- DL manuals

- ABB

- Robotics

- IRB 260

- Product Manual

ABB IRB 260 Product Manual

Summary of IRB 260

Page 1

Abb robotics product manual irb 260

Page 2

Trace back information: workspace r13-1 version a6 checked in 2013-03-31 skribenta version 1184.

Page 3

Product manual irb 260 m2004 document id: 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved..

Page 4

The information in this manual is subject to change without notice and should not be construed as a commitment by abb. Abb assumes no responsibility for any errors that may appear in this manual. Except as may be expressly stated anywhere in this manual, nothing herein shall be construed as any kind...

Page 5: Table Of Contents

Table of contents 9 overview of this manual ................................................................................................................... 12 product documentation, m2004 ....................................................................................................... 14 h...

Page 6

92 2.5 electrical connections ........................................................................................ 92 2.5.1 connectors on robot ................................................................................ 93 2.5.2 robot cabling and connection points .............................

Page 7

215 6 decommissioning 215 6.1 environmental information .................................................................................. 217 7 reference information 217 7.1 introduction ...................................................................................................... 218 7.2 a...

Page 8

This page is intentionally left blank.

Page 9: Overview Of This Manual

Overview of this manual about this manual this manual contains instructions for: • mechanical and electrical installation of the robot • maintenance of the robot • mechanical and electrical repair of the robot. The manual also contains reference information for all procedures detailed in the manual....

Page 10

Contents chapter useful information when performing installation, maintenance or repair work. Includes lists of necessary tools, additional documents, safety standards, etc. Reference information complete spare part list and complete list of robot components, shown in the exploded views. Spare parts...

Page 11

Description revision this revision includes the following updates: • a new block, about general illustrations, added in section how to read the product manual on page 14 . • added a km10 socket to the list of required equipment and the instructions when replacing the lower rod, see section replacing...

Page 12

Product documentation, m2004 categories for manipulator documentation the manipulator documentation is divided into a number of categories. This listing is based on the type of information in the documents, regardless of whether the products are standard or optional. All documents listed can be orde...

Page 13

An application manual generally contains information about: • the purpose of the application (what it does and when it is useful). • what is included (for example cables, i/o boards, rapid instructions, system parameters, dvd with pc software). • how to install included or required hardware. • how t...

Page 14

How to read the product manual reading the procedures the procedures contain references to figures, tools, material, and so on. The references are read as described below. References to figures the procedures often include references to components or attachment points located on the manipulator/cont...

Page 15: 1 Safety

1 safety 1.1 introduction to safety information overview the safety information in this manual is divided into two categories: • general safety aspects, important to attend to before performing any service work on the robot. These are applicable for all service work and are found in general safety i...

Page 16

1.2 general safety information 1.2.1 introduction to general safety information definitions this section details general safety information for personnel performing installation, repair and maintenance work. Sections the general safety information is divided into the following sections. Containing c...

Page 17

1.2.2 safety in the manipulator system validity and responsibility the information does not cover how to design, install and operate a complete system, nor does it cover all peripheral equipment that can influence the safety of the entire system. To protect personnel, the complete system must be des...

Page 18

1.2.3 safety risks 1.2.3.1 safety risks during installation and service work on manipulators overview this section includes information on general safety risks to be considered when performing installation and service work on the manipulator. These safety instructions have to be read and followed by...

Page 19

• the axes are affected by the force of gravity when the brakes are released. In addition to the risk of being hit by moving manipulator parts, there is a risk of being crushed by the parallel arm (if there is one). • energy stored in the manipulator for the purpose of counterbalancing certain axes ...

Page 20

Cabling description safety risk caution the cable packs are sensitive to mechanical damage! They must be handled with care, especially the connectors, in order to avoid damaging them! Cable packs are sensitive to mechanical damage! Gearboxes and motors description safety risk caution whenever partin...

Page 21

1.2.3.2 caution - hot parts may cause burns! Description during normal operation, many manipulator parts become hot, especially the drive motors and gears. Sometimes areas around these parts also become hot. Touching these may cause burns of various severity. Because of a higher environment temperat...

