- DL manuals

- ABB

- Transmitter

- AW400 Series

- Instruction Manual

ABB AW400 Series Instruction Manual

Summary of AW400 Series

Page 1

Instruction manual im/aw4tx issue 5 chlorine transmitter aw400 series.

Page 2

Abb en iso 9001:2000 cert. No. Q 05907 en 29001 (iso 9001) lenno, italy – cert. No. 9/90a stonehouse, u.K. 0255 electrical safety this equipment complies with the requirements of cei/iec 61010-1:2001-2 'safety requirements for electrical equipment for measurement, control and laboratory use'. If the...

Page 3

1 table of contents page n. 1 model number breakdown ............................................................................................................... 3 1.1 ordering guide .....................................................................................................................

Page 4

2 5 functionality .................................................................................................................................... 35 5.1 transmitter (aw401) ....................................................................................................................... 35...

Page 5

3 1 model number breakdown 1.1 ordering guide residual chlorine monitor aw4 xx x x x x transmitter type transmitter 01 transmitter with pid control (channel 1 only) 02 sensor type channel 1 chlorine cell 1 sensor type channel 2 no second input channel 0 chlorine cell 1 ph 6 orp 7 additional 4-20ma i...

Page 6

4 2 introduction 2.1 classification according to en61010-1, aw400 is classified an: • electrical equipment for measurement and test • electrical equipment for process control • electrical equipment designed to be safe at least in the following conditions: – altitude lower than 2000 m – operation tem...

Page 7

5 2.4 technical specifications • display: digital lcd display, dot matrix, 16 + 16 characters, with back light. • power supply, selectable through a soldered jumper on the rear of the power supply pc board (see sect. 3.4.1): 115 vac, ±10%, 50/60 hz 230 vac, ±10%, 50/60 hz • maximum consumption: 20 v...

Page 8

6 • measure sensitivity: parameter sensitivity ph 0.0002 unit ph orp 0.0045 mv chlorine 0.33 μg/l (ppb) chlorine dioxide 0.33 μg/l (ppb) ozone 0.15 μg/l (ppb) • weight: 3 kg • outline dimensions: 250 mm x 250 mm x 120 mm. See fig.1 for detailed outline dimensions • ambient temperature limits for sto...

Page 9

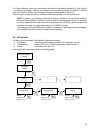

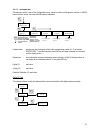

7 2.5 hardware structure of the system the aw400 hardware is structured in a modular system, whereby only the electronic p.C. Boards requested for the specific application needs to be installed, thus achieving great flexibility and relevant cost benefits for the user. The different p.C. Boards are m...

Page 10

8 second layer of p.C. Boards (analog input/output) third layer of p.C. Boards (main board): fourth layer of p.C. Boards (top): analog i/o pc board (channel cards) channel 1 channel 2 (optional) channel 3 (optional) cpu pc board display and keyboard pc board.

Page 11

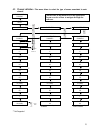

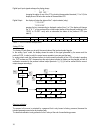

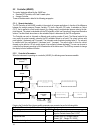

9 2.6instrument operating block diagram cpu configuration output setting alarms algorithms and routines serial communication rs485 rs422 rs232 digital i/o cci 1 freezes ch.1 cci 2 freezes ch.2 cci 1 + cci 2 when in or freeze ch.1 + ch.2 cco 1 cco 2 cco 3 cco 4 cco 5 cco 6 cco 7 watch dog g c b d ana...

Page 12

10 3 installation 3.1 dimensions and mounting side view cover for terminal board connection n° 4 cable glands, optional notes : 1 - all dimensions in mm 2 - dimensions are guaranteed only if this print is original 3 - all dimensions subject to tolerance ±3 mm. 4 - weight: microchem 2 : 3 kg microche...

Page 13

11 3.2 mounting aw400 is available with the hardware for the following types of mountings: • wall mounting (fig. 2) • 2” pipe mounting (fig. 3) 3.2.1 wall mounting aw400 wall mounting caution ! Danger follow instructions written on instruction bulletin. 120 (4.8”) cover for terminal board wiring min...

