- DL manuals

- ABB

- Power Supply

- ACS880-207

- Hardware Manual

ABB ACS880-207 Hardware Manual - Introduction To The Manual

Introduction to the manual 9

1

Introduction to the manual

What this chapter contains

This chapter gives basic information on the manual.

Applicability

The manual is applicable to the cabinet-installed ACS880-207 IGBT supply units that form

a part of an ACS880 multidrive system.

Safety instructions

Follow all safety instructions delivered with the drive.

•

Read the

complete safety instructions

before you install, commission, use or

service the drive. The complete safety instructions are given in

ACS880 multidrive and

multidrive modules safety instructions

(3AUA0000102301 [English]

)

.

•

Read the

software-function-specific warnings

and notes

before changing the

default settings of the function. For each function, the warnings and notes are given in

the section describing the related user-adjustable parameters.

•

Read the

task-specific safety instructions

before starting the task. See the section

describing the task.

Target audience

This manual is intended for people who install, start-up and service multidrives. Read the

manual before working on the drive. You are expected to know the fundamentals of

electricity, wiring, electrical components and electrical schematic symbols.

Summary of ACS880-207

Page 1

Abb industrial drives hardware manual acs880-207 igbt supply units.

Page 2

List of related manuals you can find manuals and other product documents in pdf format on the internet. See section document library on the internet on the inside of the back cover. For manuals not available in the document library, contact your local abb representative. General manuals code (englis...

Page 3: Hardware Manual

Hardware manual acs880-207 igbt supply units 3aua0000130644 rev c en effective: 2017-11-29 2017 abb oy. All rights reserved. 3. Electrical installation 5. Start-up table of contents.

Page 5: Table Of Contents

5 table of contents 1. Introduction to the manual what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

6 type designation label of the supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 type designation label of the supply module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 type designation label of the lcl filter module . . . . . . . . . . . . . . . . ...

Page 7

7 (including the input power terminals) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 6. Maintenance what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69 maintenance intervals . . . . . . . . . ...

Page 8

8 temperature derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111 altitude derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111 fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 9: Introduction To The Manual

Introduction to the manual 9 1 introduction to the manual what this chapter contains this chapter gives basic information on the manual. Applicability the manual is applicable to the cabinet-installed acs880-207 igbt supply units that form a part of an acs880 multidrive system. Safety instructions f...

Page 10: Purpose Of The Manual

10 introduction to the manual purpose of the manual this manual helps in installing, commissioning, using and maintaining a multidrive with and igbt supply unit. Contents of the manual • introduction to the manual • operation principle and hardware description • electrical installation • installatio...

Page 11: Terms And Abbreviations

Introduction to the manual 11 terms and abbreviations term/abbreviation description auxiliary control cubicle (acu) the cubicle with auxiliary devices such as auxiliary voltage circuit breakers, control electronics, measurement boards, etc. Bcon type of a control board bcu type of a control unit (co...

Page 12

12 introduction to the manual igbt insulated gate bipolar transistor; a voltage-controlled semiconductor type widely used in drives due to their easy controllability and high switching frequency igbt supply module igbt type rectifier and related components enclosed inside a metal frame or enclosure....

Page 13: Operation Principle And

Operation principle and hardware description 13 2 operation principle and hardware description what this chapter contains this chapter describes the operation basics and the hardware of the igbt supply unit (acs880-207). Operation principle igbt supply unit rectifies three-phase ac current to direct...

Page 14

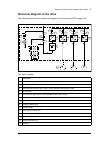

14 operation principle and hardware description main circuit diagram the following figure shows the simplified main circuit diagram of the rectifier. Charging charging is always needed to power up the dc link capacitors smoothly. Discharged capacitors cannot be connected to the full supply voltage. ...

Page 15

Operation principle and hardware description 15 overview diagram of the drive the following figure shows a single-line diagram of a drive with an igbt supply unit. The figure includes: description 1. Auxiliary voltage transformer ([t21], option +g344) 2. Auxiliary voltage switch [q21] 3. Main switch...

Page 16: Scope Version)

16 operation principle and hardware description layout drawing of an igbt supply unit 1×r8i (limited scope version) note that there is also another version of 1×r8i supply unit available, see the drawings below. The multidrive version contains separate auxiliary control and incoming cubicles. No. De...

Page 17

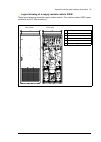

Operation principle and hardware description 17 overview drawing of a drive this drawing shows an example of a drive with an igbt supply unit and an inverter unit. Cables enter the cabinet through the bottom. Description a auxiliary control cubicle (acu). Contains control electronics and customer i/...

