- DL manuals

- ABB

- Control Unit

- ACSM1

- Manual

ABB ACSM1 Manual

Summary of ACSM1

Page 1

Abb motion control drives firmware manual acsm1 motion control program.

Page 2

List of related manuals * ) a multilingual quick installation guide is included with the delivery. You can find manuals and other product documents in pdf format on the internet. See section document library on the internet on the inside of the back cover. For manuals not available in the document l...

Page 3: Firmware Manual

Acsm1 motion control program firmware manual 3afe68848270 rev h en effective: 2015-06-26 2015 abb oy. All rights reserved..

Page 5: Table of Contents

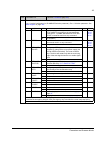

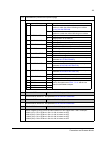

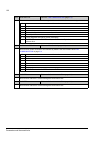

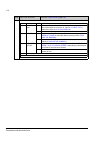

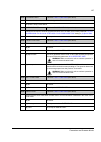

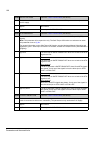

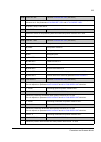

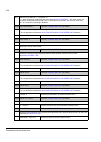

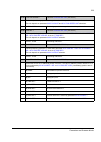

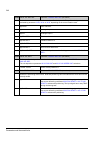

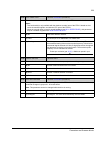

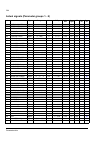

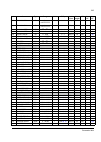

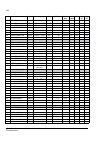

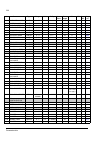

Table of contents 5 table of contents table of contents introduction to the manual what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

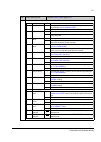

Table of contents 6 drive control chain for positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 motor control features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 scala...

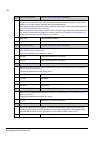

Page 7

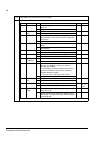

Table of contents 7 group 11 start/stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126 start/stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126 group 12 digital ...

Page 8

Table of contents 8 group 51 fba settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209 group 52 fba data in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211 group 53 ...

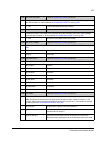

Page 9

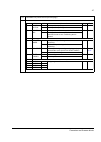

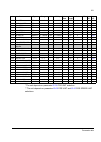

Table of contents 9 fault tracing what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303 safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 10

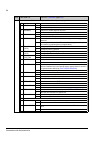

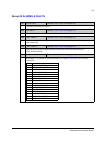

Table of contents 10 ge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349 gt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

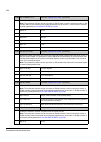

Page 11

Table of contents 11 filt1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392 parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 12

Table of contents 12 appendix b – drive-to-drive link what this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431 general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 13: Introduction to The Manual

Introduction to the manual 13 introduction to the manual what this chapter contains the chapter includes a description of the contents of the manual. In addition it contains information about the compatibility, safety and intended audience. Compatibility the manual is compatible with acsm1 motion co...

Page 14: Contents

Introduction to the manual 14 contents the manual consists of the following chapters: • start-up instructs in setting up the control program and how to control the drive through the i/o interface. • drive programming using pc tools introduces programming via pc tool (drivestudio and/or drivespc). • ...

Page 15: Start-Up

Start-up 15 start-up what this chapter contains this chapter describes the basic start-up procedure of the drive and instructs in how to control the drive through the i/o interface. How to start up the drive the drive can be operated: • locally from pc tool or control panel • externally via i/o conn...

Page 16

Start-up 16 safety the start-up may only be carried out by a qualified electrician. The safety instructions must be followed during the start-up procedure. See the safety instructions on the first pages of the appropriate hardware manual. Check the installation. See the installation checklist in the...

Page 17

Start-up 17 motor data entering open the parameter and signal list by selecting the parameter browser of the appropriate drive. Select the language. Parameters are set as follows: select the parameter group (in this case 99 start-up data) by double-clicking it. Select the appropriate parameter by do...

Page 18

Start-up 18 - motor nominal current allowed range: approximately 1/6 · i 2n … 2 · i 2n of the drive (0…2 · i 2nd if parameter 99.05 motor ctrl mode = (1) scalar ). With multimotor drives, see section multimotor drives on page 19 . 99.06 mot nom current - motor nominal voltage allowed range: 1/6 · u ...

Page 19

Start-up 19 multimotor drives ie, more than one motor is connected to one drive. Check that the motors have the same relative slip (only for asynchronous motors), nominal voltage and number of poles. If the manufacturer motor data is insufficient, use the following formulas to calculate the slip and...

Page 20

Start-up 20 id run (motor identification run) warning! With normal or reduced id run the motor will run at up to approximately 50…100% of the nominal speed during the motor id run. Ensure that it is safe to run the motor before performing the motor id run! Note: ensure that possible safe torque off ...

Page 21

Start-up 21 select the motor identification method by parameter 99.13 idrun mode . During the motor id run, the drive will identify the characteristics of the motor for optimum motor control. The motor id run is performed at the next start of the drive. Note: the motor shaft must not be locked and t...

Page 22

Start-up 22 start the motor to activate the motor id run. Note: run enable must be active. 10.09 run enable motor id run is indicated by alarm id-run and by a rotating display on the 7-segment display. Alarm: id-run 7-segment display: if the motor id run is not successfully completed, fault id-run f...

Page 23

Start-up 23 if the direction of rotation is selected as forward, check that the actual speed ( 1.08 encoder 1 speed / 1.10 encoder 2 speed ) is positive: • if the actual direction of rotation is forward and the actual speed negative, the phasing of the pulse encoder wires is reversed. • if the actua...

Page 24

Start-up 24 safe torque off the safe torque off function disables the control voltage of the power semiconductors of the drive output stage, thus preventing the inverter from generating the voltage required to rotate the motor. For safe torque off wiring, see the appropriate hardware manual and appl...

Page 25

Start-up 25 start function select the start function. Setting 11.01 start mode to (2) automatic selects a general- purpose start function. This setting also makes flying start (starting to a rotating motor) possible. The highest possible starting torque is achieved when 11.01 start mode is set to (0...

Page 26

Start-up 26 speed filtering the measured speed always has a small ripple because of electrical and mechanical interferences, couplings and encoder resolution (i.E. Small pulse number). A small ripple is acceptable as long as it does not affect the speed control chain. The interferences in the speed ...

Page 27

Start-up 27 fieldbus control follow these instructions when the drive is controlled from a fieldbus control system via fieldbus adapter fxxx. The adapter is installed in drive slot 3. Enable the communication between the drive and fieldbus adapter. 50.01 fba enable connect the fieldbus control syste...

Page 28

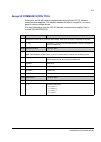

Start-up 28 how to control the drive through the i/o interface the table below instructs how to operate the drive through the digital and analogue inputs, when the default parameter settings are valid. Preliminary settings ensure the control connections are wired according to the connection diagram ...

Page 29: What This Chapter Contains

Drive programming using pc tools 29 drive programming using pc tools what this chapter contains this chapter introduces the drive programming using the drivestudio and drivespc applications. For more information, see drivestudio user manual [3afe68749026 (english)] and drivespc user manual [3afe6883...

Page 30: Programming Via Parameters

Drive programming using pc tools 30 the following picture presents a view from drivespc. The application program template visible through drivespc is presented in chapter application program template (page 407 ). Programming via parameters parameters can be set via drivestudio, drive control panel (...

Page 31: Application Programming

Drive programming using pc tools 31 application programming application programs are created with the drivespc pc tool. The normal delivery of the drive does not include an application program. The user can create an application program with the standard and firmware function blocks. Abb also offers...

Page 32

Drive programming using pc tools 32 program execution the application program is loaded to the permanent (non-volatile) memory of the memory unit (jmu). When the loading finishes, the drive control board is automatically reset, and the downloaded program started. The program is executed in real time...

Page 33

Drive programming using pc tools 33 operation modes the drivespc tool offers the following operation modes: off-line when the off-line mode is used without a drive connection, the user can • open a application program file (if exists). • modify and save the application program. • print the program p...

Page 34

Drive programming using pc tools 34.

Page 35: Drive Control and Features

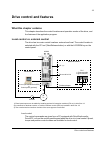

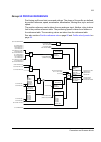

Drive control and features 35 drive control and features what this chapter contains this chapter describes the control locations and operation modes of the drive, and the features of the application program. Local control vs. External control the drive has two main control locations: external and lo...

Page 36: Operating Modes of The Drive

Drive control and features 36 local control is mainly used during commissioning and maintenance. The control panel always overrides the external control signal sources when used in local control. Changing the control location to local can be disabled by parameter 16.01 local lock . The user can sele...