Page 22

1.2.3.3 safety risks related to tools/work pieces safe handling it must be possible to safely turn off tools, such as milling cutters, etc. Make sure that guards remain closed until the cutters stop rotating. It should be possible to release parts by manual operation (valves). Safe design grippers/e...

Page 23

1.2.3.4 safety risks related to pneumatic/hydraulic systems general special safety regulations apply to pneumatic and hydraulic systems. Note all components that remain pressurized after separating the machine from the power supply must be provided with clearly visible drain facilities and a warning...

Page 24

1.2.3.5 safety risks during operational disturbances general • the industrial manipulator is a flexible tool that can be used in many different industrial applications. • all work must be carried out professionally and in accordance with the applicable safety regulations. • care must be taken at all...

Page 25

1.2.3.6 risks associated with live electric parts voltage related risks, general work on the electrical equipment of the manipulator must be performed by a qualified electrician in accordance with electrical regulations. • although troubleshooting may, on occasion, need to be carried out while the p...

Page 26

Voltage related risks, manipulator a danger of high voltage is associated with the manipulator in: • the power supply for the motors (up to 800 vdc). • the user connections for tools or other parts of the installation (max. 230 vac). See chapter installation and commissioning on page 53 . Voltage re...

Page 27

1.2.4 safety actions 1.2.4.1 safety fence dimensions general install a safety cell around the manipulator to ensure safe manipulator installation and operation. Dimensioning dimension the fence or enclosure to enable it to withstand the force created if the load being handled by the manipulator is d...

Page 28

1.2.4.2 fire extinguishing note use a carbon dioxide (co 2 ) extinguisher in the event of a fire in the manipulator system (manipulator or controller)! 28 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 1 safety 1.2.4.2 fire extinguishing.

Page 29

1.2.4.3 emergency release of the manipulator’s arm description in an emergency situation, any of the manipulator's axes may be released manually by pushing the brake release buttons on the manipulator. How to release the brakes is detailed in the section: • manually releasing the brakes on page 64 ....

Page 30

1.2.4.4 brake testing when to test during operation, the holding brake of each axis normally wears down. A test can be performed to determine whether the brake can still perform its function. How to test the function of the holding brake of each axis motor may be checked as described below: 1 run ea...

Page 31

1.2.4.5 risk of disabling function "reduced speed 250 mm/s" note do not change transm gear ratio or other kinematic system parameters from the flexpendant or a pc. This will affect the safety function "reduced speed 250 mm/s". 3hac026048-001 revision: e 31 © copyright 2006-2013 abb. All rights reser...

Page 32

1.2.4.6 safe use of the flexpendant enabling device the enabling device is a manually operated, constant pressure push-button which, when continuously activated in one position only, allows potentially hazardous functions but does not initiate them. In any other position, hazardous functions are sto...

Page 33

1.2.4.7 work inside the manipulator's working range warning if work must be carried out within the manipulator’s work area, the following points must be observed: • the operating mode selector on the controller must be in the manual mode position to render the enabling device operational and to bloc...

Page 34

1.2.5 safety stops 1.2.5.1 what is an emergency stop? Definition of emergency stop an emergency stop is a state that overrides any other manipulator control, disconnects drive power from the manipulator motors, stops all moving parts, and disconnects power from any potentially dangerous functions co...

Page 35

Classification of stops the safety standards that regulate automation and manipulator equipment define categories in which each type of stop applies: ... Then it is classified as... If the stop is... Category 0 (zero) uncontrolled category 1 controlled emergency stop devices in a manipulator system ...

Page 36

1.3 safety related instructions 1.3.1 safety signals in the manual introduction to safety signals this section specifies all dangers that can arise when doing the work described in this manual. Each danger consists of: • a caption specifying the danger level (danger, warning, or caution) and the typ...

Page 37

Significance designation symbol describes important facts and conditions. Note xx0100000004 describes where to find additional information or how to do an operation in an easier way. Tip xx0100000098 3hac026048-001 revision: e 37 © copyright 2006-2013 abb. All rights reserved. 1 safety 1.3.1 safety ...

