- DL manuals

- ABB

- Measuring Instruments

- Advance Optima caldos25

- Operator's Manual

ABB Advance Optima caldos25 Operator's Manual - Configuring Profibus

7-C-14

Chapter 7: Gas Analyzer Configuration

42/24-10 EN Rev. 9

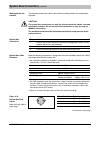

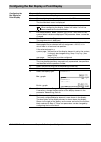

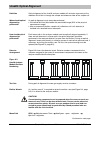

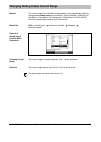

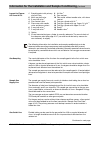

Configuring Profibus

Menu Path

MENU

→ Configure → System → Network → Profibus

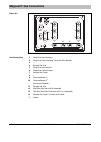

Figure 7-C-4

Profibus

Configuration

Parameter Selection

Profibus address 1 to 126

Profibus DP

Connection to the RS485 interface

Profibus type

Profibus PA

Connection to the MBP interface (non-intrinsically safe)

RS485 interface

automatically,

9600 Baud, 19200 Baud, 93750 Baud, 187.5 KBaud,

500 KBaud, 1500 KBaud, 3000 KBaud, 6000 KBaud

Profibus baudrate

MBP interface

set to 31250 Baud

Profibus inputs

Measured values, Bus analog outputs, Analog inputs, Analog

outputs, Digital inputs, Bus digital outputs, Digital outputs

Profibus map

Profibus outputs

Bus analog inputs, Bus digital inputs

Warm start

With Warm start the Profibus stack is reset, comparable with a

power off/on.

Profibus restart

Cold start

With Cold start, all the parameters which are stored in the

Profibus stack as store parameters are reset to the default

value.

For additional Profibus information see the “AO2000 Profibus DP/PA Interface”

technical bulletin (Publication No. 30/24-315 EN).

Summary of Advance Optima caldos25

Page 1

Advance optima continuous gas analyzers ao2000 series software version 5.0 operator’s manual 42/2410 en rev. 9.

Page 3: Ao2000 Series

Advance optima continuous gas analyzers ao2000 series software version 5.0 operator’s manual publication no. 42/2410 en rev. 9 edition march 2009 this operator’s manual is protected by copyright. The translation, duplication and distribution in any form, even in a revised edition or in extracts, in ...

Page 4: Table Of Contents

Ii ao2000 series operator’s manual 42/24-10 en rev. 9 table of contents page preface viii relationship between operator’s manual and software version x important safety information xi safety tips for handling electronic measurement devices xii explosion-protected version with type of protection ii 3...

Page 5: Table Of Contents,

42/24-10 en rev. 9 ao2000 series operator’s manual iii table of contents, continued page chapter 4 electrical connection electronics module connections 4-1 profibus module: electrical connections 4-2 modbus module: electrical connections 4-3 2-way analog output module: electrical connections 4-4 4-w...

Page 6: Table Of Contents,

Iv ao2000 series operator’s manual 42/24-10 en rev. 9 table of contents, continued page chapter 7 gas analyzer configuration section a measurement component-specific functions measurement range switching 7-a-1 modifying measurement range limits 7-a-2 limas11, uras26: notes for changing measurement r...

Page 7: Table Of Contents,

42/24-10 en rev. 9 ao2000 series operator’s manual v table of contents, continued page chapter 8 gas analyzer calibration section a principles calibration control 8-a-1 manual calibration 8-a-2 automatic calibration 8-a-4 test gas supply control for automatic calibration 8-a-6 externally controlled ...

Page 8: Table Of Contents,

Vi ao2000 series operator’s manual 42/24-10 en rev. 9 table of contents, continued page chapter 9 inspection and maintenance inspection 9-1 checking gas path seal integrity 9-2 magnos27: thermal link replacement 9-3 uras26: optical alignment 9-4 uras26: phase alignment 9-6 limas11, uras26: measureme...

Page 9: Table Of Contents,

42/24-10 en rev. 9 ao2000 series operator’s manual vii table of contents, continued page appendix 1 gas analyzer overview gas analyzer a-1-1 analyzer modules a-1-2 gas module a-1-2 electronics module a-1-3 system housing a-1-4 display and control unit a-1-4 appendix 2 analyzer module operating speci...

Page 10: Preface

Viii ao2000 series operator’s manual 42/24-10 en rev. 9 preface content of the operator’s manual this operator’s manual contains all the information you will need to safely and effi- ciently install, start-up, operate and maintain the ao2000 series gas analyzers. This operator’s manual contains info...

Page 11: Preface,

42/24-10 en rev. 9 ao2000 series operator’s manual ix preface, continued additional information on cd-rom a cd-rom with the following content is added to the gas analyzer: • operator’s manuals, • data sheets, • technical information sheets, • spare parts lists, • certificates, • software tools. Furt...

Page 12

X ao2000 series operator’s manual 42/24-10 en rev. 9 relationship between operator’s manual and software version software version the software of the ao2000 series gas analyzers is modular in design. The system controller and the analyzer modules are all equipped with their own processor and softwar...

Page 13: Important Safety Information

42/24-10 en rev. 9 ao2000 series operator’s manual xi important safety information intended application the ao2000 series gas analyzers are designed for continuous measurement of the concentration of individual components in gases or vapors. The non-explosion protected models of the ao2000 series ga...

Page 14

Xii ao2000 series operator’s manual 42/24-10 en rev. 9 safety tips for handling electronic measurement devices protective lead connection the protective lead (ground) should be attached to the protective lead connector before any other connection is made. Risks of a disconnect- ed protective lead th...

Page 15

42/24-10 en rev. 9 ao2000 series operator’s manual xiii explosion-protected version with type of protection ii 3g for measurement of non-flammable gases and vapors: description and special conditions for operation intended application the ao2000 series gas analyzers with type of protection ii 3g are...

Page 17: Chapter 1

42/24-10 en rev. 9 chapter 1: preparing the installation 1-1 chapter 1 preparing the installation installation location requirements short gas paths install the gas analyzer as close as possible to the sampling location. Locate the gas preparation and calibration assemblies as close as possible to t...

Page 18

1-2 chapter 1: preparing the installation 42/24-10 en rev. 9 installation location requirements, continued installation location altitude the maximum installation location altitude is 2000 m. Vibrations if the gas analyzer is installed in a cabinet the maximum acceleration amplitude is 0.01 ms –2 in...

Page 19

42/24-10 en rev. 9 chapter 1: preparing the installation 1-3 sample gas inlet and outlet conditions gas inlet conditions the following sample gas and, if applicable, flowing reference gas inlet conditions apply to the analyzer modules and the gas module. Module temperature pressure p e 3) flow rate ...

Page 20

1-4 chapter 1: preparing the installation 42/24-10 en rev. 9 sample gas inlet and outlet conditions, continued flammable, corrosive or toxic gases a housing purge is required if the sample gas contains flammable, corrosive or toxic components (see “housing purge” section, page 3-5). Please observe a...

Page 21: Test Gases For Calibration

42/24-10 en rev. 9 chapter 1: preparing the installation 1-5 test gases for calibration analyzer module zero calibration span calibration caldos25, caldos27 test gas or sample- component-free process gas or substitute gas test gas or process gas having a known sample gas concentration or substitute ...

Page 22: Purge Gas For Housing Purge

1-6 chapter 1: preparing the installation 42/24-10 en rev. 9 purge gas for housing purge purge gas the following purge gases can be used: • nitrogen when measuring flammable gases or • instrument air when measuring corrosive gases (quality per iso 8573-1 class 3, i.E. Max. Particle size of 40 μm, ma...

Page 23: Power Supply Information

42/24-10 en rev. 9 chapter 1: preparing the installation 1-7 power supply information gas analyzer power supply there is a power supply in the gas analyzer’s central unit (see “power supply” section, page 1-8). It provides the supply voltage to power the electronics module and one analyzer module. A...

Page 24: Power Supply

1-8 chapter 1: preparing the installation 42/24-10 en rev. 9 power supply application the central unit power supply provides 24 vdc for the electronics module and one analyzer module built-in in the central unit or one external analyzer module. Input voltage 100–240 vac, –15 %, +10 % input current m...