Page 37

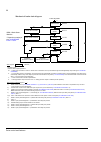

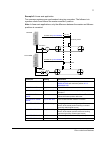

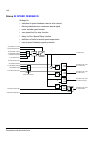

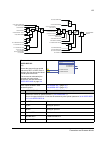

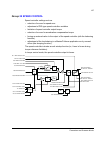

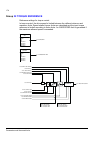

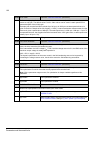

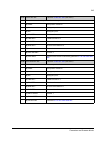

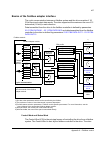

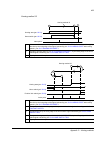

Drive control and features 37 !" # # $ % &&' (& ) # *+ , -# ) . ) (/ 0 . 1 2 )3 ) ) 0 1 4 )5 2 2 2 ) 3 0 3 " * " & 5 1 - #* + # & 1 1 ##/ # 6 ##/ 7 drive control cha in for spee d and to rqu e control.

Page 38

Drive control and features 38 position control in position control, the load is positioned along a single axis from the start position to the defined target position. A position reference is given to the drive to indicate the target position. The path to the target position is calculated by the posi...

Page 39

Drive control and features 39 homing control homing establishes a correspondence between the actual position of the driven machinery and the drive internal zero position. An encoder must always be used in homing control. See section position correction on page 68 . Note: homing control is not availa...

Page 40

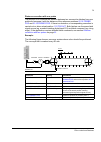

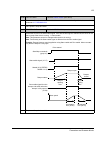

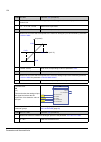

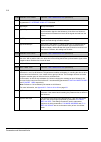

Drive control and features 40 5 8 0 1 4 0 0) 6 '" # # # " # 6 # # 6 # 1 0 0 ##/ 6 ** 6 # * 6 '" 9 "# ##/ 6 ** 6 # * 6 '" 9 "# #(/ ##/ 5 : ##/ # 6 ##/ 7 ( ; ; # *+ !(* = (6 $ ! >3 > 1 6' "# # 6' "# # ' # "/ 1 ! 1" *- = 6 '" # # ' ' ( # 6? 8 0 5 9( * # 6 ' !" # ##/ # 6 @ 8 0 drive co ntro l chain for ...

Page 41: Motor Control Features

Drive control and features 41 motor control features scalar motor control it is possible to select scalar control as the motor control method instead of direct torque control (dtc). In scalar control mode, the drive is controlled with a frequency reference. However, the performance of dtc is not ach...

Page 42

Drive control and features 42 autophasing autophasing is an automatic measurement routine to determine the angular position of the magnetic flux of a permanent magnet synchronous motor or the magnetic axis of a synchronous reluctance motor. The motor control requires the absolute position of the rot...

Page 43

Drive control and features 43 note: the same parameter is used by the autophasing routine which always writes its result to parameter 97.20 pos offset user . Autophasing id run results are updated even if the user mode is not enabled (see parameter 97.01 use given params ). Several autophasing modes...

Page 44

Drive control and features 44 flux braking the drive can provide greater deceleration by raising the level of magnetization in the motor. By increasing the motor flux with 40.10 flux braking , the energy generated by the motor during braking can be converted to motor thermal energy. The drive monito...

Page 45

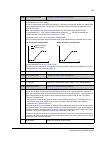

Drive control and features 45 thermal motor protection model the drive calculates the temperature of the motor on the basis of the following assumptions: 1) when power is applied to the drive for the first time, the motor is at ambient temperature (defined by parameter 45.05 ambient temp ). After th...

Page 46

Drive control and features 46 the figure below shows typical kty84 sensor resistance values as a function of the motor operating temperature. It is possible to adjust the motor temperature supervision limits and select how the drive reacts when overtemperature is detected. Warning! As the thermistor...

Page 47: Dc Voltage Control Features

Drive control and features 47 for encoder interface module fen-xx connection, see the user’s manual of the appropriate encoder interface module. Dc voltage control features overvoltage control overvoltage control of the intermediate dc link is needed with two-quadrant line-side converters when the m...

Page 48

Drive control and features 48 automatic identification of the supply voltage is performed every time the drive is powered. Automatic identification can be disabled by parameter 47.03 supplvoltauto-id ; the user can define the voltage manually at parameter 47.04 supply voltage . The intermediate dc c...

Page 49

Drive control and features 49 the value of parameter 47.08 ext pu supply or its source should be set to 1 (true) when a supply below 270 v dc – such as a battery – is used. In such a configuration, an additional dc power supply (jpo-01) is needed to power the main circuit electronics. With an ac sup...

Page 50: Speed Control Features

Drive control and features 50 speed control features jogging jogging is typically used during servicing or commissioning to control the machinery locally. It involves rotating the motor in small increments until the desired load position is achieved. Two jogging functions (1 or 2) are available. Whe...

Page 51

Drive control and features 51 notes: • jogging is not operational when the drive start command is on, or when the drive is in local control. • normal start is inhibited when jog enable is active. • the ramp shape time is set to zero during jogging. Speed controller tuning the speed controller of the...

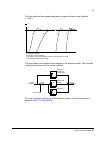

Page 52

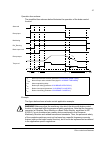

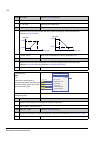

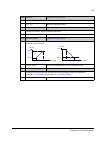

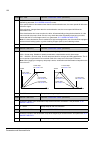

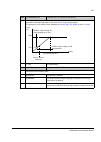

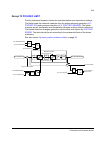

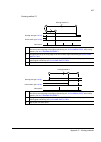

Drive control and features 52 the figure below illustrates the motor speed and torque behaviour during an autotuning routine. The prerequisites for performing the autotune routine are: • the motor id run has been successfully completed • speed, torque, current and acceleration limits (parameter grou...

Page 53

Drive control and features 53 the figure below shows speed responses at a speed reference step (typically 1…20%). The figure below is a simplified block diagram of the speed controller. The controller output is the reference for the torque controller. For more information on the use of the autotune ...

Page 54: Motor Feedback Features

Drive control and features 54 motor feedback features motor encoder gear function the drive provides motor encoder gear function for compensating of mechanical gears between the motor shaft, the encoder and the load. Motor encoder gear application example: the motor encoder gear parameters 22.03 mot...

Page 55: Mechanical Brake Control

Drive control and features 55 mechanical brake control the program supports the use of a mechanical brake to hold the motor and load at zero speed when the drive is stopped or not powered. Mechanical brake control (with or without acknowledgement) is activated by parameter 35.01 brake control . The ...

Page 56

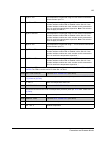

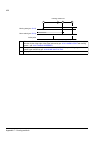

Drive control and features 56 mechanical brake state diagram close brake from any state 0/1/1/0 1/1/1/1 1) 2) 3) 6) 7) 11) 12) 13) 5) 0/0/1/1 8) state (symbol ) - nn: state name - w/x/y/z: state outputs/operations w: 1 = brake open command is active. 0 = brake close command is active. (controlled th...

Page 57

Drive control and features 57 operation time scheme the simplified time scheme below illustrates the operation of the brake control function. Example the figure below shows a brake control application example. Warning! Make sure that the machinery into which the drive with brake control function is ...

Page 58

Drive control and features 58 motor m 230 vac jcu unit mechanical brake brake control hardware emergency brake x2 1 ro1 2 ro1 3 ro1 x3 11 di5 13 +24 v the brake on/off is controlled via signal 3.15 brake command . The source for the brake supervision is selected by parameter 35.02 brake acknowl . Th...

Page 59

Drive control and features 59 position/synchron control features position calculation the actual position of the drive is measured using a position feedback device. During normal operation, the actual position is calculated by keeping track of the position change between the current time and the las...

Page 60

Drive control and features 60 with absolute encoders and resolvers, there is often a need to change the position calculation zero permanently without physically rotating the motor. This is possible by using parameter 62.20 pos act offset . The value of the parameter is added to the position feedback...

Page 61

Drive control and features 61 load encoder gear function positioning uses the measured speed and position of the load. The load encoder gear function calculates the actual load position on the basis of the measured motor shaft position. Load encoder gear application examples: the load encoder gear p...

Page 62

Drive control and features 62 because the drive speed control uses motor speed, a gear function between position control (load side) and speed control (motor side) is needed. This gear function is formed from the motor gear function and inverted load gear function. The gear function is applied to th...

Page 63

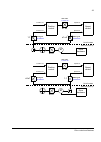

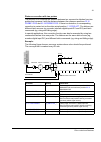

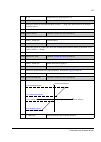

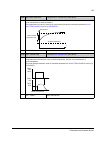

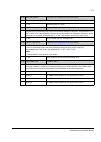

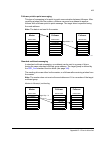

Drive control and features 63 drive firmware position control position ref. Speed control gear ratio 71.07 / 71.08 speed ref. Speed act. N1:n2 position act. 1:1 load gear 60.03 / 60.04 n1:n2 motor gear 22.03 / 22.04 n2:n1 m mechanical set-up drive hardware drive firmware position control position re...

