- DL manuals

- ABB

- Robotics

- IRB 140 type C

- Product Manual

ABB IRB 140 type C Product Manual

Summary of IRB 140 type C

Page 1

Product manual articulated robot irb 140 type c irb 140t type c irb 140-6/0.8 type c irb 140t-6/0.8 type c m2004.

Page 3

© co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Product manual irb 140 type c irb 140t type c irb 140-6/0.8 type c irb 140t-6/0.8 type c m2004 document id: 3hac027400-001 revision: c.

Page 4

© co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. The information in this manual is subject to change without notice and should not be construed as a commitment by abb. Abb assumes no responsibility for any errors that may appear in this manual. Except as may be expressly stated anywhere in ...

Page 5

Table of contents 3 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 product documentation, m2004 ....

Page 6

Table of contents 4 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3 maintenance 59 3.1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 3.2 maintenance ...

Page 7

Table of contents 5 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 5 calibration information 163 5.1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163 5.2 ...

Page 8

Table of contents 6 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed..

Page 9

Overview 7 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Overview about this manual this manual contains instructions for • mechanical and electrical installation of the robot • maintenance of the robot • mechanical and electrical repair of the robot. Usage thi...

Page 10

Overview 3hac027400-001 revision: c 8 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. References revisions reference document id product manual - irc5 3hac021313-001 product specification - irb 140 3hac9041-1 operating manual - irc5 with flexpendant 3hac16590-1 operating manual - calibrati...

Page 11

Product documentation, m2004 9 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Product documentation, m2004 general the robot documentation may be divided into a number of categories. This listing is based on the type of information contained within the documents...

Page 12

Product documentation, m2004 3hac027400-001 revision: c 10 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Operating manuals this group of manuals is aimed at those having first hand operational contact with the robot, i.E. Production cell operators, programmers and trouble shooters. The g...

Page 13

How to read the product manual 11 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. How to read the product manual reading the procedures the procedures contain references to figures, tools, material etc. The references are read as described below. References to fi...

Page 14

How to read the product manual 3hac027400-001 revision: c 12 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed..

Page 15: 1 Safety

1 safety 1.1. Introduction 13 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1 safety 1.1. Introduction overview the safety information in this manual is divided in two categories: • general safety aspects, important to attend to before performing any service wo...

Page 16

1 safety 1.2.1. Safety in the robot system 3hac027400-001 revision: c 14 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2 general safety information 1.2.1. Safety in the robot system validity and responsibility the information does not cover how to design, install and operate a complete...

Page 17

1 safety 1.2.2.1. Safety risks during installation and service work on robot 15 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.2. Safety risks 1.2.2.1. Safety risks during installation and service work on robot overview this section includes information of g...

Page 18

1 safety 1.2.2.1. Safety risks during installation and service work on robot 3hac027400-001 revision: c 16 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Complete robot cabling gearboxes and motors safety risk description hot components! Caution! Motors and gears are hot after running the...

Page 19

1 safety 1.2.2.2. Safety risks related to tools/workpieces 17 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.2.2. Safety risks related to tools/workpieces safe handling it must be possible to safely turn off tools, such as milling cutters, etc. Make sure tha...

Page 20

1 safety 1.2.2.3. Safety risks related to pneumatic/hydraulic systems 3hac027400-001 revision: c 18 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.2.3. Safety risks related to pneumatic/hydraulic systems general special safety regulations apply to pneumatic and hydraulic systems. Resi...

Page 21

1 safety 1.2.2.4. Safety risks during operational disturbances 19 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.2.4. Safety risks during operational disturbances general • the industrial robot is a flexible tool which can be used in many different industria...

Page 22

1 safety 1.2.2.5. Risks associated with live electric parts 3hac027400-001 revision: c 20 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.2.5. Risks associated with live electric parts voltage related risks, general • although troubleshooting may, on occasion, have to be carried out wh...

Page 23

1 safety 1.2.3.1. Safety fence dimensions 21 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.3. Safety actions 1.2.3.1. Safety fence dimensions general install a safety cell around the robot to ensure safe robot installation and operation. Dimensioning dimens...

Page 24

1 safety 1.2.3.2. Fire extinguishing 3hac027400-001 revision: c 22 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.3.2. Fire extinguishing note! Use a carbon dioxide (co 2 ) extinguisher in the event of a fire in the robot system (manipulator or controller)!.

Page 25

1 safety 1.2.3.3. Emergency release of the robot’s arm 23 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.3.3. Emergency release of the robot’s arm description in an emergency situation, any of the robot's axes may be released manually by pushing the brake re...

Page 26

1 safety 1.2.3.4. Brake testing 3hac027400-001 revision: c 24 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.3.4. Brake testing when to test during operation the holding brake of each axis motor wear normally. A test may be performed to determine whether the brake can still perform it...

Page 27

1 safety 1.2.3.5. Risk of disabling function "reduced speed 250 mm/s" 25 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.3.5. Risk of disabling function "reduced speed 250 mm/s" note! Do not change "transm gear ratio" or other kinematic system parameters from...

Page 28

1 safety 1.2.3.6. Safe use of the flexpendant 3hac027400-001 revision: c 26 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.3.6. Safe use of the flexpendant note! The enabling device is a push button located on the side of the flexpendant which, when pressed halfway in, takes the syste...

Page 29

1 safety 1.2.3.7. Work inside the manipulator's working range 27 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.3.7. Work inside the manipulator's working range warning! If work must be carried out within the robot’s work envelope, the following points must ...

Page 30

1 safety 1.2.3.8. Translate the information on safety and information labels 3hac027400-001 revision: c 28 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.2.3.8. Translate the information on safety and information labels labels on the product both the robot and the controller are marked ...

Page 31

1 safety 1.3.1. Safety signals, general 29 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.3 safety related instructions 1.3.1. Safety signals, general general this section specifies all dangers that may arise from performing the work detailed in the manual. Ea...

