and operating modes operating modes of the drive the drive can operate in several operating modes with different types of reference. The mode is selectable for each control location (local, ext1 and ext2) in parameter group 19 operation mode . The following is a general represen...

Page 27

Control locations and operating modes 27 speed control mode the motor follows a speed reference given to the drive. This mode can be used either with estimated speed as feedback, or with an encoder or resolver for better speed control accuracy. Speed control mode is available in both local and exter...

Page 28

28 control locations and operating modes.

Page 29: Quick Start-Up Guide

Quick start-up guide 29 4 quick start-up guide contents of this chapter this chapter contains the basic start-up sequence of the drive and additional alternative checklists for starting up the drive with the esp control program. In this chapter, the drive is set up using acs-ap-i control panel. You ...

Page 30

30 quick start-up guide warning! Make sure that the machinery into which the drive with brake control function is integrated fulfills the personnel safety regulations. Note that the frequency converter (a complete drive module or a basic drive module, as defined in iec 61800-2), is not considered as...

Page 31

Quick start-up guide 31 in the home view, press ( menu ). The main menu (right) appears. Highlight settings on the menu using and and press ( select ). In the settings menu, highlight date & time (if not already highlighted) and press ( select ). In the date & time menu, highlight date (if not alrea...

Page 32

32 quick start-up guide set the correct date: • use and to move the cursor left and right. • use and to change the value. • press ( save ) to accept the new setting. Check/adjust all the remaining settings in the date & time menu. The show clock setting determines whether the time is shown at all ti...

Page 33

Quick start-up guide 33 highlight parameters and press ( select ). Highlight complete list using and and press ( select ). A listing of parameter groups is displayed. Select motor type. Note: esp control program supports asynchronous and permanent magnet synchronous motors. 99.03 motor type verify u...

Page 34

34 quick start-up guide set motor nominal frequency. 99.08 motor nominal frequency set motor nominal speed. 99.09 motor nominal speed set motor nominal power. 99.10 motor nominal power set motor cos Φ . Note : this value is not mandatory, but can be entered to improve the control accuracy. If not kn...

Page 35

Quick start-up guide 35 4 – jumpers position check the positions of jumpers j1 and j2 on the control unit of the drive. These jumpers determine whether analog inputs ai1 and ai2 are current or voltage. Check/adjust the following parameters. Select the unit to either ma or v, corresponding to jumper ...

Page 36

36 quick start-up guide configure analog outputs if used for drive control: parameter 13.12 – select the source for analog output ao1 (by default, motor speed in rpm). Parameters 13.17 and 13.18 – set low and high source signal values that correspond to the actual analog output values defined in par...

Page 37

Quick start-up guide 37 set the "at setpoint" limits for frequency control of the drive. When the absolute difference between reference and actual frequency ( 01.06 output frequency ) is smaller than 46.22 at frequency hysteresis , the drive is considered to be "at setpoint". This is indicated by bi...

Page 38

38 quick start-up guide esp application minimum configuration this section contains the following alternative control schemes for starting up the drive with the esp control program. Note: for other esp control program features, refer to the corresponding chapter of this manual. Esp control in case f...

Page 39

Quick start-up guide 39 configure acceleration assistance function. • set speed limit for the acceleration assistance. • set current boost to help motor to accelerate high inertia. 75.40 acceleration assistance enable 75.42 acceleration assistance speed limit 75.46 acceleration assistance current co...

Page 40

40 quick start-up guide voltage control consider activating energy optimization in order to set drive automatically minimize current fed to the motor based on actual mechanical load conditions. 80.01 energy optimization enable configure u/f curve settings. Note: automatic energy optimization functio...

Page 41: Esp Program Features

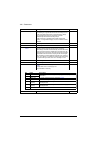

Esp program features 41 5 esp program features what this chapter contains this chapter describes the functions within the control program that are specific to esp application, how to use them and how to program them to operate. Overview of esp control program the electric submersible pump (esp) cont...

Page 42

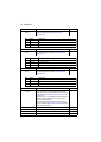

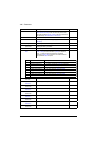

42 esp program features backspin supervision backspin supervision set of functions can be used to monitor the status of pump- motor shaft after production operation is interrupted. The function prevents undesired premature restart of the pump before fluid column is sufficiently drained. Restart dela...

Page 43

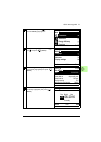

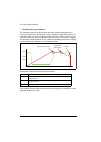

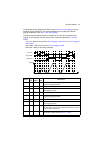

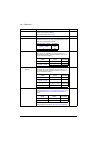

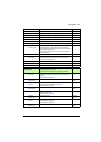

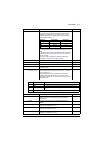

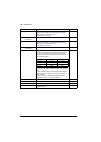

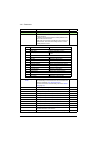

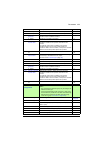

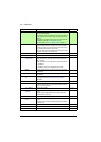

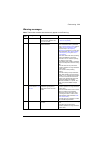

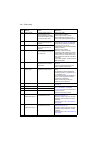

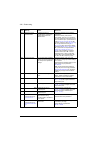

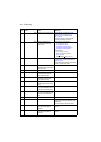

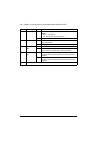

Esp program features 43 the figure below shows the control scenarios of restart delay and backspin speed observer functions. The table below describes the control scenarios of restart delay and backspin speed observer functions. Control scenario description 1 parameter 74.20 restart delay enable fun...

Page 44

44 esp program features 5 drive stops measuring the actual pump-motor speed if start command if off when parameter 09.41 restart delay remaining timer is still counting. 6 parameter 74.30 speed observer enable is set on, so that when restart delay time is elapsed, the speed measurement function star...

Page 45

Esp program features 45 backspin speed observer constraints backspin speed measurement is a special drive control mode that requires physical cable connection to the motor. Therefore, the motor contactor should be closed all the time for the function to work. If the contact to the motor gets impaire...

Page 46

46 esp program features starting the motor in some cases pump motor can be difficult to restart. This might be caused by solids and/or sedimentation clogging the pump. Thus, it requires higher starting torque to break through the blockage. Another difficulty occurs with a complex electric circuit be...

Page 47

Esp program features 47 kick-start kick-start function provides sometime to motor to develop starting torque sufficient to start spinning. The fast acceleration rate settings create risk for the motor to pull out before it gets to follow the frequency reference. Instead, the function gives current b...

Page 48

48 esp program features current pulse-start current pulse-start function enables when regular starting routines are not enough to accelerate the motor. The most common reason can be pump waxing or sedimentation. The function produces a series of thrusts to the pump impeller by sending short high-cur...

Page 49

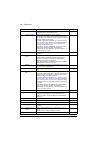

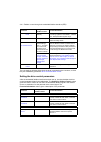

Esp program features 49 esp production mode the esp control program can be used to control motor speed using manual mode and automatic process control mode. Manual mode in manual mode, the drive will control motor speed with user defined acceleration/deceleration ramp rates. Typically, it is desired...

Page 50

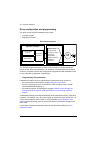

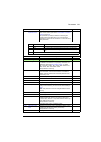

50 esp program features automatic process control mode the pump can be started immediately in automatic process control mode. However, due to a relatively slow nature of the artificial lift process, it usually takes some time before process variable feedback is ready for the closed loop control. To ...

Page 51

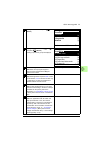

Esp program features 51 in the figure below, the drive starts in manual mode following the user defined pump speed reference. As speed reaches the minimum production speed value defined by the user, only then the automatic process control takes over. Settings parameter group 75 esp reference setup (...

Page 52

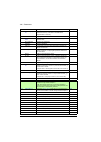

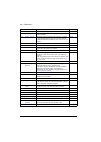

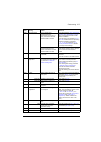

52 esp program features underload and overload protection load protection functions can constantly monitor selected load signal against defined limit which are fixed along the motor speed range or vary according to the load curve settings. Each underload and overload protection function limit type c...

Page 53

Esp program features 53 the action (none, warning or fault) taken when the signal exits the allowed operation area can be selected separately for overload and underload conditions (parameters 79.19 and 79.49 respectively). Each condition also has an optional timer to delay the selected action ( 79.1...

Page 54

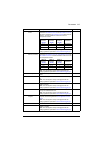

54 esp program features underload ride through recovery sequence the underload protection function protects the motor casing in the presence of fluid flowing over the motor cases. When an esp is pumping the fluid (oil), gas might be ingested by the esp. This results in a reduction or removal of a fl...

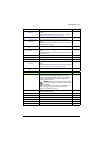

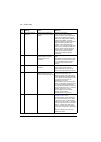

Page 55

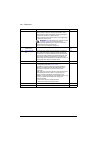

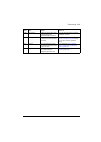

Esp program features 55 the figures below illustrates various scenarios with underload ride through recovery sequence. Load signal / limit reference + boost % underload delay underload act underload recovery active underload drop active warning fault shutdown reference underload boost active delay t...