Page 18

18 operation principle and hardware description layout drawings of the cubicles in the supply unit this section contains layout drawings of cubicles that are included in a supply unit: auxiliary control cubicle, incoming cubicle and supply module cubicle. The components, layout and size of the cubic...

Page 19

Operation principle and hardware description 19 no. Desig. Description 1 s21, etc. Control panel and operating switches. See section supply unit control devices on page 29 . 2 f111 fuses, direct-on-line cooling fans of the module (option +c188) 3 f101 fuses, ip54 roof fans (option +b055) 4 f21 fuses...

Page 20

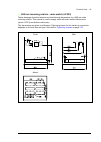

20 operation principle and hardware description layout drawings of incoming cubicles this section shows examples of the incoming cubicle layouts. The input power cables are connected to the incoming cubicle and it contains the main switching and disconnecting devices. The components, layout and size...

Page 21

Operation principle and hardware description 21 layout drawing of a 600 mm incoming cubicle these layout drawings show a 600 mm wide incoming cubicle. Options used with this cubicle are bottom cable entry (standard) and main switch-disconnector (option +f253). 1 5 6 7 8 11 10 4 3 door closed door op...

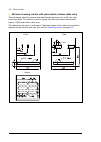

Page 22

22 operation principle and hardware description layout drawing of a 1000 mm incoming cubicle these layout drawings show a 1000 mm wide incoming cubicle. The cubicle contains the circuit breaker. No. Description 1. Auxiliary voltage switch handle 2. Earthing/grounding switch handle ([q9], option +f25...

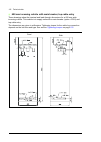

Page 23

Operation principle and hardware description 23 layout drawing of a supply module cubicle 2×r8i these layout drawings show the supply module cubicle. The cubicle contains igbt supply module(s) and lcl filter module(s). No. Description 1. Supply module (see page 24 ) 2. Lcl filter module (see page 25...

Page 24

24 operation principle and hardware description layout drawings of supply and lcl filter modules igbt supply module (frame r8i) description a isu module, frame size r8i, front b isu module, frame size r8i, back 1. Dc output busbars 2. Handle 3. Leds, fiber optic connectors of the module (wired to th...

Page 25

Operation principle and hardware description 25 lcl filter module (blcl-1x-x) description a lcl filter module, front b lcl filter module, back 1. Input (ac) connection 2. Output (ac) connection 3. Handle 4. Fan 5. Wheels a b 5 2 3 4 1.

Page 26

26 operation principle and hardware description lcl filter module (blcl-2x-x) description a lcl filter module, front b lcl filter module, back 1. Input (ac) connection 2. Output (ac) connection 3. Handle 4. Fan 5. Wheels a b 5 2 3 4 1.

Page 27

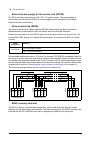

Operation principle and hardware description 27 overview of power and control connections input power connections of the igbt supply unit are terminals l1, l2 and l3 located in the lower part of the incoming cubicle. Power cables enter the cabinet via lead-throughs on the floor of the cubicle as sta...

Page 28

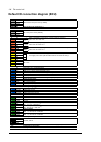

28 operation principle and hardware description overview of the control connections on the bcu control unit bcu control unit is used with frame size r8i igbt supply module. The diagram shows the control connections and interfaces of the bcu control unit. No. Description no. Description 1 2 3 analog ...

Page 29

Operation principle and hardware description 29 supply unit control devices the following figure shows examples of the door control devices of the igbt supply unit. The selection and exact location of control devices varies in different deliveries. The purpose of the devices is explained in the foll...

Page 30

30 operation principle and hardware description door switches and devices for frame r8i cabinet no. Desig. Description / see section … 1. Q1 main switch-disconnector / breaker on page 31 . 2. Q21 auxiliary voltage switch on page 31 . 3. S21 operating switch on page 31 . 4. A59 the acs-ap-w control p...

Page 31

Operation principle and hardware description 31 main switch-disconnector / breaker the supply unit is equipped with a main switch-disconnector ([q1], option +f253) or a main breaker in high powers ([q1], option +f255) as standard. With this device, you can isolate the main circuit of the drive from ...

Page 32

32 operation principle and hardware description will be closed and the charging contactor [q4] opened. The supply module starts operating. • the off position: the control program opens the main contactor [q2] and the supply module stops rectifying. Emergency stop button the emergency stop button is ...