Page 32

1 safety 1.3.1. Safety signals, general 3hac027400-001 revision: c 30 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Electrostatic discharge (esd) electrostatic discharge (esd) the electrostatic discharge (esd) symbol indicates electrostatic hazards which could result in severe damage to ...

Page 33

1 safety 1.3.2. Danger - moving manipulators are potentially lethal! 31 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.3.2. Danger - moving manipulators are potentially lethal! Description any moving manipulator is a potentially lethal machine. When running th...

Page 34

1 safety 1.3.3. Danger - first test run may cause injury or damage! 3hac027400-001 revision: c 32 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.3.3. Danger - first test run may cause injury or damage! Description since performing a service activity often requires disassembly of the rob...

Page 35

1 safety 1.3.4. Warning - the unit is sensitive to esd! 33 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.3.4. Warning - the unit is sensitive to esd! Description esd (electro static discharge) is the transfer of electrical static charge between two bodies at ...

Page 36

1 safety 1.3.5. Warning - safety risks during work with gearbox oil 3hac027400-001 revision: c 34 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 1.3.5. Warning - safety risks during work with gearbox oil description when handling the gearbox oil, there are several dangers to both personal...

Page 37

2 installation and commissioning 2.1. Introduction 35 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2 installation and commissioning 2.1. Introduction general this chapter contains information for installing the robot to the working site. More detailed technica...

Page 38

2 installation and commissioning 2.2.1. Pre-installation procedure 3hac027400-001 revision: c 36 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.2 unpacking 2.2.1. Pre-installation procedure general this instruction is primarily intended for use when unpacking and installing the robot fo...

Page 39

2 installation and commissioning 2.2.1. Pre-installation procedure 37 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Loads on foundation, robot the table below shows the different forces and torques working on the robot during different kinds of operation. Note!...

Page 40

2 installation and commissioning 2.2.1. Pre-installation procedure 3hac027400-001 revision: c 38 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Protection classes the table below shows the protection class of the main parts of the robot system: equipment protection class robot ip 67 contr...

Page 41

2 installation and commissioning 2.2.2. Working range, irb 140 39 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.2.2. Working range, irb 140 working range axis 2 -3 the illustration below shows the unrestricted working range axis 2-3. Xx0200000058 pos position...

Page 42

2 installation and commissioning 2.2.2. Working range, irb 140 3hac027400-001 revision: c 40 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Working range axis 1 the illustrations below shows the unrestricted working range of axis 1. Xx0200000061 continued.

Page 43

2 installation and commissioning 2.2.3. Risk of tipping/stability 41 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.2.3. Risk of tipping/stability general the section below details instructions for making sure the manipulator does not tip over when it has not ...

Page 44

2 installation and commissioning 2.3.1. Lifting manipulator with lifting slings 3hac027400-001 revision: c 42 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.3 on-site installation 2.3.1. Lifting manipulator with lifting slings general this section details how to lift the manipulator usi...

Page 45

2 installation and commissioning 2.3.2. Manually releasing the brakes 43 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.3.2. Manually releasing the brakes general the section below details how to release the holding brakes of each axis' motor. This may be done...

Page 46

2 installation and commissioning 2.3.2. Manually releasing the brakes 3hac027400-001 revision: c 44 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Using the brake release unit with an external power supply this section details how to release the holding brakes with the internal brake rele...

Page 47

2 installation and commissioning 2.3.2. Manually releasing the brakes 45 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Using external power supply this section details how to release the holding brakes using a external voltage supply. If the positions of the ro...

Page 48

2 installation and commissioning 2.3.3. Orienting and securing the manipulator 3hac027400-001 revision: c 46 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.3.3. Orienting and securing the manipulator general this section details how to orient and secure the manipulator to the foundation...

Page 49

2 installation and commissioning 2.3.4. Restricting the working space 47 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.3.4. Restricting the working space general when installing the manipulator, make sure that it can move freely within its entire working spac...

Page 50

2 installation and commissioning 2.3.5. Fitting equipment on manipulator 3hac027400-001 revision: c 48 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.3.5. Fitting equipment on manipulator general the manipulator features mounting holes for additional equipment. In addition to the stock ...

Page 51

2 installation and commissioning 2.3.5. Fitting equipment on manipulator 49 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Illustration, holes on mounting flange the illustration below shows the stock holes available for fitting equipment on the mounting flange....

Page 52

2 installation and commissioning 2.3.6. Loads 3hac027400-001 revision: c 50 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.3.6. Loads general any loads mounted on the manipulator must be defined correctly and carefully (with regard to the position of centre of gravity and inertia factor...

Page 53

2 installation and commissioning 2.3.7. Suspended mounting 51 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.3.7. Suspended mounting general initially the system is configured for mounting on the floor, without leaning. The method for mounting the robot in a s...

Page 54

2 installation and commissioning 2.3.7. Suspended mounting 3hac027400-001 revision: c 52 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Xx0200000066 defining the parameter the value of the system parameter gravity beta must be redefined when changing the mounting angle of the robot. The p...

Page 55

2 installation and commissioning 2.3.8. Bolt pattern 53 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.3.8. Bolt pattern hole configuration the illustration below shows the hole configuration used when securing the manipulator: xx0200000085 continues on next p...

Page 56

2 installation and commissioning 2.3.8. Bolt pattern 3hac027400-001 revision: c 54 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Cross section, guide sleeve hole the illustration below shows the cross section of the guide sleeve holes: xx0200000086 continued.

Page 57

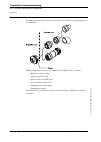

2 installation and commissioning 2.4.1. Customer connections on manipulator 55 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.4 electrical connections 2.4.1. Customer connections on manipulator general for connection of extra equipment on the manipulator there...

