- DL manuals

- ABB

- Measuring Instruments

- AnalyzeIT AX460

- User Manual

ABB AnalyzeIT AX460 User Manual

Summary of AnalyzeIT AX460

Page 1

Analyze it single and dual input analyzers for ph/redox (orp) ax416, ax436, ax460, ax466 & ax468 user guide im/ax4ph_5.

Page 2

Abb electrical safety this instrument complies with the requirements of cei/iec 61010-1:2001-2 'safety requirements for electrical equipment for measurement, control and laboratory use'. If the instrument is used in a manner not specified by the company, the protection provided by the instrument may...

Page 3

1 contents section page 1 introduction .............................................................. 2 1.1 system description ................................................. 2 1.2 pid control ............................................................. 2 1.3 ax400 series analyzer options ..........

Page 4

2 all models incorporate a wash facility for system cleaning; the alarm 3 relay can be configured to control the wash system either automatically or manually. The relay can be programmed to deliver either a continuous or pulsed signal to control an external power supply to a solenoid or pump and the...

Page 5

3 fig. 2.1 location of controls and displays fig. 2.2 membrane key functions 2.1 powering up the analyzer warning. Ensure all connections are made correctly, especially to the earth stud – see section 6.3. 1) ensure the input sensor(s) is/are connected correctly. 2) switch on the power supply to the...

Page 6

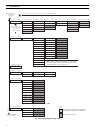

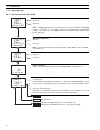

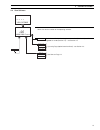

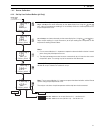

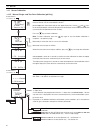

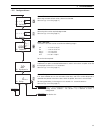

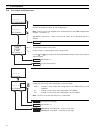

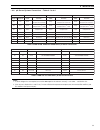

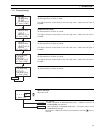

4 …2 operation fig. 2.3a overall programming chart key view setpoints view outputs view hardware view software a1: setpoint analog output 1 sensor a module ax400/2000 issue a2: setpoint analog output 2 sensor b module a3: setpoint analog output 3 option board a4: setpoint analog output 4 a5: setpoin...

Page 7

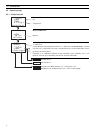

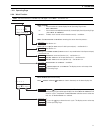

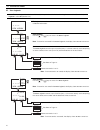

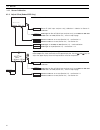

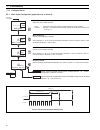

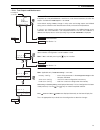

5 2 operation… fig. 2.3b overall programming chart config.Alarms config. Alarm 1 a1: type a1: assign a1: failsafe a1: action a1: setpoint a1: hysteresis a1: delay config. Alarm 2 a2: type a2: assign a2: failsafe a2: action a2: setpoint a2: hysteresis a2: delay a3: assign a3: failsafe a3: action a3: ...

Page 8

6 measured values ph. Temperature. Measured millivolts millivolts. % slope and ph check value % slope value. A value between the programmed minimum % slope value (see set min slope – section 5.3) and 105% is displayed. If the value is outside these limits, check the electrode system. Ph check value ...

Page 9

7 measured ph sensor a. Sensor b. Measured temperature sensor a. Sensor b. Measured millivolts sensor a. Sensor b. % slope and ph check value – sensor a % slope value. A value between the programmed minimum % slope value (see set min slope – section 5.3) and 105% is displayed. If the value is outsid...

Page 10

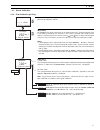

8 measured values millivolts. Temperature. Offset – sensor a displays the offset value for the sensor set in a: adjust offset – see section 4.1.3. See section 3.1. See section 4.1. A3: type set to wash (section 5.5) – see section 2.3.6. A3: type not set to wash (section 5.5) – return to top of page....