Page 25: Scope of Delivery

42/24-10 en rev. 9 chapter 1: preparing the installation 1-9 scope of delivery quantity description 1 ao2000 gas analyzer 1 “analyzer data sheet” (in the system housing) 1 operator’s manual 1 cd-rom containing technical documentation and communication software 1 power cord, 5 meters long, with groun...

Page 26

1-10 chapter 1: preparing the installation 42/24-10 en rev. 9 material needed for installation (not delivered) gas connections • threaded connections with 1/8 npt threads and ptfe sealing tape flow meter • in the caldos25 and uras26 versions with flowing reference gas a flow meter with a needle valv...

Page 27

42/24-10 en rev. 9 chapter 1: preparing the installation 1-11 list of figures related to installation figure see page dimensional diagrams 19-inch housing 2-4 wall-mount housing 2-4 gas connections magnos206 3-1 magnos27 3-2 magnos27 (sample cell direct connection) 3-3 caldos25, caldos27 3-4 caldos2...

Page 28

1-12 chapter 1: preparing the installation 42/24-10 en rev. 9 guideline for installation and start-up step action see page follow safety precautions xi, xii, xiii prepare the installation installation location 1-1 sample gas inlet and outlet conditions 1-3 test gases for calibration 1-5 purge gas fo...

Page 29: Chapter 2

42/24-10 en rev. 9 chapter 2: gas analyzer unpacking and installation 2-1 chapter 2 gas analyzer unpacking and installation gas analyzer unpacking caution! The gas analyzer can weigh from 18 to 23 kg (40 to 50 pounds). Two persons are needed for unpacking and carrying. Step action 1 remove the gas a...

Page 30: Gas Analyzer Identification

2-2 chapter 2: gas analyzer unpacking and installation 42/24-10 en rev. 9 gas analyzer identification what do we mean by “gas analyzer identification”? When we say “gas analyzer identification” we mean answering the following questions: • for what tasks is the gas analyzer intended? • what are the c...

Page 31: Gas Analyzer Identification,

42/24-10 en rev. 9 chapter 2: gas analyzer unpacking and installation 2-3 gas analyzer identification, continued analyzer data sheet for the central unit and each analyzer module the analyzer data sheet contains the following information: • order number (a-no.), • part number (p-no.) • production da...

Page 32: Dimensional Diagrams

2-4 chapter 2: gas analyzer unpacking and installation 42/24-10 en rev. 9 dimensional diagrams figure 2-2 19-inch housing (dimensions in mm) error maint power 483 17 7 413 35 563 597 figure 2-3 wall-mount housing (dimensions in mm) error maint power additional notes • the connection box shown with d...

Page 33: Gas Connections Installation

42/24-10 en rev. 9 chapter 2: gas analyzer unpacking and installation 2-5 gas connections installation since the gas ports are now easily accessible, connect the gas lines to the analyzer module before the gas analyzer is installed. Gas port design the analyzer module gas ports have 1/8-npt internal...

Page 34: Gas Analyzer Installation

2-6 chapter 2: gas analyzer unpacking and installation 42/24-10 en rev. 9 gas analyzer installation caution! A system housing with an electronics module and an analyzer module weighs from 18 to 23 kg (40 to 50 pounds). The following points should be observed: • two persons are needed for installatio...

Page 35: Chapter 3

42/24-10 en rev. 9 chapter 3: gas line connection 3-1 chapter 3 gas line connection magnos206: gas connections figure 3-1 1 2 3 4 13 14 12 11 10 9 8 7 1 sample gas inlet 2 sample gas outlet 3 purge gas inlet analyzer 2) 4 purge gas outlet analyzer 2) 7 purge gas inlet housing 1) 8 purge gas outlet h...

Page 36: Magnos27: Gas Connections

3-2 chapter 3: gas line connection 42/24-10 en rev. 9 magnos27: gas connections figure 3-2 1 2 3 4 5 6 7 8 9 10 11 12 14 13 1 purge gas inlet housing 1) 2 purge gas outlet housing 1) (also with flow sensor) 3 – 4 sample gas inlet 5 purge gas inlet analyzer 6 purge gas outlet analyzer 7 sample gas ou...

Page 37: Magnos27: Gas Connections

42/24-10 en rev. 9 chapter 3: gas line connection 3-3 magnos27: gas connections sample cell direct connection, only in wall-mount housing figure 3-3 1 2 10 9 4 7 6 8 5 1 purge gas inlet housing 1) 2 purge gas outlet housing 1) (also with flow sensor) 4 sample gas inlet 5 purge gas inlet analyzer 6 p...

Page 38

3-4 chapter 3: gas line connection 42/24-10 en rev. 9 caldos25, caldos27: gas connections figure 3-4 1 2 3 4 7 8 9 10 12 11 14 13 1 sample gas inlet 2 sample gas outlet 3 purge gas inlet analyzer 4 purge gas outlet analyzer 7 purge gas inlet housing 1) 8 purge gas outlet housing 1) (also with flow s...

Page 39: Caldos25: Gas Connections

42/24-10 en rev. 9 chapter 3: gas line connection 3-5 caldos25: gas connections corrosive sample gas or flowing reference gas figure 3-5 1 2 3 4 7 8 9 10 12 11 14 13 6 5 1 sample gas inlet 2 sample gas outlet 3 purge gas inlet analyzer 4 purge gas outlet analyzer 5 reference gas inlet 2) 6 reference...

Page 40: Limas11: Gas Connections

3-6 chapter 3: gas line connection 42/24-10 en rev. 9 limas11: gas connections standard cell, quartz cell, quartz cell with center connection figure 3-6 7 8 9 1 3 4 6 bus service 24 v dc 1 sample gas inlet 3 purge gas inlet housing 1) 4 sample gas outlet 6 purge gas outlet housing 1) 7 pressure sens...

Page 41: Limas11: Gas Connections

42/24-10 en rev. 9 chapter 3: gas line connection 3-7 limas11: gas connections quartz cell with pfa tubes figure 3-7 7 1 3 4 6 bus service 24 v dc 1 sample gas inlet 3 purge gas inlet housing 1) 4 sample gas outlet 6 purge gas outlet housing 1) 7 pressure sensor gas connections 1) option.

Page 42: Limas11: Gas Connections

3-8 chapter 3: gas line connection 42/24-10 en rev. 9 limas11: gas connections safety cell figure 3-8 7 1 2 3 4 5 6 bus service 24 v dc 1 sample gas inlet 2 sample gas outlet 3 purge gas inlet housing 1) 4 purge gas inlet sample cell 5 purge gas outlet sample cell 6 purge gas outlet housing 1) 7 pre...

Page 43: Uras26: Gas Connections

42/24-10 en rev. 9 chapter 3: gas line connection 3-9 uras26: gas connections figure 3-9 1 2 3 4 5 6 7 8 9 10 11 12 13 14 1 pressure sensor for external pressure measurement 1) 2 – 3 sample gas inlet gas path 1 4 sample gas outlet gas path 1 5 purge gas inlet housing 1) 6 purge gas outlet housing 1)...

Page 44: Gas Diagrams

3-10 chapter 3: gas line connection 42/24-10 en rev. 9 gas diagrams figure 3-10 analyzer module and gas module with 3 solenoid valves o 2 p mg ng eg e c opt. Gas module test gas connection for caldos27, magnos206, magnos27, limas11 without calibration cells, uras26 without calibration cells option: ...

Page 45: Pressure Sensor

42/24-10 en rev. 9 chapter 3: gas line connection 3-11 pressure sensor analyzer module pressure sensor uras26, limas11, caldos27 built-in at the factory caldos25 not necessary magnos206, magnos27 built-in at the factory as an option which analyzer modules have a pressure sensor? Multifid14 cannot be...

Page 46: Housing Purge

3-12 chapter 3: gas line connection 42/24-10 en rev. 9 housing purge when should the housing be purged? A housing purge is required if the sample gas contains combustible, corrosive or toxic components. Housing design a housing purge is possible if the system housing is designed for ip54 (with conne...

Page 47: Gas Line Connection

42/24-10 en rev. 9 chapter 3: gas line connection 3-13 gas line connection caution! The lines and fittings must be free of any residues (e.G. Particles left over from manufacturing). Contaminants can enter the analyzer and damage it or lead to false measurement results. • gas port installation is de...