Page 56

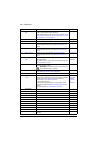

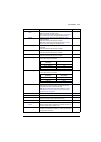

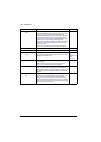

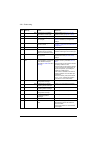

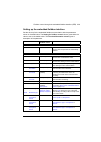

56 esp program features overload recovery sequence the overload protection function protects the motor against overheating due to continuous exposure to high electrical current in absence of appropriate cooling. An overload situation can occur for different reasons and is more likely to occur on new...

Page 57

Esp program features 57 the figure below illustrates various scenarios with overload ride through recovery sequence. Settings parameter group 79 load protection (page 429 ). Recovery - warning (not recovered) recovery - warning (recovered) load signal / limit overload delay overload act overload sav...

Page 58

58 esp program features motor voltage control the motor voltage control function monitors voltage control settings. In step-up applications, motor control is complicated with sophisticated electrical circuit between drive and motor. Incorrect voltage settings and varying load might result in less th...

Page 59

Esp program features 59 pump impeller cleaning the pump impeller cleaning procedure consists of a programmable sequence of motor running forward and reverse for the defined number of cycles. The cleaning function removes the solids stuck to impeller blades and thus reduces the friction and inertial ...

Page 60

60 esp program features pump curves q-h pump curves typically provided by the pump manufacturer can be used for the actual flow rate estimation, provided that total dynamic head measurement is available. You can connect both, intake and discharge pressure measurement signals directly to the drive th...

Page 61: Program Features

Program features 61 6 program features what this chapter contains the control program contains all of the parameters (including actual signals) within the drive. This chapter describes some of the more important functions within the control program, how to use them and how to program them to operate...

Page 62

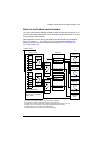

62 program features drive configuration and programming the drive control program is divided into two parts: • firmware program • application program. The firmware program performs the main control functions, including speed and torque control, drive logic (start/stop), i/o, feedback, communication ...

Page 63

Program features 63 adaptive programming conventionally, the user can control the operation of the drive by parameters. However, the standard parameters have a fixed set of choices or a setting range. To further customize the operation of the drive, an adaptive program can be constructed out of a se...

Page 64

64 program features control interfaces programmable analog inputs the control unit has two programmable analog inputs. Each of the inputs can be independently set as a voltage (0/2…10 v or -10…10 v) or current (0/4…20 ma) input by a jumper or switch on the control unit. Each input can be filtered, i...

Page 65

Program features 65 settings parameter groups 10 standard di, ro (page 184 ) and 11 standard dio, fi, fo (page 191 ). Programmable relay outputs the control unit has three relay outputs. The signal to be indicated by the outputs can be selected by parameters. The relay outputs on the control unit ar...

Page 66

66 program features settings • parameter groups 14 i/o extension module 1 (page 204 ), 15 i/o extension module 2 (page 223 ), 16 i/o extension module 3 (page 227 ). • parameter 60.41 (page 401 )..

Page 67

Program features 67 fieldbus control the drive can be connected to several different automation systems through its fieldbus interfaces. See chapters fieldbus control through the embedded fieldbus interface (efb) (page 607 ) and fieldbus control through a fieldbus adapter (page 631 ). Settings param...

Page 68

68 program features master/follower functionality general the master/follower functionality can be used to link several drives together so that the load can be evenly distributed between the drives. This is ideal in applications where the motors are coupled to each other via gearing, chain, belt, et...

Page 69

Program features 69 the master drive is typically speed-controlled and the other drives follow its torque or speed reference. In general, a follower should be • torque-controlled when the motor shafts of the master and the follower are rigidly coupled by gearing, chain etc. So that no speed differen...

Page 70

70 program features notes: • the function can be enabled only when the drive is a speed-controlled follower in remote control mode. • drooping ( 25.08 drooping rate ) is ignored when the load share function is active. • the master and follower should have the same speed control tuning values. • the ...

Page 71

Program features 71 to indicate faults in the followers, each follower must be configured to transmit its status word as one of the above-mentioned data words. In the master, the corresponding target parameter must be set to follower sw . The action to be taken when a follower is faulted is selected...

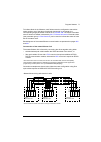

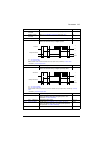

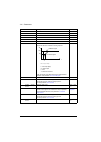

Page 72

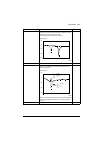

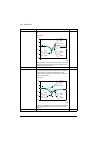

72 program features ring configuration with fiber optic cables t = transmitter; r = receiver follower 2 (zcu) control unit fdco r t follower 1 (bcu) control unit rdco r t ch2 master (zcu) control unit fdco r t follower 3 (zcu) control unit f dco follower 1 star configuration with fiber optic cables ...

Page 73

Program features 73 example parameter settings the following is a checklist of parameters that need to be set when configuring the master/follower link. In this example, the master broadcasts the follower control word, a speed reference and a torque reference. The follower returns a status word and ...

Page 74

74 program features follower settings: • master/follower link activation • 60.01 m/f communication port (fiber optic channel or xd2d selection) • 60.02 m/f node address = 2…60 • 60.03 m/f mode = ddcs follower (for both fiber optic and wire connection) • 60.05 m/f hw connection ( ring or star for fib...

Page 75

Program features 75 external controller interface general the drive can be connected to an external controller (such as the abb ac 800m) using either fiber optic or twisted-pair cable. The acs880 is compatible with both the modulebus and drivebus connections. Note that some features of drivebus (suc...

Page 76

76 program features the communication uses data sets 10…33. The contents of the data sets are freely configurable, but data set 10 typically contains the control word and one or two references, while data set 11 returns the status word and selected actual values. For modulebus communication, the acs...

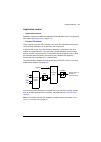

Page 77

Program features 77 control of a supply unit (lsu) general with drives that consist of a supply unit and one inverter unit, the supply unit can be controlled through the inverter unit. (in drive systems consisting of multiple inverter units, this feature is not typically used.) for example, the inve...

Page 78

78 program features with acs880 single drives with a separate supply unit, the basic communication is initialized by parameter 95.20 hw options word 1 . This will make several parameters visible (see below). If the supply unit is regenerative (such as an igbt supply unit), it is possible to send a d...

Page 79

Program features 79 motor control direct torque control (dtc) the motor control of the acs880 is based on direct torque control (dtc), the abb premium motor control platform. The switching of the output semiconductors is controlled to achieve the required stator flux and motor torque. The switching ...

Page 80

80 program features special acceleration/deceleration ramps the acceleration/deceleration times for the jogging function can be defined separately; see section jogging (page 92 ) . The change rate of the motor potentiometer function (page 106 ) is adjustable. The same rate applies in both directions...

Page 81

Program features 81 reference exits the range. Any instant change in the output is smoothed out by the ramping function further in the reference chain. The function is also available for scalar motor control with a frequency reference. The input of the function is shown by 28.96 frequency ref act 7 ...

Page 82

82 program features ( 99 motor data ). The calculated maximum speed during the routine is the initial speed (ie. Speed when the routine is activated) + 25.39 autotune speed step , unless limited by 30.12 maximum speed or 99.09 motor nominal speed . The diagram below shows the behavior of speed and t...

Page 83

Program features 83 autotune modes autotuning can be performed in three different ways depending on the setting of parameter 25.34 speed controller autotune mode . The selections smooth , normal and tight define how the drive torque reference should react to a speed reference step after tuning. The ...

Page 84

84 program features the figure below is a simplified block diagram of the speed controller. The controller output is the reference for the torque controller. Warning indications a warning message, af90 speed controller autotuning , will be generated if the autotune routine does not complete successf...

Page 85

Program features 85 tuning procedure for oscillation damping note: changing the speed error low-pass filter time constant or the integration time of the speed controller can affect the tuning of the oscillation damping algorithm. It is recommended to tune the speed controller before the oscillation ...

Page 86

86 program features the function is based on a pi controller. The proportional gain and integration time can be defined by parameters. Setting these to zero disables rush control. Settings parameters 26.81 rush control gain and 26.82 rush control integration time (page 285 ). Encoder support the pro...

Page 87

Program features 87 encoder echo and emulation both encoder echo and emulation are supported by the above-mentioned fen-xx interfaces. Encoder echo is available with ttl, ttl+ and htl encoders. The signal received from the encoder is relayed to the ttl output unchanged. This enables the connection o...

Page 88

88 program features mentioned above are 1:1. The ratios can only be changed with the drive stopped; new settings require validation by 91.10 encoder parameter refresh . Position counter the control program contains a position counter feature that can be used to indicate the position of the load. The...

Page 89

Program features 89 pos counter init cmd source , such as a proximity switch connected to a digital input, is activated. A successful initialization is indicated by bit 4 of 90.35 pos counter status . Any subsequent initialization of the counter must first be enabled by 90.69 reset pos counter init ...

Page 90

90 program features for example, to read parameter 90.07 load position scaled int through fieldbus, set the selection parameter of the desired dataset (in group 52) to other – 90.07 , and select the format. If you select a 32-bit format, the subsequent data word is also automatically reserved. Confi...