Page 64

Drive control and features 64 position profile generator the position profile generator moves the position reference to the selected target position, taking the positioning speed acceleration/deceleration into account. The generator continuously calculates the speed from which the drive can decelera...

Page 65

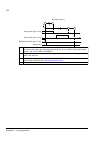

Drive control and features 65 parameters 66.05 pos enable and 65.03 pos start 1 / 65.11 pos start 2 control the operation of the position profile generator. The following figure shows the positioning commands and signals when parameter 65.24 pos start mode is set to (0) normal . The following figure...

Page 66

Drive control and features 66 position reference sets the user can define two different position reference sets. Each reference set consists of • position reference • positioning speed reference • positioning acceleration reference • positioning deceleration reference • positioning reference filter ...

Page 67

Drive control and features 67 start: linear axis, absolute synchronisation used when the master and the follower are to be driven equal distances. 60.02 pos axis mode is set to (0) linear . 68.07 synchron mode is set (0) absolute . To catch the master position, the follower accelerates up to its max...

Page 68

Drive control and features 68 position correction homing normally, before first homing, the actual position of the driven machinery does not correspond to the internal zero position in the drive position control (for example, with an incremental encoder after each power-up). Homing establishes a cor...

Page 69

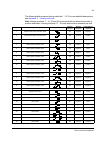

Drive control and features 69 the following table presents homing methods 1…35. For more detailed descriptions, see appendix c – homing methods . Note : homing methods 1…14, 33 and 34 do not work with an absolute encoder or position estimation. Homing methods 17…30 work with position estimation as w...

Page 70

Drive control and features 70 preset functions preset functions are used to set the position system according to a parameter value (preset position) or actual position. The physical position of the driven machinery is not changed, but the new position value is used as home position. Preset functions...

Page 71

Drive control and features 71 cyclic position correction cyclic position correction functions are used to change or correct the system position continuously according to data measured by external probe signals, for example, if there is play in the machinery. The cyclic position correction functions ...

Page 72

Drive control and features 72 actual position correction the purpose of the actual position correction is to compare the difference between 62.16 probe1 pos and the actual encoder position at the moment when the triggering conditions are fulfilled. If there is a deviation, a corresponding correction...

Page 73

Drive control and features 73 t 1 : rising edge of encoder digital input di1 signal (proximity switch signal) is detected when the load position should be 90°. The actual position of the encoder is 120° (stored to signal 4.03 probe1 pos meas ). Distance between the load position and the actual posit...

Page 74

Drive control and features 74 t 1 : rising edge of encoder digital input di1 signal (proximity switch signal) is detected when the master (motor) position should be 60°. The used position reference is 90° (stored to signal 4.03 probe1 pos meas ). The master reference correction function calculates t...

Page 75

Drive control and features 75 master/follower distance correction the purpose of the master/follower distance correction is to measure the distance between the two probe positions and compare it with the distance between reference positions 62.16 probe1 pos and 62.18 probe2 pos . If there is a devia...

Page 76

Drive control and features 76 t 1 : rising edge of encoder di2 signal (proximity switch signal) is detected when the master position is 0°. The follower position is -130° (stored to signal 4.04 probe2 pos meas ). T 2 : rising edge of encoder di1 signal (proximity switch signal) is detected when the ...

Page 77

Drive control and features 77 example 2: linear axis application two conveyer systems are synchronised using two encoders. The follower is in synchron control and follows the master encoder 2 position. Note: in linear axis applications, only the difference between the master and follower positions i...

Page 78

Drive control and features 78 t 1 : rising edge of encoder digital input di1 signal (proximity switch signal) is detected. The actual position is 20 mm (stored to signal 4.04 probe2 pos meas ). The distance between the follower position and the actual position is 15 mm - 20 mm = - 5 mm t 2 : rising ...

Page 79

Drive control and features 79 distance correction with one probe the purpose is to measure the distance between two consecutive latches from one probe and compare it with the distance of the reference positions 62.16 probe1 pos and 62.18 probe2 pos . If there is a deviation, a corresponding correcti...

Page 80

Drive control and features 80 • rising edge of encoder di1 (proximity switch signal) is detected at the first mark of the belt. Position 0 mm is stored to signal 4.03 probe1 pos meas . • next rising edge of encoder di1 (proximity switch signal) is detected at the second mark of the belt. Position 30...

Page 81

Drive control and features 81 distance correction with two probes the purpose is to measure the distance between two consecutive latches from two probes and compare it with the distance between the reference positions 62.16 probe1 pos and 62.18 probe2 pos . If there is a deviation, a corresponding c...

Page 82: Emergency Stop

Drive control and features 82 • rising edge of encoder di1 (proximity switch signal) is detected at the first mark of the belt. Position 0 mm is stored to signal 4.03 probe1 pos meas . • falling edge of encoder di2 (proximity switch signal) is detected at the second mark of the belt. Position 40 mm ...

Page 83: Miscellaneous Features

Drive control and features 83 miscellaneous features backup and restore of drive contents general the drive offers a possibility of backing up numerous settings and configurations to external storage such as a pc file (using the drivestudio tool) and the internal memory of the control panel. These s...

Page 84

Drive control and features 84 for example, retaining the existing motor id run results in the drive will make a new motor id run unnecessary. Restore of individual parameters can fail for the following reasons: • the restored value does not fall within the minimum and maximum limits of the drive par...

Page 85

Drive control and features 85 fan control logic the fan operation can be controlled via parameter 46.13 fan ctrl mode . The parameter provides the following four operation modes: normal, force off, force on and advanced. The control logic (normal or advanced) can be overridden by forcing the fan on ...

Page 86

Drive control and features 86.

Page 87: What This Chapter Contains

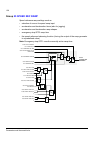

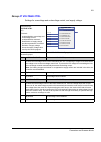

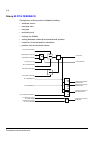

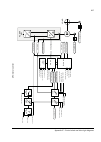

Default connections of the control unit 87 default connections of the control unit what this chapter contains this chapter shows the default control connections of the jcu control unit. More information on the connectivity of the jcu is given in the hardware manual of the drive..

Page 88

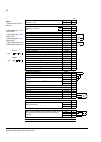

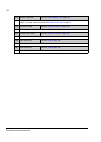

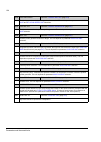

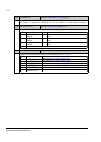

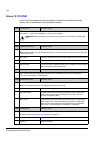

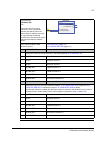

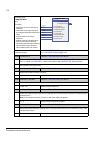

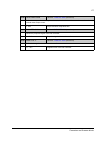

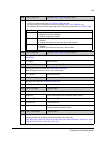

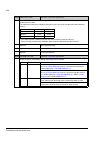

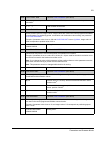

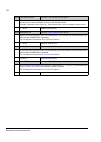

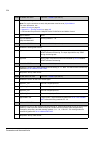

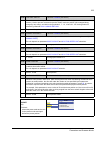

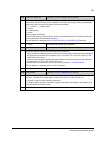

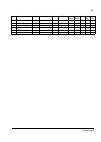

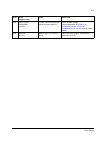

Default connections of the control unit 88 notes: *total maximum current: 200 ma 1) selected by par. 12.01 dio1 conf. 2) selected by par. 12.02 dio2 conf. 3) selected by par. 12.03 dio3 conf. 4) selected by jumper j1. 5) selected by jumper j2. X1 external power input 24 v dc, 1.6 a +24vi 1 gnd 2 x2 ...

Page 89: What This Chapter Contains

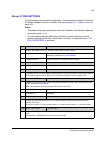

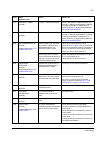

Parameters and firmware blocks 89 parameters and firmware blocks what this chapter contains this chapter lists and describes the parameters provided by the firmware. Types of parameters parameters are user-adjustable operation instructions of the drive (groups 10…99). There are four basic types of p...

Page 90: Firmware Blocks

Parameters and firmware blocks 90 note: pointing to a non-existing bit will be interpreted as 0 (false). For additional parameter data, eg, update cycles and fieldbus equivalents, see chapter parameter data . Firmware blocks firmware blocks accessible from the drivespc pc tool are described in the p...

Page 91: Group

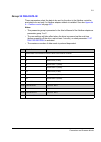

Parameters and firmware blocks 91 group 01 actual values this group contains basic actual signals for monitoring the drive. 01 firmware block: actual values (1) 1.01 speed act fw block: speed feedback (page 149 ) filtered actual speed in rpm. Used speed feedback is defined by parameter 22.01 speed f...

Page 92

Parameters and firmware blocks 92 1.10 encoder 2 speed fw block: encoder (page 256 ) encoder 2 speed in rpm. 1.11 encoder 2 pos fw block: encoder (page 256 ) actual position of encoder 2 within one revolution. 1.12 pos act fw block: pos feedback (page 219 ) actual position of the encoder. The unit d...

Page 93

Parameters and firmware blocks 93 1.27 run time counter fw block: actual values (see above) motor run time counter. The counter run when the drive modulates. The counter can be reset using the drivestudio tool. 1.28 fan on-time fw block: actual values (see above) running time of the drive cooling fa...