Page 58

2 installation and commissioning 2.4.1. Customer connections on manipulator 3hac027400-001 revision: c 56 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Recommended parts to connect power and signal conductors to the upper arm connector, the following parts are recommended xx0200000132 ab...

Page 59

2 installation and commissioning 2.5.1. Additional installation procedure 57 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2.5 making robot ready for operation, cleanroom 2.5.1. Additional installation procedure general cleanroom robots are specially designed t...

Page 60

2 installation and commissioning 2.5.1. Additional installation procedure 3hac027400-001 revision: c 58 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed..

Page 61: 3 Maintenance

3 maintenance 3.1. Introduction 59 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3 maintenance 3.1. Introduction structure of this chapter this chapter details all maintenance activities recommended for the robot and any external units of the robot. It is based...

Page 62

3 maintenance 3.2.1. Maintenance schedule, irb 140 3hac027400-001 revision: c 60 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3.2 maintenance schedules 3.2.1. Maintenance schedule, irb 140 general the robot, consisting of manipulator and controller cabinet, must be maintained regularly ...

Page 63

3 maintenance 3.2.1. Maintenance schedule, irb 140 61 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Battery type selection the table below shows the selection criteria for the three available battery types. No longer change interval than 60 months are allowed r...

Page 64

3 maintenance 3.3.1. Inspection, damper axes 2, 3 and 5 3hac027400-001 revision: c 62 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3.3 inspection activities 3.3.1. Inspection, damper axes 2, 3 and 5 location of dampers the figure below shows the location of all the dampers to be inspect...

Page 65

3 maintenance 3.3.1. Inspection, damper axes 2, 3 and 5 63 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Required equipment inspection, dampers the procedure below details how to inspect the dampers. Equipment art. No. Note standard toolkit - the contents are d...

Page 66

3 maintenance 3.3.2. Inspection, robot cabling 3hac027400-001 revision: c 64 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3.3.2. Inspection, robot cabling location, robot cabling the robot cabling comprises the cabling between the robot and controller cabinet as well as the externally v...

Page 67

3 maintenance 3.3.3. Inspection, timing belts 65 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3.3.3. Inspection, timing belts location of timing belts axes 3, 5 and 6 are fitted with timing belts. These are located as shown in the figures below. A more detaile...

Page 68

3 maintenance 3.3.3. Inspection, timing belts 3hac027400-001 revision: c 66 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Xx060000326 required equipment r timing belt, axis 6 u timing belt, axis 5 equipment, etc. Art. No. Note standard toolkit 3hac020812-001 the contents are defined in s...

Page 69

3 maintenance 3.3.3. Inspection, timing belts 67 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Inspection the procedure below details how to inspect the timing belts. Warning! Please observe the following before commencing any repair work on the manipulator: • ...

Page 70

3 maintenance 3.4.1. Cleaning, complete robot 3hac027400-001 revision: c 68 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3.4 cleaning activities 3.4.1. Cleaning, complete robot general the protection class of foundry and wash versions is ip 67, i.E. The robot is watertight. Required equ...

Page 71

3 maintenance 3.5.1. Oil change, gearbox axes 5 and 6 69 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3.5 changing/ replacing activities 3.5.1. Oil change, gearbox axes 5 and 6 location of oil plugs the gearboxes for axes 5 and 6 are located in the wrist unit ...

Page 72

3 maintenance 3.5.1. Oil change, gearbox axes 5 and 6 3hac027400-001 revision: c 70 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Draining, wrist unit the procedure below details how to drain oil from the gearboxes in the wrist unit. Action note/illustration 1. Danger! Turn off all elect...

Page 73

3 maintenance 3.5.1. Oil change, gearbox axes 5 and 6 71 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Filling oil, wrist unit the procedure below details how to fill oil in the gearboxes in the wrist unit. Action note/illustration 1. Danger! Turn off all elect...

Page 74

3 maintenance 3.5.1. Oil change, gearbox axes 5 and 6 3hac027400-001 revision: c 72 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed..

Page 75: 4 Repair

4 repair 4.1. Introduction 73 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4 repair 4.1. Introduction structure of this chapter this chapter details all repair activities recommended for the robot and any external units of the robot. It is made up of separate ...

Page 76

4 repair 4.2.1. Replacement of cable harness 3hac027400-001 revision: c 74 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.2 complete robot 4.2.1. Replacement of cable harness location of cable harness the cable harness runs from the base to the motors of axes 3-6. A more detailed view o...

Page 77

4 repair 4.2.1. Replacement of cable harness 75 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal, cable harness the procedure below details how to remove the cable harness. Warning! Please observe the following before commencing any repair work on the mani...

Page 78

4 repair 4.2.1. Replacement of cable harness 3hac027400-001 revision: c 76 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3. Remove the cable holder by unscrewing its attachment screws. Xx0300000091 • a: cable holder • b: attachment screws • c: cable securing screws 4. Remove the cables f...

Page 79

4 repair 4.2.1. Replacement of cable harness 77 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 8. Disconnect connectors in the rear of the upper arm. Xx0300000092 connectors: • a: r2.Cs • b: pressurized air connection • c: r3.Fb4 • d: r3.Fb5 • e: r3.Fb6 • f: r3....

Page 80

4 repair 4.2.1. Replacement of cable harness 3hac027400-001 revision: c 78 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 11. Disconnect the connectors inside the lower arm. Xx0200000449 • g: connectors r3.Mp3 and r3.Fb3 12. Pull the cables out of the upper arm. 13. Remove the cover, cons...

Page 81

4 repair 4.2.1. Replacement of cable harness 79 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting, cable harness the procedure below details how to refit the cable harness. Warning! Please observe the following before commencing any repair work on the man...

Page 82

4 repair 4.2.1. Replacement of cable harness 3hac027400-001 revision: c 80 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3. Cable layout in the lower arm. Xx0200000449 • a: cable ties • b: pressurized air hose • c: power cables, axes 4, 5 and 6 • d: customer cables, signal • e: signal ca...