Page 11

9 2 operation… measured millivolts sensor a. Sensor b. Note. If probe type for both sensor a and sensor b is set to orp (section 5.3), the lower display line shows dual orp . Sample temperature sensor a. Sensor b. Note. The measured temperature is displayed only if temp. Sensor is not set to none – ...

Page 12

10 …2.3 operating page 2.3.5 dual input ph and redox (orp) measured ph and millivolts sensor a. Sensor b. Note. The probe type for sensors a and b can be set to any combination of ph , redox or orp – see section 5.3. The display indications change depending on probe type settings, e.G. If sensor a i...

Page 13

11 2 operation …2.3 operating page 2.3.6 wash function note. The wash function is available only if a3: type is set to wash – see section 5.5. Wash function off – wash function off. Lower display line of operating page shows wash inhibited . On – wash function controlled automatically. Lower display...

Page 14

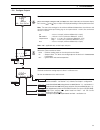

12 8.30 ph a1: setpoint sen.A temp.A view setpoints ----- 35.0 deg.C a2: setpoint sen.B 6.80 a3: setpoint temp.B 55.0 deg.C a4: setpoint ----- off a5: setpoint view outputs sensor cal. Security code config. Display view setpoints ph view set points this page shows alarm set points. The value of each...

Page 15

13 …3.1 view set points note. The menu displayed when pressing the key from the operator view pages depends on analyzer configuration, i.E.: single input analyzers sensor cal. Probe type set to ph probe type set to redox or orp enable cals set to yes (section 5.3) – see section 4.1. Security code pr...

Page 16

14 …3 operator view 3.2 view outputs theoretical analog output there are up to four analog outputs, each showing information for one sensor. Note. Analog outputs 3 and 4 available only if option board fitted and analog features enabled – see section 7.3. Live current output value being retransmitted...

Page 17

15 3 operator views… 3.4 view software 1.00 ax400/2000 issue view software ----- view logbook sensor cal. Security code config. Display view software monitoring ph redox (orp) dual redox ph/redox (orp) issue shows the version number of the operating software. Option board fitted and analog features ...

Page 18

16 …3 operator views the logbook stores data entries for alarm events, sensor errors, power failures and ph calibration information. View logbook use the and keys to access the alarms logbook. Note. If no entries are stored in the alarms logbook, the display shows no more entries . Alarms the alarms...

Page 19

17 …3.5 view logbook view logbook use the and keys to access the power logbook. Note. If no entries are stored in the power logbook, the display shows no more entries . Power the power logbook contains up to 2 entries (entry 1 is the most recent), each comprising the power state (on or off) and the ...

Page 20

18 date shows the current date. Time shows the current time. Operating page – see section 2.3. See note on page 13. …3 operator views ----- date 01:02:04 view clock ----- ----- time 12:00 monitoring ph sensor cal. Security code config. Display view clock redox (orp) dual redox ph/redox (orp) 3.6 vie...

Page 21

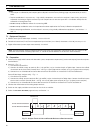

19 4 setup 4.1.1 set buffer type (ph only) sensor calibration sensor calibration security code note. This frame is displayed only if alter cal. Code is not set to zero – see section 5.8. Enter the required code number (between 0000 and 19999) to access the sensor calibration pages. If an incorrect v...

Page 22

20 set buffer 1 set the ph value of the buffer 1 solution – see appendix a for ph tables. Set buffer 2 set the ph value of the buffer 2 solution. Note. The solution selected for buffer 2 must be at least 2ph greater than that selected for buffer 1, e.G. If buffer 1 is set to 7ph, buffer 2 must be se...

Page 23

21 solution a: enter point 1 (to 5) deg.C and adjust are shown alternately on the upper display line. Using the and keys, adjust the temperature reading (in 5 increments) to the first of the temperatures on the ph/temperature curve. Ph and adjust are shown alternately on the center display line. U...

Page 24

22 calibrate sensor a sensor b (dual input analyzers only) calibration is identical to sensor a calibration. Probe type for sensor b (dual input analyzers only) set to redox or orp and enable cals. Set to no (section 5.3) – return to top of page. Alter sec. Code not set to zero (section 5.8) – see s...