Page 33: Type Designation Labels

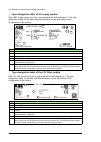

Operation principle and hardware description 33 pc connection there is a usb connector on the front of the panel that can be used to connect a pc to the drive. When a pc is connected to the control panel, the control panel keypad is disabled. See also section connecting a pc on page 60 . Fieldbus co...

Page 34

34 operation principle and hardware description type designation label of the supply module each igbt supply module also has a type designation label attached to it. The type designation stated on the label contains information on the specifications and configuration of the module. Type designation ...

Page 35: Type Designation Keys

Operation principle and hardware description 35 type designation keys type designation key of the cabinet-installed igbt supply unit type designation describes the composition of the unit in short. The type designation is visible on the label (sticker) which is attached to the cabinet. The complete ...

Page 36

36 operation principle and hardware description filters e202 emc 1st environment, restricted (max 1070a, only 400 v and 500 v) e210 emc 2nd environment switchgear f250 line contactor, standard in small power, (always with disconnector, option +f253) f253 disconnector switch (door interlocked), stand...

Page 37

Operation principle and hardware description 37 control panel and pc options j400 control panel acs-ap-w (max. 4 panels on the door) j401 led monitoring display j410 drive control panel connection kit j411 remote supply on/off control (from upper controller) j412 common control panel for a line up f...

Page 38

38 operation principle and hardware description type designation key of the igbt supply module type designation describes the composition of the module in short. The type designation is visible on the label (sticker) which is attached to the module. The complete designation code is divided in subcod...

Page 39

Operation principle and hardware description 39 type designation key of the filter module the designation code of the blcl filter is divided in subcodes: • the first 4 letters and two numbers give the type of the filter, for example, blcl-25-7. • the plus codes follow the basic code. Each plus code ...

Page 40

40 operation principle and hardware description.

Page 41: Electrical Installation

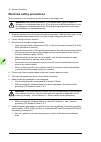

Electrical installation 41 3 electrical installation what this chapter contains this chapter instructs how to check the insulation of the assembly and how to install the input power cables and control cables. The information is valid for cabinet-installed acs880-207 supply units. For more informatio...

Page 42

42 electrical installation electrical safety precautions this information is for all personnel who do work on the supply unit. Warning! Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. If you are not a qualified electrician, do not do installation o...

Page 43

Electrical installation 43 checking the insulation of the assembly supply unit do not make any voltage tolerance or insulation resistance tests on the supply unit. Every drive system has been insulation tested between the main circuit and the chassis at the factory. Also, there may be voltage-limiti...

Page 44

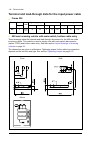

44 electrical installation connecting the input power cables connection diagram (frame 1×r8i, limited scope version) 1) fuses or other protection means. Use a separate grounding pe cable 2) or a cable with a separate pe conductor 3) if the conductivity of the shield does not meet the requirements fo...

Page 45

Electrical installation 45 connection diagram (frame r8i and multiples) notes: 1) fuses or other protection means. Use a separate grounding pe cable 2) or a cable with separate pe conductor 3) if the conductivity of the shield does not meet the requirements for the pe conductor. See electrical plann...

Page 46

46 electrical installation connection procedure (frame r8i, limited scope version) the cable lead-through details, and cable connection details are shown in chapter terminal and lead-through data for the input power cable on page 118 . Warning! Only qualified electricians are allowed to this work. R...

Page 47

Electrical installation 47 2a 2b.

Page 48

48 electrical installation recommendation: 360° grounding of the cable shield at the lead-through suppresses interference. 3 4.

Page 49

Electrical installation 49 connection procedure (frame r8i and multiples) the cable lead-through details, and cable connection details are shown in chapter terminal and lead-through data for the input power cable , page 118 . Warning! Only qualified electricians are allowed to do this work. Read the...

Page 50

50 electrical installation 5 pe pe 3.

Page 51

Electrical installation 51 pe 9 7 6 10 11.

Page 52: Transformers (Option +G344)

52 electrical installation setting the voltage range of the auxiliary voltage transformers (option +g344) the auxiliary voltage transformer ([t21, t101, t111], option +g344) connections are made at the factory according to the supply voltage and desired output voltage and you do not need to change t...

Page 53

Electrical installation 53 [t21/t101] connections (690 v units) 690 v 1 660 v 2 600 v 3 575 v 4 540 v 5 525 v 6 7 u1 8 tp 9 tp 10 t21_x1 or t101_x1 t21_x2 or t101_x2 1 230 v 2 3 4 5 n Θ 1 115 v 2 115 v 3 n 4 5 n without +g304 with +g304.