Page 94: Group

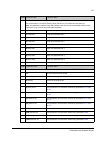

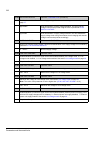

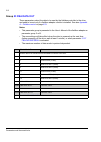

Parameters and firmware blocks 94 group 02 i/o values this group contains information on the i/os of the drive. 02 2.01 di status fw block: di (page 131 ) status word of the digital inputs. Example: 000001 = di1 is on, di2 to di6 are off. 2.02 ro status fw block: ro (page 131 ) status of relay outpu...

Page 95

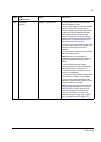

Parameters and firmware blocks 95 2.12 fba main cw fw block: fieldbus (page 205 ) control word for fieldbus communication. Log. = logical combination (ie, bit and/or selection parameter). Par. = selection parameter. See state diagram on page 429. Bit name val. Information log. Par. 0 stop* 1 stop ac...

Page 96

Parameters and firmware blocks 96 2.12 fba main cw (continued from previous page) bit name val. Information log. Par. 10 jogging 2 1 activate jogging function 2. See section jogging on page 50 . Or 10.14 0 jogging function 2 disabled 11 remote cmd 1 fieldbus control enabled - - 0 fieldbus control di...

Page 97

Parameters and firmware blocks 97 2.12 fba main cw (continued from previous page) bit name val. Information log. Par. 21 position- ing ena 1 enable position profile generator. Or 66.05 0 disable position profile generator. 22 po ref lim ena 1 enable position reference. Or 70.03 0 disable position re...

Page 98

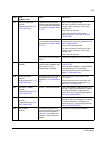

Parameters and firmware blocks 98 2.13 fba main sw fw block: fieldbus (page 205 ) status word for fieldbus communication. See state diagram on page 429. Bit name value information 0 ready 1 drive is ready to receive start command. 0 drive is not ready. 1 enabled 1 external run enable signal is recei...

Page 99

Parameters and firmware blocks 99 2.13 fba main sw (continued from previous page) 2.14 fba main ref1 fw block: fieldbus (page 205 ) scaled fieldbus reference 1. See parameter 50.04 fba ref1 modesel . 2.15 fba main ref2 fw block: fieldbus (page 205 ) scaled fieldbus reference 2. See parameter 50.05 f...

Page 100

Parameters and firmware blocks 100 2.17 d2d main cw fw block: d2d communication (page 214 ) drive-to-drive control word received through the drive-to-drive link. See also actual signal 2.18 below. 2.18 d2d follower cw fw block: drive logic (page 120 ) drive-to-drive control word sent to the follower...

Page 101: Group

Parameters and firmware blocks 101 group 03 control values 03 3.01 speed ref1 fw block: speed ref sel (page 155 ) speed reference 1 in rpm. 3.02 speed ref2 fw block: speed ref sel (page 155 ) speed reference 2 in rpm. 3.03 speedref ramp in fw block: speed ref mod (page 156 ) used speed reference ram...

Page 102

Parameters and firmware blocks 102 3.15 brake command fw block: mech brake ctrl (page 186 ) brake on/off command. 0 = close. 1 = open. For brake on/off control, connect this signal to a relay output (or a digital output). See section mechanical brake control on page 55 . 3.16 flux ref used fw block:...

Page 103: Group

Parameters and firmware blocks 103 group 04 pos ctrl values 04 4.01 speed ref pos fw block: pos control (page 253 ) position controller output (speed reference) for the speed controller in rpm. 4.02 speed act load fw block: pos feedback (page 219 ) filtered actual speed of the load. The unit depends...

Page 104

Parameters and firmware blocks 104 4.12 pos end speed fw block: profile ref sel (page 234 ) positioning speed used after the target has been reached.The unit depends on parameter 60.05 pos unit and 60.10 pos speed unit selections. 4.13 pos ref ipo fw block: profile generator (page 242 ) position ref...

Page 105: Group

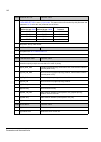

Parameters and firmware blocks 105 group 06 drive status 06 6.01 status word 1 fw block: drive logic (page 120 ) status word 1. Bit name val. Information 0 ready 1 drive is ready to receive start command. 0 drive is not ready. 1 enabled 1 external run enable signal is received. 0 no external run ena...

Page 106

Parameters and firmware blocks 106 6.02 status word 2 fw block: drive logic (page 120 ) status word 2. Bit name val. Information 0 start act 1 drive start command is active. 0 drive start command is inactive. 1 stop act 1 drive stop command is active. 0 drive stop command is inactive. 2 ready relay ...

Page 107

Parameters and firmware blocks 107 6.03 speed ctrl stat fw block: drive logic (page 120 ) speed control status word. 6.05 limit word 1 fw block: drive logic (page 120 ) limit word 1. Bit name val. Information 0 speed act neg 1 actual speed is negative. 1 zero speed 1 actual speed has reached the zer...

Page 108

Parameters and firmware blocks 108 6.07 torq lim status fw block: drive logic (page 120 ) torque controller limitation status word. Bit name val. Information 0 undervoltage 1 intermediate circuit dc undervoltage * 1 overvoltage 1 intermediate circuit dc overvoltage * 2 minimum torque 1 torque refere...

Page 109

Parameters and firmware blocks 109 6.09 pos ctrl status fw block: drive logic (page 120 ) position control status word. Bit name val. Information 0 in position 1 position reference generator has reached the used position reference. 0 position reference generator is active, ie, calculating the positi...

Page 110

Parameters and firmware blocks 110 6.10 pos ctrl status2 fw block: drive logic (page 120 ) additional position control status word. Bit name val. Information 0* in sync pos 1 position profile generator distance to target is below the absolute value of the synchron error limit, ie, value of 4.14 dist...

Page 111

Parameters and firmware blocks 111 6.11 pos corr status fw block: drive logic (page 120 ) position correction status word. Bit name val. Information 0 homing start 1 homing start is active. Source for the homing start is selected by parameter 62.03 homing start . 0 homing start is inactive. 1 homing...

Page 112

Parameters and firmware blocks 112 6.12 op mode ack fw block: reference ctrl (page 183 ) operation mode acknowledge: 0 = stopped, 1 = speed, 2 = torque, 3 = min, 4 = max, 5 = add, 6 = position, 7 = synchron, 8 = homing, 9 = prof vel, 10 = scalar, 11 = forced magn (ie, dc hold). 6.14 superv status fw...

Page 113: Group

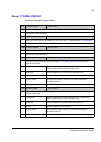

Parameters and firmware blocks 113 group 08 alarms & faults 08 8.01 active fault fw block: fault functions (page 196 ) fault code of the latest (active) fault. 8.02 last fault fw block: fault functions (page 196 ) fault code of the 2nd latest fault. 8.03 fault time hi fw block: fault functions (page...

Page 114

Parameters and firmware blocks 114 8.06 alarm logger 2 fw block: fault functions (page 196 ) alarm logger 2. For possible causes and remedies, see chapter fault tracing . Can be reset by entering a 0. 8.07 alarm logger 3 fw block: fault functions (page 196 ) alarm logger 3. For possible causes and r...

Page 115

Parameters and firmware blocks 115 8.08 alarm logger 4 fw block: fault functions (page 196 ) alarm logger 4. For possible causes and remedies, see chapter fault tracing . Can be reset by entering a 0. 8.09 alarm logger 5 fw block: fault functions (page 196 ) alarm logger 5. For possible causes and r...

Page 116

Parameters and firmware blocks 116 8.15 alarm word 1 fw block: fault functions (page 196 ) alarm word 1. For possible causes and remedies, see chapter fault tracing . This alarm word is refreshed, ie, when the alarm goes off, the corresponding alarm bit is cleared from the signal. 8.16 alarm word 2 ...

Page 117

Parameters and firmware blocks 117 8.17 alarm word 3 fw block: fault functions (page 196 ) alarm word 3. For possible causes and remedies, see chapter fault tracing . This alarm word is refreshed, ie, when the alarm goes off, the corresponding alarm bit is cleared from the signal. 8.18 alarm word 4 ...

Page 118: Group

Parameters and firmware blocks 118 group 09 system info 09 9.01 drive type fw block: none displays the drive application type. (2) acsm1 motion: motion control application 9.02 drive rating id fw block: none displays the inverter type of the drive. (0) unconfigured, (1) acsm1-xxax-02a5-4, (2) acsm1-...

Page 119

Parameters and firmware blocks 119 9.20 option slot 1 fw block: none displays the type of the optional module in option slot 1. (0) no option, (1) no comm, (2) unknown, (3) fen-01, (4) fen-11, (5) fen-21, (6) fio-01, (7) fio-11, (8) fpba-01, (9) fpba-02, (10) fcan-01, (11) fdna-01, (12) fena-01, (13...

Page 120: Group

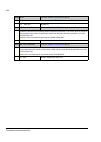

Parameters and firmware blocks 120 group 10 start/stop settings for • selecting start/stop/direction signal sources for external control locations ext1 and ext2 • selecting sources for external fault reset, run enable and start enable signals • selecting sources for emergency stop (off1 and off3) • ...