Page 14

12 3.2.2 2” pipe mounting without sunshade ! Cover for, terminal board connections 800 (32”) minimum clearance 0.00 500 (20”) ! Cover for terminal board connections 800 (32”) minimum clearance 0.00 500 (20”) minimum clearance power supply cable caution ! Danger follow instructions written on instruc...

Page 15

13 3.3 location the transmitter location should meet the following requirements: - the site of installation should be free of vibrations - the atmosphere should be free of corrosive substances - enough space has to be left around the transmitter to allow easy operation and maintenance - the transmit...

Page 16

14 3.4 electrical connections 3.4.1 power supply p.C. Board the power supply is connected to the terminal board tb1. The aw400 is shipped with the input voltage jumper set to 220 vac. The selection between the 110 vac or 220 vac power settings can be changed by moving a jumper (in position jp1) on t...

Page 17

15 3.4.1.1 power supply cable power supply cable has to be supplied by the customer and installed by the maintenance staff. In accordance to en61010-1 power supply cable has to satisfy the following requirements: • power supply cable must be certified (e.G. Imq, ul, csa...) or approved by an officia...

Page 18

16 unauthorised personnel must not be able to open the instrument. Aw400 is defined as an instrument "with no accessible parts under dangerous voltage". 3.4.2 digital i/o pc board 3.4.2.1 digital outputs aw400 digital outputs are provided by seven (7) relays. The function of each output contact depe...

Page 19

17 3.4.2.2 digital inputs aw400 digital input are represented in fig. 6. Characteristics of digital input cables are: • shielded • two-cores, section 0.5 – 1.0 mm2 • the shields has to be connected to ground shield terminal strip inside aw400. Fig. 6 – digital inputs terminal barrier 3.4.3 analog in...

Page 20

18 fig. 7 – analog input /output terminal barrier 3.4.3.1 temperature compensation the thermo-compensation pt100 is not necessarily present in each sensor, in fact in some installations the different sensors are installed in the same cell, and therefore the reference temperature can be read from one...

Page 21

19 in case not all the connections are required, the most important rules to follow are: • never run cable for power supply with other cables • never run analog i/o cables with other cables • never run cco cables or wires with other cables pleases notice that cable gland for power supply cable inclu...

Page 22

20 4 set-up and configuration 4.1 keyboard functionality all the keys have dual functionality, except the enter key. Blue background keys are the ones whose second function is only used in controller option (aw402). The selection between numbers and functions is automatically recognised by the instr...

Page 23

21 wash starts a cleaning sequence when this option is activated and allowed (timers set at any value different from zero). 8: digit 8 when allowed cancel cancel is used to load default parameters (power the instrument down and power it up while keeping the cancel key pressed) cancel is also used to...

Page 24

22 4.2 display the aw400 display shows the instantaneous value of the parameter measured, it’s identification symbol and the temperature of the sampled liquid. Here is an example of the standard one-channel display: 1 2 . 5 2 p h 1 5 . 5 ° c if the instrument is configured to support two sensors, th...

Page 25

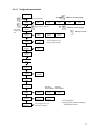

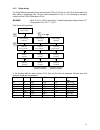

23 4.3 channel definition -this menu allows to select the type of sensor associated to each channel : operation display process password xxxxx menu calibration chann. Definition chann. Definition channel1 chann. Definition channel2 chann. Definition channel3 channel1 f* channel2 f* channel3 f* chann...

Page 26

24 notes: 1.When changing channel definition from one parameter to another, the aw400 transmitter/controller will set the alarm outputs and the pid parameters to the default values. 2.If chlorine (cl) is selected, the type of cl measurement must be defined as either a cell (kc4000ab) or a probe (cl4...

Page 27

25 the channel definition menus are in accordance to the number of the channels installed (e.G. If only channel 1 is installed, only channel 1 definition menu appears; if two channels are installed, both channel 1 definition menu and channel 2 definition menu will appear. The same principle applies ...