Page 38

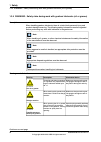

1.3.2 safety symbols on manipulator labels introduction to labels this section describes safety symbols used on labels (stickers) on the manipulator. Symbols are used in combinations on the labels, describing each specific warning. The descriptions in this section are generic, the labels can contain...

Page 39

Description symbol see user documentation xx0900000813 read user documentation for details. Which manual to read is defined by the symbol: • no text: product manual . • eps: application manual - electronic position switches . Before dismantling see product manual xx0900000816 do not dismantle xx0900...

Page 40

Description symbol crush xx0900000817 risk of crush injuries. Heat xx0900000818 risk of heat that can cause burns. Moving robot xx0900000819 the robot can move unexpectedly. Xx1000001141 brake release buttons xx0900000820 xx1000001140 continues on next page 40 3hac026048-001 revision: e © copyright ...

Page 41

Description symbol lifting bolt xx0900000821 chain sling with shortener xx1000001242 lifting of robot xx0900000822 oil xx0900000823 can be used in combination with prohibition if oil is not allowed. Mechanical stop xx0900000824 no mechanical stop xx1000001144 stored energy xx0900000825 warns that th...

Page 42

Description symbol pressure xx0900000826 warns that this part is pressurized. Usually contains additional text with the pressure level. Shut off with handle xx0900000827 use the power switch on the controller. 42 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 1 safety 1.3...

Page 43

1.3.3 danger - moving manipulators are potentially lethal! Description any moving manipulator is a potentially lethal machine. When running, the manipulator may perform unexpected and sometimes irrational movements. Moreover, all movements are performed with great force and may seriously injure any ...

Page 44

1.3.4 danger - first test run may cause injury or damage! Description since performing a service activity often requires disassembly of the robot, there are several safety risks to take into consideration before the first test run. Elimination follow the procedure below when performing the first tes...

Page 45

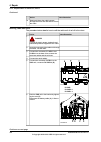

1.3.5 danger - make sure that the main power has been switched off! Description working with high voltage is potentially lethal. Persons subjected to high voltage may suffer cardiac arrest, burn injuries, or other severe injuries. To avoid these dangers, do not proceed working before eliminating the...

Page 46

Elimination, dual cabinet controller note/illustration action xx0600002783 switch off the main switch on the drive module. 1 k: main switch, drive module a: main switch, control module switch off the main switch on the control module. 2 46 3hac026048-001 revision: e © copyright 2006-2013 abb. All ri...

Page 47

1.3.6 warning - the unit is sensitive to esd! Description esd (electrostatic discharge) is the transfer of electrical static charge between two bodies at different potentials, either through direct contact or through an induced electrical field. When handling parts or their containers, personnel not...

Page 48

Panel mounted controller xx0600003249 panel mounted control module a panel mounted drive module b wrist strap button note! When not used, the wrist strap must always be attached to the wrist strap button. C 48 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 1 safety 1.3.6 ...

Page 49

1.3.7 warning - safety risks during handling of batteries description under normal conditions of use, the electrode materials and liquid electrolyte in the batteries are not exposed to the outside, provided the battery integrity is maintained and seals remain intact. There is a risk of exposure only...

Page 50

1.3.8 warning - safety risks during work with gearbox lubricants (oil or grease) description when handling gearbox lubricants, there is a risk of both personal injury and product damage occurring. The following safety information must be regarded before performing any work with lubricants in the gea...

Page 51

Elimination/action description warning make sure not to overfill the gearbox when filling it with oil or grease! Overfilling of gearbox lubricant can lead to internal over-pres- sure inside the gearbox which in turn may: • damage seals and gas- kets • completely press out seals and gaskets • prevent...

Page 52

This page is intentionally left blank.

Page 53

2 installation and commissioning 2.1 introduction general this chapter contains information for installing the irb 260 at the working site. More detailed technical data can be found in the product specification for the irb 260, such as: • load diagram • permitted extra loads (equipment) • location o...

Page 54

2.2 unpacking 2.2.1 pre-installation procedure introduction this section is intended for use when unpacking and installing the robot for the first time. It also contains information useful during later re-installation of the robot. Checking the pre-requisites for installation installation craftsmen ...