Page 49: Chapter 4

42/24-10 en rev. 9 chapter 4: electrical connection 4-1 chapter 4 electrical connection electronics module connections figure 4-1 electronics module connections 1 6 1 6 1 6 -x29 -x27 -x25 -x26 -x24 -x22 -x20 -x28 -x23 -x21 -x07 -x01 -x08 -x09 for connection see -x01 power supply connection page 4-18...

Page 50

4-2 chapter 4: electrical connection 42/24-10 en rev. 9 profibus module: electrical connections figure 4-2 profibus module connection diagram 1 6 rs485 mbp 1 2 3 4 rs485 interface: 1 – not used 2 m24 24 v output ground 3 rxd/txd-p receive / transmit data plus, b-line 4 – not used 5 dgnd data transmi...

Page 51

42/24-10 en rev. 9 chapter 4: electrical connection 4-3 modbus module: electrical connections figure 4-3 modbus module connection diagram 1 6 1 6 rs232 rs485 rs232 interface: 2 rxd 3 txd 5 gnd design: 9-pin sub-d male connector rs485 interface: 2 rtxd– 3 rtxd+ 5 gnd design: 9-pin sub-d female connec...

Page 52

4-4 chapter 4: electrical connection 42/24-10 en rev. 9 2-way analog output module: electrical connections 1 2 3 4 figure 4-4 2-way analog output module connection diagram 1 2 3 4 ao1 + - ao2 + - 0/4 to 20 ma, max. 750 Ω 0/4 to 20 ma, max. 750 Ω ao1-ao2 analog outputs: 0 / 4-20 ma (configurable, fac...

Page 53

42/24-10 en rev. 9 chapter 4: electrical connection 4-5 4-way analog output module: electrical connections 1 2 3 4 5 6 7 8 figure 4-5 4-way analog output module connection diagram 1 2 3 4 5 6 7 8 ao3 ao1 + + - - ao4 ao2 + + - - 0/4 to 20 ma, max. 750 Ω 0/4 to 20 ma, max. 750 Ω 0/4 to 20 ma, max. 750...

Page 54

4-6 chapter 4: electrical connection 42/24-10 en rev. 9 4-way analog input module: electrical connections 2 4 6 8 10 9 7 5 3 1 figure 4-6 4-way analog input module connection diagram 1 2 3 4 5 6 7 8 9 10 50 Ω 50 Ω 50 Ω 50 Ω ai1 ai3 i i c c ai2 ai4 i i c c +24 v gnd 0 to 20 ma into 50 Ω 0 to 20 ma in...

Page 55

42/24-10 en rev. 9 chapter 4: electrical connection 4-7 digital i/o module: electrical connections 2 1 3 5 7 9 11 13 15 17 19 21 23 4 6 8 10 12 14 16 18 20 22 24 di4 do3 do2 do1 do4 di3 di2 di1 figure 4-7 digital i/o module connection diagram 13 15 17 14 16 18 19 21 23 20 22 24 do4 no common nc do3 ...

Page 56

4-8 chapter 4: electrical connection 42/24-10 en rev. 9 digital i/o module: electrical connections, continued status signals / externally controlled calibration: single status signals: collective status signal: do1 failure collective status do2 maintenance mode limit value do3 maintenance request li...

Page 57

42/24-10 en rev. 9 chapter 4: electrical connection 4-9 standard terminal connections basic principles the terminal connections are allocated • in the order of the registered analyzer modules and • within an analyzer module, in the order of the sample components. The order of the analyzer modules an...

Page 58: System Bus Connection

4-10 chapter 4: electrical connection 42/24-10 en rev. 9 system bus connection system bus the functional components of the gas analyzer, i.E. The electronics module, the external i/o devices and the analyzer modules communicate with each other via the system bus. The system bus structure is linear w...

Page 59: System Bus Connection,

42/24-10 en rev. 9 chapter 4: electrical connection 4-11 system bus connection, continued what materials are needed? The required system bus cables, tees and terminating resistors are supplied per the order. Caution! For system bus connections use only the yellow system bus cables, tees and terminat...

Page 60: System Bus Connection,

4-12 chapter 4: electrical connection 42/24-10 en rev. 9 system bus connection, continued step action 1 open the internal system bus connection between the existing analyzer module and the electronics module. 2 place a tee on the system bus connection (designated “bus”) of each module (electronics a...

Page 61

42/24-10 en rev. 9 chapter 4: electrical connection 4-13 signal, control and interface line connection caution! Follow local regulations on installing and connecting electrical wiring. • locate the signal, control and interface lines separately from the power supply lines. • locate the analog and di...

Page 62

4-14 chapter 4: electrical connection 42/24-10 en rev. 9 signal, control and interface line connection, continued ip20 version of system housing: step action 1 connect the wiring to the connector housing according to the connection diagrams. 2 connect the connector housings to the terminal strips. W...

Page 63

42/24-10 en rev. 9 chapter 4: electrical connection 4-15 power supply line connection – safety notes caution! Follow all applicable national safety regulations for the preparation and operation of electrical devices as well as the following safety precautions. The gas analyzer voltage must be set to...

Page 64

4-16 chapter 4: electrical connection 42/24-10 en rev. 9 power supply line connection to the analyzer module • the following information and instructions should be followed when connecting the 24-vdc power supply to an analyzer module that is not installed in the central unit but in a separate syste...

Page 65

42/24-10 en rev. 9 chapter 4: electrical connection 4-17 power supply line connection to the analyzer module, continued step action 1 connect the supplied connection cable with receptacle to the 24-vdc connection on the analyzer module or the i/o base module. 24-vdc connection 2 connect the wires on...

Page 66: Power Supply Line Connection

4-18 chapter 4: electrical connection 42/24-10 en rev. 9 power supply line connection what materials are needed? The gas analyzer is supplied with a power cord and a separate two-prong grounded plug. The power cord is 5 meters (16.4 feet) long and has a three-prong grounded-instrument plug for conne...

Page 67: Chapter 5

42/24-10 en rev. 9 chapter 5: gas analyzer start-up 5-1 chapter 5 gas analyzer start-up installation check installation check make sure the gas analyzer is correctly installed before carrying out any start-up procedures. Use the following check list: check • is the gas analyzer securely fastened? (s...

Page 68

5-2 chapter 5: gas analyzer start-up 42/24-10 en rev. 9 gas path and housing initial purge take note of the instructions in the “housing purge” section, page 3-12. Purge prior to start-up the gas paths and if necessary, the system housing should be purged prior to starting the gas analyzer. First th...

Page 69: Power Supply Activation

42/24-10 en rev. 9 chapter 5: gas analyzer start-up 5-3 power supply activation caution! For gas analyzers with limas11 or multifid14 analyzer modules: before activating the power supply check once again that the gas analyzer operating voltage setting matches the line voltage. The sample gas supply ...

Page 70: Warm-Up Phase

5-4 chapter 5: gas analyzer start-up 42/24-10 en rev. 9 warm-up phase warm-up phase the duration of the warm-up phase depends on which analyzer module is installed in the gas analyzer. Analyzer module warm-up phase duration caldos25 1.5 hours caldos27 approx. 30 / 60 minutes for class 1/ 2 measureme...

Page 71: Operation

42/24-10 en rev. 9 chapter 5: gas analyzer start-up 5-5 operation readiness at the end of the warm-up phase the gas analyzer is ready to carry out measure- ments. Calibration verification the gas analyzer is calibrated in the factory. Transport stresses as well as pressure and temperature conditions...

Page 73: Chapter 6

42/24-10 en rev. 9 chapter 6: gas analyzer operation 6-1 chapter 6 gas analyzer operation display and control unit overview the display and control unit contains: • the screen with • menu line • information field • softkey line • status led’s • numeric keypad • cancel keys • softkeys in both system ...

Page 74: Screen

6-2 chapter 6: gas analyzer operation 42/24-10 en rev. 9 screen screen error maint power 7 8 9 6 5 4 1 2 3 0 . The backlit graphics screen has a 320x240-pixel resolution. The screen is divided into three panels (see figure 6-1): • menu line • information field • softkey line menu line the menu line ...