Page 121

Parameters and firmware blocks 121 block outputs located in other parameter groups 2.18 d2d follower cw (page 100 ) 6.01 status word 1 (page 105 ) 6.02 status word 2 (page 106 ) 6.03 speed ctrl stat (page 107 ) 6.05 limit word 1 (page 107 ) 6.07 torq lim status (page 108 ) 6.09 pos ctrl status (page...

Page 122

Parameters and firmware blocks 122 10.02 ext1 start in1 fw block: drive logic (see above) selects the source 1 for the start and stop commands in external control location ext1. See parameter 10.01 ext1 start func selections (1) in1 and (2) 3-wire . Note: this parameter cannot be changed while the d...

Page 123

Parameters and firmware blocks 123 (6) in1s in2dir the source selected by 10.05 ext2 start in1 is the start signal (0 = stop, 1 = start), the source selected by 10.06 ext2 start in2 is the direction signal (0 = forward, 1 = reverse). 10.05 ext2 start in1 fw block: drive logic (see above) selects the...

Page 124

Parameters and firmware blocks 124 bit pointer: group, index and bit 10.11 em stop off1 fw block: drive logic (see above) selects the source for the emergency stop off1. 0 = off1 active: the drive is stopped with the active deceleration time. Emergency stop can also be activated through fieldbus ( 2...

Page 125

Parameters and firmware blocks 125 10.16 d2d cw used fw block: drive logic (see above) selects the source for the control word for drive-to-drive communication. By default, the source is parameter 2.17 d2d main cw . Value pointer: group and index 10.17 start enable fw block: drive logic (see above) ...

Page 126: Group

Parameters and firmware blocks 126 group 11 start/stop mode these parameters select the start and stop functions as well as the autophasing mode, define the dc magnetising time of the motor, and configure the dc hold function. 11 firmware block: start/stop mode (11) 11.01 start mode fw block: start/...

Page 127

Parameters and firmware blocks 127 11.02 dc magn time fw block: start/stop mode (see above) defines the constant dc magnetising time. See parameter 11.01 start mode . After the start command, the drive automatically premagnetises the motor the set time. To ensure full magnetising, set this value to ...

Page 128

Parameters and firmware blocks 128 11.06 dc hold fw block: start/stop mode (see above) enables the dc hold function. The function makes it possible to lock the rotor at zero speed. When both the reference and the speed drop below the value of parameter 11.04 dc hold speed , the drive will stop gener...

Page 129: Group

Parameters and firmware blocks 129 group 12 digital io settings for the digital inputs and outputs, and the relay output. 12 firmware block: dio1 (6) selects whether dio1 is used as a digital input or as a digital output and connects an actual signal to the digital output. The block also shows the d...

Page 130

Parameters and firmware blocks 130 12.02 dio2 conf fw block: dio2 (see above) selects whether dio2 is used as a digital input, as a digital output or as a frequency input. (0) output dio2 is used as a digital output. (1) input dio2 is used as a digital input. (2) freq input dio2 is used as a frequen...

Page 131

Parameters and firmware blocks 131 12.10 dio3 f max scale fw block: dio3 (see above) when 12.03 dio3 conf is set to (2) freq output , defines the real value of the signal (selected by parameter 12.07 dio3 f out ptr ) that corresponds to the maximum dio3 frequency output value (defined by parameter 1...

Page 132

Parameters and firmware blocks 132 12.13 di invert mask fw block: di (see above) inverts status of digital inputs as reported by 2.01 di status . For example, a value of 0b000100 inverts the status of di3 in the signal. 0b000000…0b111111 di status inversion mask. 12.14 dio2 f max fw block: dio2 (see...

Page 133: Group

Parameters and firmware blocks 133 group 13 analogue inputs settings for the analogue inputs. The drive offers two programmable analogue inputs, ai1 and ai2. Both inputs can be used either as a voltage or a current input (-11…11 v or -22…22 ma). The input type is selected with jumpers j1 and j2 resp...

Page 134

Parameters and firmware blocks 134 13.03 ai1 min fw block: ai1 (see above) defines the minimum value for analogue input ai1. The type is selected with jumper j1 on the jcu control unit. -11…11 v / -22…22 ma minimum ai1 input value. 13.04 ai1 max scale fw block: ai1 (see above) defines the real value...

Page 135

Parameters and firmware blocks 135 13.07 ai2 max fw block: ai2 (see above) defines the maximum value for analogue input ai2. The type is selected with jumper j2 on the jcu control unit. -11…11 v / -22…22 ma maximum ai2 input value. 13.08 ai2 min fw block: ai2 (see above) defines the minimum value fo...

Page 136

Parameters and firmware blocks 136 (3) ai2 min tune current analogue input ai2 signal value is set as minimum value for ai2, parameter 13.08 ai2 min . The value reverts back to (0) no action automatically. (4) ai2 max tune current analogue input ai2 signal value is set as maximum value for ai2, para...

Page 137: Group

Parameters and firmware blocks 137 group 15 analogue outputs settings for the analogue outputs. The drive offers two programmable analogue outputs: one current output ao1 (0…20 ma) and one voltage output ao2 (-10…10 v). The resolution of the analogue outputs is 11 bits (+ sign) and the inaccuracy is...

Page 138

Parameters and firmware blocks 138 15.04 ao1 min fw block: ao1 (see above) defines the minimum value for analogue output ao1. 0…22.7 ma minimum ao1 output value. 15.05 ao1 max scale fw block: ao1 (see above) defines the real value that corresponds to the maximum analogue output value defined by para...

Page 139

Parameters and firmware blocks 139 15.09 ao2 max fw block: ao2 (see above) defines the maximum value for analogue output ao2. -10…10 v maximum ao2 output value. 15.10 ao2 min fw block: ao2 (see above) defines the minimum value for analogue output ao2. -10…10 v minimum ao2 output value. 15.11 ao2 max...

Page 140: Group

Parameters and firmware blocks 140 group 16 system local control and parameter access settings, restoration of default parameter values, save of parameters into permanent memory. 16 16.01 local lock fw block: none selects the source for disabling local control (take/release button on the pc tool, lo...

Page 141

Parameters and firmware blocks 141 16.09 user set sel fw block: none enables the save and restoration of up to four custom sets of parameter settings. The set that was in use before powering down the drive is in use after the next power-up. Note: any parameter changes made after loading a user set a...

Page 142

Parameters and firmware blocks 142 16.11 user io set lo fw block: none together with parameter 16.12 user io set hi , selects the user parameter set when parameter 16.09 user set sel is set to (10) io mode . The status of the source defined by this parameter and parameter 16.12 select the user param...

Page 143: Group

Parameters and firmware blocks 143 group 17 panel display selection of signals for panel display. 17 17.01 signal1 param fw block: none selects the first signal to be displayed on the control panel. The default signal is 1.03 frequency . Value pointer: group and index 17.02 signal2 param fw block: n...

Page 144

Parameters and firmware blocks 144 17.06 signal3 mode fw block: none defines the way the signal selected by parameter 17.01 signal1 param is displayed on the optional control panel. (-1) disabled signal not displayed. Any other signals that are not disabled are shown together with their respective s...

Page 145: Group

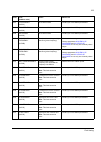

Parameters and firmware blocks 145 group 20 limits definition of drive operation limits. 20 firmware block: limits (20) adjusts the drive speed, current and torque limits, selects the source for the positive/negative speed reference enable command and enables the thermal current limitation. Block ou...

Page 146

Parameters and firmware blocks 146 20.03 pos speed ena fw block: limits (see above) selects the source of the positive speed reference enable command. 1 = positive speed reference is enabled. 0 = positive speed reference is interpreted as zero speed reference (in the figure below 3.03 speedref ramp ...

Page 147

Parameters and firmware blocks 147 20.08 therm curr lim fw block: none enables the thermal current limitation. Thermal current limit is calculated by the inverter thermal protection function. (0) disable the calculated thermal limit is not used. If the inverter output current is excessive, alarm igb...

Page 148: Group

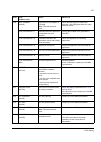

Parameters and firmware blocks 148 group 22 speed feedback settings for • selection of speed feedback used in drive control • filtering disturbances in measured speed signal • motor encoder gear function • zero speed limit for stop function • delay for zero speed delay function • definition of limit...

Page 149

Parameters and firmware blocks 149 22 firmware block: speed feedback (22) block outputs located in other parameter groups 1.01 speed act (page 91 ) 22.01 speed fb sel fw block: speed feedback (see above) selects the speed feedback value used in control. (0) estimated calculated speed estimate. (1) e...

Page 150

Parameters and firmware blocks 150 22.03 motor gear mul fw block: speed feedback (see above) defines the motor gear numerator for the motor encoder gear function. Where input speed is encoder 1/2 speed ( 1.08 encoder 1 speed / 1.10 encoder 2 speed ) or speed estimate ( 1.14 speed estimated ). Note: ...

