- DL manuals

- ABB

- Controller

- ACS880

- Supplement Manual

ABB ACS880 Supplement Manual

Summary of ACS880

Page 1

Abb industrial drives supplement acs880 centrifuge decanter control program (+n5150).

Page 2

List of related manuals you can find manuals and other product documents in pdf format on the internet. See section document library on the internet on the inside of the back cover. For manuals not available in the document library, contact your local abb representative. Drive hardware manuals code ...

Page 3: Supplement

Supplement acs880 centrifuge decanter control program (+n5150) 3xxxxxxxxxxxxx rev x en effective: 2013-05-30 copyright 2017 abb. All rights reserved. 2. Quick start-up guide table of contents 3axd50000016078 rev b en effective: 2017-08-08.

Page 5: Table Of Contents

1 table of contents 1. Introduction contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 lic...

Page 6

2 speed reference control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 decanter control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 decanter process load compensation . . . . . . . . ...

Page 7: Introduction

Introduction 3 1 introduction contents of this chapter this chapter contains information on compatibility, safety and intended audience of this manual. It also provides an overview of the contents in this manual. Compatibility this supplement is compatible with the acs880 centrifuge decanter control...

Page 8: Safety

4 introduction after the program is downloaded to the memory unit with the license key, the program remains there unless you remove it. This makes it possible for you to upgrade the centrifuge decanter application later on a separate centrifuge decanter loading package. If the program was loaded to ...

Page 9: Terms And Abbreviations

Introduction 5 terms and abbreviations this manual uses the following terms and abbreviations: cybersecurity disclaimer this product is designed to be connected to and to communicate information and data via a network interface. It is customer's sole responsibility to provide and continuously ensure...

Page 10

6 introduction.

Page 11: Quick Start-Up Guide

Quick start-up guide 7 2 quick start-up guide contents of this chapter this chapter provides the instructions to start-up the centrifuge and decanter drive. It also illustrates the default control connections for the centrifuge and decanter drive. See, • centrifuge drive start-up (page 8 ) • decante...

Page 12: Centrifuge Drive Start-Up

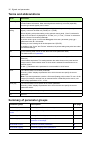

8 quick start-up guide the brake control function), but it has to be implemented as defined in the application specific regulations. Centrifuge drive start-up the checklist for centrifuge drive start-up is given below: step action 1 connect digital and analog i/os according to the wiring diagram sho...

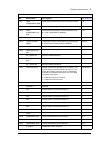

Page 13

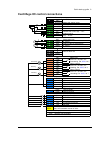

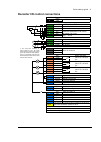

Quick start-up guide 9 centrifuge i/o control connections xpow external power input 1 +24vi 24 v dc, 2 a 2 gnd xai reference voltage and analog inputs 1 +vref 10 v dc, rl 1…10 kohm 2 -vref -10 v dc, rl1…10 kohm 3 agnd ground 4 ai1+ analog input 1 default: not in use, 0(2).....10 v 5 ai1- 6 ai2+ anal...

Page 14: Decanter Drive Start-Up

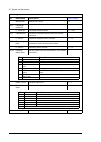

10 quick start-up guide decanter drive start-up the checklist for decanter drive start-up is given below: step action 1 connect digital and analog i/os according to the wiring diagram shown in section decanter i/o control connections . 2 perform basic start-up of the drive. See acs880 primary contro...

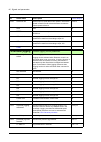

Page 15

Quick start-up guide 11 decanter i/o control connections xpow external power input 1 +24vi 24 v dc, 2 a 2 gnd xai reference voltage and analog inputs 1 +vref 10 v dc, rl 1…10 kohm 2 -vref -10 v dc, rl1…10 kohm 3 agnd ground 4 ai1+ analog input 1, 0(2)...10v speed ref (bowl)/not in use (scroll) 5 ai1...

Page 16: Optical Link For Decanter

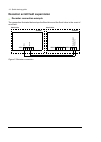

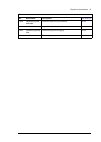

12 quick start-up guide optical link for decanter to realize the internal drives communication, an optical link is required between the bowl drive and the scroll drive. Connect channel 2 of both drives together using a pair of fibre optic cable (2 m to 10 m). Figure 1. Optical link connection (t = t...

Page 17

Quick start-up guide 13 scroll drive parameters: • 60.01 m/f communication port (fiber optic channel selection) = slot 1b. See acs880 primary control program firmware manual (3aua0000085967[english]). • 60.02 m/f node address = 2. See acs880 primary control program firmware manual (3aua0000085967[en...