Page 91

Program features 91 • ( 90.53 load gear numerator = 1) • 90.54 load gear denominator = 50 the cable drum turns one revolution per 50 revolutions of the motor shaft. • ( 90.61 gear numerator = 1) • ( 90.62 gear denominator = 1) (these parameters need not be changed as position estimate is not being u...

Page 92

92 program features in the acs880, the following settings are made: • 92.01 encoder 1 type = htl • 92.02 encoder 1 source = module 1 • 92.10 pulses/revolution = 2048 • 92.13 position estimation enable = enable • 90.51 load feedback selection = encoder 1 • 90.63 feed constant numerator = 8192 (ie. 4 ...

Page 93

Program features 93 ref ) along the defined jogging acceleration ramp ( 23.20 acc time jogging ). After the activation signal switches off, the drive decelerates to a stop along the defined jogging deceleration ramp ( 23.21 dec time jogging ). The figure and table below provide an example of how the...

Page 94

94 program features see also the block diagram on page 646 . The jogging function operates on a 2 ms time level. Notes: • jogging is not available when the drive is in local control. • jogging cannot be enabled when the drive start command is on, or the drive started when jogging is enabled. Startin...

Page 95

Program features 95 settings parameters 20.25 jogging enable (page 241 ), 20.26 jogging 1 start source (page 241 ), 20.27 jogging 2 start source (page 242 ), 22.42 jogging 1 ref (page 253 ), 22.43 jogging 2 ref (page 253 ), 23.20 acc time jogging (page 260 ) and 23.21 dec time jogging (page 260 ). S...

Page 96

96 program features settings • parameters 19.20 scalar control reference unit (page 233 ), 97.12 ir comp step- up frequency (page 491 ), 97.13 ir compensation (page 492 ) and 99.04 motor control mode (page 495 ) • parameter group 28 frequency reference chain (page 285 ). Autophasing autophasing is a...

Page 97

Program features 97 the autophasing routine is performed with permanent magnet synchronous motors and synchronous reluctance motors in the following cases: 1. One-time measurement of the rotor and encoder position difference when an absolute encoder, a resolver, or an encoder with commutation signal...

Page 98

98 program features bit 4 of 06.21 drive status word 3 indicates if the rotor position has already been determined. Autophasing modes several autophasing modes are available (see parameter 21.13 autophasing mode ). The turning mode ( turning ) is recommended especially with case 1 (see the list abov...

Page 99

Program features 99 flux braking the drive can provide greater deceleration by raising the level of magnetization in the motor. By increasing the motor flux, the energy generated by the motor during braking can be converted to motor thermal energy. The drive monitors the motor status continuously, a...

Page 100

100 program features dc magnetization dc magnetization can be applied to the motor to • heat the motor to remove or prevent condensation, or • to lock the rotor at, or near, zero speed. Pre-heating a motor pre-heating function is available to prevent condensation in a stopped motor, or to remove con...

Page 101

Program features 101 notes: • dc hold is only available in speed control in dtc motor control mode (see page 26 ). • the function applies the dc current to one phase only, depending on the position of the rotor. The return current will be shared between the other phases. Post-magnetization this feat...

Page 102

102 program features warning: the motor must be designed to absorb or dissipate the thermal energy generated by continuous magnetization, for example by forced ventilation. Settings parameters 06.21 drive status word 3 (page 171 ), 21.01 start mode , 21.02 magnetization time , 21.08 … 21.12 , 21.14 ...

Page 103

Program features 103 application control application macros application macros are predefined application parameter edits and i/o configurations. See chapter application macros (page 131 ). Process pid control there is a built-in process pid controller in the drive. The controller can be used to con...

Page 104

104 program features quick configuration of the process pid controller 1. Activate the process pid controller (parameter 40.07 set 1 pid operation mode ). 2. Select a feedback source (parameters 40.08 … 40.11 ). 3. Select a setpoint source (parameters 40.16 … 40.25 ). 4. Set the gain, integration ti...

Page 105

Program features 105 tracking in tracking mode, the pid block output is set directly to the value of parameter 40.50 (or 41.50 ) set 1 tracking ref selection . The internal i term of the pid controller is set so that no transient is allowed to pass on to the output, so when the tracking mode is left...

Page 106

106 program features motor potentiometer the motor potentiometer is, in effect, a counter whose value can be adjusted up and down using two digital signals selected by parameters 22.73 motor potentiometer up source and 22.74 motor potentiometer down source . Note that these signals have no effect wh...

Page 107

Program features 107 mechanical brake control a mechanical brake can be used for holding the motor and driven machinery at zero speed when the drive is stopped, or not powered. The brake control logic observes the settings of parameter group 44 mechanical brake control as well as several external si...

Page 108

108 program features brake state diagram state descriptions state name description brake disabled brake control is disabled (parameter 44.06 brake control enable = 0, and 44.01 brake control status b4 = 0). The brake is closed ( 44.01 brake control status b0 = 0). Brake opening : brake opening wait ...

Page 109

Program features 109 state change conditions ( ) brake closing : brake closing wait brake has been requested to close. The drive logic is requested to ramp down the speed to a stop ( 44.01 brake control status b3 = 1). The open signal is kept active ( 44.01 brake control status b0 = 1). The brake lo...

Page 110

110 program features timing diagram the simplified timing diagram below illustrates the operation of the brake control function. Refer to the state diagram above. T s start torque at brake open (parameter 44.03 brake open torque reference ) t mem stored torque value at brake close ( 44.02 brake torq...

Page 111

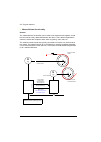

Program features 111 wiring example the figure below shows a brake control wiring example. The brake control hardware and wiring is to be sourced and installed by the customer. Warning! Make sure that the machinery into which the drive with brake control function is integrated fulfills the personnel...

Page 112

112 program features dc voltage control overvoltage control overvoltage control of the intermediate dc link is typically needed when the motor is in generating mode. The motor can generate when it decelerates or when the load overhauls the motor shaft, causing the shaft to turn faster than the appli...

Page 113

Program features 113 automatic restart it is possible to restart the drive automatically after a short (max. 5 seconds) power supply failure by using the automatic restart function provided that the drive is allowed to run for 5 seconds without the cooling fans operating. When enabled, the function ...

Page 114

114 program features settings parameters 01.11 dc voltage (page 152 ), 30.30 overvoltage control (page 300 ), 30.31 undervoltage control (page 300 ), 95.01 supply voltage (page 473 ), and 95.02 adaptive voltage limits (page 474 ). Brake chopper a brake chopper can be used to handle the energy genera...

Page 115

Program features 115 safety and protections emergency stop the emergency stop signal is connected to the input selected by parameter 21.05 emergency stop source . An emergency stop can also be generated through fieldbus (parameter 06.01 main control word , bits 0…2). The mode of the emergency stop i...

Page 116

116 program features motor thermal protection the control program features two separate motor temperature monitoring functions. The temperature data sources and warning/trip limits can be set up independently for each function. The motor temperature can be monitored using • the motor thermal protect...

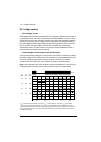

Page 117

Program features 117 voltage over the sensor. The temperature measurement function calculates the resistance of the sensor and generates an indication if overtemperature is detected. For wiring of the sensor, refer to the hardware manual of the drive. The figure below shows typical ptc sensor resist...

Page 118

118 program features fen-xx encoder interfaces (optional) also have a connection for one kty84 sensor. The figure and table below show typical kty84 sensor resistance values as a function of the motor operating temperature. The warning and fault limits can be adjusted by parameters. For the wiring o...

Page 119

Program features 119 thermal protection of motor cable the control program contains a thermal protection function for the motor cable. This function should be used, for example, when the nominal current of the drive exceeds the current-carrying capacity of the motor cable. The program calculates the...

Page 120

120 program features the action (none, warning or fault) taken when the signal exits the allowed operation area can be selected separately for overload and underload conditions (parameters 37.03 and 37.04 respectively). Each condition also has an optional timer to delay the selected action ( 37.41 a...

Page 121

Program features 121 other programmable protection functions external events (parameters 31.01 … 31.10 ) five different event signals from the process can be connected to selectable inputs to generate trips and warnings for the driven equipment. When the signal is lost, an external event (fault, war...

Page 122

122 program features overspeed protection (parameter 31.30 ) the user can set overspeed limits by specifying a margin that is added to the currently-used maximum and minimum speed limits. Ramp stop supervision (parameters 31.32 , 31.33 , 31.37 and 31.38 ) the control program has a supervision functi...

Page 123

Program features 123 diagnostics fault and warning messages, data logging see chapter fault tracing (page 565 ). Signal supervision three signals can be selected to be supervised by this function. Whenever a supervised signal exceeds or falls below predefined limits, a bit in 32.01 supervision statu...

Page 124

124 program features energy saving calculators this feature consists of the following functionalities: • an energy optimizer that adjusts the motor flux in such a way that the total system efficiency is maximized • a counter that monitors used and saved energy by the motor and displays them in kwh, ...