Page 25

23 table 4.1 calibration messages 4 setup… …4.1 sensor calibration 4.1.4 automatic, single- and two-point calibration (ph only) sensor a: buffer method (ph probes only) select the type of automatic calibration required: auto 1-pt – automatic, single-point calibration auto 2-pt – automatic, two-point...

Page 26

24 …4.1 sensor calibration …4.1.4 automatic, single- and two-point calibration (ph only) …4 setup calibrate buffer 2 (two-point calibration only) immerse sensor a in the second buffer solution. Press the key to initiate calibration. Note. To abort calibration, press the key again at any time before ...

Page 27

25 4 setup… sensor a: buffer method (ph probes only) select the type of manual calibration required: man 1-pt – manual, single-point calibration man 2-pt – manual, two-point calibration set buffer temperature deg.C (or deg.F ) and adjust are shown alternately on the center display line. Use the and ...

Page 28

26 …4.1 sensor calibration …4.1.5 manual, single- and two-point calibration (ph only) …4 setup calibrate buffer 2 (two-point calibration only) immerse sensor a in the second buffer solution. Ph and adjust are shown alternately on the upper display line. Use the and keys to set the displayed ph value...

Page 29

27 4 setup sensor a: buffer method (ph probes only) select grab calibration method. Adjust value ph and adjust are shown alternately on the upper display line. The displayed ph value is the reading sampled by the analyzer as this frame is selected and is held until the display is advanced to the nex...

Page 30

28 5 programming note. This frame is displayed only if alter sec. Code is not set to zero – see section 5.8. Enter the required code number (between 0000 and 19999), to gain access to the configuration pages. If an incorrect value is entered, access to the configuration pages is prevented and the di...

Page 31

29 5 programming… 5.2 configure display set language sets the language to be used on all displays. Language page use the and keys to select the required language. Set temperature units temperature units use the and keys to select the sample temperature display units. Set up display backlight backlig...

Page 32

30 …5 programming 5.3 configure sensors configure sensor a sensor b configuration (dual input analyzers only) is identical to sensor a configuration. Probe type select the required probe type. Orp – millivolt display redox – millivolt display ph – ph display differential input yes – select if electr...

Page 33

31 …5.3 configure sensors ph electrode type select the type of ph electrode used, glass or antimony. Temperature compensation select auto to enable the analyzer to compensate automatically for fluctuations in sample temperature. Temperature sensor (automatic temperature compensation only) select the...

Page 34

32 …5.3 configure sensors sample compensation select yes to enable boiling water compensation. Sample coefficient if sample comp. Is set to yes , enter the temperature coefficient of the sample, in ph/ c, within the range 0.020 to –0.050 (in –0.001 increments). For boiling water applications, enter...

Page 35

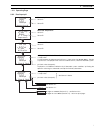

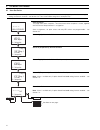

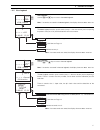

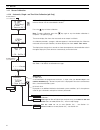

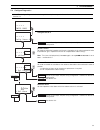

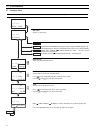

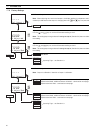

33 5 programming… config. Sensor a ----- a: ph glass ----- a: ref. Checking ----- config. Diags ----- off on off on a: ref. Alarm 50 kohm config. Alarms config. Sensor a config. Alarms config. Sensor b config. Sensor b config. Sensor b config. Sensor a on off 5.4 configure diagnostics note. The conf...

Page 36

34 …5 programming 5.5 configure alarms configure alarm 1 alarms 2 and 3 configuration (and alarms 4 and 5 if option board fitted and analog features enabled – see section 7.3) is identical to alarm 1 configuration. Alarm 3 can also be configured as a wash alarm if a3: type is set to wash – see follo...