Page 55

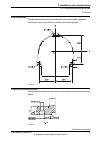

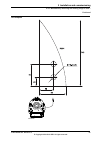

Loads on foundation, robot the illustration shows the directions of the robots stress forces. The directions are valid for all floor mounted and suspended robots. Xy xy z z t f f t xx1100000521 force in any direction in the xy plane f xy force in the z plane f z bending torque in any direction in th...

Page 56

Requirements, foundation the table shows the requirements for the foundation where the weight of the installed robot is included: note value requirement flat foundations give better repeatability of the resolver calibration compared to original settings on delivery from abb. 0.5 mm maximum deviation...

Page 57

2.2.2 working range working range this section specifies the working areas of the robot models. Irb 260 the extreme positions of the robot are specified at the tool flange center (dimensions in mm). Xx0500001926 position at mechanical stop a position at maximum working range, axis 2 b tool flange ce...

Page 58

Positions in the working range the table below specifies the positions inside the working range, shown in the figure above. Angles (º) position (mm) position in figure axis 3 axis 2 z x 0 0 1139 870 1 -17 -28 1246 510 2 31 -28 722 446 3 119 60 218 515 4 119 85 -73 607 5 26 85 210 1506 6 -17 42 1148 ...

Page 59

2.2.3 risk of tipping/stability risk of tipping if the robot is not fastened to the foundation and standing still, the robot is not stable in the whole working area. Moving the arms will displace the center of gravity, which may cause the robot to tip over. The shipping position is the most stable p...

Page 60

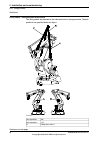

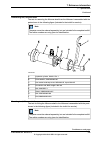

2.3 on-site installation 2.3.1 lifting of robot methods for lifting the robot can be lifted with: • lifting slings, or • lifting chains. Required equipment specification equipment lifting capacity: 500 kg. Overhead crane - lifting slings lengths: • axis 2: 950 mm • axis 3: 920 mm • upper arm: 680 mm...

Page 61

Liftings slings - attachment and axis position the lifting slings are attached to the robot as shown in the figure below. The axis positions are specified below the figure. Xx0500002140 -10º axis 2 po- sition: +35º axis 3 po- sition: continues on next page 3hac026048-001 revision: e 61 © copyright 2...

Page 62

Lifting chains - attachment and axis position the lifting chains are attached to the robot as shown in the figure below. The axis positions are specified below the figure. Xx0500002141 -28º axis 2 position: +17º axis 3 position: lifting chain, axis 2 a continues on next page 62 3hac026048-001 revisi...

Page 63

Lifting chain, axis 3 b lifting chain, upper arm c lifting of robot the procedure below details how to lift the complete robot. Note action depending on the method of lifting, the correct axis positions are shown in: • liftings slings - attachment and axis position on page 61 • lifting chains - atta...

Page 64

2.3.2 manually releasing the brakes general the holding brakes of each axis’ motor are of an electromechanical type and are released when voltage is applied. This section details how to release the brakes, using the internal brake release unit, in order to enable the axes to move manually. The brake...

Page 65

Note/illustration action xx0200000167 connect an external power supply to connector r1.Mp, at the robot base. Supply: • +24 v on pin b8 • 0 v on pin c10 2 release the brakes with the brake release unit as detailed in the previous procedure. 3 3hac026048-001 revision: e 65 © copyright 2006-2013 abb. ...

Page 66

2.3.3 orienting and securing the robot general this section details how to orient and secure the robot to the foundation in order to safely run the robot. The requirements for the foundations are shown in the tables and figures below. Bolting requirements when bolting a base plate or the base to a c...

Page 67

Hole configuration the figure below shows the hole configuration of the robot base, used when securing the robot. Cross section is shown in the following figure. Xx0200000181 cross section, guide sleeve hole the figure below shows the cross section of the guide sleeve holes (from previous figure): x...

Page 68

Guide sleeves two guide sleeves can be fitted to the two rear bolt holes to allow the same robot to be remounted without re-adjusting the program. Art. No. Equipment 2151 0024-169 guide sleeves 68 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 2 installation and commissio...