Page 28

26 4.4.1 configuration the configuration menu consents to set the general parameters of the instrument. Only those parameters which are pertinent to the selection made and to the hardware installed will appear in the menu. When a digital value is requested, pressing the enter key will cause a cursor...

Page 29

27 4.4.1.2 configuration menu flowchart language configuration password configuration serial link configuration temp.Select configuration altitude value set* configuration altitude * configuration ‘or’ cci configuration average ** configuration delta ** configuration smoothing configuration digital ...

Page 30

28 4.4.1.3 cleaning functionality the cleaning functionality implemented in the aw400 supports a sequence of operations necessary to perform a periodical cleaning of the sensors. This function is always present in the software and can be enabled or disabled by a yes/no selection in the configuration...

Page 31

29 4.4.1.4 instrument test this submenu which is part of the configuration menu, allows to perform self diagnostic routines on aw400 basic functions, sensor check and aw400 electrical calibration. Pressing any key its meaning will appear on display. To exit keep end key pressed for 3 sec. Shows all ...

Page 32

30 digital input: input signals submenu the display shows " 1 2 " " off off " changing the status of one of the cci by shorting the associated terminals (1-3 or 2-4) the display shows on below the number of the associated cci. Digital output: the display will show the status of the 7 output contacts...

Page 33

31 4.4.2 output setting the output settings menu allows to set current output (0–20 or 4–20 ma), zero (out zero) and full scale (out max) values, in engineering units. Out zero value corresponds to 0 ma or 4 ma (according to the output chosen) and the out full scale value to 20 ma. Warning! Set 0–20...

Page 34

32 4.4.2.1 output signal hardware modification 4 to 20 and 0 to 20 ma to modify output signal from 4 to 20 and 0 to 20 ma make following hardware modification on analog in put/output board: • identify jumper ip1 and jp2 on board (see figure 11); • remove jp1 (cut copper, this jumper is factory-made ...

Page 35

33 4.4.3 alarms this menu allows to set high and low alarm levels and the dead band. The alarm levels are freely selectable by the user. Select the channel and press enter to select alarms and dead band. Default levels are automatically related to the set range of output: low alarm is set at 10 % of...

Page 36

34 4.4.3.2 alarm setting menu (see par. 4.4 to get here) alarms channel 1 channel 1 low alarm cannel 1 high alarm channel 1 deadband alarms channel 2 channel 2 low alarm channel 2 high alarm channel 2 deadband alarms channel 3 channel 3 low alarm channel 3 high alarm channel 3 deadband only when cha...

Page 37

35 5 functionality the different functionality of the instrument depends on the model number selected, and it can be classified in two main groups: monitor-indicator-transmitter (aw401) or monitor-indicator-transmitter-controller (aw402). 5.1 transmitter (aw401) the transmitter can support up to thr...

Page 38

36 5.2 controller (aw402) the control strategies offered by the aw400 are: • standard pid controller, with feed forward option • average controller these will be discussed in detail in the following paragraphs. 5.2.1 general description the pid controller of the aw400 is usable in the majority of pr...

Page 39

37 default: 0 min/rep. – range 0–30 min manual reset (active when tr=0) mr numeric entry in % default: 0 - range 0–100% derivative td numeric entry in minutes default: 0 min – range 0–10 min process variable (display only) pv engineering units set point sp engineering units default: 0 control zone c...

Page 40

38 5 - contact output controller – (this menu available when option is selected - see par. 5.2.2.5) frequency / relay - function not supported at this time, leave always the selection "relay" gain gain numeric entry in %/100 default: 1 (=100%) dead zone dz numeric entry in engineering units default:...

Page 41

39 these parameters represent the absolute high and low limits allowed for the controller output. The output limits have to be set if required by the process. Default factory setting are: high limit 100%, low limit 0%. 5.2.2.2 feed forward (ff) configuration the instrument will activate this functio...

Page 42

40 5.2.2.4 error squared controller (ph applications) when the instrument detects that ph sensor has been selected for the controller, it enables a special pid algorithm with an “error squared” function. The error squared function is applied only within a band defined in the “band” parameter of the ...