Page 75: Message Display

42/24-10 en rev. 9 chapter 6: gas analyzer operation 6-3 message display message display functions the blinking message display in the softkey line has the following functions: • it prompts for the status message key to be pressed whenever a status message appears (refer to the “system status: statu...

Page 76: Status Led’S

6-4 chapter 6: gas analyzer operation 42/24-10 en rev. 9 status led’s status led’s error maint power 7 8 9 6 5 4 1 2 3 0 . The three led’s next to the screen indicate the gas analyzer’s status. Power the green “power” led lights when the power supply is on. Maint the yellow “maint” led lights when t...

Page 77: Numeric Keypad

42/24-10 en rev. 9 chapter 6: gas analyzer operation 6-5 numeric keypad numeric keypad error maint power 7 8 9 6 5 4 1 2 3 0 . The numeric keypad is located to the right of the screen, under the status led’s. 0 ... 9 , . , the operator can enter values directly with the: • numeric keys “0” through “...

Page 78: Cancel Keys

6-6 chapter 6: gas analyzer operation 42/24-10 en rev. 9 cancel keys cancel keys error maint power 7 8 9 6 5 4 1 2 3 0 . The “back” and “meas” keys located under the numeric keypad are designated as cancel keys. Back the “back” key allows the operator to cancel a function or menu item and return to ...

Page 79: Softkeys

42/24-10 en rev. 9 chapter 6: gas analyzer operation 6-7 softkeys softkeys error maint power 7 8 9 6 5 4 1 2 3 0 . The six keys under the screen and the softkey line at the lower edge of the screen are known as softkeys. A softkey is the combination of the key and its designation in the softkey line...

Page 80: Softkeys,

6-8 chapter 6: gas analyzer operation 42/24-10 en rev. 9 softkeys, continued the softkeys in menu mode in menu mode, a series of softkeys appears on the softkey line. Their descriptions and functions depend on the specific situation. In menu mode the standard softkeys have the following functions: t...

Page 81: Text Entry

42/24-10 en rev. 9 chapter 6: gas analyzer operation 6-9 text entry entering text when text, such as measurement components or user names, is to be entered an image of the numeric keypad appears on the screen. The following characters are shown using a total of four pages: • letters a-z and a-z • sy...

Page 82: Operating By Value Entry

6-10 chapter 6: gas analyzer operation 42/24-10 en rev. 9 operating by value entry value entry values are entered during measurement mode by pressing the number key that corresponds to the position of the display element in the display and is indicated above the display element. In the example below...

Page 83: Operating By Key Entry

42/24-10 en rev. 9 chapter 6: gas analyzer operation 6-11 operating by key entry key entry key entries are made during measurement mode by pressing the number key that corresponds to the position of the display element on the display and that is indicated over the display element. In the example, th...

Page 84: Password Protection

6-12 chapter 6: gas analyzer operation 42/24-10 en rev. 9 password protection elements of password protection password protection consists of three elements: • password level • user group • password password level each menu item is assigned an password level. Password levels are numbered 0, 1, 2 and...

Page 85: Password Protection,

42/24-10 en rev. 9 chapter 6: gas analyzer operation 6-13 password protection, continued viewing menu items all users can view all menu items, regardless of password level, without entering a password. Changing menu items all users can execute all password level 0 menu items without entering a pass-...

Page 86: User Interface Priority

6-14 chapter 6: gas analyzer operation 42/24-10 en rev. 9 user interface priority note the user interface is designated using the acronym “hmi”, which stands for “human machine interface”. User interfaces the ao2000 series gas analyzers have several user interfaces. • the local operation user interf...

Page 87: Access Lock

42/24-10 en rev. 9 chapter 6: gas analyzer operation 6-15 access lock access lock independent of the user interface priority adjustment (see page 6-14) it is possible to completely lock the access to the operation of the gas analyzer from a certain user interface (hmi). This lock is effected by conf...

Page 88: Menu Tree

6-16 chapter 6: gas analyzer operation 42/24-10 en rev. 9 menu tree menu tree the following table summarizes the gas analyzer menu tree. For reasons of brevity only the top level parameters and functions are shown; the menu branches more extensively at most menu items, e.G. Into the various measurem...

Page 89: Menu Tree,

42/24-10 en rev. 9 chapter 6: gas analyzer operation 6-17 menu tree, continued menu ⏐ ⏐ _ calibrate ⏐ ⏐ ⏐ ⏐ _ manual calibration 0 ⏐ ⏐ ⏐ ⏐ _ automatic calibration 0 ⏐ ⏐ _ configure ⏐ ⏐ ⏐ ⏐ _ component specific ⏐ ⏐ ⏐ _ measurement range 0 ⏐ ⏐ ⏐ _ filter 1 ⏐ ⏐ ⏐ _ pressure controller 2 ⏐ ⏐ ⏐ _ autoran...

Page 91: Chapter 7

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-a-1 chapter 7 gas analyzer configuration section a measurement component-specific functions measurement range switching menu path menu → configure → component specific → measurement range ( → select component) → … selection all measurement r...

Page 92

7-a-2 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 modifying measurement range limits menu path menu → configure → component specific → measurement range ( → select component) → … selection all measurement ranges configured (at the factory) for a sample component are displayed. Procedure...

Page 93

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-a-3 limas11, uras26: notes for changing measurement range limits physical measurement range the limas11 and uras26 analyzer modules have one physical measurement range per sample component. The limits of this measurement range are determined...

Page 94

7-a-4 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 changing the number of decimal places menu path menu → configure → component specific → measurement range ( → select component) → … selection all measurement ranges configured (at the factory) for a sample component are displayed. Proced...

Page 95: Filter Initialization

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-a-5 filter initialization menu path menu → configure → component specific → filter → select component → … range 0–60 seconds procedure parameter explanation action linear filter (caldos25, caldos27, limas11, magnos27, uras26): t90 time const...

Page 96: Auto-Range Initialization

7-a-6 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 auto-range initialization menu path menu → configure → component specific → autorange → select component → … the automatic measurement range changeover only functions properly when the measurement ranges mb1, mb2, … have been configured ...

Page 97

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-a-7 limit value monitor initialization menu path menu → configure → component specific → limit values → select limit monitor → … selection all available limit value monitors are shown. Parameter explanation action direction > = alarm on exce...

Page 98: Active Component Selection

7-a-8 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 active component selection menu path menu → configure → component-specific → active component active component the “active component” parameter appears with the caldos25 , caldos27 , magnos206 and magnos27 analyzer modules. Several sampl...

Page 99: Changing Module Name

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-a-9 changing module name menu path menu → configure → component-specific → module text module name the module name is shown in the display next to the module type. Here you can enter a name relating to the measuring point, for example. Monol...

Page 101: Section B

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-b-1 section b function blocks the function block concept what are function blocks? Function blocks are small units of the processing software with a specific function. Information is taken in at the inputs, processed in specific ways and the...

Page 102: Standard Configuration

7-b-2 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 standard configuration standard configuration various applications are factory-configured. These standard configurations are based on • standard input/output pin configuration • the available sample components some factory-configured app...

Page 103

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-b-3 the “function block” sub-menu menu ⏐ ⏐ __ calibrate ⏐ ⏐ __ configure ↓ ⏐ ⏐ __ component specific ⏐ ⏐ __ calibration data ⏐ ⏐ __ function blocks ↓ ⏐ ⏐ ⏐.

Page 105: Section C

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-c-1 section c system functions setting the time zone, date and time menu path menu → configure → system → date/time parameter explanation time zone the time zone can be selected either from the gmt (greenwich mean time) values or from the co...

Page 106

7-c-2 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 selecting user interface language menu path menu → configure → system → language language selection two user interface languages are factory-configured (per order) in the gas analyzer. In the menu item language the user can switch betwee...

Page 107: Changing The Password

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-c-3 changing the password menu path menu → configure → system → change password password protection see chapter 6 “gas analyzer operation” for basic information on “password protection”. User group access to password levels password every us...

Page 108: Inhibit Operation

7-c-4 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 inhibit operation menu path menu → configure → system → change password inhibit operation operation of the gas analyzer, i.E. Entering the main menu and thus switching to the menu mode, can be password protected. After inhibition the gas...