Page 83

4 repair 4.2.1. Replacement of cable harness 81 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4. Cable holder in the upper arm. Xx0300000094 cables: • a: customer signal • b: signal • c: pressurized air supply • d: power cables action note/illustration continue...

Page 84

4 repair 4.2.2. Replacement of complete upper arm 3hac027400-001 revision: c 82 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.2.2. Replacement of complete upper arm location of upper arm the upper arm is located on top of the manipulator as shown in the figure below. A more detailed vi...

Page 85

4 repair 4.2.2. Replacement of complete upper arm 83 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Required equipment warning! Please observe the following before commencing any repair work on the manipulator: • motors and gears are hot after running the robot!...

Page 86

4 repair 4.2.2. Replacement of complete upper arm 3hac027400-001 revision: c 84 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal, upper arm the procedure below details how to remove the complete upper arm. Action note 1. Run the manipulator arm to a horizontal position. 2. Remove al...

Page 87

4 repair 4.2.2. Replacement of complete upper arm 85 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removing the vk cover the procedure below details how to remove the vk cover from the upper arm. Xx0200000433 9. Remove the vk-cover from the upper arm/lower arm ...

Page 88

4 repair 4.2.2. Replacement of complete upper arm 3hac027400-001 revision: c 86 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting the procedure below details how to refit the complete upper arm. Action note 1. Remove the lower arm cover by unscrewing its attachment screws. 2. Tap t...

Page 89

4 repair 4.2.2. Replacement of complete upper arm 87 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Danger! When performing the first test run after a service activity (repair, installation or maintenance, it is vital that: • all the service tools and other fore...

Page 90

4 repair 4.2.3. Replacement of complete lower arm 3hac027400-001 revision: c 88 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.2.3. Replacement of complete lower arm location of lower arm the lower arm is located between upper arm and frame as shown in the figure below. A more detailed ...

Page 91

4 repair 4.2.3. Replacement of complete lower arm 89 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Required equipment removal, lower arm the procedure below details how to remove the complete lower arm. Warning! Please observe the following before commencing an...

Page 92

4 repair 4.2.3. Replacement of complete lower arm 3hac027400-001 revision: c 90 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 2. Do not under any circumstance unscrew the six screws on top of the lower arm! Doing so will cause the manipulator to require a complete rebuild! Xx0300000101 p...

Page 93

4 repair 4.2.3. Replacement of complete lower arm 91 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting, lower arm the procedure below details how to refit the complete lower arm. Action note 1. Fit the lifting device and lift the lower arm into position. ...

Page 94

4 repair 4.2.4. Replacement of base 3hac027400-001 revision: c 92 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.2.4. Replacement of base location of base the base is located at the bottom of the robot as shown in the figure below. A more detailed view of the components and its position...

Page 95

4 repair 4.2.4. Replacement of base 93 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal, base the procedure below details how to remove the base from the robot. Locking liquid loctite 574 for sealing the base to the gearbox 1-2. Grease 3hab 3537-1 for lubr...

Page 96

4 repair 4.2.4. Replacement of base 3hac027400-001 revision: c 94 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting, base the procedure below details how to refit the base to the robot. 10. Secure the weight of the base and remove the gearbox/base attachment screws and washer. Show...

Page 97

4 repair 4.2.4. Replacement of base 95 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 15. Recalibrate the robot. Calibration is detailed in a separate calibration manual, enclosed with the calibration tools. General calibration information is included in section...

Page 98

4 repair 4.3.1. Replacement of wrist unit 3hac027400-001 revision: c 96 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.3 upper arm 4.3.1. Replacement of wrist unit location of wrist unit the wrist unit is located in the frontmost part of the upper arm. A more detailed view of the compon...

Page 99

4 repair 4.3.1. Replacement of wrist unit 97 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal, wrist unit the procedure below details how to remove the complete wrist unit. Refitting, wrist unit the procedure below details how to refit the complete wrist u...

Page 100

4 repair 4.3.1. Replacement of wrist unit 3hac027400-001 revision: c 98 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7. Manually push the wrist to adjust the wrist in relation to the gear in the gearbox. Minimize the gear play as shown in the figure. Xx0200000445 a. Wrist unit, axes 5 a...

Page 101

4 repair 4.3.2. Replacement of damper, axis 3 99 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.3.2. Replacement of damper, axis 3 location of damper, axis 3 the damper, axis 3, is shown in the figure below. A more detailed view of the components and its posit...

Page 102

4 repair 4.3.2. Replacement of damper, axis 3 3hac027400-001 revision: c 100 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal, damper axis 3 the procedure below details how to remove the damper, axis 3. Refitting, damper axis 3 the procedure below details how to refit the damper, ax...

Page 103

4 repair 4.3.3. Replacement of damper, axis 5 101 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.3.3. Replacement of damper, axis 5 location of damper, axis 5 the damper, axis 5, is located as shown in the figure below! Xx0600002806 required equipment a damper...

Page 104

4 repair 4.3.3. Replacement of damper, axis 5 3hac027400-001 revision: c 102 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal, damper axis 5 the procedure below details how to remove the damper, axis 5. Refitting, damper axis 5 the procedure below details how to refit the damper, ax...

Page 105

4 repair 4.3.4. Replacement of cover, arm housing 103 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.3.4. Replacement of cover, arm housing location of cover, armhousing the cover, armhousing is located on the rear of the upper arm as shown in the figure below...

Page 106

4 repair 4.3.4. Replacement of cover, arm housing 3hac027400-001 revision: c 104 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal the procedure below details how to remove the cover, armhousing. Warning! Please observe the following before commencing any repair work on the manipulat...