Page 125

Program features 125 amplitude logger 1 is fixed to monitor motor current, and cannot be reset. With amplitude logger 1, 100% corresponds to the maximum output current of the drive ( i max , as given in the hardware manual). The measured current is logged continuously. The distribution of samples is...

Page 126

126 program features miscellaneous user parameter sets the drive supports four user parameter sets that can be saved to the permanent memory and recalled using drive parameters. It is also possible to use digital inputs to switch between user parameter sets. A user parameter set contains all editabl...

Page 127

Program features 127 settings parameters 96.53 … 96.59 (page 485 ). User lock for better cybersecurity, it is highly recommended that you set a master pass code to prevent eg. The changing of parameter values and/or the loading of firmware and other files. Warning! Abb will not be liable for damages...

Page 128

128 program features note that “ analog src ” type parameters (see page 503 ) expect a 32-bit real (floating point) source – in other words, parameters 47.01 … 47.08 can be used as a value source of other parameters while 47.11 … 47.28 cannot. To use a 16-bit integer (received in ddcs data sets) as ...

Page 129

Program features 129 7. Switch on the power to the drive/inverter unit. 8. Enter the number of inverter modules present into parameter 95.13 reduced run mode . 9. Reset all faults and start the drive/inverter unit. The maximum current is now automatically limited according to the new inverter config...

Page 130

130 program features for custom filters: parameters 97.01 switching frequency reference , 97.02 minimum switching frequency (page 489 ), 99.18 sine filter inductance and 99.19 sine filter capacitance (page 500 )..

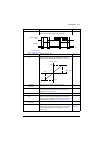

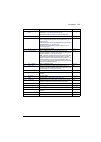

Page 131: Application Macros

Application macros 131 7 application macros what this chapter contains this chapter describes the intended use, operation and default control connections of the application macros. More information on the connectivity of the control unit is given in the hardware manual of the drive. General applicat...

Page 132

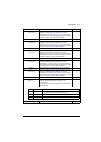

132 application macros factory macro the factory macro is suited to relatively straightforward speed control applications such as conveyors, pumps and fans, and test benches. The drive is speed-controlled with the reference signal connected to analog input ai1. The start/stop commands are given thro...

Page 133

Application macros 133 default control connections for the factory macro fault xpow external power input 1 +24vi 24 v dc, 2 a 2 gnd xai reference voltage and analog inputs 1 +vref 10 v dc, r l 1…10 kohm 2 -vref -10 v dc, r l 1…10 kohm 3 agnd ground 4 ai1+ speed reference 0(2)…10 v, r in > 200 kohm 5...

Page 134

134 application macros hand/auto macro the hand/auto macro is suited to speed control applications where two external control devices are used. The drive is speed-controlled from the external control locations ext1 (hand control) and ext2 (auto control). The selection between the control locations i...

Page 135

Application macros 135 default control connections for the hand/auto macro fault xpow external power input 1 +24vi 24 v dc, 2 a 2 gnd xai reference voltage and analog inputs 1 +vref 10 v dc, r l 1…10 kohm 2 -vref -10 v dc, r l 1…10 kohm 3 agnd ground 4 ai1+ speed reference (hand) 0(2)…10 v, r in > 2...

Page 136

136 application macros pid control macro the pid control macro is suitable for process control applications, for example closed-loop pressure, level or flow control systems such as • pressure boost pumps of municipal water supply systems • level-controlling pumps of water reservoirs • pressure boost...

Page 137

Application macros 137 default parameter settings for the pid control macro below is a listing of default parameter values that differ from those listed for the factory macro in parameter listing (page 152 ). Note: the macro selection does not affect parameter group 41 process pid set 2 . Parameter ...

Page 138

138 application macros default control connections for the pid control macro fault p i xpow external power input 1 +24vi 24 v dc, 2 a 2 gnd xai reference voltage and analog inputs 1 +vref 10 v dc, r l 1…10 kohm 2 -vref -10 v dc, r l 1…10 kohm 3 agnd ground 4 ai1+ speed reference 0(2)…10 v, r in > 20...

Page 139

Application macros 139 sensor connection examples for the pid control macro p i actual value measurement -20…20 ma. R in = 100 ohm 0/4…20 ma note: the sensor must be powered externally. P i + auxiliary voltage output (200 ma max.) + – p i drive 1 0/4…20 ma – + actual value measurement -20…20 ma. R i...

Page 140

140 application macros torque control macro this macro is used in applications in which torque control of the motor is required. These are typically tension applications, where a particular tension needs to be maintained in the mechanical system. Torque reference is given through analog input ai2, t...

Page 141

Application macros 141 default control connections for the torque control macro fault xpow external power input 1 +24vi 24 v dc, 2 a 2 gnd xai reference voltage and analog inputs 1 +vref 10 v dc, r l 1…10 kohm 2 -vref -10 v dc, r l 1…10 kohm 3 agnd ground 4 ai1+ speed reference 0(2)…10 v, r in > 200...

Page 142

142 application macros sequential control macro the sequential control macro is suited for speed control applications in which a speed reference, multiple constant speeds, and two acceleration and deceleration ramps can be used. Only ext1 is used in this macro. The macro offers seven preset constant...

Page 143

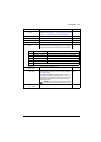

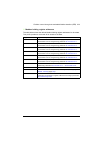

Application macros 143 selection of constant speeds by default, constant speeds 1…7 are selected using digital inputs di4…di6 as follows: default parameter settings for the sequential control macro below is a listing of default parameter values that differ from those listed for the factory macro in ...

Page 144

144 application macros default control connections for the sequential control macro fault xpow external power input 1 +24vi 24 v dc, 2 a 2 gnd xai reference voltage and analog inputs 1 +vref 10 v dc, r l 1…10 kohm 2 -vref -10 v dc, r l 1…10 kohm 3 agnd ground 4 ai1+ speed reference 0(2)…10 v, r in >...

Page 145

Application macros 145 fieldbus control macro this application macro is not supported by the current firmware version..

Page 146

146 application macros.

Page 147: Parameters

Parameters 147 8 parameters what this chapter contains the chapter describes the parameters, including actual signals of the control program..

Page 148

148 parameters terms and abbreviations term definition actual signal type of parameter that is the result of a measurement or calculation by the drive, or contains status information. Most actual signals are read-only, but some (especially counter-type actual signals) can be reset. Def (in the follo...