Page 69

2.3.4 fitting equipment on the robot and robot dimensions general this section shows the dimensions and available mounting holes on the robot. Main dimensions xx0500001928 at maximum working range axis 3 a mounting hole for safety lamp b mounting hole for external air hose c continues on next page 3...

Page 70

Fitting equipment on the robot xx0500002102 m8 (3x) depth 16 mm, r=77 a m8 (3x) depth 16 mm, r=92 b max. 35 kg total c the rear side of the robot d continues on next page 70 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 2 installation and commissioning 2.3.4 fitting equi...

Page 71

Turning radius, axis 2 xx0500001929 continues on next page 3hac026048-001 revision: e 71 © copyright 2006-2013 abb. All rights reserved. 2 installation and commissioning 2.3.4 fitting equipment on the robot and robot dimensions continued.

Page 72

Turning disk, dimensions the figure below shows the mounting holes available for fitting equipment on the turning disk. Xx0500001932 72 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 2 installation and commissioning 2.3.4 fitting equipment on the robot and robot dimension...

Page 73

2.3.5 loads general any loads mounted on the robot must be defined correctly and carefully (with regard to the position of center of gravity and mass moments of inertia) in order to avoid jolting movements and overloading motors, gears and structure. Caution incorrectly defined loads may result in o...

Page 74

2.3.6 load diagram load diagram, irb 260-30/1.5 the figure below shows the maximum permitted load mounted on the robot tool flange at different positions (center of gravity). Xx0500002100 74 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 2 installation and commissioning 2...

Page 75

2.3.7 installation of signal lamp (option) general as an option, a signal lamp can be installed on the robot. The lamp is activated when the controller is in the motors on state. Note do not use the signal lamp option in a clean rom environment. Signal lamp on robot the signal lamp is installed on t...

Page 76

Bracket e attachment screws, 2 pcs f cabling for the signal lamp (included in the robot cabling for axis 6) g required equipment note spare part no. Equipment includes all components shown in the previ- ous figure. 3hac025254-001 signal lamp the content is defined in the section standard tools on pa...

Page 77

2.4 restricting the working range 2.4.1 introduction general when installing the robot, make sure that it can move freely within its entire working space. If there is a risk that it may collide with other objects, its working space should be limited. The working range of the following axes may be re...

Page 78

2.4.2 mechanically restricting the working range of axis 1 restrictions in the working range the working range of axis 1 can be restricted within the area from 50º to 140º as shown in the figure below. The restrictions are made by fitting two extra stops to the robot base and adjusting the system pa...

Page 79

Location of the mechanical stop, axis 1 the extra mechanical stop is fitted to the robot base as shown in the figure below. Note! The stop must only be mounted in the direction shown below! Xx0200000205 stop, axis 1, removable 1 plain washer 2 hex socket head cap screw 3 required equipment note art....

Page 80

Note action place the template edge edge with the robot base, as shown in the figure location of where to drill holes for extra stops on page 81 . Use the template to mark the center of the two holes on each stop. 3 drill the holes through, Ø 10.2. Cut threads, m12. 4 note! The stops must be mounted...

Page 81

Location of where to drill holes for extra stops the figure below shows the drill pattern used when drilling for mechanical stops on axis 1. Xx0200000206 maximum working range, axis 1 a minimum working range, axis 1 b drilling pattern enclosed with the mechanical stop. C this mounting direction only...

Page 82

Hidden stiffening ribs and forbidden drilling sector xx0600002647 drilling not allowed inside this sector! C center lines for the hidden stiffening ribs d continues on next page 82 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 2 installation and commissioning 2.4.2 mecha...

Page 83

Drill template xx0200000207 3hac026048-001 revision: e 83 © copyright 2006-2013 abb. All rights reserved. 2 installation and commissioning 2.4.2 mechanically restricting the working range of axis 1 continued.

Page 84

2.4.3 installation of position switch, axis 1 general this section details how to install the position switch to axis 1. Location of position switch, axis 1 the position switch is installed between the frame and the base, as shown in the figure below. Xx0600002676 position switch a attachment screws...

Page 85

Cam e attachment screws, cam, (8 pcs for each cam) m6 x 12 f attachment plate g attachment screws, attachment plate (2 pcs) m6 x 16 h shims i bracket k attachment screws, bracket (2 pcs) m6 x 30 l mechanical stop m cable straps n attachment screw, clamp o clamp p required equipment all parts are inc...