Page 107

4 repair 4.4.1. Replacement of lower arm cover and gasket 105 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.4 lower arm 4.4.1. Replacement of lower arm cover and gasket location of lower arm cover and gasket the lower arm cover and gasket are located as shown...

Page 108

4 repair 4.4.1. Replacement of lower arm cover and gasket 3hac027400-001 revision: c 106 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Required equipment removal, lower arm cover and gasket the procedure below details how to remove the lower arm cover and gasket. Warning! Please observe ...

Page 109

4 repair 4.4.1. Replacement of lower arm cover and gasket 107 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting, lower arm cover and gasket the procedure below details how to refit the lower arm cover and gasket. Warning! Please observe the following befo...

Page 110

4 repair 4.4.2. Replacement of damper, axis 2 3hac027400-001 revision: c 108 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.4.2. Replacement of damper, axis 2 location of damper, axis 2 the damper, axis 2, is located as shown in the figure below. A more detailed view of the components a...

Page 111

4 repair 4.4.2. Replacement of damper, axis 2 109 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal, damper axis 2 the procedure below details how to remove the damper, axis 2. Refitting, damper axis 2 the procedure below details how to refit the damper, ax...

Page 112

4 repair 4.4.3. Replacement of indicator lamp 3hac027400-001 revision: c 110 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.4.3. Replacement of indicator lamp location of indicator lamp the indicator lamp is located on the side of the lower arm as shown in the figure below. A more detai...

Page 113

4 repair 4.4.3. Replacement of indicator lamp 111 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal the procedure below details how to remove the indicator lamp. Warning! Please observe the following before commencing any repair work on the manipulator: • m...

Page 114

4 repair 4.5.1. Replacement of cover, console 3hac027400-001 revision: c 112 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.5 frame and base 4.5.1. Replacement of cover, console location of cover, console the cover, console is located on top of the console as shown in the figure below. ...

Page 115

4 repair 4.5.1. Replacement of cover, console 113 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Required equipment removal the procedure below details how to remove the cover, console. Warning! Please observe the following before commencing any repair work on t...

Page 116

4 repair 4.5.1. Replacement of cover, console 3hac027400-001 revision: c 114 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting the procedure below details how to refit cover, console. Warning! Please observe the following before commencing any repair work on the manipulator: • moto...

Page 117

4 repair 4.5.2. Replacement of console 115 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.5.2. Replacement of console location of console the console is located on top of gearbox, axes 1-2 as shown in the figure below. A more detailed view of the components an...

Page 118

4 repair 4.5.2. Replacement of console 3hac027400-001 revision: c 116 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal the procedure below details how to remove the cover, console. Warning! Please observe the following before commencing any repair work on the manipulator: • motors a...

Page 119

4 repair 4.5.2. Replacement of console 117 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7. Remove the bearing hub by unscrewing its attachment screws. Xx0300000096 parts: • a: console • b: bearing hub • c: bearing hub attachment screws (6 pcs) • d: console att...

Page 120

4 repair 4.5.2. Replacement of console 3hac027400-001 revision: c 118 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting the procedure below details how to refit cover, console. Warning! Please observe the following before commencing any repair work on the manipulator: • motors and ...

Page 121

4 repair 4.5.2. Replacement of console 119 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7. Recalibrate the robot! Calibration is detailed in a separate calibration manual, enclosed with the calibration tools. General calibration information is included in sect...

Page 122

4 repair 4.5.3. Replacement of serial measurement unit and battery pack 3hac027400-001 revision: c 120 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.5.3. Replacement of serial measurement unit and battery pack location of serial measurement unit and battery pack the serial measurement ...

Page 123

4 repair 4.5.3. Replacement of serial measurement unit and battery pack 121 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal the procedure below details how to remove the serial measurement unit and battery pack. Warning! Please observe the following befor...

Page 124

4 repair 4.5.3. Replacement of serial measurement unit and battery pack 3hac027400-001 revision: c 122 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3. Remove the serial measurement unit by unscrewing its attachment screws . The removal is simplified by pushing the unit to the side and t...

Page 125

4 repair 4.5.3. Replacement of serial measurement unit and battery pack 123 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting the procedure below details how to refit the serial measurement unit and battery pack. Warning! Please observe the following befo...

Page 126

4 repair 4.5.3. Replacement of serial measurement unit and battery pack 3hac027400-001 revision: c 124 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 6. Secure the rear cable cover to the base of the robot with its attachment screws. Shown in the figure location of serial measurement unit...

Page 127

4 repair 4.5.4. Replacement of control cable 125 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.5.4. Replacement of control cable location of control cable the control cable is located on the rear of the manipulator base as shown in the figure below. A more de...

Page 128

4 repair 4.5.4. Replacement of control cable 3hac027400-001 revision: c 126 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Control cable, spare 3hac 13089-1 30 m standard and foundry versions cover gasket included control cable, spare 3hac 10476-4 3 m clean room versions cover gasket incl...

Page 129

4 repair 4.5.4. Replacement of control cable 127 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal the procedure below details how to remove the control cable. Warning! Please observe the following before commencing any repair work on the manipulator: • mot...

Page 130

4 repair 4.5.4. Replacement of control cable 3hac027400-001 revision: c 128 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting the procedure below details how to refit control cable. Warning! Please observe the following before commencing any repair work on the manipulator: • motors...

Page 131

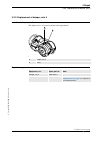

4 repair 4.6.1. Replacement of motor, axis 1 129 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.6 motors 4.6.1. Replacement of motor, axis 1 location of motor axis 1 the motor axis 1 is located on the rear of the manipulator as shown in the figure below: a mor...

Page 132

4 repair 4.6.1. Replacement of motor, axis 1 3hac027400-001 revision: c 130 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal the procedure below details how to remove motor, axis 1. Caution! If the manipulator normally works in an inverted position, it must be removed from this posi...