Page 151

Parameters and firmware blocks 151 22.06 zero speed delay fw block: speed feedback (see above) defines the delay for the zero speed delay function. The function is useful in applications where a smooth and quick restarting is essential. During the delay the drive knows accurately the rotor position....

Page 152

Parameters and firmware blocks 152 22.08 speed tripmargin fw block: speed feedback (see above) defines, together with 20.01 maximum speed and 20.02 minimum speed , the maximum allowed speed of the motor (overspeed protection). If the actual speed ( 1.01 speed act ) exceeds the speed limit defined by...

Page 153

Parameters and firmware blocks 153 22.10 spd superv est fw block: fault functions (see page 196 ) defines the activation level for encoder supervision. The drive reacts according to 22.09 speed fb fault when: • the estimated speed ( 1.14 speed estimated ) is greater than 22.10 spd superv est and • t...

Page 154: Group

Parameters and firmware blocks 154 group 24 speed ref mod settings for • speed reference selection • speed reference modification (scaling and inversion) • constant speed and jogging references • definition of absolute minimum speed reference. Depending on user selection, either speed reference 1 or...

Page 155

Parameters and firmware blocks 155 24 firmware block: speed ref sel (23) selects the sources for two speed references, ref1 or ref2, from a selection list. Also shows the values of both speed references. The sources can alternatively be selected with value pointer parameters. See firmware block spee...

Page 156

Parameters and firmware blocks 156 (6) d2d ref2 drive to drive reference 2. (7) enc1 speed encoder 1 ( 1.08 encoder 1 speed ). (8) enc2 speed encoder 2 ( 1.10 encoder 2 speed ). 24.02 speed ref2 sel fw block: speed ref sel (see above) selects the source for speed reference 2 ( 3.02 speed ref2 ). See...

Page 157

Parameters and firmware blocks 157 -8…8 scaling factor for speed reference 1/2. 24.07 speedref neg ena fw block: speed ref mod (see above) selects the source for the speed reference inversion. 1 = sign of the speed reference is changed (inversion active). Bit pointer: group, index and bit 24.08 cons...

Page 158: Group

Parameters and firmware blocks 158 group 25 speed ref ramp speed reference ramp settings such as • selection of source for speed ramp input • acceleration and deceleration times (also for jogging) • acceleration and deceleration ramp shapes • emergency stop off3 ramp time • the speed reference balan...

Page 159

Parameters and firmware blocks 159 25 firmware block: speed ref ramp (25) this block • selects the source for the speed ramp input • adjusts acceleration and deceleration times (also for jogging) • adjusts acceleration/deceleration ramp shapes • adjusts ramp time for emergency stop off3 • forces the...

Page 160

Parameters and firmware blocks 160 25.04 dec time fw block: speed ref ramp (see above) defines the deceleration time, ie, the time required for the speed to change from the speed value defined by parameter 25.02 speed scaling to zero. If the speed reference decreases slower than the set deceleration...

Page 161

Parameters and firmware blocks 161 25.08 shape time dec2 fw block: speed ref ramp (see above) selects the shape of the deceleration ramp at the end of the deceleration. See parameter 25.05 shape time acc1 . 0…1000 s ramp shape at end of deceleration. 25.09 acc time jogging fw block: speed ref ramp (...

Page 162: Group

Parameters and firmware blocks 162 group 26 speed error speed error is determined by comparing the speed reference and speed feedback. The error can be filtered using a first-order low-pass filter if the feedback and reference have disturbances. In addition, a torque boost can be applied to compensa...

Page 163

Parameters and firmware blocks 163 26 firmware block: speed error (26) this block • selects the source for speed error calculation (speed reference - actual speed) in different control modes • selects the sources for speed reference and speed reference feedforward • defines the speed error filtering...

Page 164

Parameters and firmware blocks 164 value pointer: group and index 26.05 speed step fw block: speed error (see above) defines an additional speed step given to the input of the speed controller (added to the speed error value). -30000…30000 rpm speed step. 26.06 spd err ftime fw block: speed error (s...

Page 165

Parameters and firmware blocks 165 26.08 acc comp dertime fw block: speed error (see above) defines the derivation time for acceleration (deceleration) compensation. Used to improve the speed control dynamic reference change. In order to compensate inertia during acceleration, a derivative of the sp...

Page 166

Parameters and firmware blocks 166 (1) absolute speed error window control active. The boundaries defined by parameters 26.11 and 26.12 are absolute. (2) relative speed error window control active. The boundaries defined by parameters 26.11 and 26.12 are relative to speed reference. 26.11 speed win ...

Page 167: Group

Parameters and firmware blocks 167 group 28 speed control speed controller settings such as • selection of source for speed error • adjustment of pid-type speed controller variables • limitation of speed controller output torque • selection of source for acceleration compensation torque • forcing an...

Page 168

Parameters and firmware blocks 168 28 firmware block: speed control (28) this block • selects the source for speed error • adjusts pid-type speed controller variables • defines limits for speed controller output torque • selects the source for acceleration compensation torque • configures the balanc...

Page 169

Parameters and firmware blocks 169 28.03 integration time fw block: speed control (see above) defines the integration time of the speed controller. The integration time defines the rate at which the controller output changes when the error value is constant and the proportional gain of the speed con...

Page 170

Parameters and firmware blocks 170 28.04 derivation time fw block: speed control (see above) defines the derivation time of the speed controller. Derivative action boosts the controller output if the error value changes. The longer the derivation time, the more the speed controller output is boosted...

Page 171

Parameters and firmware blocks 171 28.07 drooping rate fw block: speed control (see above) defines the droop rate (in percent of the motor nominal speed). The drooping slightly decreases the drive speed as the drive load increases. The actual speed decrease at a certain operating point depends on th...

Page 172

Parameters and firmware blocks 172 28.12 pi adapt max spd fw block: speed control (see above) maximum actual speed for speed controller adaptation. Speed controller gain and integration time can be adapted according to actual speed. This is done by multiplying the gain ( 28.02 proport gain ) and int...

Page 173

Parameters and firmware blocks 173 28.16 pi tune mode fw block: none activates the speed controller autotune function. The autotune will automatically set parameters 28.02 proport gain and 28.03 integration time , as well as 1.31 mech time const . If the user autotune mode is chosen, also 26.06 spd ...

Page 174: Group

Parameters and firmware blocks 174 group 32 torque reference reference settings for torque control. In torque control, the drive speed is limited between the defined minimum and maximum limits. Speed-related torque limits are calculated and the input torque reference is limited according to these li...

Page 175

Parameters and firmware blocks 175 32 firmware block: torq ref sel (32) selects the source for torque reference 1 (from a parameter selection list) and the source for torque reference addition (used, eg, for compensating mechanical interferences). Also shows the torque reference and reference additi...

Page 176

Parameters and firmware blocks 176 firmware block: torq ref mod (33) this block • selects the source for the torque reference • scales the input torque reference according to the defined load share factor • defines limits for the torque reference • defines ramp-up and ramp-down times for the torque ...

Page 177

Parameters and firmware blocks 177 32.08 torq ramp down fw block: torq ref mod (see above) defines the torque reference ramp-down time, ie, the time for the reference to decrease from the nominal motor torque to zero. 0…60 s torque reference ramp-down time. 32.09 rush ctrl gain fw block: torq ref mo...

Page 178: Group

Parameters and firmware blocks 178 group 33 supervision configuration of signal supervision. 33 firmware block: supervision (17) block outputs located in other parameter groups 6.14 superv status (page 112 ) 33.01 superv1 func fw block: supervision (see above) selects the mode of supervision 1. (0) ...

Page 179

Parameters and firmware blocks 179 33.03 superv1 lim hi fw block: supervision (see above) sets the upper limit for supervision 1. See parameter 33.01 superv1 func . -32768…32768 upper limit for supervision 1. 33.04 superv1 lim lo fw block: supervision (see above) sets the lower limit for supervision...

Page 180

Parameters and firmware blocks 180 33.09 superv3 func fw block: supervision (see above) selects the mode of supervision 3. (0) disabled supervision 3 not in use. (1) low when the signal selected by parameter 33.10 superv3 act falls below the value of parameter 33.12 superv3 lim lo , bit 2 of 6.14 su...

Page 181

Parameters and firmware blocks 181 di4 digital input di4 (as indicated by 2.01 di status , bit 3). Di5 digital input di5 (as indicated by 2.01 di status , bit 4). Di6 digital input di6 (as indicated by 2.01 di status , bit 5). Ro1 relay output ro1 (as indicated by 2.02 ro status , bit 0). Ro2 relay ...

Page 182: Group

Parameters and firmware blocks 182 group 34 reference ctrl reference source and type selection. Using the parameters in this group, it is possible to select whether external control location ext1 or ext2 is used (either one is active at a time). These parameters also select the control mode (speed/t...

Page 183

Parameters and firmware blocks 183 34 firmware block: reference ctrl (34) this block • defines the selection method between external control locations ext1 and ext2 • configures control mode (speed/ torque/min/max/add) selection • selects the torque reference used in local and external control • sho...