Page 86

Note action 2 pcs, m6 x 16. Fit the attachment plate to the base of the robot with the two attachment screws. 6 shown in the figure location of position switch, axis 1 on page 84 . Fit the switches to the attachment plate. Adjust the height of the switches with shims until each roller aligns with co...

Page 87

2.4.4 mechanically restricting the working range of axis 2 general the stops are installed as standard, not movable and must always be installed during operation of the robot! Restrictions in working range the mechanical stops are not movable or optional! They function as solid stops and must be ins...

Page 88

Installation, mechanical stops axis 2 the procedure below details how to fit the mechanical stops to the axis 2. Note action shown in section calibration scale and correct axis position on page 209 . Move the robot to its calibration position. 1 danger turn off all electric power, hydraulic and pneu...

Page 89

Note action the system parameters that must be changed ( upper joint bound and lower joint bound ) are described in technical reference manual - system parameters . Adjust the software working range limita- tions (system parameter configuration) to correspond to the mechanical limita- tions. 6 warni...

Page 90

2.4.5 mechanically restricting the working range of axis 3 general the stop of axis 3 is installed as standard, not movable and must always be installed during operation of robot! Restrictions in working range the mechanical stop is not movable or optional! It functions as a solid stop and must be i...

Page 91

Installation, mechanical stop the procedure below details how to fit the mechanical stop to the robot. Note action danger turn off all electric power, hydraulic and pneumatic pressure supplies to the robot! 1 shown in the figure location of mechan- ical stop on page 90 . Fit the mechanical stop to t...

Page 92

2.5 electrical connections 2.5.1 connectors on robot connectors on the robot the figure below shows all connections of the robot cabling, including the customer connections. Xx0500002434 92 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 2 installation and commissioning 2....

Page 93

2.5.2 robot cabling and connection points introduction connect the robot and controller to each other after securing them to the foundation. The lists below specify which cables to use for each respective application. Main cable categories all cables between the robot and controller are divided into...

Page 94

Art. No. Cable 3hac7998-4 robot cable signal, shielded: 30 m position switch cables, robot base to controller (option) these cables are not included in the standard delivery, but are included in the delivery if the position switch option is ordered. The position switches can also be ordered without ...

Page 95: 3 Maintenance

3 maintenance 3.1 introduction structure of this chapter this chapter describes all the maintenance activities recommended for the irb 260. It is based on the maintenance schedule found at the beginning of the chapter. The schedule contains information about required maintenance activities including...

Page 96

3.2 maintenance schedule 3.2.1 specification of maintenance intervals introduction the intervals are specified in different ways depending on the type of maintenance activity to be carried out and the working conditions of the irb 260: • calendar time: specified in months regardless of whether the s...

Page 97

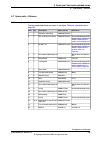

3.2.2 maintenance schedule general the robot must be maintained regularly to ensure proper function. The maintenance activities and intervals are specified in the table below. Non-predictable situations also give rise to inspections of the robot. Any damages must be attended to immediately! The insp...

Page 98

3.3 inspection activities 3.3.1 inspection of information labels location of labels the labels are located on the robot as shown in the figure below. Xx0600002622 instruction plate. Specified further in the following table. A, b rating label (silver coloured) c calibration label. Specified further i...

Page 99

Note spare part no. Equipment item f in the figure. 3hac1589-1 warning sign lightning flash. Inspection, labels note action danger turn off all electric power, hydraulic and pneumatic pressure supplies to the robot! 1 shown in the figure location of labels on page 98 . Inspect that all labels are fi...

Page 100

3.4 changing activities 3.4.1 type of lubrication in gearboxes introduction this section describes where to find information about the type of lubrication , article number and the amount of lubrication in the specific gearbox. It also describes the equipment needed when working with lubrication. Loc...

Page 101

Type and amount of oil in gearboxes information about the type of lubrication , article number as well as the amount in the specific gearbox can be found in technical reference manual - lubrication in gearboxes . Document number is presented in references on page 10 . In order to always get the late...