Page 54

54 electrical installation [t111] connections checking the settings of the cooling fan transformer the cooling fan transformer connections are made at the factory. 3~ input 3~ input 3~ output supply voltage terminals tap settings terminals a1– b1– c1– 400 v (50 hz) 320/340 v (60 hz) 690 v a1, b1, c1...

Page 55

Electrical installation 55 connecting the control cables for the supply unit default i/o connection diagram see chapter the control unit . Connection procedure (frame r8i, limited scope version) the following procedure instructs how to connect the control cables of a supply unit. See the circuit dia...

Page 56

56 electrical installation the detailed figure of step 4 has been rotated 180 degrees. 2a 2b 3 4.

Page 57

Electrical installation 57 connection procedure (frame r8i and multiples) warning! Only qualified electricians are allowed to do this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Disconnect the ...

Page 58

58 electrical installation note: if the outer surface of the shield is non-conductive: • cut the shield at the midpoint of the bare part. Be careful not to cut the conductors or the grounding wire (if present). • turn the shield inside out to expose its conductive surface. • cover the turned shield ...

Page 59

Electrical installation 59 note for top entry of cables: when each cable has its own rubber grommet, sufficient ip and emc protection can be achieved. However, if very many control cables come to one cabinet, plan the installation beforehand as follows: 1. Make a list of the cables coming to the cab...

Page 60: +Q963, +Q964 Or +Q979

60 electrical installation wiring the functional safety options +q951, +q952, +q963, +q964 or +q979 the wiring instructions for the functional safety options +q951, +q952, +q963, +q964 and +q979 are given in separate option manuals. For the manuals, see section list of related manuals on page 2 . Co...

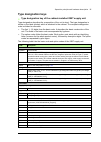

Page 61: Installation Checklist

Installation checklist 61 4 installation checklist what this chapter contains this chapter contains a list for checking the installation of the acs880-207 igbt supply unit. Checklist check the mechanical and electrical installation of the drive before start-up. Go through the checklist together with...

Page 62

62 installation checklist if the drive has been stored over one year: the electrolytic dc capacitors in the dc link of the drive have been reformed. See the separate reforming instructions (available in the internet or from your local abb representative). There is an adequately sized protective eart...

Page 63: Start-Up

Start-up 63 5 start-up what this chapter contains this chapter describes the start-up procedure of the igbt supply unit. The information is valid for cabinet-installed acs880-207 igbt supply units. The underlined tasks are needed for certain cases only. The option codes (if any) are given in bracket...

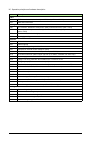

Page 64: Start-Up Procedure

64 start-up start-up procedure tasks safety warning! Follow the safety instructions during the start-up procedure. See safety instructions for acs880 multidrive cabinets and modules (3aua0000102301 [english]) . Only qualified electricians are allowed to start-up the drive. Checks/settings with no vo...

Page 65

Start-up 65 setting up the supply unit parameters check the correct voltage range, parameter 195.01 supply voltage . If your supply unit consists of more than one module, parameters 195.30 parallel type filter and 195.31 parallel connection rating id need to be set. First, select the correct voltage...

Page 66: Switching Off The Unit

66 start-up switching off the unit 1. Stop the motors connected to igbt supply units. See the igbt supply unit firmware manual. 2. Turn the operating switch [s21] to the off (0) position to deactivate the run enable signal of the supply unit and to switch the main contactor [q2] off. Disconnecting a...

Page 67

Start-up 67 disconnecting and temporary grounding the drive (including the input power terminals) 1. Perform the tasks listed in section disconnecting and temporary grounding the drive (excluding the input power terminals) on page 66 . 2. Switch off and disconnect the breaker of the supply transform...

Page 68

68 start-up.

Page 69: Maintenance

Maintenance 69 6 maintenance what this chapter contains this chapter instructs how to maintain the igbt supply unit and how to interpret its fault indications. The information is valid for cabinet-installed acs880-207 igbt supply units. Warning! Only qualified electricians are allowed to do the work...

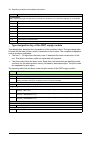

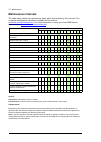

Page 70: Maintenance Intervals

70 maintenance maintenance intervals the table below shows the maintenance tasks which can be done by the end user. The complete maintenance schedule is available on the internet ( www.Abb.Com/drivesservices) . For more information, consult your local abb service representative ( www.Abb.Com/searchc...