Page 184

Parameters and firmware blocks 184 (2) torque torque control. Torque reference is 3.11 torq ref rushlim , which is the output of the torq ref mod firmware block. Torque reference source can be changed by parameter 34.09 tref torq src . (3) min combination of selections (1) speed and (2) torque : tor...

Page 185

Parameters and firmware blocks 185 34.07 local ctrl mode fw block: reference ctrl (see above) selects the control mode for local control. Note: this parameter cannot be changed while the drive is running. (1) speed speed control. Torque reference is 3.08 torq ref sp ctrl , which is the output of the...

Page 186: Group

Parameters and firmware blocks 186 group 35 mech brake ctrl settings for the control of a mechanical brake. See also section mechanical brake control on page 55 . 35 firmware block: mech brake ctrl (35) block outputs located in other parameter groups 3.14 brake torq mem (page 101 ) 3.15 brake comman...

Page 187

Parameters and firmware blocks 187 35.03 brake open delay fw block: mech brake ctrl (see above) defines the brake open delay (= the delay between the internal open brake command and the release of the motor speed control). The delay counter starts when the drive has magnetised the motor and risen th...

Page 188

Parameters and firmware blocks 188 35.09 brake fault func fw block: mech brake ctrl (see above) defines how the drive reacts in case of mechanical brake control error. If brake control supervision has not been activated by parameter 35.01 brake control , this parameter is disabled. (0) fault the dri...

Page 189: Group

Parameters and firmware blocks 189 group 40 motor control motor control settings, such as • flux reference • drive switching frequency • motor slip compensation • voltage reserve • flux optimisation • ir compensation for scalar control mode. Flux optimisation flux optimisation reduces the total ener...

Page 190

Parameters and firmware blocks 190 40.03 slip gain fw block: motor control (see above) defines the slip gain which is used to improve the estimated motor slip. 100% means full slip gain; 0% means no slip gain. The default value is 100%. Other values can be used if a static speed error is detected de...

Page 191

Parameters and firmware blocks 191 40.07 ir compensation fw block: motor control (see above) defines the relative output voltage boost at zero speed (ir compensation). The function is useful in applications with high break-away torque when no dtc motor can be applied. This parameter is only effectiv...

Page 192: Group

Parameters and firmware blocks 192 group 45 mot therm prot settings for thermal protection of the motor. See also section thermal motor protection on page 44 . 45 firmware block: mot therm prot (45) configures motor overtemperature protection and temperature measurement. Also shows the estimated and...

Page 193

Parameters and firmware blocks 193 (1) kty jcu the temperature is supervised using a kty84 sensor connected to drive thermistor input th. (2) kty 1st fen the temperature is supervised using a kty84 sensor connected to encoder interface module fen-xx installed in drive slot 1/2. If two encoder interf...

Page 194

Parameters and firmware blocks 194 45.06 mot load curve fw block: mot therm prot (see above) defines the load curve together with parameters 45.07 zero speed load and 45.08 break point . The value is given in percent of nominal motor current. When the parameter is set to 100%, the maximum load is eq...

Page 195

Parameters and firmware blocks 195 45.09 motnom temp rise fw block: mot therm prot (see above) defines the temperature rise of the motor when the motor is loaded with nominal current. See the motor manufacturer's recommendations. The temperature rise value is used by the motor thermal protection mod...

Page 196: Group

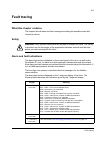

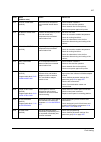

Parameters and firmware blocks 196 group 46 fault functions definition of drive behaviour upon a fault situation. An alarm or a fault message indicates abnormal drive status. For the possible causes and remedies, see chapter fault tracing . 46 firmware block: fault functions (46) this block • config...

Page 197

Parameters and firmware blocks 197 46.01 external fault fw block: fault functions (see above) selects an interface for an external fault signal. 0 = external fault trip. 1 = no external fault. Bit pointer: group, index and bit 46.02 speed ref safe fw block: fault functions (see above) defines the fa...

Page 198

Parameters and firmware blocks 198 46.06 suppl phs loss fw block: fault functions (see above) selects how the drive reacts when a supply phase loss is detected. This parameter is only used with an ac supply. (0) no no reaction. (1) fault drive trips on supply phase fault. 46.07 sto diagnostic fw blo...

Page 199

Parameters and firmware blocks 199 46.09 stall function fw block: fault functions (see above) selects how the drive reacts to a motor stall condition. A stall condition is defined as follows: • the drive is at stall current limit ( 46.10 stall curr lim ), and • the output frequency is below the leve...

Page 200

Parameters and firmware blocks 200 (0) coast stop by cutting off the motor power supply. The motor coasts to stop. (1) emergency ramp stop the drive is stopped along the emergency stop ramp time, 25.11 em stop time ..

Page 201: Group

Parameters and firmware blocks 201 group 47 voltage ctrl settings for overvoltage and undervoltage control, and supply voltage. 47 firmware block: voltage ctrl (47) this block • enables/disables overvoltage and undervoltage control • enables/disables automatic identification of supply voltage • prov...

Page 202

Parameters and firmware blocks 202 47.03 supplvoltauto-id fw block: voltage ctrl (see above) enables the auto-identification of the supply voltage. See also section voltage control and trip limits on page 47 . (0) disable auto-identification of supply voltage disabled. The drive sets the voltage con...

Page 203: Group

Parameters and firmware blocks 203 group 48 brake chopper configuration of an internal braking chopper. 48 firmware block: brake chopper (48) this block configures the braking chopper control and supervision. 48.01 bc enable fw block: brake chopper (see above) enables the braking chopper control. No...

Page 204

Parameters and firmware blocks 204 48.05 r br fw block: brake chopper (see above) defines the resistance value of the braking resistor. The value is used for braking chopper protection. 0.1…1000 ohm resistance. 48.06 br temp faultlim fw block: brake chopper (see above) selects the fault limit for th...

Page 205: Group

Parameters and firmware blocks 205 group 50 fieldbus basic settings for fieldbus communication. See also appendix a – fieldbus control on page 423 . 50 firmware block: fieldbus (50) this block • initialises the fieldbus communication • selects communication supervision method • defines scaling of th...

Page 206

Parameters and firmware blocks 206 (3) last speed communication break detection active. Upon a communication break, the drive generates alarm fieldbus comm and freezes the speed to the level the drive was operating at. The speed is determined by the average speed over the previous 10 seconds. Warnin...

Page 207

Parameters and firmware blocks 207 50.06 fba act1 tr src fw block: fieldbus (see above) selects the source for fieldbus actual value 1 when parameter 50.04 fba ref1 modesel / 50.05 fba ref2 modesel is set to (0) raw data . Value pointer: group and index 50.07 fba act2 tr src fw block: fieldbus (see ...

Page 208

Parameters and firmware blocks 208 50.12 fba cycle time fw block: fieldbus (see above) selects the fieldbus communication speed. The default selection is (2) fast . Lowering the speed reduces the cpu load. The table below shows the read/write intervals for cyclic and cyclic low data with each parame...

Page 209: Group

Parameters and firmware blocks 209 group 51 fba settings further fieldbus communication configuration. These parameters need to be set only if a fieldbus adapter module is installed. See also appendix a – fieldbus control on page 423 . Notes: • this parameter group is presented in the user’s manual ...

Page 210

Parameters and firmware blocks 210 51.30 mapping file ver fw block: none displays the fieldbus adapter module mapping file revision stored in the memory of the drive. In hexadecimal format. Example: 0x107 = revision 1.07. 51.31 d2fba comm sta fw block: none displays the status of the fieldbus adapte...

Page 211: Group

Parameters and firmware blocks 211 group 52 fba data in these parameters select the data to be sent by the drive to the fieldbus controller, and need to be set only if a fieldbus adapter module is installed. See also appendix a – fieldbus control on page 423 . Notes: • this parameter group is presen...

Page 212: Group

Parameters and firmware blocks 212 group 53 fba data out these parameters select the data to be sent by the fieldbus controller to the drive, and need to be set only if a fieldbus adapter module is installed. See also appendix a – fieldbus control on page 423 . Notes: • this parameter group is prese...

Page 213: Group

Parameters and firmware blocks 213 group 55 communication tool settings for an rs-485 network implemented using optional jpc-01 network communication adapters. The network enables the use of a single pc or control panel to control multiple drives. For more information, see the jpc-01 network communi...

Page 214: Group

Parameters and firmware blocks 214 group 57 d2d communication drive-to-drive communication settings. See appendix b – drive-to-drive link on page 431 . 57 firmware block: d2d communication (57) this block sets up the drive-to-drive communication. It also shows the main drive-to-drive control word an...

Page 215

Parameters and firmware blocks 215 57.03 node address fw block: d2d communication (see above) sets the node address for a follower drive. Each follower must have a dedicated node address. Note: if the drive is set to be the master on the drive-to-drive link, this parameter has no effect (the master ...

Page 216

Parameters and firmware blocks 216 57.09 kernel sync mode fw block: d2d communication (see above) determines which signal the time levels of the drive are synchronised with. An offset can be defined by parameter 57.10 kernel sync offs if desired. (0) nosync no synchronisation. (1) d2dsync if the dri...