Page 43

41 5.2.3 standard controller this section deals with the functionality which is specific of the standard controller. 5.2.3.1 std controller display the standard controller display shows the following values: • instantaneous value of process variable measure • process variable temperature (not presen...

Page 44

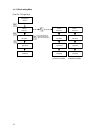

42 5.2.3.2 std controller analog output assignment the assignment of the analog output signals depends on the number of channels installed and on the type of configuration select ed for the controller output, whether it is to operate on a 4–20 analog signal or on contacts closure, as per the followi...

Page 45

43 5.2.3.4 std controller digital output assignment the assignment of the digital output signals depends on the number of channels installed, on the type of configuration selected , for the controller output, whether it is to operate on a 4–20 analog signal or on contacts closure, and on the cleanin...

Page 46: 6 Calibration

44 6 calibration calibration is required to align the sensor sensitivity. This operation is necessary at the start-up of the instrument and at periodical intervals. New sensors have to be let in operation for at least 24 hours, to allow the electrode to recover complete sensitivity, before performin...

Page 47

45 6.1.2 calibration menu flow chart channel 2 *s.P.C. Channel 2 calibration p1 channel 2 calibration p2 only when channel 3 pc board is installed only when channel 2 pc board is installed channel 1 *s.P.C. Channel 1 calibration p1 channel 1 calibration p2 channel 3 calibration p1. Channel 3 calibra...

Page 48

46 put the two standard buffer solutions in two beakers in a sufficient amount to cover the sensor. Wash the probe with de-mineralised water, dry it and dip it in the standard ph 7 buffer solution. Stir softly but continuously the probe: in this way a lower stabilisation time will be required. Press...

Page 49

47 when a double point calibration is performed the s.P..C value is forced to 0.00. 500 400 300 200 100 0 -100 -200 -300 -400 -500 2 0 4 6 8 10 12 14 o c urve relative to the initial calibration c urve relative to electrode ageing c urve corrected w ith a single point calibration fig. 14 - ph calibr...

Page 50

48 6.1.4.1 "oxidation potential with negative values" arrangement p1 will be the value of the oxidant standard solution, and p2 the value of the reducent standard solution. In case both the standard solution have the same sign, p1 will be the standard solution with the lower value. Press the menu ke...

Page 51

49 6.1.5 chlorine / chlorine dioxide / ozone the calibration procedure is necessary to standardise the sensor sensitivity. The calibration procedure allows to set both the slope and the offset of the curve giving the chlorine/chlorine dioxide/ozone concentration as a function of the µa from the cell...

Page 52

50 remark : if the sample is a chlorine dioxide solution and the displayed indication is desired to be in "ppm clo2" multiply the dpd analysis reading by 1.9. Warning ! It is advisable to repeat the calibration after 24 hours and after 2 or 3 days..

Page 53

51 7 start up before start up it is recommended to verify the following points: • the power supply is in agreement with the value indicated in the tag fixed on aw400 side • power supply wiring is in agreement with the indications of sect. 3.4 and subsections • all electrical connections to aw400 are...

Page 54

52 4. Verify that the selected measuring ranges correspond to the desired values; if not, modify ranges as needed; 5. If the alarm levels are required at values that are not the 10 % and 90 % of measuring range, enter the alarms menu and set low alarm and high alarm level as required. Refer to sect....

Page 55

53 8 maintenance aw400 housing can be externally cleaned with a cloth slightly wetted with alcohol and water, paying attention not to damage the keyboard. 8.1 periodical operations all monitors need cleaning of the sensors at periodical intervals, this depends on type of sensor and process character...

Page 56

54 9 error messages & troubleshooting different levels of messages are generated by the instrument at need. 9.1 messages at power up, the aw400 instrument shows the following sequence of messages: "microchem ii" "s.Rel...." "transmitter" 9.1.1 operation messages messages displayed during operation t...

Page 57

55 9.1.3 alarms page it is accessed by pressing the enter key in display mode. If no alarm or no abnormal condition is present the display will show nothing. The following messages are displayed with the indicated meaning: a1l = low alarm on channel 1 a2l = low alarm on channel 2 a3l = low alarm on ...