Page 71: Cabinet

Maintenance 71 maintenance timers and counters the control program has maintenance timers and counters that can be configured to generate a warning when a pre-defined limit is reached. Each timer/counter can be set to monitor any parameter. This feature is especially useful as a service reminder. Fo...

Page 72

72 maintenance cleaning the door air inlets (ip22 and ip42, option +b054) warning! Use a vacuum cleaner with an antistatic hose and nozzle. Using a normal vacuum cleaner creates static discharges which can damage circuit boards. Check the dustiness of the air inlet meshes. If the dust cannot be remo...

Page 73

Maintenance 73 cleaning the door air inlets (ip54, option +b055) 1. Recommendation: de-energize the fans by switching off the supply unit. 2. Remove the fasteners at the top of the grating. 3. Lift the grating and pull it away from the door. 4. Remove the air filter mat. 5. Place the new filter mat ...

Page 74

74 maintenance replacing the outlet (roof) filters (ip54, option +b055) warning! De-energize the fans by switching off the supply unit. Make sure that no restart is possible during the maintenance work. Rotating fan blades can cause serious hand injury. 1. Remove the front and back gratings of the f...

Page 75: Fans

Maintenance 75 fans the lifespan of the cooling fan depends on the running time of the fan, ambient temperature and dust concentration. See the firmware manual for the actual signal which indicates the running time of the cooling fan. To reset the running time signal after a fan replacement, contact...

Page 76

76 maintenance 8 4 5 6 7.

Page 77

Maintenance 77 replacing the direct-on-line (option +c188) module fan (frame r8i) if the module is equipped with a standard speed-controlled cooling fan, see page 75 . Warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the inst...

Page 78

78 maintenance replacing the circuit board compartment fan (frame r8i) the r8i module is equipped with a fan blowing air through the circuit board compartment. The fan is accessible from the front of the module. Warning! Only qualified electricians are allowed to this work. Read the complete safety ...

Page 79

Maintenance 79 8. Put the fan onto the threaded studs on the fan holder with the airflow direction arrow pointing towards the fan holder. 9. Install and tighten the four nuts removed earlier. 10. Connect the fan cable. 11. Align and push the fan holder into the module. 12. Install and tighten the tw...

Page 80

80 maintenance replacing the fan of the lcl filter (blcl-1x-x) warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. Warning! Wear protective gloves ...

Page 81

Maintenance 81 replacing the fan of the lcl filter (blcl-2x-x) warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Disconnect the drive from the...

Page 82

82 maintenance replacing the fan in the incoming cubicle warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Disconnect the drive from the ac po...

Page 83

Maintenance 83 replacing the fan in the auxiliary control cubicle warning! Only qualified electricians are allowed to do this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Disconnect the drive fr...

Page 84

84 maintenance replacing the roof fan for ip54 cabinet (option +b055) warning! Only qualified electricians are allowed to do this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Disconnect the driv...

Page 85: Igbt Supply Module

Maintenance 85 igbt supply module cleaning the module the supply module heatsink fins pick up dust from the cooling air. Modules run into overtemperature warnings and faults if the heatsink is not clean. Warning! Only qualified electricians are allowed to this work. Read the complete safety instruct...

Page 86

86 maintenance reduced run the reduced run function is available for igbt supply units consisting of parallel- connected igbt supply modules. The function makes it possible to continue operation with limited current even if one (or more) module is out of service, for example, because of maintenance ...

Page 87

Maintenance 87 replacing the igbt supply module (limited scope version) warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. Warning! Ignoring the f...

Page 88

88 maintenance 1. Disconnect the drive from the ac power line and make sure it is safe to start the work. See section electrical safety precautions on page 42 . 2. Open the cubicle door. 3. Undo the screws of the shroud in the upper part of the cubicle. Remove the shroud. 4. Unplug the signal connec...

Page 89

Maintenance 89 5 6 10 3 4 7 9 8.

Page 90

90 maintenance replacing the igbt supply module (frame r8i and multiples) warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. Warning! Ignoring the...

Page 91

Maintenance 91 1. Disconnect the drive from the ac power line and make sure it is safe to start the work. See section electrical safety precautions on page 42 . 2. Open the cubicle door. 3. Undo the screws of the shroud in the upper part of the cubicle. Remove the shroud. 4. Unplug the signal connec...

Page 92

92 maintenance 5 6 10 3 4 7 9 8.