Page 133

4 repair 4.6.1. Replacement of motor, axis 1 131 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting the procedure below details how to refit motor, axis 1. Warning! Please observe the following before commencing any repair work on the manipulator: • - moto...

Page 134

4 repair 4.6.1. Replacement of motor, axis 1 3hac027400-001 revision: c 132 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 8. Tighten the motor attachment screws. Tightening torque: approx 11 nm ± 1 nm 9. Disconnect the brake release voltage. 10. Make sure the cable gland gasket has not b...

Page 135

4 repair 4.6.2. Replacement of motor, axis 2 133 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.6.2. Replacement of motor, axis 2 location of motor axis 2 the motor axis 2 is located on the front of the robot as shown in the figure below. A more detailed view ...

Page 136

4 repair 4.6.2. Replacement of motor, axis 2 3hac027400-001 revision: c 134 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal, motor axis 2 the procedure below details how to remove the axis 2 motor. Power supply - 24 vdc, 1.5 a. For releasing the brakes. Other tools and procedures m...

Page 137

4 repair 4.6.2. Replacement of motor, axis 2 135 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting, motor axis 2 the procedure below details how to refit the axis 2 motor. 8. Warning! Oil will be running out of the motor attachment hole when removing the ...

Page 138

4 repair 4.6.2. Replacement of motor, axis 2 3hac027400-001 revision: c 136 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 10. Tighten the motor attachment screws. Tightening torque: approx 11 nm ± 1 nm 11. Disconnect the brake release voltage. 12. Make sure the cable gland cover gasket h...

Page 139

4 repair 4.6.3. Replacement of motor and timing belt, axis 3 137 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.6.3. Replacement of motor and timing belt, axis 3 location of motor axis 3 the motor axis 3 is located behind the lower arm cover on the right hand ...

Page 140

4 repair 4.6.3. Replacement of motor and timing belt, axis 3 3hac027400-001 revision: c 138 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Required equipment removal the procedure below details how to remove motor, axis 3. Warning! Please observe the following before commencing any repair...

Page 141

4 repair 4.6.3. Replacement of motor and timing belt, axis 3 139 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 3. Cut the cable ties to facilitate accessing the motor. Xx0200000449 • a: cable ties • b: pressurized air hose • c: power cables, axes 4, 5 and 6 • d...

Page 142

4 repair 4.6.3. Replacement of motor and timing belt, axis 3 3hac027400-001 revision: c 140 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting the procedure below details how to refit motor, axis 3. Warning! Please observe the following before commencing any repair work on the manip...

Page 143

4 repair 4.6.3. Replacement of motor and timing belt, axis 3 141 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 5. Adjust the position of the motor in such a way that the correct belt tension is achieved. Correct belt tension f=35 - 60 n 6. Do not adjust the bel...

Page 144

4 repair 4.6.4. Replacement of motor, axis 4 3hac027400-001 revision: c 142 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.6.4. Replacement of motor, axis 4 location of motor the motor axis 4 is located on the left hand side of the upper arm as shown in the figure below. A more detailed...

Page 145

4 repair 4.6.4. Replacement of motor, axis 4 143 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal, motor axis 4 the procedure below details how to remove the motor, axis 4. Other tools and procedures may be required. See references to these procedures in t...

Page 146

4 repair 4.6.4. Replacement of motor, axis 4 3hac027400-001 revision: c 144 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting, motor axis 4 the procedure below details how to refit the motor, axis 4. Action note 1. Clean the mating surfaces on the motor and the gearbox. Shown in th...

Page 147

4 repair 4.6.5. Replacement of motor and timing belt, axes 5 or 6 145 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.6.5. Replacement of motor and timing belt, axes 5 or 6 location of motor and timing belt, axes 5 or 6 the motor and timing belt axes 5 or 6 are...

Page 148

4 repair 4.6.5. Replacement of motor and timing belt, axes 5 or 6 3hac027400-001 revision: c 146 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Required equipment n attachment screws, motor console r timing belt, axis 6 s pulley, axis 6 u timing belt, axis 5 v pulley, axis 5 w motor conso...

Page 149

4 repair 4.6.5. Replacement of motor and timing belt, axes 5 or 6 147 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal the procedure below details how to remove motor, axis 5 or 6. Warning! Please observe the following before commencing any repair work on ...

Page 150

4 repair 4.6.5. Replacement of motor and timing belt, axes 5 or 6 3hac027400-001 revision: c 148 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Refitting the procedure below details how to refit motor, axis 5. Warning! Please observe the following before commencing any repair work on the ...

Page 151

4 repair 4.6.5. Replacement of motor and timing belt, axes 5 or 6 149 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 5. Tighten the motor attachment screws to enable the motor to be shifted slightly. This will facilitate adjustment of the belt tension. 6. Adjust...

Page 152

4 repair 4.6.5. Replacement of motor and timing belt, axes 5 or 6 3hac027400-001 revision: c 150 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 19. Refit any brackets securing any exterior cabling to the upper arm with their attachment screws respectively. 20. Recalibrate the robot. Calib...

Page 153

4 repair 4.6.6.1. Measuring the gear play, axis 5 151 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.6.6. Adjustments and measurements 4.6.6.1. Measuring the gear play, axis 5 general after reassembly due to repair work or any other reason, the gear play must ...

Page 154

4 repair 4.6.6.1. Measuring the gear play, axis 5 3hac027400-001 revision: c 152 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Measurement the procedure below details how to measure the gear play for axis 5. Action note 1. Manually, turn axis 4 90°. 2. Fit the dial fitting arm and dial t...

Page 155

4 repair 4.6.6.2. Measuring the gear play, axis 6 153 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.6.6.2. Measuring the gear play, axis 6 general after reassembly due to repair work or any other reason, the gear play must be checked to ensure the repetition ...