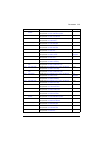

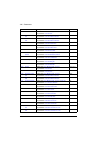

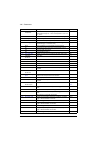

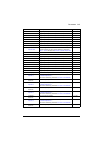

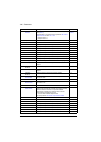

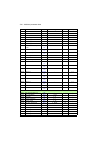

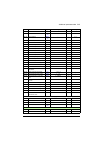

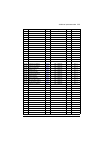

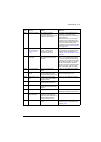

Page 149

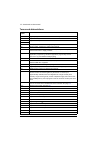

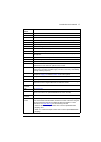

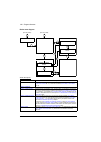

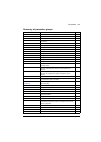

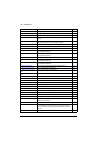

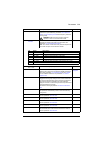

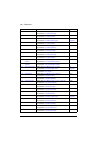

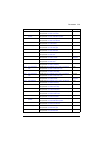

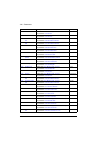

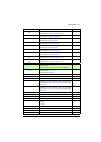

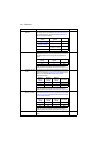

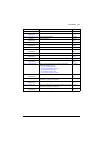

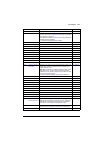

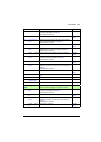

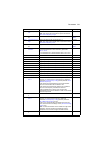

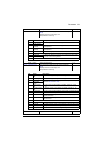

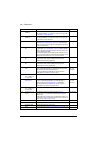

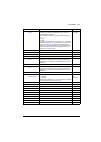

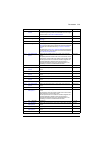

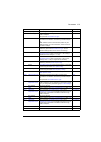

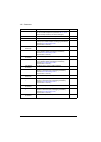

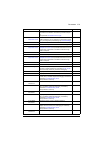

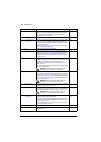

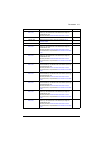

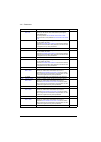

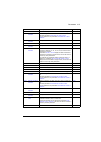

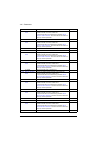

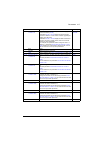

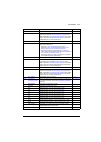

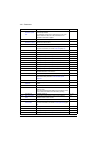

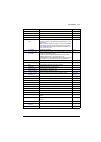

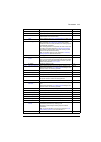

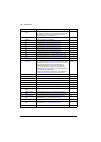

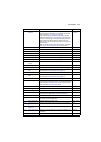

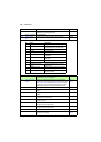

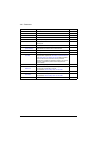

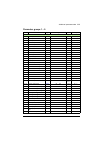

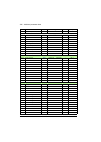

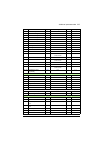

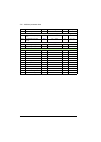

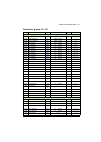

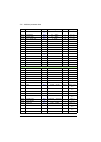

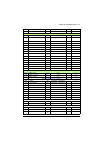

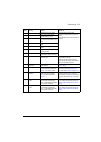

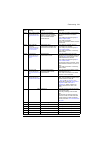

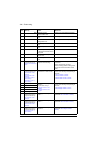

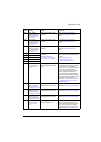

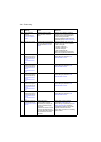

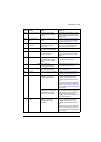

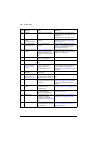

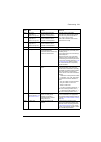

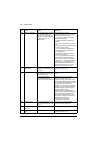

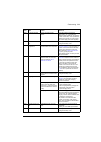

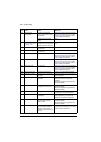

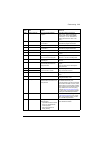

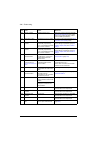

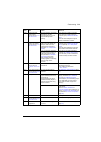

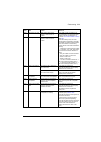

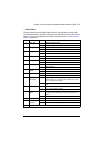

Parameters 149 summary of parameter groups group contents page 01 actual values basic signals for monitoring the drive. 152 03 input references values of references received from various sources. 156 04 warnings and faults information on warnings and faults that occurred last. 157 05 diagnostics var...

Page 150

150 parameters 43 brake chopper settings for the internal brake chopper. 355 44 mechanical brake control configuration of mechanical brake control. 357 45 energy efficiency settings for the energy saving calculators. 361 46 monitoring/scaling settings speed supervision settings; actual signal filter...

Page 151

Parameters 151 98 user motor parameters motor values supplied by the user that are used in the motor model. 493 99 motor data motor configuration settings. 495 200 safety fso-xx settings. 501 group contents page.

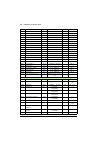

Page 152

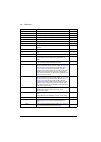

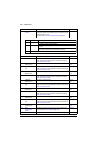

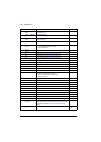

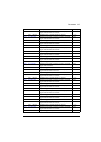

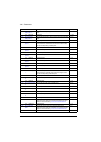

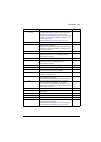

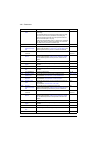

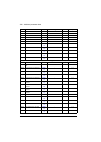

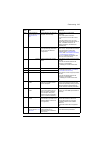

152 parameters parameter listing no. Name/value description def / fbeq16 01 01 actual values basic signals for monitoring the drive. All parameters in this group are read-only unless otherwise noted. 01.01 motor speed used measured or estimated motor speed depending on which type of feedback is used...

Page 153

Parameters 153 01.13 output voltage calculated motor voltage in v ac. - 0…2000 v motor voltage. 1 = 1 v 01.14 output power drive output power. The unit is selected by parameter 96.16 unit selection . A filter time constant for this signal can be defined by parameter 46.14 filter time power out . - -...

Page 154

154 parameters 01.30 nominal torque scale torque that corresponds to 100% of nominal motor torque. The unit is selected by parameter 96.16 unit selection note: this value is copied from parameter 99.12 motor nominal torque if entered. Otherwise the value is calculated from other motor data. - 0.000…...

Page 155

Parameters 155 01.65 abs output power absolute value of 01.14 output power . - 0.00 … 32767.00 kw or hp output power. 1 = 1 unit 01.66 abs output power % motor nom absolute value of 01.15 output power % of motor nom . - 0.00 … 300.00% output power. 10 = 1% 01.68 abs motor shaft power absolute value ...

Page 156

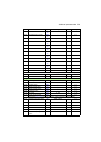

156 parameters 01.114 grid reactive power (only visible when igbt supply unit control activated by 95.20 ) estimated reactive power being transferred through the supply unit. - -30000.00 … 30000.00 kvar estimated reactive power. 10 = 1 kvar 01.116 lsu cos Φ (only visible when igbt supply unit contro...

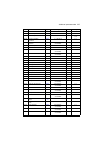

Page 157

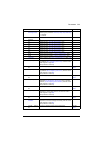

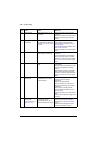

Parameters 157 03.11 ddcs controller ref 1 reference 1 received from the external (ddcs) controller. The value has been scaled according to parameter 60.60 ddcs controller ref1 type . See also section external controller interface (page 75 ). 1 = 10 -30000.00 … 30000.00 scaled reference 1 received f...

Page 158

158 parameters 04.10 active warning 5 code of the 5th active warning. - 0000h…ffffh 5th active warning. 1 = 1 04.11 latest fault code of the 1st stored (non-active) fault. - 0000h…ffffh 1st stored fault. 1 = 1 04.12 2nd latest fault code of the 2nd stored (non-active) fault. - 0000h…ffffh 2nd stored...

Page 159

Parameters 159 04.21 fault word 1 acs800-compatible fault word 1. The bit assignments of this word correspond to fault word 1 in the acs800. Parameter 04.120 fault/warning word compatibility determines whether the bit assignments are according to the acs800 standard or acs800 system control program....

Page 160

160 parameters 04.22 fault word 2 acs800-compatible fault word 2. The bit assignments of this word correspond to fault word 2 in the acs800. Parameter 04.120 fault/warning word compatibility determines whether the bit assignments are according to the acs800 standard or acs800 system control program....

Page 161

Parameters 161 04.31 warning word 1 acs800-compatible warning (alarm) word 1. The bit assignments of this word correspond to alarm word 1 in the acs800. Parameter 04.120 fault/warning word compatibility determines whether the assignments are according to the acs800 standard or acs800 system control ...

Page 162

162 parameters 04.32 warning word 2 acs800-compatible warning (alarm) word 2. The bit assignments of this word correspond to alarm word 2 in the acs800. Parameter 04.120 fault/warning word compatibility determines whether the bit assignments are according to the acs800 standard or acs800 system cont...

Page 163

Parameters 163 04.41 event word 1 bit 0 code selects the hexadecimal code of an event (warning, fault or pure event) whose status is shown as bit 0 of 04.40 event word 1 . The event codes are listed in chapter fault tracing (page 565 ). 0000h 0000h…ffffh code of event. 1 = 1 04.42 event word 1 bit 0...

Page 164

164 parameters acs800 system ctrl program the bit assignments of parameters 04.21 … 04.32 correspond to the acs800 system control program as follows: 04.21 fault word 1 : 09.01 fault word 1 04.22 fault word 2 : 09.02 fault word 2 04.31 warning word 1 : 09.04 alarm word 1 04.32 warning word 2 : 09.05...

Page 165

Parameters 165 05.42 aux. Fan service counter displays the age of the auxiliary cooling fan as a percentage of its estimated lifetime. The estimate is based on the duty, operating conditions and other operating parameters of the fan. When the counter reaches 100%, a warning ( a8c0 fan service counte...

Page 166

166 parameters 06.04 fba b transparent control word displays the unaltered control word received from the plc through fieldbus adapter b when a transparent communication profile is selected eg. By parameter group 54 fba b settings . See section control word and status word (page 634 ). This paramete...

Page 167

Parameters 167 06.16 drive status word 1 drive status word 1. This parameter is read-only. - 0000h…ffffh drive status word 1. 1 = 1 no. Name/value description def / fbeq16 bit name description 0 enabled 1 = both run enable (see par. 20.12 ) and start enable ( 20.19 ) signals are present, and safe to...

Page 168

168 parameters 06.17 drive status word 2 drive status word 2. This parameter is read-only. - 0000h…ffffh drive status word 2. 1 = 1 no. Name/value description def / fbeq16 bit name description 0 identification run done 1 = motor identification (id) run has been performed 1 magnetized 1 = the motor h...

Page 169

Parameters 169 06.18 start inhibit status word start inhibit status word. This word specifies the source of the inhibiting condition that is preventing the drive from starting. After the condition is removed, the start command must be cycled. See bit-specific notes see also parameter 06.25 drive inh...

Page 170

170 parameters 06.19 speed control status word speed control status word. This parameter is read-only. - 0000h…ffffh speed control status word. 1 = 1 no. Name/value description def / fbeq16 bit name description 0 zero speed 1 = drive is running at zero speed, ie. The absolute value of par. 90.01 mot...

Page 171

Parameters 171 06.20 constant speed status word constant speed/frequency status word. Indicates which constant speed or frequency is active (if any). See also parameter 06.19 speed control status word , bit 7, and section constant speeds/frequencies (page 80 ). This parameter is read-only. - 0000h…f...