Page 93: Lcl Filter

Maintenance 93 lcl filter replacing the lcl filter (limited scope version) warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. Warning! Ignoring th...

Page 94

94 maintenance 1. Disconnect the drive from the ac power line and make sure it is safe to start the work. See section electrical safety precautions on page 42 . 2. Open the cubicle door. 3. Undo the four screws of the shroud in the upper part of the cubicle. Remove the shroud. 4. Unplug the signal c...

Page 95

Maintenance 95 5 6 3 4 8 9 7.

Page 96

96 maintenance replacing the lcl filter (frame r8i and multiples) warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. Warning! Ignoring the followi...

Page 97

Maintenance 97 1. Disconnect the drive from the ac power line and make sure it is safe to start the work. See section electrical safety precautions on page 42 . 2. Open the cubicle door. 3. Undo the four screws of the shroud in the upper part of the cubicle. Remove the shroud. 4. Unplug the signal c...

Page 98

98 maintenance 5 6 3 4 7.

Page 99

Maintenance 99 6 8 7 11 10 9.

Page 100: Capacitors

100 maintenance capacitors the dc circuit of a supply module contains several electrolytic capacitors. Their lifespan depends on the operating time, loading and ambient temperature. Capacitor life can be prolonged by lowering the ambient temperature. Capacitor failure is usually followed by damage t...

Page 101: Fuses

Maintenance 101 fuses checking and replacing the dc fuses (limited scope version) warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Disconnect...

Page 102

102 maintenance 3 4 5 6.

Page 103

Maintenance 103 checking and replacing the ac fuses (limited scope version) warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Disconnect the d...

Page 104

104 maintenance checking and replacing the dc fuses (frame r8i and multiples) warning! Only qualified electricians are allowed to this work. Read the complete safety instructions of the drive. Ignoring the instructions can cause physical injury or death, or damage to the equipment. 1. Disconnect the...

Page 105

Maintenance 105 3 4a 4b 4a.

Page 106: Control Panel

106 maintenance control panel replacing the battery 1. Turn the lid on the back of the panel counter-clockwise until the lid opens. 2. Replace the battery with a new cr2032 battery. 3. Put the lid back and tighten it by turning it clockwise. 4. Dispose of the old battery according to local disposal ...

Page 107: Memory Unit

Maintenance 107 memory unit when a drive is replaced, the parameter settings can be retained by transferring the memory unit from the defective drive to the new drive. The memory unit is located on the control board. After power-up, the drive will scan the memory unit. If different parameter setting...

Page 108

108 maintenance leds and other status indicators this section instructs how to interpret the status indications of the acs880-207 igbt supply unit. Warnings and faults reported by the control program are displayed on the control panel on the cabinet door. For further information, see the firmware ma...

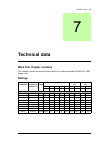

Page 109: Technical Data

Technical data 109 7 technical data what this chapter contains this chapter contains the technical data valid for the cabinet-installed acs880-207 igbt supply units. Ratings unit type acs880-207- … consists of module type acs880- 104 - … frame no-overload use light-overload use heavy-duty use i n i ...

Page 110

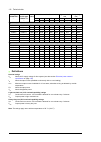

110 technical data definitions note: the ratings apply at an ambient temperature of 40 °c (104 °f). U n = 500 v (with u1 = 3~400/480/500 v ac and u2 = 566/679/707 v dc) 0400a-5 0440a-5 r8i 480 396 624 340 343 461 326 359 254 0530a-5 0590a-5 r8i 644 531 837 455 460 618 437 482 341 0730a-5 0810a-5 r8i...

Page 111

Technical data 111 derating temperature derating in the temperature range +40…50 °c (+104…122 °f), the rated output current is derated by 1% for every added 1 °c (1.8 °f). The output current can be calculated by multiplying the current given in the rating table by the derating factor ( k ): altitude...

Page 112: Fuses

112 technical data fuses main circuit ac fuses unit type acs880-207-... Rating type example qty u n = 400 v (range 380 … 415 v) 0420a-3 630 a, 690 v, size 3 flush end type 170m6410 3 0580a-3 1000 a, 690 v, size 3 flush end type 170m6414 3 0810a-3 1250 a, 690 v, size 3 flush end type 170m6416 3 1130a...

Page 113

Technical data 113 main circuit dc fuses fuses on cvar board the fuse type is ferraz a070grb10t13/g330010 (10 a 700 v ac). Unit type acs880-207-... Rating type example qty u n = 400 v (range 380 … 415 v) 0420a-3 900 a, 690 v, size 3 flush end contact 170m6413 2 0580a-3 1100 a, 690 v, size 3 flush en...