Page 37

35 5 programming… …5.5 configure alarms alarm 1 failsafe select yes to enable failsafe action, otherwise select no . See also figs. 5.2 to 5.6 (page 37). Alarm 1 action select the alarm action required, high or low . See also figs. 5.2 to 5.6 (page 37). Alarm 1 set point the alarm 1 set point can be...

Page 38

36 …5 programming wash mode select the wash mode required. Cont. – (continuous) the relay remains energized for the wash duration pulsed – the relay is switched on and off every second for the duration of the wash, – see fig. 5.1 wash frequency set the wash frequency required. Wash frequency is set ...

Page 39

37 5 programming… fig. 5.2 high failsafe alarm without hysteresis and delay fig. 5.3 high failsafe alarm with hysteresis but no delay fig. 5.4 high failsafe alarm with hysteresis and delay fig. 5.5 high non–failsafe alarm without delay and hysteresis fig. 5.6 high failsafe alarm with delay but no hy...

Page 40

38 …5 programming 5.6 configure outputs configure output 1 output 2 configuration (and outputs 3 and 4 if option board fitted and analog features enabled – see section 7.3) is identical to output 1 configuration. Assign select the sensor and analog output required: sen.A – ph/redox (orp)/mv for the ...

Page 41

39 5 programming… …5.6 configure outputs zero value ph (or mv or deg.C or deg.F or a-b ) and adjust are shown alternately on the center display line. Use the and keys to adjust the displayed reading to the required zero value: note. The zero value setting plus the minimum differential determines the...

Page 42

40 …5 programming 5.7 configure clock note. The configure clock function is available only if the option board is fitted and analog features enabled – see section 7.3. Set clock set the system clock. Return to main menu. Option board fitted and serial communications feature enabled (section 7.3) – s...

Page 43

41 5 programming… 5.8 configure security configure logbook use the and keys to to set the logbook on or off . If off is selected, all data entries in the logbook are cleared. Return to main menu. See section 5.10. Alter sec. Code 0000 alter cal. Code 0000 config. Security ----- config. Logbook confi...

Page 44

42 5.10 test outputs and maintenance test outputs displays the output test details for the analog outputs. Note. Outputs 3 and 4 are available only if the option board is fitted and analog features enabled – see section 7.3. Test output 1 frame only is shown; the format of frames for the remaining o...

Page 45

43 load/save config ----- ----- yes no load save user config. Factory config. ----- press to set. Press to abort test/maintenance yes factory settings test/maintenance automatic time hrs 30 mins factory settings load/save config maintenance 1 hold outputs set to auto. Automatic time if required, set...

Page 46: Ip66

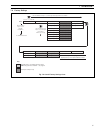

44 6.1 siting requirements notes. • mount in a location free from excessive vibration. • mount away from harmful vapours and/or dripping fluids. • where possible, mount the analyzer at eye level to allow an unrestricted view of the front panel displays and controls. Fig. 6.1 siting requirements 6 in...

Page 47

45 6 installation… fig. 6.2 overall dimensions fig. 6.3 wall-/pipe-mounting 6.2 mounting 6.2.1 wall-/pipe-mount analyzers – figs. 6.2 and 6.3 175 (6.9) 150 (5.9) 25 210 (8.23) 192 (7.56) 96 (3.76) r10 (0 .4) 192 (7.56) Ø 6.50 (0.26) dimensions in mm (in.) fixing centers fixing centers 94 (3.7) b – p...

Page 48

46 …6 installation fig. 6.4 overall dimensions fig. 6.5 panel-mounting …6.2 mounting 6.2.2 panel-mount analyzers – figs. 6.4 and 6.5 note. The clamp must fit flat on the analyzer casing. If the clamp is bowed, the securing screw is overtight and sealing problems may occur. Dimensions in mm (in.) 96 ...

Page 49

47 6.3 connections, general warnings. • the instrument is not fitted with a switch therefore a disconnecting device such as a switch or circuit breaker conforming to local safety standards must be fitted to the final installation. It must be fitted in close proximity to the instrument within easy re...