Page 172

172 parameters 06.25 drive inhibit status word 2 drive inhibit status word 2. This word specifies the source of the inhibiting condition that is preventing the drive from starting. After the condition is removed, the start command must be cycled. See bit-specific notes. See also parameter 06.18 star...

Page 173

Parameters 173 06.32 msw bit 13 sel selects a binary source whose status is transmitted as bit 13 of 06.11 main status word . False false 0. 0 true 1. 1 other [bit] source selection (see terms and abbreviations on page 148 ). - 06.33 msw bit 14 sel selects a binary source whose status is transmitted...

Page 174

174 parameters 06.39 internal state machine lsu cw (only visible when supply unit control activated by 95.20 ) shows the control word sent to the supply unit from the inu- lsu (inverter unit/supply unit) state machine. This parameter is read-only. - 0000h…ffffh supply unit control word. 1 = 1 06.40 ...

Page 175

Parameters 175 mcw user bit 0 bit 12 of 06.01 main control word (see page 165 ). 2 mcw user bit 1 bit 13 of 06.01 main control word (see page 165 ). 3 mcw user bit 2 bit 14 of 06.01 main control word (see page 165 ). 4 mcw user bit 3 bit 15 of 06.01 main control word (see page 165 ). 5 other [bit] s...

Page 176

176 parameters mcw user bit 1 bit 13 of 06.01 main control word (see page 165 ). 3 mcw user bit 2 bit 14 of 06.01 main control word (see page 165 ). 4 mcw user bit 3 bit 15 of 06.01 main control word (see page 165 ). 5 other [bit] source selection (see terms and abbreviations on page 148 ). - 06.48 ...

Page 177

Parameters 177 06.63 user status word 1 bit 3 sel selects a binary source whose status is shown as bit 3 of 06.50 user status word 1 . Magnetized false 0. 0 true 1. 1 magnetized bit 1 of 06.17 drive status word 2 (see page 168 ). 2 other [bit] source selection (see terms and abbreviations on page 14...

Page 178

178 parameters true 1. 1 torque control bit 2 of 06.17 drive status word 2 (see page 168 ). 2 other [bit] source selection (see terms and abbreviations on page 148 ). - 06.71 user status word 1 bit 11 sel selects a binary source whose status is shown as bit 11 of 06.50 user status word 1 . Zero spee...

Page 179

Parameters 179 06.101 user control word 2 user-defined control word 2. - 0000h…ffffh user-defined control word 2. 1 = 1 06.116 lsu drive status word 1 (only visible when igbt supply unit control activated by 95.20 ) drive status word 1 received from the supply unit. See also section control of a sup...

Page 180

180 parameters 06.118 lsu start inhibit status word (only visible when igbt supply unit control activated by 95.20 ) this word specifies the source of the inhibiting condition that is preventing the supply unit from starting. See also section control of a supply unit (lsu) (page 77 ), and parameter ...

Page 181

Parameters 181 07.21 application environment status 1 (only visible with option +n8010 [application programmability]) shows which tasks of the application program are running. See the drive (iec 61131-3) application programming manual (3aua0000127808 [english]). - 0000h…ffffh application program tas...

Page 182

182 parameters 07.30 adaptive program status shows the status of the adaptive program. See section adaptive programming (page 63 ). - 0000h…ffffh adaptive program status. 1 = 1 07.40 iec application cpu usage peak (only visible with option +n8010 [application programmability]) displays the peak load...

Page 183

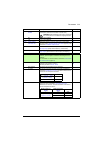

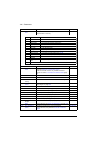

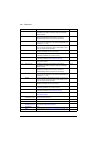

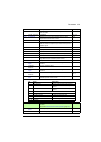

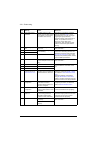

Parameters 183 09 09 esp signals esp signals to monitor the pump. 09.01 esp status word displays the current state of the esp application functions. 09.09 drive control state displays the current state of drive control. Drive not ready drive not ready drive is not ready for operation. 0 id run undon...

Page 184

184 parameters -600.00...600.00 hz esp frequency. 10 = 1hz 09.22 speed reference % displays esp speed/frequency reference in percent scale. 0.00 -1200.00 ...1200.00 % speed reference. 10 = 1% 09.23 speed reference used displays the speed reference currently produced by the esp control program. 0.0 -...

Page 185

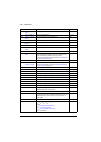

Parameters 185 10.03 di force selection the electrical statuses of the digital inputs can be overridden for eg. Testing purposes. A bit in parameter 10.04 di force data is provided for each digital input, and its value is applied whenever the corresponding bit in this parameter is 1. 0000h 0000h…fff...

Page 186

186 parameters 10.07 di2 on delay defines the activation delay for digital input di2. 0.0 s t on = 10.07 di2 on delay t off = 10.08 di2 off delay *electrical status of digital input. Indicated by 10.01 di status . **indicated by 10.02 di delayed status . 0.0 … 3000.0 s activation delay for di2. 10 =...

Page 187

Parameters 187 10.11 di4 on delay defines the activation delay for digital input di4. 0.0 s t on = 10.11 di4 on delay t off = 10.12 di4 off delay *electrical status of digital input. Indicated by 10.01 di status . **indicated by 10.02 di delayed status . 0.0 … 3000.0 s activation delay for di4. 10 =...

Page 188

188 parameters 10.15 di6 on delay defines the activation delay for digital input di6. 0.0 s t on = 10.15 di6 on delay t off = 10.16 di6 off delay *electrical status of digital input. Indicated by 10.01 di status . **indicated by 10.02 di delayed status . 0.0 … 3000.0 s activation delay for di6. 10 =...

Page 189

Parameters 189 remote control bit 9 of 06.11 main status word (see page 166 ). 24 supervision 1 bit 0 of 32.01 supervision status (see page 312 ). 33 supervision 2 bit 1 of 32.01 supervision status (see page 312 ). 34 supervision 3 bit 2 of 32.01 supervision status (see page 312 ). 35 ro/dio control...

Page 190

190 parameters 10.28 ro2 on delay defines the activation delay for relay output ro2. 0.0 s ( 95.20 b3) t on = 10.28 ro2 on delay t off = 10.29 ro2 off delay 0.0 … 3000.0 s activation delay for ro2. 10 = 1 s 10.29 ro2 off delay defines the deactivation delay for relay output ro2. See parameter 10.28 ...

Page 191

Parameters 191 10.99 ro/dio control word storage parameter for controlling the relay outputs and digital input/outputs eg. Through the embedded fieldbus interface. To control the relay outputs (ro) and the digital input/outputs (dio) of the drive, send a control word with the bit assignments shown b...

Page 192

192 parameters ready ref bit 2 of 06.11 main status word (see page 166 ). 8 at setpoint bit 8 of 06.11 main status word (see page 166 ). 9 reverse bit 2 of 06.19 speed control status word (see page 170 ). 10 zero speed bit 0 of 06.19 speed control status word (see page 170 ). 11 above limit bit 10 o...

Page 193

Parameters 193 11.09 dio2 function selects whether dio2 is used as a digital output or input, or a frequency output. Output output dio2 is used as a digital output. 0 input dio2 is used as a digital input. 1 frequency dio2 is used as a frequency output. 2 11.10 dio2 output source selects a drive sig...

Page 194

194 parameters 11.42 freq in 1 min defines the minimum for the frequency actually arriving at frequency input 1 (dio1 when it is used as a frequency input). The incoming frequency signal ( 11.38 freq in 1 actual value ) is scaled into an internal signal ( 11.39 freq in 1 scaled ) by parameters 11.42...

Page 195

Parameters 195 speed ref ramp in 23.01 speed ref ramp input (page 257 ). 10 speed ref ramped 23.02 speed ref ramp output (page 257 ). 11 speed ref used 24.01 used speed reference (page 263 ). 12 torq ref used 26.02 torque reference used (page 279 ). 13 freq ref used 28.02 frequency ref ramp output (...

Page 196

196 parameters 11.60 freq out 1 at src min defines the minimum value of frequency output 1. See diagrams at parameter 11.58 freq out 1 src min . 0 hz 0…16000 hz minimum value of frequency output 1. 1 = 1 hz 11.61 freq out 1 at src max defines the maximum value of frequency output 1. See diagrams at ...

Page 197

Parameters 197 speed ref safe drive generates a warning ( a8a0 ai supervision ) and sets the speed to the speed defined by parameter 22.41 speed ref safe (or 28.41 frequency ref safe when frequency reference is being used). Warning! Make sure that it is safe to continue operation in case of a commun...

Page 198

198 parameters 12.15 ai1 unit selection selects the unit for readings and settings related to analog input ai1. Note: this setting must match the corresponding hardware setting on the drive control unit (see the hardware manual of the drive). Control board reboot (either by cycling the power or thro...

Page 199

Parameters 199 12.19 ai1 scaled at ai1 min defines the real internal value that corresponds to the minimum analog input ai1 value defined by parameter 12.17 ai1 min . (changing the polarity settings of 12.19 and 12.20 can effectively invert the analog input.) 0.000 -32768.000 … 32767.000 real value ...