Page 114: Lcl Filters

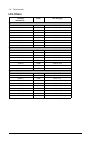

114 technical data lcl filters unit type acs880-207-... Frame lcl filter type u n = 400 v (range 380 … 415 v) 0420a-3 r8i blcl-13-5 0580a-3 r8i blcl-13-5 0810a-3 r8i blcl-15-5 1130a-3 2×r8i blcl-24-5 1330a-3 2×r8i blcl-24-5 1580a-3 2×r8i blcl-25-5 2350a-3 3×r8i 2×blcl-24-5 3110a-3 4×r8i 2×blcl-25-5 ...

Page 115: Dimensions

Technical data 115 dimensions unit type acs880-207-… height 1 height 2 width 1 width 2 depth 1 depth 2 mm in mm in mm in mm in mm in mm in u n = 400 v (range 380 … 415 v) 0420a-3 2145 84.5 2315 91.1 1000 39.4 1600 63.0 636 25 756 29.8 0580a-3 2145 84.5 2315 91.1 1000 39.4 1600 63.0 636 25 756 29.8 0...

Page 116: Free Space Requirements

116 technical data free space requirements unit type acs880-207-… above 2) front 1) left right mm in mm in mm in mm in u n = 400 v (range 380 … 415 v) 0420a-3 400 15.7 700 27.6 15 0.6 15 0.6 0580a-3 400 15.7 700 27.6 15 0.6 15 0.6 0810a-3 400 15.7 700 27.6 15 0.6 15 0.6 1130a-3 400 15.7 700 27.6 15 ...

Page 117

Technical data 117 losses, cooling data and noise front door turn radius (more space preferred for safety exit) left possible end plate right possible end plate unit type acs880-207-… p lossisu p losslcl p losstotal air flow noise efficiency kw kw kw m 3 /h ft 3 /min db % u n = 400 v (range 380 … 41...

Page 118

118 technical data terminal and lead-through data for the input power cable frame r8i 400 mm incoming cubicle with main switch, bottom cable entry these drawings show the terminal and lead-through dimensions for the 400 mm wide incoming cubicle. This cubicle is used in supply units with main switch-...

Page 119

Technical data 119 600 mm incoming cubicle – main switch (+f253) these drawings show the terminal and lead-through dimensions for a 600 mm wide incoming cubicle. This cubicle is used in supply units with main switch-disconnector (option +f253) and bottom cable entry. The dimensions are given in mill...

Page 120

120 technical data 600 mm incoming cubicle with main switch, bottom cable entry these drawings show the terminal and lead-through dimensions for a 600 mm wide incoming cubicle. This cubicle is used in supply units with main switch-disconnector (option +f253) and bottom cable entry. The dimensions ar...

Page 121

Technical data 121 600 mm incoming cubicle with main breaker, bottom cable entry these drawings show the terminal and lead-through dimensions for a 600 mm wide incoming cubicle. This cubicle is in supply units with a main breaker (option +f255) and bottom cable entry. The dimensions are given in mil...

Page 122

122 technical data 600 mm incoming cubicle with main breaker, top cable entry these drawings show the terminal and lead-through dimensions for a 600 mm wide incoming cubicle. This cubicle is in supply units with a main breaker (option +f255) and top cable entry. The dimensions are given in millimete...

Page 123

Technical data 123 1000 mm incoming cubicle with main breaker, bottom cable entry these drawings show the terminal and lead-through dimensions for a 1000 mm wide incoming cubicle. This cubicle is in high-power supply units with a main breaker (option +f255) and bottom cable entry. The dimensions are...

Page 124

124 technical data 1000 mm incoming cubicle with main breaker, top cable entry these drawings show the terminal and lead-through dimensions for a 1000 mm wide incoming cubicle. This cubicle is in high-power supply units with a main breaker (option +f255) and top cable entry. The dimensions are given...

Page 125: Tightening Torques

Technical data 125 tightening torques unless a tightening torque is specified in the text, the following torques can be used. Cable lugs electrical connections mechanical connections insulation supports size max. Torque n·m note m8 15 strength class 8.8 m10 32 strength class 8.8 m12 50 strength clas...

Page 126

126 technical data electrical power network specification supply voltage 400 v ac units; 380/400/415 v ac 3-phase ± 10%. This is indicated in type designation label as typical input voltage levels (3~ 400 v ac). 500 v ac units; 380/400/415/440/460/480/500 v ac 3-phase ± 10%. This is indicated in typ...