Page 109: Setting Up System Modules

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-c-5 setting up system modules menu path menu → configure → system → setup system modules figure 7-c-1 setting up system modules function if system modules are added to a gas analyzer, replaced (changed) or removed, this modification must be ...

Page 110: Setting Up System Modules,

7-c-6 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 setting up system modules, continued serial number the 14-digit serial number is found in the analyzer data sheet and on a label affixed to the module, generally on the cpu board. The serial number contains the following information (for...

Page 111: Adding A System Module

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-c-7 adding a system module • if no system module is configured or an added system module is not yet config- ured in a gas analyzer, the new softkey will appear on the screen. Press this softkey to go directly to the setup system modules menu...

Page 112: Replacing A System Module

7-c-8 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 replacing a system module removing and reinstalling an existing system module as a rule, when an existing system module is removed and reinstalled (e.G. After a repair) it does not require any setup. When the system module is reconnected...

Page 113: Removing A System Module

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-c-9 removing a system module sequence when removing system modules when removing system modules from the gas analyzer proceed according to the following sequence: 1. Remove the system module in the software (see below for instructions) 2. Di...

Page 114: Saving The Configuration

7-c-10 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 saving the configuration menu path menu → configure → system → save configuration automatic saving the database containing the configuration data and logbook recordings is auto- matically saved in two configuration files. The database i...

Page 115: Configuring Status Signals

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-c-11 configuring status signals menu path menu → configure → system → status signals function the status signal configuration is set at the factory per the customer’s order. Generally this configuration does not have to be changed in the fie...

Page 116

7-c-12 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 configuring an ethernet connection menu path menu → configure → system → network → tcp/ip network figure 7-c-2 tcp/ip configuration function both ethernet 10 / 100 / 1000base-t interfaces can be used to link the gas analyzer to an ether...

Page 117

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-c-13 configuring a modbus connection menu path menu → configure → system → network → modbus figure 7-c-3 modbus configuration function the gas analyzer can be connected to a network with modbus protocol via the rs232 or the rs485 interface. ...

Page 118: Configuring Profibus

7-c-14 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 configuring profibus menu path menu → configure → system → network → profibus figure 7-c-4 profibus configuration parameter selection profibus address 1 to 126 profibus dp connection to the rs485 interface profibus type profibus pa conn...

Page 119: Configuring Bus I/os

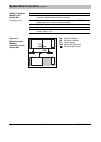

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-c-15 configuring bus i/os menu path menu → configure → system → network → bus io figure 7-c-5 bus i/o configuration number of bus i/os changing the number of bus i/os will affect the modbus address range, profibus image and ethernet linking....

Page 121: Section D

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-d-1 section d display display features the display can be configured in measurement mode the gas analyzer screen is freely configurable. A standard layout is configured on each delivered unit (see below). Display elements display elements ar...

Page 122: Display Features,

7-d-2 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 display features, continued function blocks as sources the values of all the function blocks in the system can be configured as a source for the display. The source of the display of value entries or key entries is also a function block ...

Page 123: Display Overview

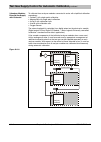

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-d-3 display overview figure 7-d-2 display overview explanations the screen overview contains the following information: page name of page on which the value is displayed pos. Position of the value on the page (see figure 7-d-1) description n...

Page 124: Page Overview

7-d-4 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 page overview figure 7-d-3 page overview explanations the page overview contains the following information: no. Page number and status (“on” or “off”) name name of the page assignment page assignment type system: pages configured by syst...

Page 125: Parameter Overview

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-d-5 parameter overview figure 7-d-4 parameter overview explanations the display parameters have the following functions: name the name of the display element is set by the system and cannot be changed. Measuring point the description entered...

Page 126: User Page Configuration

7-d-6 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 user page configuration step action 1 select the display menu item. 2 call up the page overview. 3 start configuring a new page with new. Either: enter the page name. The page overview is displayed. 4 or: go directly to the page overview...

Page 127

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-d-7 moving a display element from one page to another step action 1 select the menu item display. 2 select the display element in the display overview. 3 select the parameter page. 4 in the displayed page overview, select the target page. On...

Page 128

7-d-8 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 moving a display element within a page step action 1 select menu item display. 2 select the display element in the display overview. 3 select the parameter position. The nine possible positions are graphically represented. If the display...

Page 129

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-d-9 configuring the bar display or point display step action 1 select menu item display. 2 start configuring the new display element with new. 3 select the parameter source. The function block menu is displayed. Select the function block who...

Page 130: Value Entry

7-d-10 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 value entry figure 7-d-5 configuring the value entry description the source of the display element value entry is the function block constant that is automatically generated during configuration. The output of this function block accept...

Page 131: Configuring Value Entries

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-d-11 configuring value entries step action 1 select the menu item display. 2 start configuring the new display element with new. 3 select the parameter page. The page overview is displayed. Select the page on which the display element is to ...

Page 132: Key Entry

7-d-12 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 key entry figure 7-d-6 configuring the key entry description the source of the display element key entry is one or more constant function blocks that is automatically generated during configuration. Upon “actuation”, the output of this ...

Page 133: Configuring Key Entries

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-d-13 configuring key entries step action 1 select the menu item display. 2 start configuration of the new display element with new. 3 select the parameter page. The page overview is displayed. Select the page on which the display element is ...

Page 134

7-d-14 chapter 7: gas analyzer configuration 42/24-10 en rev. 9 example: entering and displaying the pump output configuring and using a value entry the configuration and use of a value entry will be explained using the following example of entering and displaying the pump output. Figure 7-d-7 shows...

Page 135

42/24-10 en rev. 9 chapter 7: gas analyzer configuration 7-d-15 example: entering and displaying the pump output, continued figure 7-d-8 configuring value entries figure 7-d-9 configuring bar display figure 7-d-10 linking function blocks figure 7-d-11 left: display with elements: “value entry” and “...

Page 137: Chapter 8

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-a-1 chapter 8 gas analyzer calibration section a principles calibration control calibration control depending on the gas analyzer version and equipment, there are three methods for controlling calibration: • manual calibration • automatic cali...

Page 138: Manual Calibration

8-a-2 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 manual calibration definition manual calibration means: zero and span are calibrated separately by pressing the gas analyzer display and control unit softkeys. Test gas supply the test gas supply can be started by activating a multiple pat...

Page 139: Manual Calibration,

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-a-3 manual calibration, continued waiting period following manual calibration if the output current response parameter is set to hold, current output is halted for a specific time to allow the measurement value to stabilize after manual calibr...

Page 140: Automatic Calibration

8-a-4 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 automatic calibration definition automatic calibration means: zero and span calibration run automatically after starting. Test gas supply the test gas supply can be started automatically by means of the gas module’s solenoid valves or via ...

Page 141: Automatic Calibration,

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-a-5 automatic calibration, continued blocking automatic calibration the “block automatic calibration” control signal is needed for blocking automatic calibration: level high level (12–24 v). Automatic calibration is blocked as long as the high...

Page 142

8-a-6 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 test gas supply control for automatic calibration test gas supply the test gas supply for automatic calibration can be started by means of the gas module’s integral solenoid valves or via external solenoid valves. Depending on the gas supp...

Page 143

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-a-7 test gas supply control for automatic calibration, continued 1 analyzer module, external gas supply with 1 solenoid to calibrate analyzer modules with simplified calibration procedures: • caldos27 with single-point calibration • magnos206 ...

Page 144

8-a-8 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 test gas supply control for automatic calibration, continued 3 analyzer modules, external gas supply with 1 solenoid to calibrate three analyzer modules connected in series with simplified calibration procedures: • caldos27 with single-poi...

Page 145

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-a-9 externally controlled calibration definition externally controlled calibration means: zero and span value alignment is triggered by control signals from an external control unit. Test gas supply the test gases should be started automatical...

Page 146: Calibration Methods

8-a-10 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 calibration methods calibration method an analyzer module (detector) can have one or more (gas) components with one or more measurement ranges each. To calibrate the analyzer module, establish whether the components and ranges should be c...

Page 147: Calibration Methods,

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-a-11 calibration methods, continued overview the following table summarizes the various calibration methods. Quantity calibration sc mr method to configure ... Calibrate ... Calibration affects ... 1 1 test gas / single • zero • span individua...