Page 58

56 10 serial communication note: this section applies only to instruments equipped with the optional serial communication p.C. Board. 10.1 standard of communications two digital communication standard are supported by the serial communication board of aw400, one port is an rs232 serial interface and...

Page 59

57 10.1.2 communication protocol the communication protocol requires the host to initiate all transactions. There are two basic categories of message types: interrogate , which is used to read data from an addressed aw400, and change , which is used to alter a value in an addressed aw400. The addres...

Page 60

58 10.1.3 message types and commands description the types of messages that are sent between the host and the aw400 are formatted as follows: host to aw400 1. Interrogate – this message requests up to 20h consecutively stored bytes, beginning at the specified memory address location of the addressed...

Page 61

59 10.2 communication transaction examples 10.2.1 transaction a example host requests 9 bytes of data beginning at hexadecimal memory address 1000 h from the aw400 at data-link address 03: 1. Host sends interrogate message: 01111110 11100011 00001001 00000000 00010000 11111100 soh command num lo add...

Page 62

60 10.3 serial link signal connection the aw400 optional serial communication p.C. Board is equipped with modular telephone rj45 type jack supporting both for rs 232 and rs 422/485 standards: rj45 telephone signal connection jack lay-out: pin n. Rs 232 rs 422 rs 485 1 gnd ground tx + data transmissi...

Page 63

61 10.4 data-link terminator the datalink impedance should be 110 ohm. When the serial communication standard is selected as rs422 or rs485, and more than one aw400 are installed on the same datalink, it is necessary to activate a terminator resistance, which is available on the serial communication...

Page 64

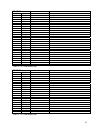

62 10.5 aw400 memory map increment: (figures between brackets ‘[x]’ indicate the number of similar variables repeated). Char type: 1 byte int type: 2 bytes float type: 4 bytes string type: 1 byte x string length type hex addr. Name description int 0x0000 pgmmode program mode (0-4) transmitter, washi...

Page 65

63 pid 1 data int 0x0134 reserved float 0x0136 pb proportional band float 0x013a tr reset time float 0x013e mr manual reset float 0x0142 td rate time float 0x0146 setpoint set point float 0x014a controlzone control zone int 0x014e rsw direct/reverse action float 0x0150 span span int 0x0154 ohlp floa...

Page 66

64 outputs int 0x01e2 washseq actual washing sequence int 0x01e4 out_state[8] cco state int 0x01f4 in_state[8] cci state float 0x0204 dev[2] pid 1,2 dev float 0x020c out[2] pid 1,2 out float 0x0214 ff[2] pid 1,2 ff …int 0x021c hial ch1-3 [3] hi alarm channel 1-3 …int 0x0222 loal ch1-3 [3] lo alarm c...

Page 67

65 11 appendices 11.1 ec declaration ec declaration aw400 line (t17m*4000a) fulfils the compliance to the mandatory tests specified by the applicable harmonised generic rules to apply the ce mark, according to european directive 89/336/eec and subsequent modifications. As the final environment may b...

Page 68: 12 Spare Parts

66 12 spare parts aw400 transmitter spare parts power supply board aw401054 display board aw401115 cpu board aw401055 analogue i/o board aw401015 digital i/o & serial board aw401119 ribbon cable cpu to psu aw401116 ribbon cable digital i/o to cpu aw401117 interconnect cable psu to digital i/o aw4011...

Page 69

67 notes.

Page 70

68.

Page 71

Products & customer support products automation systems • for the following industries: – chemical & pharmaceutical – food & beverage – manufacturing – metals and minerals – oil, gas & petrochemical – pulp and paper drives and motors • ac and dc drives, ac and dc machines, ac motors to 1kv • drive s...

Page 72

Im /a w4 t x issue 5 abb has sales & customer support expertise in over 100 countries worldwide www.Abb.Com the company’s policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice. Printed in uk (06.09) © abb 2009 abb limited ...