Page 18

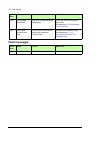

14 quick start-up guide decanter scroll fault supervision decanter connection example the connection illustrated below stops the bowl drive and the scroll drive in the event of scroll fault. Figure 2. Decanter connection acs880 +2 4v d d iil r e la y o u tp ut 3 f a ul t (-1 ) bowl drive 1 xd24 2 3 ...

Page 19: Centrifuge Program Features

Centrifuge program features 15 3 centrifuge program features contents of this chapter this chapter describes the operational sequence of centrifuge drive and also includes the important functions within the control program that are specific to the centrifuge application. Centrifuge control program c...

Page 20

16 centrifuge program features unloading speed and a discharger removes the product from the basket. An alternative unloading method allows top removal of product in a filter bag. Operating mode centrifuge operation can be set with parameter 74.01 centrifuge/ decanter function selection . For using ...

Page 21

Centrifuge program features 17 how to start and stop the centrifuge the start command starts the centrifuge operating sequence or continues the sequence after the stop command. The stop command stops the centrifuge at any phase of the sequence. Note: • to start the centrifuge after a fault or power ...

Page 22

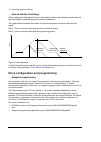

18 centrifuge program features how to halt the centrifuge after receiving the halt signal, the drive immediately shifts to deceleration phase and runs the centrifuge to standstill along the remaining sequence. The graph below illustrates two cases on how the sequence continues after the halt signal....

Page 23: Decanter Program Features

Decanter program features 19 4 decanter program features contents of this chapter this chapter describes the operational sequence of the decanter drive and also includes the important functions within the control program that are specific to the decanter application. Decanter features the main featu...

Page 24: Decanter Operation

20 decanter program features decanter operation decanter operating principle the decanter control fulfills the common requirement of two-shaft decanters, where the machinery consists of a bowl and a scroll (screw conveyer). Figure 6. Two-shaft decanter a two-shaft decanter operates on the principle ...

Page 25: Decanter Control Modes

Decanter program features 21 decanter control modes the three basic control modes of decanter are: local control, speed reference control and decanter control. Local control this mode is selected using the loc/rem key on the panel. The “local” is visible on the first row of the panel display. In loc...

Page 26

22 decanter program features decanter process load compensation the load compensation of scroll drive enables compensating the process load variations of a decanter. This means that, it is possible to influence the quality of the end product automatically through a differential speed correction. See...

Page 27: Differential Speed Control

Decanter program features 23 78.14 torque reference 78.15 torque gain 78.16 torque integration time 78.19 torque to delta speed see also decanter control chain diagram of scroll drive on page 24 . Direct torque compensation the operating principle of the direct torque compensation is based on actual...

Page 28

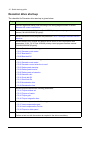

24 decanter program features decanter control chain diagram of scroll drive va lu e 7 8 .0 5 d e lta s peed r e f s e le ct io n va lu e s e le c tio n > 3 .05 f iel dbus r e f 1 va lu e 12 .22 s cal ed a i2 78 .06 d e lta s peed r e fe renc e va lu e 12 .12 s cal ed a i1 7 8 .21 d e lta s peed max ...

Page 29: Decanter Examples

Decanter program features 25 decanter examples the below examples depict the mechanical and electrical configuration of a back drive and forward drive in a decanter/centrifuge application. Back drive, variant a figure 7. Back drive, variant a decanter centrifuge if bowl motor is rotating in the forw...

Page 30

26 decanter program features bowl drive parameter settings: 78.01 decanter mode select = bowl 78.07 bowl belt d1 = value of d1 78.08 bowl belt d2 = value of d2 scroll drive parameter settings: 78.01 decanter mode select = scroll 78.04 delta speed function = backward drive 78.07 bowl belt d1 = value ...

Page 31

Decanter program features 27 since scroll motor is directly coupled to gearbox, parameters corresponding to d3 and d4 (belt roller diameter) must be set to 1. The communication between scroll drive and bowl drive is maintained through ddcs (m/f) link. Bowl drive parameter settings: 78.01 decanter mo...

Page 32: Decanter Jogging

28 decanter program features if bowl motor is rotating in the forward direction, scroll motor must also be rotating in the forward direction. This can be achieved by setting the parameters in group 78 decanter control . D1 and d2 are bowl and scroll motor drives as represented in the above figure. S...

Page 33: Signals And Parameters

Signals and parameters 29 5 signals and parameters contents of this chapter this chapter describes the actual signals and user-adjustable parameters specific to the centrifuge and decanter control program. Refer these parameters in addition to the actual signals and parameters described in the acs88...

Page 34: Terms And Abbreviations

30 signals and parameters terms and abbreviations summary of parameter groups term definition actual signal type of parameter that is the result of a measurement or calculation by the drive, or contains status information. Most actual signals are read-only, but some (especially counter-type actual s...