Page 217

Parameters and firmware blocks 217 57.12 ref1 mc group fw block: d2d communication (see above) selects the multicast group the drive belongs to. See parameter 57.11 ref 1 msg type . 0…62 multicast group (0 = none). 57.13 next ref1 mc grp fw block: d2d communication (see above) specifies the next mul...

Page 218: Group

Parameters and firmware blocks 218 group 60 pos feedback configuration of drive position feedback including • feedback source • load gear ratio • axis type • positioning unit • scalings for fieldbus • scaling between rotational and translational systems • resolution of internal position calculation ...

Page 219

Parameters and firmware blocks 219 60 firmware block: pos feedback (60) this block • selects the source for measured actual position value (encoder 1, encoder 2 or estimated position) • selects whether positioning is executed along linear or rollover axis • configures the load encoder gear function ...

Page 220

Parameters and firmware blocks 220 60.03 load gear mul fw block: pos feedback (see above) defines the numerator for the load encoder gear function. See also section load encoder gear function on page 61 . Note: when load encoder gear function is set, the gear function defined by parameters 71.07 gea...

Page 221

Parameters and firmware blocks 221 60.07 feed const den fw block: pos feedback (see above) defines, together with parameter 60.06 feed const num , the feed constant for the position calculation. 1… 2 31 -1 feed constant denominator. 60.08 pos2int scale fw block: pos feedback (see above) scales posit...

Page 222

Parameters and firmware blocks 222 60.12 pos speed scale fw block: pos feedback (see above) defines an additional scaling for internal positioning speed, acceleration and deceleration values. Can be used, eg, to improve calculation accuracy at low and high speeds. Example: if parameter value is set ...

Page 223: Group

Parameters and firmware blocks 223 group 62 pos correction settings for position correction functions (homing, presets, and cyclic corrections). With these functions, the user can define the relationship between the actual position of the drive positioning system and the driven machinery. Some of th...

Page 224

Parameters and firmware blocks 224 62.01 homing method fw block: homing (see above) selects the homing method. Note: for cyclic corrections to work, this parameter must be set to (0) no method . For more information, see • section homing on page 68 • appendix c – homing methods on page 443 • cia sta...

Page 225

Parameters and firmware blocks 225 62.06 pos limit switch fw block: homing (see above) selects the source for the positive limit switch signal (ie, external latch signal source for the maximum position). Used to prevent movement beyond a certain maximum position (drive stopped along emergency stop r...

Page 226

Parameters and firmware blocks 226 62.11 preset mode fw block: preset (see above) selects the preset mode. Presets are used to set the position system to a parameter value (preset position) or actual position. The physical position of the driven machinery is not changed, but the new position value i...

Page 227

Parameters and firmware blocks 227 62.13 preset position fw block: preset (see above) defines the preset position. The unit depends on parameter 60.05 pos unit selection. -32768…32768 preset position. Firmware block: cyclic correction (64) this block • selects the cyclic correction mode • defines th...

Page 228

Parameters and firmware blocks 228 (3) enc1 di2 _– encoder 1 position rising edge of di2 (4) enc1 di2 –_ encoder 1 position falling edge of di2 (5) reserved. (6) enc1 zerop encoder 1 position zero pulse (7) enc1 di1_– z encoder 1 position first zero pulse after rising edge of di1 (8) enc1 di1–_ z en...

Page 229

Parameters and firmware blocks 229 (28) enc2 di2=0 z encoder 2 position first zero pulse when di2 = 0 (29) probe1 sw encoder 1 position the trigger signal is selected by parameter 62.22 trig probe1 sw . (30) probe2 sw encoder 1 position the trigger signal is selected by parameter 62.23 trig probe2 s...

Page 230

Parameters and firmware blocks 230 62.21 pos cor mode fw block: homing (see above) determines if the position change made in homing or in preset mode 2 or 3 is forced permanently into the drive memory by saving it to parameter 62.20 pos act offset , or only until the next power- down. (0) normal the...

Page 231

Parameters and firmware blocks 231 62.26 z-pulse source 2 fw block: homing (see above) selects which zero pulse is used for probe 2 latching when a zero pulse dependent triggering condition is selected by parameter 62.17 trig probe2 . (0) probepossrc the source of the zero pulse is the same as the s...

Page 232

Parameters and firmware blocks 232 62.30 probe trig filt fw block: homing (see above) to avoid false latch events due to signal disturbances, latchings are verified on the basis of a low-pass filtered signal. The signal is filtered using the time constant ( τ ) defined by this parameter. In effect, ...

Page 233: Group

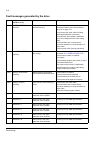

Parameters and firmware blocks 233 group 65 profile reference positioning profile and start command settings. The shape of the profile are defined by position reference, speed, acceleration, deceleration, filtering time, style, and end speed. The position reference can be taken from an analogue inpu...

Page 234

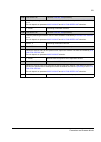

Parameters and firmware blocks 234 65 firmware block: profile ref sel (65) this block • selects the source for position reference • selects the source for position reference set 1/2 selection • defines the position reference sets 1 and 2 • selects the source for an additional position reference • se...

Page 235

Parameters and firmware blocks 235 65.02 prof set sel fw block: profile ref sel (see above) selects the source for position reference set 1 or 2 selection. 0 = position reference set 1, 1 = position reference set 2. See parameters 65.04 pos ref 1 sel and 65.12 pos ref 2 sel . Bit pointer: group, ind...

Page 236

Parameters and firmware blocks 236 0…1000 ms position reference filter time for position reference set 1. 65.09 pos style 1 fw block: profile ref sel (see above) determines the behaviour of the position profile generator when position reference set 1 is used. The figures below display the behaviour ...

Page 237

Parameters and firmware blocks 237 bit 2 1 = positioning to the target position along the shortest path, regardless of bit 0 and 1 values. 0 = positioning to the target position according to bits 0 and 1. Bit 3 1 = before the positioning is started, the position system is reset. 0 = the position sys...

Page 238

Parameters and firmware blocks 238 bit 7 effective only when bit 4 = 1 and bit 2 = 0. 1 = when positioning is started by the rising edge of 65.03 pos start 1 , the motor rotates one revolution exactly according to bits 0 and 1. This feature is provided in the roll-over mode only. 0 = one revolution ...

Page 239

Parameters and firmware blocks 239 65.18 pos end speed 2 fw block: profile ref sel (see above) defines the positioning speed when target is reached when position reference set 1 is used. The unit depends on parameter 60.05 pos unit and 60.10 pos speed unit selections. -32768…32768 positioning speed ...

Page 240

Parameters and firmware blocks 240 65.22 prof vel ref sel fw block: profile ref sel (see above) selects the source for the speed reference in profile velocity mode. The profile velocity mode is activated by parameter 34.03 , 34.04 or 34.05 , depending on the control location used. (0) zero zero refe...

Page 241: Group

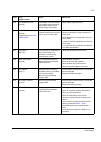

Parameters and firmware blocks 241 group 66 profile generator position profile generator settings. With these settings, the user can change the positioning speed during positioning, define positioning speed limits (for example, because of limited power), and set the window for target position. See a...

Page 242

Parameters and firmware blocks 242 66 firmware block: profile generator (66) this block • selects the source for position profile generator input position reference • defines the online positioning speed multiplier • defines a positioning speed value above which the acceleration/ deceleration time i...

Page 243

Parameters and firmware blocks 243 66.03 prof acc weak sp fw block: profile generator (see above) defines a positioning speed value (for the profile generator), above which acceleration/deceleration is slowed down. Because the drive power depends on the torque and angular velocity, this parameter de...

Page 244: Group

Parameters and firmware blocks 244 group 67 sync ref sel synchronisation reference source selection that is used in synchron control mode. Synchron reference can be smoothed with fine interpolation if the reference is updated too slowly or changes drastically because of missing data. If the referenc...

Page 245

Parameters and firmware blocks 245 67.01 sync ref sel fw block: sync ref sel (see above) selects the source for the position reference in synchron control. (0) zero zero position reference. (1) ai1 analogue input 1. (2) ai2 analogue input 2. (3) fba ref1 fieldbus reference 1. (4) fba ref2 fieldbus r...

Page 246

Parameters and firmware blocks 246 67.03 interpolat mode fw block: sync ref sel (see above) selects whether the synchronisation reference selected by parameter 67.01 sync ref sel is interpolated or not. This function can be used to smooth out short breaks in the reference. (0) none interpolation is ...

Page 247: Group

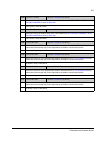

Parameters and firmware blocks 247 group 68 sync ref mod synchronisation reference modification settings that are used to select between absolute or relative synchronisation, to set an electrical gear ratio between the synchronisation reference and the drive positioning system, and to filter the ref...

Page 248

Parameters and firmware blocks 248 68.02 sync gear mul fw block: sync ref mod (see above) defines the numerator for the synchron gear function. The gear function modifies the position alterations of the synchron position reference value in order to obtain a certain ratio between the master and follo...

Page 249: Group