Page 156

4 repair 4.6.6.2. Measuring the gear play, axis 6 3hac027400-001 revision: c 154 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Measurement the procedure below details how to measure the gear play for axis 6. Action note 1. Manually, turn axis 4 90°. 2. Fit the dial fitting arm and dial t...

Page 157

4 repair 4.7.1. Replacement of gearbox, axes 1-2 and damper, axis 1 155 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.7 gearboxes 4.7.1. Replacement of gearbox, axes 1-2 and damper, axis 1 location of gearbox unit, axes 1-2 the gearboxes of axes 1 and 2 are l...

Page 158

4 repair 4.7.1. Replacement of gearbox, axes 1-2 and damper, axis 1 3hac027400-001 revision: c 156 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Illustration, base xx0200000423 locking liquid - loctite 574 sealing ring 3hac 6965-1 replace only when damaged! Lifting slings - standard tool...

Page 159

4 repair 4.7.1. Replacement of gearbox, axes 1-2 and damper, axis 1 157 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal, gearbox unit axes 1-2 the procedure below details how to remove the complete gearbox unit, axes 1-2. Action note 1. Danger! Turn off a...

Page 160

4 repair 4.7.1. Replacement of gearbox, axes 1-2 and damper, axis 1 3hac027400-001 revision: c 158 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Removal of damper, axis 1 the procedure below details how to remove the damper, axis 1. Refitting of damper, axis 1 the procedure below details...

Page 161

4 repair 4.7.1. Replacement of gearbox, axes 1-2 and damper, axis 1 159 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 9. Secure the base to the foundation attachment bolts and the tightening torque are specified in section attachment screws on page 46 10. Refit...

Page 162

4 repair 4.7.2. Service work on gearbox, axis 4 3hac027400-001 revision: c 160 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.7.2. Service work on gearbox, axis 4 general the gearbox, axis 4, is intended to run without requiring any repairs or maintenance work. This implies that it must...

Page 163

4 repair 4.7.3. Amount of oil 161 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 4.7.3. Amount of oil overview when a part is replaced or repaired it is offen nessecary to add oil into the gearboxes. Type and amount of oil in gearboxes gearbox type of oil art. N...

Page 164

4 repair 4.7.3. Amount of oil 3hac027400-001 revision: c 162 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed..

Page 165: 5 Calibration Information

5 calibration information 5.1. Introduction 163 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 5 calibration information 5.1. Introduction general this chapter includes general information about different calibration methods and also details procedures that do n...

Page 166

5 calibration information 5.2. Calibration methods 3hac027400-001 revision: c 164 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 5.2. Calibration methods overview this section specifies the different types of calibration and the calibration methods that are supplied from abb. Types of cal...

Page 167

5 calibration information 5.2. Calibration methods 165 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Calibration methods each calibration method is detailed in a separate manual. Below is a brief description of the methods available. Calibration pendulum - stan...

Page 168

5 calibration information 5.3. Calibration scales and correct axis position 3hac027400-001 revision: c 166 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 5.3. Calibration scales and correct axis position introduction this section specifies the calibration scale positions and/or correct ax...

Page 169

5 calibration information 5.4. Calibration movement directions for all axes 167 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 5.4. Calibration movement directions for all axes overview when calibrating, the axis must consistently be run towards the calibration ...

Page 170

5 calibration information 5.5. Updating revolution counters 3hac027400-001 revision: c 168 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 5.5. Updating revolution counters general this section details how to perform a rough calibration of each robot axis, i.E. Updating the revolution coun...

Page 171

5 calibration information 5.5. Updating revolution counters 169 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Step 2 - storing the revolution counter setting with the flexpendant this procedure details the second step when updating the revolution counter; stori...

Page 172

5 calibration information 5.5. Updating revolution counters 3hac027400-001 revision: c 170 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 6. Caution! If a revolution counter is incorrectly updated, it will cause incorrect robot positioning, which in turn may cause damage or injury! Check ...

Page 173

5 calibration information 5.6. Checking the calibration position 171 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 5.6. Checking the calibration position general check the calibration position before beginning any programming of the robot system. This may be do...

Page 174

5 calibration information 5.6. Checking the calibration position 3hac027400-001 revision: c 172 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed..

Page 175: 6 Robot Description

6 robot description 6.1. Type c of irb 140 173 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 6 robot description 6.1. Type c of irb 140 type c- new upper arm and wrist type c of irb 140 have a new upper arm, complete and a new wrist unit. As a result of this, t...

Page 176

6 robot description 6.1. Type c of irb 140 3hac027400-001 revision: c 174 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed..

Page 177: 7 Reference Information

7 reference information 7.1. Introduction 175 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7 reference information 7.1. Introduction general this chapter includes general information, complementing the more specific information in the product manual (part 1 of...

Page 178

7 reference information 7.2. Unit conversion 3hac027400-001 revision: c 176 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7.2. Unit conversion converter table use the table below to convert units used in this manual. Quantity units length 1 m 3.28 ft 39.37 in weight 1 kg 2.21 lb pressure...

Page 179

7 reference information 7.3. Screw joints 177 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7.3. Screw joints general this section details how to tighten the various types of screw joints on the robot. The instructions and torque values are valid for screw join...

Page 180

7 reference information 7.3. Screw joints 3hac027400-001 revision: c 178 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Tightening torque before tightening any screw, note the following: • determine whether a standard tightening torque or special torque is to be applied. The standard torq...

Page 181

7 reference information 7.3. Screw joints 179 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. The table below specifies the recommended standard tightening torque for water and air connectors when one or both connectors are made of brass. Dimension tightening tor...

Page 182

7 reference information 7.4. Weight specifications 3hac027400-001 revision: c 180 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7.4. Weight specifications definition in installation, repair and maintenance procedures, weights of the components handled are sometimes specified. All compone...