Page 102

3.4.2 oil change, gearbox axis 6 (wrist unit) location of oil plugs, gearbox the gearbox is located in the frontmost part of the upper arm. Oil plugs are located as shown in the figure below. Xx0500001949 oil plug, draining a oil plug, filling b required equipment note equipment information about th...

Page 103

Note action warning handling gearbox oil involves several safety risks. Before proceeding, please read the safety information in the section warning - safety risks during work with gearbox lubricants (oil or grease) on page 50 . 2 place the oil collecting vessel underneath the gearbox of axis 6. 3 s...

Page 104

3.4.3 replacement of smb battery note the battery low alert (38213 battery charge low ) is displayed when the battery needs to be replaced. The recommendation to avoid an unsynchronized robot is to keep the power to the controller turned on until the battery is to be replaced. For an smb board with ...

Page 105

Location of smb battery unit the smb battery unit is located inside the robot base, as shown in the figure below. Xx0300000067 smb battery (2-pole battery contact) a smb battery cable b continues on next page 3hac026048-001 revision: e 105 © copyright 2006-2013 abb. All rights reserved. 3 maintenanc...

Page 106

A b c xx1300000288 smb battery cable a cable strap b smb battery rmu (3-pole battery contact) c required equipment note there are two variants of smb units and batteries. One with 2-pole battery contact and one with 3-pole battery contact. The variant with the 3-pole battery contact has longer lifet...

Page 107

Note spare part no. Equipment rmu 3hac044075-001 battery pack (3-pole battery contact) lithium battery. Can only be used with smb unit 3hac046277-001 containing smb board 3hac044168-001. Always replace with a new one! 3hac3200-1 gasket, cover the content is defined in the section standard tools on p...

Page 108

3.5 cleaning activities 3.5.1 cleaning, robot warning turn off all electrical power supplies to the manipulator before entering its work space. General to secure high uptime it is important that the robot is cleaned regularly. The frequency of cleaning depends on the environment in which the robot w...

Page 109

Cables movable cables need to be able to move freely: • remove waste material, such as sand, dust and chips, if it prevents cable movement. • clean the cables if they have a crusty surface, for example from dry release agents. Dos and don'ts! The section below specifies some special considerations w...

Page 110

This page is intentionally left blank.

Page 111: 4 Repair

4 repair 4.1 introduction structure of this chapter this chapter describes all repair activities recommended for the irb 260 and any external unit. It is made up of separate procedures, each describing a specific repair activity. Each procedure contains all the information required to perform the ac...

Page 112

4.2 general procedures 4.2.1 performing a leak-down test general after refitting any motor and gearbox, the integrity of all seals enclosing the gearbox oil must be tested. This is done in a leak-down test. Required equipment note art. No. Equipment, etc. 3hac0207-1 leakdown tester - leak detection ...

Page 113

4.2.2 mounting instructions for bearings general this section describes how to mount and grease different types of bearings on the robot. Equipment note art. No. Equipment, etc. Used to grease the bearings, if not specified otherwise. 3hab3537-1 grease assembly of all bearings follow the following i...

Page 114

• ensure that grease is handled and stored properly to avoid contamination. Grease the different types of bearings as following description: • grooved ball bearings must be filled with grease from both sides. • tapered roller bearings and axial needle bearings must be greased in the split condition....

Page 115

4.2.3 mounting instructions for seals general this section describes how to mount different types of seals onto the robot. Equipment note art. No. Equipment, etc. Used to lubricate the seals. 3hab3537-1 grease rotating seals the procedure below describes how to fit rotating seals. Caution please obs...

Page 116

Flange seals and static seals the following procedure describes how to fit flange seals and static seals. Action check the flange surfaces. They must be even and free from pores. 1 it is easy to check flatness using a gauge on the fastened joint (without sealing com- pound). If the flange surfaces a...

Page 117

4.3 complete robot 4.3.1 replacement of cable unit, axes 1-3 location of cabling the cable unit of axes 1-3 is run from the base of the robot to the motors, axes 1, 2 and 3, as shown in the figure below. A more detailed view of the component and its position may be found in section axes 1-3, spare p...