Page 127: Degrees Of Protection

Technical data 127 control unit connection data (bcu) see chapter the control unit on page 131 . Degrees of protection degrees of protection (iec/en 60529) ip22 (standard), ip42 (option +b054), ip54 (option +b055) enclosure types (ul50) ul type 1 (standard), ul type 1 filtered (option +b054), ul typ...

Page 128: Ambient Conditions

128 technical data ambient conditions the unit is to be used in a heated indoor controlled environment. Operation installed for stationary use storage in the protective package transportation in the protective package installation site altitude above sea level 0...2000 m (0...6561.7 ft) for altitude...

Page 129: Materials

Technical data 129 materials applicable standards see electrical planning instructions for acs880 multidrive cabinets and modules (3aua0000102324 [english]). Markings see electrical planning instructions for acs880 multidrive cabinets and modules (3aua0000102324 [english]). Module enclosure hot-dip ...

Page 130: Disclaimers

130 technical data disclaimers generic disclaimer the manufacturer shall have no obligation with respect to any product which (i) has been improperly repaired or altered; (ii) has been subjected to misuse, negligence or accident; (iii) has been used in a manner contrary to the manufacturer's instruc...

Page 131: The Control Unit

The control unit 131 8 the control unit what this chapter contains this chapter • describes the connections of the control units used in acs880 multidrives • contains the specifications of the inputs and outputs of the control units. Note: in this manual, the name “bcu-x2” represents the control uni...

Page 132: Layout And Connections

132 the control unit layout and connections the layout and connections of the bcu-x2 are shown below. Description i/o i/o terminals (see following diagram) slot 1 i/o extension, fieldbus adapter module connection. (this is the sole location for an fdpi-02 diagnostics and panel interface.) slot 2 i/o...

Page 133

The control unit 133 description xai analog inputs xao analog outputs xdi digital inputs, digital input interlock (diil) xdio digital input/outputs xd2d drive-to-drive link xd24 +24 v output (for digital inputs) xeth ethernet port xpow external power input xro1 relay output ro1 xro2 relay output ro2...

Page 134

134 the control unit default i/o connection diagram (bcu) xd2d drive-to-drive link 1 b drive-to-drive link (not in use by default) 2 a 3 bgnd 4 shield d2d.Term drive-to-drive link termination 1) x485 rs485 connection 5 b not in use (not in use by default) 6 a 7 bgnd 8 shield xro1…xro3 relay outputs ...

Page 135

The control unit 135 the table above shows the control connections of the igbt supply unit, and the default meaning or use of the signals in the control program. Most i/o connections are reserved and wired for the internal use at the factory. Do not change the connections. Wire sizes and tightening ...

Page 136

136 the control unit external power supply for the control unit (xpow) the bcu must be powered from a 24 v dc, 2 a power supply. The power supply is connected to terminal block xpow. A second supply can be connected to the same terminal block for redundancy. Drive-to-drive link (xd2d) the drive-to-d...

Page 137

The control unit 137 control unit connector data power supply (xpow) connector pitch 5 mm, wire size 2.5 mm 2 24 v (±10%) dc, 2 a external power input. Two supplies can be connected to bcu for redundancy. Relay outputs ro1…ro3 (xro1…xro3) connector pitch 5 mm, wire size 2.5 mm 2 250 v ac / 30 v dc, ...

Page 138

138 the control unit analog outputs ao1 and ao2 (xao) connector pitch 5 mm, wire size 2.5 mm 2 0…20 ma, r load frequency range: 0…500 hz resolution: 11 bit + sign bit inaccuracy: 2% of full scale range drive-to-drive link (xd2d) connector pitch 5 mm, wire size 2.5 mm 2 physical layer: rs-485 termina...

Page 139

The control unit 139 *ground selector (dicom=diognd) settings ground isolation diagram dicom=diognd: on all digital inputs share a common ground (dicom connected to diognd). This is default setting. Dicom= diognd: off ground of digital inputs di1...Di% and diil (dicom) is isolated from dio signal gr...

Page 140

140 the control unit.

Page 141

Further information product and service inquiries address any inquiries about the product to your local abb representative, quoting the type designation and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to www.Abb.Com/searchcha...

Page 142

Contact us www.Abb.Com/drives www.Abb.Com/drivespartners 3aua0000130644 rev c (en) 2017-11-29.