Page 183

7 reference information 7.5. Document references 181 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7.5. Document references general the contents of this manual may include references to additional documentation necessary to perform certain procedures. This sect...

Page 184

7 reference information 7.6. Standard toolkit 3hac027400-001 revision: c 182 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7.6. Standard toolkit general all service (repairs, maintenance and installation) procedures contain lists of tools required to perform the specified activity. All s...

Page 185

7 reference information 7.7. Special tools 183 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7.7. Special tools general all service instructions contain lists of tools required to perform the specified activity. The required tools are a sum of standard tools, d...

Page 186

7 reference information 7.8. Performing a leak-down test 3hac027400-001 revision: c 184 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7.8. Performing a leak-down test general after refitting any motor and any gearbox, the integrity of all seals enclosing the gearbox oil must be tested. T...

Page 187

7 reference information 7.9. Lifting equipment and lifting instructions 185 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7.9. Lifting equipment and lifting instructions general many repair and maintenance activities require different pieces of lifting equipmen...

Page 188

7 reference information 7.10. Mounting instructions for bearings 3hac027400-001 revision: c 186 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7.10. Mounting instructions for bearings general this section details how to mount and grease different types of bearings on the robot. Equipment ...

Page 189

7 reference information 7.11. Mounting instructions for seals 187 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 7.11. Mounting instructions for seals general this sections details how to mount different types of seals to the robot. Equipment rotating seals the ...

Page 190

7 reference information 7.11. Mounting instructions for seals 3hac027400-001 revision: c 188 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Flange seals and static seals the procedure below details how to fit flange seals and static seals. O-rings the procedure below details how to fit o-...

Page 191

8 spare part lists and exploded views 8.1. Introduction 189 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 8 spare part lists and exploded views 8.1. Introduction definitions this chapter specifies all spare parts and replacement articles of the robot..

Page 192

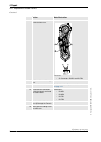

8 spare part lists and exploded views 8.2. Spare parts - robot irb 140 3hac027400-001 revision: c 190 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 8.2. Spare parts - robot irb 140 robot irb 140, spare parts list the items specified below are shown in the figures robot irb 140, exploded ...

Page 193

8 spare part lists and exploded views 8.2. Spare parts - robot irb 140 191 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 36 1 3hac 11331-1 control cable spare std/f l = 15 m 37 1 3hac 11331-2 control cable spare cr l = 15 m 38 1 3hac 13089-1 control cable spare...

Page 194

8 spare part lists and exploded views 8.2. Spare parts - robot irb 140 3hac027400-001 revision: c 192 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 109 1 3hac 7880-1 damper axis 2 110 1 3haa 2356-14 washer srkb 6.4x18x1.6 111 4 3hab 3402-15 hex. Socket head cap screw m5x20 8.8 gleitmo 61...

Page 195

8 spare part lists and exploded views 8.2. Spare parts - robot irb 140 193 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 182 550 ml 3hac 0860-1 lubricating oil optimol optigear bm 100 183 1 3hac 026581-003 upper arm, spare cr 184 1 3hac 026569-003 186 1 3hac 10...

Page 196

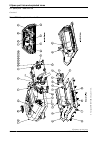

8 spare part lists and exploded views 8.2. Spare parts - robot irb 140 3hac027400-001 revision: c 194 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Robot irb 140, exploded view 1 of 5 xx0600003264 continued continues on next page.

Page 197

8 spare part lists and exploded views 8.2. Spare parts - robot irb 140 195 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Robot irb 140, exploded view 2 of 5 xx0600003265 continued continues on next page.

Page 198

8 spare part lists and exploded views 8.2. Spare parts - robot irb 140 3hac027400-001 revision: c 196 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Robot irb 140, exploded view 3 of 5 xx0600003266 continued continues on next page.

Page 199

8 spare part lists and exploded views 8.2. Spare parts - robot irb 140 197 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Robot irb 140, exploded view 4 of 5 xx0600003267 continued continues on next page.

Page 200

8 spare part lists and exploded views 8.2. Spare parts - robot irb 140 3hac027400-001 revision: c 198 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. Robot irb 140, exploded view 5 of 5 xx0600003268 continued.

Page 201: 9 Circuit Diagram

9 circuit diagram 9.1. Introduction 199 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. 9 circuit diagram 9.1. Introduction overview this chapter includes the circuit diagram for the robot..

Page 202

9 circuit diagram 9.1. Introduction 3hac027400-001 revision: c 200 © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed..

Page 203

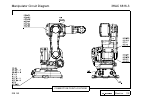

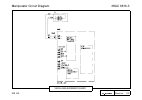

Circuit diagram contents page irb 140 manipulator, diagram 3hac 6816-3, rev. 0 ..............................................................101-108.

Page 204

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 101 list of contents.

Page 205

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 102 connection point locations.

Page 206

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 103 serial measurement board.

Page 207

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 104 motor axis 1 - 3.

Page 208

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 105 feedback axis 1 - 3.

Page 209

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 106 motor axis 4 - 6.

Page 210

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 107 feed-back axis 4 - 6.

Page 211

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 108 customer connections.

Page 212

Index 201 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. A absolute accuracy, calibration 165 b base brake release buttons 43 replacing 92 screws, tightening torque 94 spare part number 92 brake release unit releasing the brakes 43 brakes testing function 24 bra...

Page 213

Index 202 3hac027400-001 revision: c © co py rig h t 200 6- 200 8 abb. All righ ts reser v ed. O oil change gearbox axes 5 and 6 69 safety risks 34 wrist unit 69 operators manual, article number 181 p position, robot 166 when draining wrist unit 70 when filling oil in wrist unit 71 positive directio...

Page 215

Abb ab robotics products s-721 68 vÄsterÅs sweden telephone: +46 (0) 21 344000 telefax: +46 (0) 21 132592 3h a c 027 400 -00 1, r ev is ion c , en.