Page 50

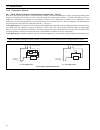

48 fig. 6.6 relay contact protection nc c no external dc supply + – relay contacts load diode nc c no external ac supply l n relay contacts c r load a – ac applications b – dc applications …6 installation …6.3 connections, general 6.3.1 relay contact protection and interference suppression – fig. 6....

Page 51

49 6 installation… 5 place the blade of a small, flat bladed screwdriver into the knockout groove and tap the screwdriver smartly to remove the knockout (see note below) smooth the edges of the hole with a small round or half-round file fit an 'o' ring seal to the the cable gland insert the cable gl...

Page 52

50 …6 installation terminal block a terminal block b terminal block c (option board) case earth (ground) stud release the four captive screws and remove the terminal cover plate fig. 6.8 access to terminals, wall-/pipe-mount analyzer 6.4 wall-/pipe-mount analyzer connections 6.4.1 access to terminal...

Page 53

51 6 installation… temperature compensator connections b16 b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 tc thir d lead common tc thir d lead common temperature compensator connections used for optional rs485 connections – refer to im/probus before making any electrical connections, see warning...

Page 54

52 terminal block c (option board) terminal block b terminal block a case earth (ground) stud fig. 6.10 access to terminals, panel-mount analyzers …6 installation 6.5 panel-mount analyzer connections 6.5.1 access to terminals – fig. 6.10

Page 55

53 note. Relay 3 can be configured to control the wash facility – see section 5.4. Fig. 6.11 connections, panel-mount analyzers l line n neutral e connect supply earth (ground) to stud on case a4 c a5 nc relay 1 a6 no a7 c a8 nc relay 2 a9 no a10 c a11 nc relay 3 (see note below) a12 no a13 + analog...

Page 56

54 …6 installation b k c o l b l a n i m r e t ) d o r d n u o r g ( h t r a e n o i t u l o s t u o h t i w 0 6 6 7 d n a 0 5 6 7 w o l e b 1 e t o n e e s – ) d o r d n u o r g ( h t r a e n o i t u l o s h t i w 0 6 6 7 b r o s n e s a r o s n e s r o l o c n o i t c n u f r o l o c n o i t c n u...

Page 57

55 6 installation b k c o l b l a n i m r e t s r o s n e s s e i r e s 0 0 1 p a ) w o l e b e t o n e e s ( s r o s n e s s e i r e s 0 0 2 p a s r o s n e s s e i r e s 0 0 3 p a b r o s n e s a r o s n e s r o l o c n o i t c n u f r o l o c n o i t c n u f r o l o c n o i t c n u f 1 b 9 b d e ...

Page 58

56 7 calibration terminal link ph/redox input simulator temperature simulator b10 b11 b12 b13 b14 b9 sensor a terminal numbers sensor b terminal numbers b2 b3 b4 b5 b6 b1 b15 b16 b7 b8 –ve +ve fig. 7.1 analyzer terminal links and decade resistance box connections notes. • the analyzer is calibrated ...

Page 59

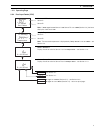

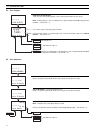

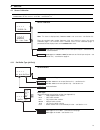

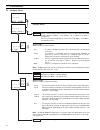

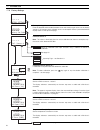

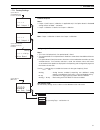

57 7 calibration… 7.3 factory settings fig. 7.2 overall factory settings chart factory settings factory set code cal. Sensor a a:mv zero (-1v) a:mv span (+1v) a:t.Zero (100r) a:t.Span (150r) cal. Sensor b b:t.Zero (100r) b:t.Span (150r) cal. Output 1 o1: adjust 4ma o1: adjust 20ma to operating page ...

Page 60

58 …7 calibration …7.3 factory settings factory settings access code enter the required code number (between 0000 and 19999) to gain access to the factory settings. If an incorrect value is entered, access to subsequent frames is prevented and the display reverts to the top of the page. Calibrate se...