Page 149: Section B

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-b-1 section b calibration data the “calibration data” sub-menu menu ⏐ ⏐ __ calibrate ⏐ ⏐ __ configure ↓ ⏐ ⏐ __ component specific ⏐ ⏐ __ calibration data ↓ ⏐ ⏐ __ manual calibration ⏐ ⏐ __ test gas concentration ⏐ ⏐ __ calibration method ⏐ ⏐ _...

Page 150

8-b-2 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 calibration data for manual calibration menu path menu → configure → calibration data → manual calibration → ... Test gas concentration the zero and span test gas concentrations to be used as set points for manual calibration need to be se...

Page 151

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-b-3 calibration data for automatic calibration menu path menu → configure → calibration data → automatic calibration → ... Activation automatic calibration is only performed when activated. The “off” setting applies only to the interval-contro...

Page 152

8-b-4 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 calibration data for automatic calibration, continued pump this determines whether the pump is on or off during automatic calibration. This setting also applies to manual calibration. Purge time this determines the length of the interval d...

Page 153: Validation

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-b-5 validation validation procedure validation runs in principle just like an automatic calibration. The difference is that during validation a measurement value deviation from the set point values is not corrected automatically. Instead the p...

Page 154: Output Current Response

8-b-6 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 calibration data for externally controlled calibration menu path menu → configure → calibration data → ext. Controlled cal. → ... The menu path refers to the externally controlled calibration function block. The zero and span calibration p...

Page 155: Section C

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-c-1 section c notes for calibrating analyzer modules caldos25: notes for calibrating sample components the caldos25 analyzer module has at least one sample component with one measurement range. Associated gas influence the caldos25 analyzer mo...

Page 156

8-c-2 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 caldos27: notes for calibrating sample components the caldos27 analyzer module has at least one sample component with one measurement range and, for measurement ranges ≥ class 1, the standard gas substitute gas component. Associated gas in...

Page 157

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-c-3 caldos27: single-point calibration with standard gas single-point calibration with standard gas for measurement ranges ≥ measurement range class 1 in the caldos27 analyzer module, standard gas can be used for single-point calibration. This...

Page 158

8-c-4 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 caldos25 and caldos27: substitute gas calibration example substitute gas calibration in the caldos25 and caldos27 is described using the example of co 2 measurement in flue gas. Co 2 measurement in flue gas the composition of the various c...

Page 159

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-c-5 limas11: notes for calibrating calibration calibration can be performed in range 1 and range 2 for each sample component. It is always a common calibration and thus affects both ranges. For additional information on measurement ranges, ple...

Page 160

8-c-6 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 limas11: notes for calibrating, continued limas11 with internal cross-sensitivity correction during calibration cross-sensitivity and / or carrier gas corrections by other meas- urement components are switched off. Therefore, the following...

Page 161

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-c-7 magnos206: notes for calibrating sample components the magnos206 analyzer module has at least one sample component normally with four measurement ranges. Test gases zero calibration: oxygen-free process gas or substitute gas span calibrati...

Page 162

8-c-8 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 magnos206: single-point calibration single-point calibration the long-term sensitivity drift of the magnos206 analyzer module is less than 0.05 vol.-% o 2 per year for measurement ranges up to 25 vol.-% o 2 . Thus a regular offset correcti...

Page 163

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-c-9 magnos206: single-point calibration, continued calibration data for manual calibration calibration method common single-point calibration calibration measurement range 0-25 vol.-% o 2 test gas concentration 20.96 vol.-% o 2 calibration dat...

Page 164

8-c-10 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 magnos206: substitute gas calibration example substitute gas calibration of the magnos206 analyzer module is described using the example of purity measurement of co 2 . Purity measurement of co 2 for co 2 purity measurements, the smallest...

Page 165

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-c-11 magnos27: notes for calibrating sample components the magnos27 analyzer module has at least one sample component with one measurement range and one measurement range for flue gas measurements of the o 2 in n 2 substitute gas component. As...

Page 166

8-c-12 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 magnos27: substitute gas calibration example substitute gas calibration of the magnos27 analyzer module is described using the example of oxygen measurement in flue gas. Oxygen measurement in flue gas the sample gas composition is known i...

Page 167

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-c-13 uras26: notes for calibrating calibration calibration can be performed in range 1 and range 2 for each sample component. It is always a common calibration and thus affects both ranges. For additional information on measurement ranges, ple...

Page 168

8-c-14 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 uras26: notes for calibrating, continued uras26 with internal cross-sensitivity correction during calibration cross-sensitivity and / or carrier gas corrections by other meas- urement components are switched off. Therefore, the following ...

Page 169

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-c-15 oxygen sensor: notes for calibrating test gases the oxygen sensor zero is not calibrated since it is fundamentally stable. Ambient (non-process) air with a constant oxygen content (e.G. 20.96 vol.-%) is required for span calibration. Synt...

Page 171: Section D

42/24-10 en rev. 9 chapter 8: gas analyzer calibration 8-d-1 section d calibration analyzer module manual calibration for information on the calibration data for manual calibration, please refer to page 8-b-2. To optimize accuracy, perform a manual zero calibration prior to calibrating the span valu...

Page 172

8-d-2 chapter 8: gas analyzer calibration 42/24-10 en rev. 9 manual start of the automatic calibration for information on the calibration data for automatic calibration, please refer to pages 8-b-3 and 8-b-4. Manual start of the automatic calibration automatic calibration is started • only as zero c...

Page 173: Chapter 9

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-1 chapter 9 inspection and maintenance caution! The tasks described in this chapter require special training and under some circumstances involve working with the gas analyzer open and powered up. Therefore, they should only be performed by ...

Page 174

9-2 chapter 9: inspection and maintenance 42/24-10 en rev. 9 checking gas path seal integrity when should gas path seal integrity be checked? Gas path seal integrity should be checked periodically. It must be verified after the gas paths inside or outside the gas analyzer have been opened (e.G. Afte...

Page 175

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-3 magnos27: thermal link replacement the service handbooks describe the procedure for replacing the caldos25, caldos27, magnos206 and uras26 thermal link. When is replacement needed? The thermal link should be replaced if a thermal link fail...

Page 176: Uras26: Optical Alignment

9-4 chapter 9: inspection and maintenance 42/24-10 en rev. 9 uras26: optical alignment definition optical alignment of the uras26 analyzer module will minimize asymmetry of the radiation which falls in through the sample and reference sides of the sample cell. When should optical alignment be perfor...

Page 177: Uras26: Optical Alignment,

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-5 uras26: optical alignment, continued step action 1 turn on the zero gas supply. 2 open the 19-inch housing front plate or the wall housing cover. 3 select the optical adjustm. Menu item. 4 select the sample component to be measured in the ...

Page 178: Uras26: Phase Alignment

9-6 chapter 9: inspection and maintenance 42/24-10 en rev. 9 uras26: phase alignment definition sample / reference signal phasing is optimized in the uras26 by performing a phase alignment. When should phase alignment be performed? A phase alignment must always be performed after optical alignment w...

Page 179

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-7 limas11, uras26: measurement of calibration cells definition the measurement of a calibration cell in the limas11 and uras26 analyzer modules means: determining what calibration cell “deflection” is equivalent to the test gas calibration r...

Page 180

9-8 chapter 9: inspection and maintenance 42/24-10 en rev. 9 limas11, uras26: relinearization when should relinearization be performed? Sample component relinearization should be performed • if the linearity deviation exceeds the permissible 1% of span • if the start of a suppressed measurement rang...

Page 181

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-9 limas11: thermal link replacement when should a thermal link be replaced? A defective thermal link will usually be indicated by an insufficient sample cell temperature ( t-re.K) or lamp temperature (t-re.L) error message (see “status messa...

Page 182

9-10 chapter 9: inspection and maintenance 42/24-10 en rev. 9 limas11: aluminum sample cell cleaning when should the sample cell be cleaned? Sample cell contamination can result in unstable measurement values due to low lamp intensity (see “limas11 problems”, page 10-20). Status messages when beam i...