Page 200

200 parameters 12.27 ai2 min defines the minimum site value for analog input ai2. Set the value actually sent to the drive when the analog signal from plant is wound to its minimum setting. See also parameter 12.01 ai tune . 0.000 ma or v -22.000 … 22.000 ma or v minimum value of ai2. 1000 = 1 ma or...

Page 201

Parameters 201 motor torque 01.10 motor torque (page 152 ). 6 dc voltage 01.11 dc voltage (page 152 ). 7 power inu out 01.14 output power (page 153 ). 8 speed ref ramp in 23.01 speed ref ramp input (page 257 ). 10 speed ref ramp out 23.02 speed ref ramp output (page 257 ). 11 speed ref used 24.01 us...

Page 202

202 parameters 13.17 ao1 source min defines the real minimum value of the signal (selected by parameter 13.12 ao1 source ) that corresponds to the minimum required ao1 output value (defined by parameter 13.19 ao1 out at ao1 src min ). Programming 13.17 as the maximum value and 13.18 as the minimum v...

Page 203

Parameters 203 13.21 ao2 actual value displays the value of ao2 in ma. This parameter is read-only. - 0.000 … 22.000 ma value of ao2. 1000 = 1 ma 13.22 ao2 source selects a signal to be connected to analog output ao2. Alternatively, sets the output to excitation mode to feed a constant current to a ...

Page 204

204 parameters 13.28 ao2 source max defines the real maximum value of the signal (selected by parameter 13.22 ao2 source ) that corresponds to the maximum required ao2 output value (defined by parameter 13.30 ao2 out at ao2 src max ). See parameter 13.27 ao2 source min . 100.0 -32768.0 … 32767.0 rea...

Page 205

Parameters 205 14.03 module 1 status displays the status of i/o extension module 1. No option no option no module detected in the specified slot. 0 no communication a module has been detected but cannot be communicated with. 1 unknown the module type is unknown. 2 fio-01 an fio-01 module has been de...

Page 206

206 parameters 14.08 di filter time (visible when 14.01 module 1 type = fdio-01 ) defines a filtering time for parameter 14.05 di status . 10.0 ms 0.8 … 100.0 ms filtering time for 14.05 . 10 = 1 ms 14.08 dio filter time (visible when 14.01 module 1 type = fio-01 or fio-11 ) defines a filtering time...

Page 207

Parameters 207 ro/dio control word bit8 bit 8 of 10.99 ro/dio control word (see page 191 ). 43 ro/dio control word bit9 bit 9 of 10.99 ro/dio control word (see page 191 ). 44 other [bit] source selection (see terms and abbreviations on page 148 ). - 14.12 di1 on delay (visible when 14.01 module 1 ty...

Page 208

208 parameters 14.14 dio2 function (visible when 14.01 module 1 type = fio-01 or fio-11 ) selects whether dio2 of the extension module is used as a digital input or output. Input output dio2 is used as a digital output. 0 input dio2 is used as a digital input. 1 14.16 dio2 output source (visible whe...

Page 209

Parameters 209 speed ref safe drive generates a warning ( a8a0 ai supervision ) and sets the speed to the speed defined by parameter 22.41 speed ref safe (or 28.41 frequency ref safe when frequency reference is being used). Warning! Make sure that it is safe to continue operation in case of a commun...

Page 210

210 parameters ai3 max tune (visible when 14.01 module 1 type = fio-11 ) the measured value of ai3 is set as the maximum value of ai3 into parameter 14.64 ai3 max . 6 14.22 di3 on delay (visible when 14.01 module 1 type = fdio-01 ) defines the activation delay for digital input di3. See parameter 14...

Page 211

Parameters 211 14.27 dio4 on delay (visible when 14.01 module 1 type = fio-01 or fio-11 ) defines the activation delay for digital input/output dio4. See parameter 14.12 dio1 on delay . 0.00 s 0.00 … 3000.00 s activation delay for dio4. 10 = 1 s 14.27 ai1 scaled value (visible when 14.01 module 1 ty...

Page 212

212 parameters 250 us 250 microseconds. 2 500 us 500 microseconds. 3 1 ms 1 millisecond. 4 2 ms 2 milliseconds. 5 4 ms 4 milliseconds. 6 7.9375 ms 7.9375 milliseconds. 7 14.32 ai1 filter time (visible when 14.01 module 1 type = fio-11 or faio-01 ) defines the filter time constant for analog input ai...

Page 213

Parameters 213 14.35 ro1 on delay (visible when 14.01 module 1 type = fio-01 or fdio-01 ) defines the activation delay for relay output ro1. 0.00 s t on = 14.35 ro1 on delay t off = 14.36 ro1 off delay 0.00 … 3000.00 s activation delay for ro1. 10 = 1 s 14.35 ai1 scaled at ai1 min (visible when 14.0...

Page 214

214 parameters 14.38 ro2 on delay (visible when 14.01 module 1 type = fio-01 or fdio-01 ) defines the activation delay for relay output ro2. See parameter 14.35 ro1 on delay . 0.00 s 0.00 … 3000.00 s activation delay for ro2. 10 = 1 s 14.39 ro2 off delay (visible when 14.01 module 1 type = fio-01 or...

Page 215

Parameters 215 125 us 125 microseconds. 1 250 us 250 microseconds. 2 500 us 500 microseconds. 3 1 ms 1 millisecond. 4 2 ms 2 milliseconds. 5 4 ms 4 milliseconds. 6 7.9375 ms 7.9375 milliseconds. 7 14.47 ai2 filter time (visible when 14.01 module 1 type = fio-11 or faio-01 ) defines the filter time c...

Page 216

216 parameters 14.50 ai2 scaled at ai2 min (visible when 14.01 module 1 type = fio-11 or faio-01 ) defines the real value that corresponds to the minimum analog input ai2 value defined by parameter 14.48 ai2 min . 0.000 -32768.000 … 32767.000 real value corresponding to minimum ai2 value. 1 = 1 14.5...

Page 217

Parameters 217 ma milliamperes. 10 14.60 ai3 unit selection (visible when 14.01 module 1 type = fio-11 ) selects the unit for readings and settings related to analog input ai3. Note: this setting must match the corresponding hardware setting on the i/o extension module (see the manual of the i/o ext...

Page 218

218 parameters 14.63 ai3 min (visible when 14.01 module 1 type = fio-11 ) defines the minimum value for analog input ai3. See also parameter 14.21 ai tune . 0.000 ma or v -22.000 … 22.000 ma or v minimum value of ai3. 1000 = 1 ma or v 14.64 ai3 max (visible when 14.01 module 1 type = fio-11 ) define...

Page 219

Parameters 219 14.76 ao1 actual value (visible when 14.01 module 1 type = fio-11 or faio-01 ) displays the value of ao1 in ma. This parameter is read-only. - 0.000 … 22.000 ma value of ao1. 1000 = 1 ma 14.77 ao1 source (visible when 14.01 module 1 type = fio-11 or faio-01 ) selects a signal to be co...

Page 220

220 parameters 14.79 ao1 filter time (visible when 14.01 module 1 type = fio-11 or faio-01 ) defines the filtering time constant for analog output ao1. 0.100 s 0.000 … 30.000 s filter time constant. 1000 = 1 s no. Name/value description def / fbeq16 63 % 100 t t o = i × (1 - e -t /t ) i = filter inp...

Page 221

Parameters 221 14.80 ao1 source min (visible when 14.01 module 1 type = fio-11 or faio-01 ) defines the real value of the signal (selected by parameter 14.77 ao1 source ) that corresponds to the minimum ao1 output value (defined by parameter 14.82 ao1 out at ao1 src min ). 0.0 -32768.0 … 32767.0 rea...

Page 222

222 parameters 14.86 ao2 actual value (visible when 14.01 module 1 type = faio-01 ) displays the value of ao2 in ma. This parameter is read-only. - 0.000 … 22.000 ma value of ao2. 1000 = 1 ma 14.87 ao2 source (visible when 14.01 module 1 type = faio-01 ) selects a signal to be connected to analog ou...

Page 223

Parameters 223 14.91 ao2 source max (visible when 14.01 module 1 type = faio-01 ) defines the real value of the signal (selected by parameter 14.87 ao2 source ) that corresponds to the maximum ao2 output value (defined by parameter 14.93 ao2 out at ao2 src max ). See parameter 14.90 ao2 source min ....

Page 224

224 parameters 15.14 dio2 function (visible when 15.01 module 2 type = fio-01 or fio-11 ) see parameter 14.14 dio2 function . Input 15.16 dio2 output source (visible when 15.01 module 2 type = fio-01 or fio-11 ) see parameter 14.16 dio2 output source . Not energized 15.17 di2 on delay (visible when ...

Page 225

Parameters 225 15.29 ai1 hw switch position (visible when 15.01 module 2 type = fio-11 or faio-01 ) see parameter 14.29 ai1 hw switch position . - 15.30 ai1 unit selection (visible when 15.01 module 2 type = fio-11 or faio-01 ) see parameter 14.30 ai1 unit selection . Ma 15.31 ro status (visible whe...