Page 61

59 7 calibration… temperature span (150r) set the temperature simulator to 150 the display advances automatically to the next step once a stable and valid value is recorded. Temperature zero (1k0) set the temperature simulator to 1000 the display advances automatically to the next step once a stable...

Page 62

60 calibrate output 1 note. When adjusting the 4 and 20ma outputs, the display reading is unimportant and is used only to indicate that the output is changing when the and keys are pressed. See below. Adjust 4ma use the and keys to set the milliammeter reading to 4ma. Note. The analog output range s...

Page 63

61 7 calibration calibrate output 3 notes. • output 3 (and output 4) calibration is applicable only if the option board is fitted and analog features enabled – see below. • output 3 calibration is identical to output 2 calibration. Calibrate output 4 note. Output 4 calibration is identical to output...

Page 64

62 8 simple fault finding 8.1 error messages if erroneous or unexpected results are obtained, the fault may be indicated in the operating page by an error message – see table 8.1. However, some faults may cause problems with analyzer calibration or give discrepancies when compared with independent l...

Page 65

63 specification ph/redox (orp) – ax460 and ax466 inputs one or two* ph or mv inputs and solution earth one or two* temperature sensors enables connection to glass or enamel ph and reference sensors and redox (orp) sensors *ax466 only input resistance glass >1 x 10 13 reference 1 x 10 13 range –2 to...

Page 66

64 …specification relay outputs – on/off number of relays three supplied as standard or five with option board fitted number of set points three supplied as standard or five with option board fitted set point adjustment configurable as normal or failsafe high/low or diagnostic alert hysteresis of re...

Page 67

65 environmental data operating temperature limits –20 to 65 c (–4 to 149f) storage temperature limits –25 to 75 c (–13 to 167f) operating humidity limits up to 95%rh non condensing emc emissions and immunity meets requirements of: en61326 (for an industrial environment) en50081-2 en50082-2 haza...

Page 68

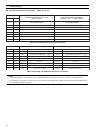

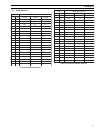

66 table a3 merck buffer solutions p m e t s r e f f u b k c r e m c f h p 4 h p 7 h p 9 h p 0 1 0 2 3 5 0 . 4 3 1 . 7 4 2 . 9 6 2 . 0 1 5 1 4 4 0 . 4 7 0 . 7 6 1 . 9 7 1 . 0 1 0 1 0 5 2 0 . 4 5 0 . 7 1 1 . 9 1 1 . 0 1 5 1 9 5 1 0 . 4 2 0 . 7 5 0 . 9 5 0 . 0 1 0 2 8 6 0 0 . 4 0 0 . 7 0 0 . 9 0 0 ....

Page 69

67 …a1 buffer solutions appendix a table a4 nist buffer solutions p m e t s r e f f u b t s i n c f h p 1 0 . 4 h p 6 8 . 6 h p 8 1 . 9 0 2 3 3 0 0 . 4 2 8 9 . 6 0 6 4 . 9 5 1 4 8 9 9 . 3 9 4 9 . 6 2 9 3 . 9 0 1 0 5 6 9 9 . 3 1 2 9 . 6 1 3 3 . 9 5 1 9 5 6 9 9 . 3 8 9 8 . 6 6 7 2 . 9 0 2 8 6 9 9 9 ...

Page 70

68 notes.

Page 71

Products & customer support products automation systems • for the following industries: – chemical & pharmaceutical – food & beverage – manufacturing – metals and minerals – oil, gas & petrochemical – pulp and paper drives and motors • ac and dc drives, ac and dc machines, ac motors to 1kv • drive s...

Page 72

Im/ax4ph issue 5 the company’s policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice. Printed in uk (11.04) © abb 2004 abb limited oldends lane, stonehouse gloucestershire, gl10 3ta uk tel: +44 (0)1453 826661 fax: +44 (0)1...