Page 183

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-11 limas11: aluminum sample cell cleaning, continued step action sample cell installation: 10 place the sample cell in its housing. The index pin should be on the side of the sample cell that is toward the beam splitter. Turn the sample cell...

Page 184

9-12 chapter 9: inspection and maintenance 42/24-10 en rev. 9 limas11: quartz sample cell cleaning when should the sample cell be cleaned? Sample cell contamination can result in unstable measurement values due to low lamp intensity (see “limas 11 problems”, page 10-20). Status messages when beam in...

Page 185

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-13 limas11: quartz sample cell cleaning, continued step action sample cell cleaning: wash the sample cell with a warm detergent / water mixture. Acids, alkalis or solvents can be used as cleansers in case of severe contamination. 7 be sure t...

Page 186

9-14 chapter 9: inspection and maintenance 42/24-10 en rev. 9 limas11: quartz sample cell cleaning, continued step action restarting the analyzer module: 19 close the system housing. Light penetration during operation leads to erroneous measure- ment values and measurement range overflows (“intensit...

Page 187

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-15 limas11: safety cell cleaning description of the safety cell the safety cell comprises three components: • sample cell of stainless steel 1.4571, • beam guide tube 1 of brass (on the side pointing to the beam splitter), • beam guide tube ...

Page 188

9-16 chapter 9: inspection and maintenance 42/24-10 en rev. 9 limas11: safety cell cleaning, continued when should the sample cell be cleaned? Sample cell contamination can result in unstable measurement values due to low lamp intensity (see “limas 11 problems”, page 10-20). Status messages when bea...

Page 189

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-17 limas11: safety cell cleaning, continued caution! It is imperative that the following procedure is carried out step by step and with the greatest of care. Otherwise there is a danger that the safety cell is no longer absolutely tight afte...

Page 190

9-18 chapter 9: inspection and maintenance 42/24-10 en rev. 9 limas11: safety cell cleaning, continued step action sample cell removal: 7 undo the 2 couplings 1 of the purge gas lines on the rear of the analyzer module and pull the purge gas hoses into the interior of the device. Remove the purge ga...

Page 191

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-19 limas11: safety cell cleaning, continued step action cleaning the sample cell and sample gas tubing: 16 clean the sample cell with a warm detergent/water mixture. If necessary, use a circular brush with plastic bristles. Clean the sample ...

Page 192

9-20 chapter 9: inspection and maintenance 42/24-10 en rev. 9 limas11: safety cell cleaning, continued step action 24 hold the sample cell with 2 open-end wrenches (clamp 1 open-end wrench in the vise, in order to fix the sample cell in position) and screw in the beam guide tubes 10 and 11 as far as...

Page 193

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-21 limas11 uv: lamp (edl) replacement when should the lamp be replaced? Over a period of 2-3 years the plasma-discharge fill gas will dissipate, causing a loss of lamp intensity. The lamp must be replaced when its intensity reaches a value a...

Page 194

9-22 chapter 9: inspection and maintenance 42/24-10 en rev. 9 limas11 uv: lamp (edl) replacement, continued step action restart the analyzer module: close the system housing. 15 light penetration during operation leads to erroneous measure- ment values and measurement range overflows (“intensity” st...

Page 195

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-23 limas11: amplification optimization definition the amplification optimization procedure automatically seeks and identifies the optimum measurement range for the sample and reference receiver analog/digital converter. When should amplifica...

Page 196

9-24 chapter 9: inspection and maintenance 42/24-10 en rev. 9 limas11: amplification optimization, continued menu path menu → maintenance/test → analyzer spec. Adjustm. → amplification optimization step action 1 turn on the zero gas supply. If a solenoid valve is used to switch to zero gas, the supp...

Page 197

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-25 gas module: disposable filter replacement when should the disposable filter be replaced? The gas module disposable filter should be changed if it is stained by contami- nants. We recommend changing the disposable filter (catalog number 23...

Page 198

9-26 chapter 9: inspection and maintenance 42/24-10 en rev. 9 pump activation, pump output adjustment pump activation the pump installed in the internal gas module and external pumps connected to appropriately configured digital outputs can be activated and deactivated manually, for instance in emer...

Page 199

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-27 changing analog output current range method the current range of the individual analog outputs can be modified by initializing the applicable analog output function blocks.Technical bulletin “ao2000 func- tion blocks – descriptions and co...

Page 200: Air Pressure Correction

9-28 chapter 9: inspection and maintenance 42/24-10 en rev. 9 air pressure correction air pressure effect a specific amount of change in air pressure will result in a specific change in a measurement value, depending on the measurement principle employed by the analyzer module. Measures to minimize ...

Page 201

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-29 air pressure value correction an incorrect air pressure value will produce erroneous measurement values. When should the air pressure value be set? The air pressure value must be checked and readjusted as required in the following cases: ...

Page 202: Calibration Reset

9-30 chapter 9: inspection and maintenance 42/24-10 en rev. 9 calibration reset what does the calibration reset do? A calibration reset returns the analyzer module’s calibration to basic calibration values. Additionally, the offset drift and amplification drift are electronically returned to basic c...

Page 203: Basic Calibration

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-31 basic calibration what does the basic calibration do? A basic calibration of an analyzer module places the module’s calibration status back in an initial state. The offset drift and amplification drift are set to zero. The drift history i...

Page 204: Cross-Sensitivity Alignment

9-32 chapter 9: inspection and maintenance 42/24-10 en rev. 9 cross-sensitivity alignment electronic cross- sensitivity correction ao2000 offers the ability to electronically correct cross sensitivity, in contrast to using purely physical methods (for example, for infrared absorption, optical filter...

Page 205: Carrier Gas Alignment

42/24-10 en rev. 9 chapter 9: inspection and maintenance 9-33 carrier gas alignment electronic carrier gas correction in principle, the electronic carrier gas correction operates in the same manner as the cross sensitivity correction (see “cross sensitivity alignment” section, page 9-32). Carrier ga...

Page 207: Chapter 10

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-1 chapter 10 status messages, troubleshooting caution! The tasks described in this chapter require special training and under some circumstances involve working with the gas analyzer open and powered up. Therefore, they should only b...

Page 208

10-2 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 system status: status messages where are status messages generated? Status messages are generated • by the gas analyzer, i.E. • the system controller (signal processing, calibration, system bus) • the analyzer modules • the gas mod...

Page 209

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-3 system status: status messages, continued status message display the status message softkey appears as soon as a status message is gener- ated. By pressing the softkey the user can recall the status message summary and view status ...

Page 210

10-4 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 system status: status signals overall status or individual status the status signal is factory-configured to output as an overall or individual status indicator (refer to “configuring status signals” section, page 7-c-9). Overall s...

Page 211: Status Message Categories

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-5 status message categories status message categories in terms of operator reaction, there are three categories of status messages (see the summary on the following page): • status messages not requiring acknowledgment • status messa...

Page 212: Status Message Categories,

10-6 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 status message categories, continued summary the following table shows • the time sequence of the three status message categories (phases 1-3) • the identifier used to identify the status messages in the summary (a, a and i). Phase...

Page 213: Status Messages

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-7 status messages list layout the status message list contains the following information: no. Number of the status message as shown in the detailed display text full text of the status message as shown in the detailed display o x = s...

Page 214: Status Messages,

10-8 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 status messages, continued no. Text o e m f reaction / remark runtime error 1–21 runtime error 1 to 21 notify service if these status messages occur repeatedly. System controller 101 system controller shut down at for information; ...

Page 215: Status Messages,

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-9 status messages, continued no. Text o e m f reaction / remark system bus 201 the selected system bus module could not be found. X x check plug connections and terminating resistors on the system bus. Make sure the system bus module...

Page 216: Status Messages,

10-10 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 status messages, continued no. Text o e m f reaction / remark 308 a computer error occurred during calculation of the measurement value. X x notify service. 309 the temperature regulator is defective. X see the status message from...

Page 217: Status Messages,

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-11 status messages, continued no. Text o e m f reaction / remark multifid 321 the detector temperature is below the lowest permissible temperature. X x status message during the warm-up phase. If the status message appears after warm...

Page 218: Status Messages,

10-12 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 status messages, continued no. Text o e m f reaction / remark 336 a computer error occurred during calculation of the measurement value. X x check the configuration and calibration of the analog inputs and outputs. 337 broken anal...