Page 226

226 parameters 15.49 ai2 max (visible when 15.01 module 2 type = fio-11 or faio-01 ) see parameter 14.49 ai2 max . 10.000 ma or v 15.50 ai2 scaled at ai2 min (visible when 15.01 module 2 type = fio-11 or faio-01 ) see parameter 14.50 ai2 scaled at ai2 min . 0.000 15.51 ai2 scaled at ai2 max (visible...

Page 227

Parameters 227 15.86 ao2 actual value (visible when 15.01 module 2 type = faio-01 ) see parameter 14.86 ao2 actual value . - 15.87 ao2 source (visible when 15.01 module 2 type = faio-01 ) see parameter 14.87 ao2 source . Zero 15.88 ao2 force data (visible when 15.01 module 2 type = faio-01 ) see par...

Page 228

228 parameters 16.13 dio1 off delay (visible when 16.01 module 3 type = fio-01 or fio-11 ) see parameter 14.13 dio1 off delay . 0.00 s 16.14 dio2 function (visible when 16.01 module 3 type = fio-01 or fio-11 ) see parameter 14.14 dio2 function . Input 16.16 dio2 output source (visible when 16.01 mod...

Page 229

Parameters 229 16.28 ai1 force data (visible when 16.01 module 3 type = fio-11 or faio-01 ) see parameter 14.28 ai1 force data . 0.000 ma 16.29 ai1 hw switch position (visible when 16.01 module 3 type = fio-11 or faio-01 ) see parameter 14.29 ai1 hw switch position . - 16.30 ai1 unit selection (visi...

Page 230

230 parameters 16.48 ai2 min (visible when 16.01 module 3 type = fio-11 or faio-01 ) see parameter 14.48 ai2 min . 0.000 ma or v 16.49 ai2 max (visible when 16.01 module 3 type = fio-11 or faio-01 ) see parameter 14.49 ai2 max . 10.000 ma or v 16.50 ai2 scaled at ai2 min (visible when 16.01 module 3...

Page 231

Parameters 231 16.83 ao1 out at ao1 src max (visible when 16.01 module 3 type = fio-11 or faio-01 ) see parameter 14.83 ao1 out at ao1 src max . 10.000 ma 16.86 ao2 actual value (visible when 16.01 module 3 type = faio-01 ) see parameter 14.86 ao2 actual value . - 16.87 ao2 source (visible when 16.0...

Page 232

232 parameters di2 digital input di2 ( 10.02 di delayed status , bit 1). 4 di3 digital input di3 ( 10.02 di delayed status , bit 2). 5 di4 digital input di4 ( 10.02 di delayed status , bit 3). 6 di5 digital input di5 ( 10.02 di delayed status , bit 4). 7 di6 digital input di6 ( 10.02 di delayed stat...

Page 233

Parameters 233 19.17 local control disable enables/disables local control (start and stop buttons on the control panel, and the local controls on the pc tool). Warning! Before disabling local control, ensure that the control panel is not needed for stopping the drive. No no local control enabled. 0 ...

Page 234

234 parameters in1 start fwd; in2 start rev the source selected by 20.03 ext1 in1 source is the forward start signal; the source selected by 20.04 ext1 in2 source is the reverse start signal. The state transitions of the source bits are interpreted as follows: 3 in1p start; in2 stop the sources of t...

Page 235

Parameters 235 fieldbus a the start and stop commands are taken from fieldbus adapter a. Note: the start signal is always level-triggered with this setting regardless of parameter 20.02 ext1 start trigger type . 12 embedded fieldbus the start and stop commands are taken from the embedded fieldbus in...

Page 236

236 parameters 20.06 ext2 commands selects the source of start, stop and direction commands for external control location 2 (ext2). See also parameters 20.07 … 20.10 . Not selected not selected no start or stop command sources selected. 0 in1 start the source of the start and stop commands is select...

Page 237

Parameters 237 in1p start; in2 stop; in3 dir the sources of the start and stop commands are selected by parameters 20.08 ext2 in1 source and 20.09 ext2 in2 source . The source selected by 20.10 ext2 in3 source determines the direction. The state transitions of the source bits are interpreted as foll...

Page 238

238 parameters 20.07 ext2 start trigger type defines whether the start signal for external control location ext2 is edge-triggered or level-triggered. Note: this parameter is only effective when parameter 20.06 ext2 commands is set to in1 start , in1 start; in2 dir , in1 start fwd; in2 start rev , o...

Page 239

Parameters 239 diil diil input ( 10.02 di delayed status , bit 15). 33 active control source mcw bit 3 control word bit 3 received from the active control source. Notes: • if the drive is running in fieldbus control, switching bit 3 off effectively removes both the start and run enable signals. In t...

Page 240

240 parameters 20.23 positive speed enable selects the source of the positive speed enable command. 1 = positive speed enabled. 0 = positive speed interpreted as zero speed reference. In the figure below, 23.01 speed ref ramp input is set to zero after the positive speed enable signal has cleared. A...

Page 241

Parameters 241 20.25 jogging enable selects the source for a jog enable signal. (the sources for jogging activation signals are selected by parameters 20.26 jogging 1 start source and 20.27 jogging 2 start source .) 1 = jogging is enabled. 0 = jogging is disabled. Note: jogging can be enabled only w...

Page 242

242 parameters 20.27 jogging 2 start source if enabled by parameter 20.25 jogging enable , selects the source for the activation of jogging function 2. (jogging function 2 can also be activated through fieldbus regardless of parameter 20.25 .) 1 = jogging 2 active. For the selections, see parameter ...

Page 243

Parameters 243 constant time the drive pre-magnetizes the motor before start. The pre- magnetizing time is defined by parameter 21.02 magnetization time . This mode should be selected if constant pre-magnetizing time is required (e.G. If the motor start must be synchronized with the release of a mec...

Page 244

244 parameters ramp stop along the active deceleration ramp. See parameter group 23 speed reference ramp on page 257 . 1 torque limit stop according to torque limits (parameters 30.19 and 30.20 ). 2 21.04 emergency stop mode selects the way the motor is stopped when an emergency stop command is rece...

Page 245

Parameters 245 di6 digital input di6 ( 10.02 di delayed status , bit 5). 8 dio1 digital input/output dio1 ( 11.02 dio delayed status , bit 0). 11 dio2 digital input/output dio2 ( 11.02 dio delayed status , bit 1). 12 other [bit] source selection (see terms and abbreviations on page 148 ). - 21.06 ze...

Page 246

246 parameters 21.08 dc current control activates/deactivates the dc hold and post-magnetization functions. See section dc magnetization (page 100 ). Notes: • these functions are only available in speed control in dtc motor control mode (see page 26 ). • dc magnetization causes the motor to heat up....

Page 247

Parameters 247 on 1. 1 other [bit] source selection (see terms and abbreviations on page 148 ). - 21.13 autophasing mode selects the way autophasing is performed. See section autophasing on page 96 . Turning turning this mode gives the most accurate autophasing result. This mode can be used, and is ...

Page 248

248 parameters 21.18 auto restart time the motor can be automatically started after a short supply power failure using the automatic restart function. See section automatic restart (page 113 ). When this parameter is set to 0.0 seconds, automatic restarting is disabled. Otherwise, the parameter defi...

Page 249

Parameters 249 di4 digital input di4 ( 10.02 di delayed status , bit 3). 6 di5 digital input di5 ( 10.02 di delayed status , bit 4). 7 di6 digital input di6 ( 10.02 di delayed status , bit 5). 8 dio1 digital input/output dio1 ( 11.02 dio delayed status , bit 0). 11 dio2 digital input/output dio2 ( 1...

Page 250

250 parameters pid 40.01 process pid output actual (output of the process pid controller). 16 control panel (ref saved) control panel reference, with initial value from last-used panel reference. See section using the control panel as an external control source (page 25 ). 18 control panel (ref copi...

Page 251

Parameters 251 22.15 speed additive 1 source defines a reference to be added to the speed reference after reference selection (see page 644 ). For the selections, see parameter 22.11 speed ref1 source . Note: for safety reasons, the additive is not applied when any of the stop functions are active. ...

Page 252

252 parameters 22.22 constant speed sel1 when bit 0 of parameter 22.21 constant speed function is 0 (separate), selects a source that activates constant speed 1. When bit 0 of parameter 22.21 constant speed function is 1 (packed), this parameter and parameters 22.23 constant speed sel2 and 22.24 con...

Page 253

Parameters 253 22.27 constant speed 2 defines constant speed 2. 0.00 rpm -30000.00 … 30000.00 rpm constant speed 2. See par. 46.01 22.28 constant speed 3 defines constant speed 3. 0.00 rpm -30000.00 … 30000.00 rpm constant speed 3. See par. 46.01 22.29 constant speed 4 defines constant speed 4. 0.00...

Page 254

254 parameters 22.51 critical speed function enables/disables the critical speeds function. Also determines whether the specified ranges are effective in both rotating directions or not. See also section critical speeds/frequencies (page 80 ). 0000b 0000b…0011b critical speeds configuration word. 1 ...

Page 255