Page 35: Parameters Listing

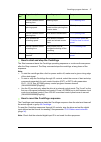

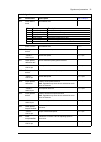

Signals and parameters 31 parameters listing actual signals no. Name/value description def / fbeq16 09 09 centrifuge centrifuge and decanter actual signals. All parameters in this group are read-only unless otherwise specified. 09.01 centrifuge status word status bit signals of centrifuge. - 0000h.....

Page 36

32 signals and parameters manual halt manual halt is active. 10 9.03 centrifuge reference shows final reference at different stages. - 0...18000 rpm centrifuge reference speed. 1 = 1 rpm 9.04 elapsed time shows the completed sequence time from the start command. - 0...32767 s sequence completion tim...

Page 37

Signals and parameters 33 9.12 scroll status word scroll status word. - 0000h...Ffffh scroll status word. 1 = 1 9.16 bowl speed actual shows actual bowl speed sent to scroll. - -18000.0... 18000.0 rpm actual bowl speed. 1 = 1 rpm 9.17 delta speed reference act shows differential (delta) speed refere...

Page 38

34 signals and parameters parameters no name/value description def / fbeq16 74 74 centrifuge decanter control selecting centrifuge or decanter control. 74.01 centrifuge/ decanter function selection selects centrifuge or decanter function. Centrifuge not selected not selected. 0 decanter decanter fun...

Page 39

Signals and parameters 35 other see terms and abbreviations on page 30 - 75.03 accelerate to spin selection selects the source for acceleration start command. Di5 not selected not selected. 0 selected selected 1 di1 acceleration command through di1. 2 di2 acceleration command through di2. 3 di3 acce...

Page 40

36 signals and parameters 77.09 dec time to zero speed defines deceleration time from unload speed to stop at zero speed. 20 s 0...3000 s deceleration time to zero speed in seconds. 1 = 1 s 77.10 prewashing time defines pre-washing time. 10 s 0...3000 s pre-washing time in seconds. 1 = 1 s 77.11 was...

Page 41

Signals and parameters 37 di1 start decanter through di1. 2 di2 start decanter through di2. 3 di3 start decanter through di3. 4 di4 start decanter through di4. 5 di5 start decanter through di5. 6 di6 start decanter through di6. 7 comm cw fieldbus communication control word. 8 bowl drive the scroll r...

Page 42

38 signals and parameters 78.10 scroll belt d3 defines mechanical drive factor of scroll motor belt roller d3. 1.00 -1000.00...1000.00 scroll belt d3 mechanical drive factor. - 78.11 scroll belt d4 defines mechanical drive factor of scroll motor belt roller d4. 1.00 -1000.00...1000.00 scroll belt d4...

Page 43

Signals and parameters 39 78.17 load compensation gain defines load compensation function proportional gain. 0.0 0.0...100.0 load compensation gain. - 78.18 load compensation int time defines load compensation function integration time. 0 = load compensation is disabled. 0.0 s 0.0...3000.0 s load co...

Page 44

40 signals and parameters 78.25 scroll ref sel selects input of actual bowl motor speed in scroll drive. Speed is used in scroll drive as decanter controls the master speed reference. Ddcs zero zero 0 ddcs the actual bowl motor speed will be read from the ddcs link. 1 ai1 scaled analog input 1 scale...

Page 45

Signals and parameters 41 79.04 decanter jog time backward defines time period to jog backwards. 20.0 s 0...3000.0 s jog backward time in seconds. 10 = 1 s 79.05 decanter jog ramp time defines ramping time for jogging. 20.0 s 0...3000.0 s decanter jog ramp time. 10 = 1 s parameters no name/value des...

Page 46

42 signals and parameters.

Page 47: Fault Tracing

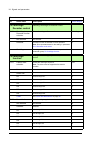

Fault tracing 43 6 fault tracing about this chapter this chapter lists all the warning and fault messages including possible causes and corrective actions for the centrifuge decanter drive. For the complete list of warning and fault messages, see acs880 primary control program firmware manual (3aua0...

Page 48: Fault Messages

44 fault tracing fault messages e203 filling stage interrupted end of fill is triggered before filling stage. Check the source of activation (end of fill). See parameter 75.03accelerate to spin selection . E204 cycle time exceeds max time total machine cycle time is higher than maximum machine time....

Page 49

Further information product and service inquiries address any inquiries about the product to your local abb representative, quoting the type designation and serial number of the unit in question. A listing of abb sales, support and service contacts can be found by navigating to www.Abb.Com/searchcha...

Page 50

Www.Abb.Com/drives www.Abb.Com/drivespartners 3axd50000016078 rev b (en) 2017-08-08 contact us.