Page 219: Status Messages,

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-13 status messages, continued no. Text o e m f reaction / remark 360 filter wheel 1 cannot be initialized. X x notify service. 361 filter wheel 2 cannot be initialized. X x notify service. 362 the calibration filter wheel cannot be i...

Page 220: Status Messages,

10-14 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 status messages, continued no. Text o e m f reaction / remark 382 meas. Value is influenced by shock. X x flow controller 398 no new measuring values from analog/digital converter. X x notify service. 399 the measuring value excee...

Page 221: Status Messages,

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-15 status messages, continued no. Text o e m f reaction / remark 509 automatic calibration started. For information 510 automatic calibration ended. For information 511 automatic calibration externally interrupted. For information 51...

Page 222: Status Messages,

10-16 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 status messages, continued no. Text o e m f reaction / remark 529 calibration stopped because no raw measurement values were found. X x 530 calibration stopped because the pressure switch did not detect any calibration gas. X x 53...

Page 223: Status Messages,

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-17 status messages, continued no. Text o e m f reaction / remark system cooler 1100 cooler temperature too high. X x 1101 cooler temperature too low. X x 1102 condensate penetration in cooler. X x sample gas feed module pump is autom...

Page 224: Gas Analyzer Problems

10-18 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 gas analyzer problems blinking measurement value readout measured signal violates measurement range limits note: measurement value > +130 % mrs or measurement value additionally, status messages 344 or 345 are generated. Blinking ...

Page 225: Gas Analyzer Problems,

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-19 gas analyzer problems, continued temperature problem gas analyzer still in warm-up phase • the duration of the warm-up phase depends on which analyzer module is installed in the system. Analyzer module warm-up phase duration caldo...

Page 226: Temperature Problem

10-20 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 caldos25, caldos27, magnos206, magnos27 problems temperature problem faulty temperature sensor or heater connections • check the connecting lines and plugs. • check the line seating in the insulated jackets. Defective thermal link...

Page 227: Limas11 Problems

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-21 limas11 problems temperature problem faulty temperature sensor or heater connections • check the connecting lines and plugs. • check the line seating in the insulated jackets. Defective thermal link • check thermal link continuity...

Page 228: Uras26 Problems

10-22 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 uras26 problems temperature problem faulty temperature sensor or heater connections • check the connecting lines and plugs. • check the line seating in the insulated jackets. Defective thermal link • check thermal link continuity ...

Page 229: Gas Module Problems

42/24-10 en rev. 9 chapter 10: status messages, troubleshooting 10-23 gas module problems flow problem condensation in the flow meter • disconnect the gas analyzer from the gas preparation system. • dry the flow meter by heating it and blowing it with compressed air. • check the operation of the ups...

Page 230: Notify Service

10-24 chapter 10: status messages, troubleshooting 42/24-10 en rev. 9 notify service who to contact for further help? Contact your local abb service representative. For emergencies, please contact: abb service, telephone: +49-(0)180-5-222580, telefax: +49-(0)621-38193129031, e-mail: automation.Servi...

Page 231: Chapter 11

42/24-10 en rev. 9 chapter 11: gas analyzer shutdown and packing 11-1 chapter 11 gas analyzer shutdown and packing gas analyzer shutdown step action gas analyzer shutdown temporary shutdown: 1 turn off the sample gas and, if applicable, reference gas supplies. 2 purge the gas lines and analyzer modu...

Page 232

11-2 chapter 11: gas analyzer shutdown and packing 42/24-10 en rev. 9 preparing the gas analyzer for shipping and packing caution! A system housing with an electronics module and an analyzer module weighs from 18 to 23 kg. Two persons are needed for removal. Step action 1 remove the system bus termi...

Page 233: Appendix 1

42/24-10 en rev. 9 appendix 1: gas analyzer overview a-1-1 appendix 1 gas analyzer overview gas analyzer components the ao2000 series continuous gas analyzers consist of: • analyzer modules and • a central unit. The central unit consists of: • the electronics module, consisting of the system control...

Page 234: Analyzer Modules

A-1-2 appendix 1: gas analyzer overview 42/24-10 en rev. 9 analyzer modules analyzer modules • caldos25 thermal conductivity analyzer module • caldos27 thermal conductivity analyzer module • limas11 process photometer analyzer module • ls25 laser analyzer module • magnos206 oxygen analyzer module • ...

Page 235: Electronics Module

42/24-10 en rev. 9 appendix 1: gas analyzer overview a-1-3 electronics module system controller the system controller carries out the following functions: • processing and communicating the measurement values supplied by the analyzer module sensor electronics • compensating the measurement values, e...

Page 236: System Housing

A-1-4 appendix 1: gas analyzer overview 42/24-10 en rev. 9 system housing versions the system housing is available as a 19-inch housing or a wall-mount housing with ip 20 or ip 54 housing protection. Ip 65 protection is in effect if no power supply and no display and control unit is installed in the...

Page 237: Appendix 2

42/24-10 en rev. 9 appendix 2: analyzer module operating specifications a-2-1 appendix 2 analyzer module operating specifications the analyzer module characteristics indicated apply only when operated in conjunction with the central unit. The performance characteristics have been determined accordin...

Page 238

A-2-2 appendix 2: analyzer module operating specifications 42/24-10 en rev. 9 caldos27 operating specifications linearity deviation ≤ 2 % of span repeatability ≤ 1 % of span zero drift ≤ 2 % of the smallest possible measurement range per week sensitivity drift ≤ 0.5 % of the smallest possible measur...

Page 239

42/24-10 en rev. 9 appendix 2: analyzer module operating specifications a-2-3 limas11 operating specifications linearity deviation ≤ 1 % of span repeatability ≤ 0.5 % of span zero drift ≤ 2 % of span per week; for ranges smaller than class 1 to class 2: ≤ 1.5 % of span per day (recommendation: daily...

Page 240

A-2-4 appendix 2: analyzer module operating specifications 42/24-10 en rev. 9 magnos206 operating specifications linearity deviation ≤ 0.5 % of span repeatability ≤ 50 ppm o 2 (time base for gas exchange ≥ 5 minutes) zero drift ≤ 3 % of span of the smallest measurement range (per order) per week, mi...

Page 241

42/24-10 en rev. 9 appendix 2: analyzer module operating specifications a-2-5 magnos27 operating specifications linearity deviation ≤ 2 % of span repeatability ≤ 1 % of span zero drift ≤ 1 % of span per week sensitivity drift ≤ 2 % of measured value per week output fluctuation (2 σ) ≤ 0.5 % of small...

Page 242

A-2-6 appendix 2: analyzer module operating specifications 42/24-10 en rev. 9 uras26 operating specifications linearity deviation ≤ 1 % of span repeatability ≤ 0.5 % of span zero drift ≤ 1 % of span per week; for ranges smaller than class 1 to class 2: ≤ 3 % of span per week sensitivity drift ≤ 1 % ...

Page 243

42/24-10 en rev. 9 appendix 2: analyzer module operating specifications a-2-7 oxygen sensor operating specifications linearity deviation linear in the range > 1 vol.-% o 2 repeatability ≤ 0.5 % of span zero drift stable over long-term due to absolute zero point sensitivity drift ≤ 1 % of measurement...

Page 244: Electrical Safety

A-2-8 appendix 2: analyzer module operating specifications 42/24-10 en rev. 9 electrical safety test per en 61010-1: 2001 protection class central unit with electronics module (power supply): i analyzer module without electronics module (power supply): iii overload category / pollution level electro...

Page 245: Appendix 3

42/24-10 en rev. 9 appendix 3: zo23 trace oxygen analyzer module a-3-1 appendix 3 zo23 trace oxygen analyzer module safety information warning! The analyzer module must not be used for measurement of ignitable gas/air or gas/oxygen mixtures. The concentration of flammable gases in the sample gas mus...

Page 246: Sample Gas Inlet Conditions

A-3-2 appendix 3: zo23 trace oxygen analyzer module 42/24-10 en rev. 9 requirements at the installation site ambient temperature +5 to +45 °cwith installation in a system housing with an electronics module heat sources and magnetic fields no heat sources or instruments which generate strong magnetic...

Page 247: Test Gases