Page 118

Note art. No. Spare part no. Equipment, etc. Sealing in the base for the cables. Always use a new sealing. 3hac4113-1 sealing 3hac3200-1 gasket, cover 2166 2055-3 cable straps, outdoor loctite 574 12340011-116 flange sealing see the chapter circuit dia- gram on page 261 . Circuit diagram the content...

Page 119

Note/illustration action xx0200000398 loosen the nuts (d) and remove the smb unit carefully from the bracket. The cable (a) between the battery (b) and the smb unit (c) may stay connected, in order to avoid recalibration of the robot. Be careful not to let the weight of the smb unit strain the cable...

Page 120

Note/illustration action xx0200000401 disconnect all the connectors at the motors of axes 1, 2 and 3. 12 r3.Mp1-3 r3.Fb1-3 connection box remove the three screws of the connection box for the motors of axes 1, 2 and 3. 13 gently pull the cable harness out. 14 refitting, cable unit, axes 1-3 the proc...

Page 121

Note/illustration action xx0200000404 fit the cable guide to the harness and secure the holder to the frame with its two attach- ment screws (a). 7 note! Different robot versions are fitted with different versions of the holder. Make sure the correct one is used to avoid cable failure. Xx0200000402 ...

Page 122

Note/illustration action xx0200000398 refit the smb unit to the bracket with the nuts (d). Be careful not to let the weight of the smb-unit strain the cable! (a). 10 note! The cable (a) between the battery (b) and the smb-unit (c) may stay con- nected, in order to avoid recalibration of the robot. X...

Page 123

4.3.2 replacement of cable unit, axis 6 location of cable unit, axis 6 the cabling of axis 6 is run throughout the robot, from the base to the wrist unit. Besides the power and signal cable, the cable unit also includes a customer cable, an ul lamp cable and an air hose. Xx0500002540 cable bracket i...

Page 124

Customer cable 3 air hose 4 required equipment note spare part no. Equipment 3hac024115-001 cable unit axis 6 the content is defined in the section standard tools on page 225 . - standard toolkit see the chapter circuit diagram on page 261 . - circuit diagram removal, cable unit axis 6 the procedure...

Page 125

Note/illustration action xx0200000398 loosen the nuts (d) and remove the smb- unit from the bracket carefully. Leaving the cable (a) between the battery (b) and the smb-unit (c) connected avoids recalibration of the robot. But be careful not to let the weight of the smb-unit strain the cable! In ord...

Page 126

Note/illustration action gently pull down the cable harness through the lower arm and remove it from the robot. 12 refitting, cable unit axis 6 the procedure below details how to refit the cable unit of axis 6 to the robot. Note/illustration action danger turn off all electric power, hydraulic and p...

Page 127

Note/illustration action shown in the figure location of cable unit, axis 6 on page 123 . Secure the cable bracket inside the base . 7 shown in the figure location of cable unit, axis 6 on page 123 . Insert the cabling through the cable guide in the middle of the frame and secure the guide with the ...

Page 128

4.4 upper arm 4.4.1 replacement of shaft and bearings, tilthouse location of shaft and bearings the tilthouse is located in the front part of the upper arm, linked to the upper arm with a shaft, as shown in the figure below. A more detailed view of the component and its position may be found in sect...

Page 129

Required equipment note art. No. Spare part no. Equipment 3hac024867-001 shaft 2 pcs. 3haa2103-14 taper roller bearing always replace with a new one! 3hab3701-25 sealing ring with dust lip always replace with a new one! 3hac7877-2 sealing ring 2 pcs. Always replace with a new one! 3haa2166-15 vk-cov...

Page 130

Xx0600002589 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c connection rod, m16, length= 400 mm d nut, 3hac5507-1 e sleeve, 3hac023963-027 f nut, 3hac023963-028 g pad, 3hac023963-029 j dismantling tool, bearing race, upper arm...

Page 131

Xx0600002656 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c nut, 3hac5507-1 e sleeve, 3hac023963-027 f nut, 3hac023963-028 g press sleeve, 3hac023963-038 h connection rod, 3hac025192-006 i dismantling tool, bearing race, tilth...

Page 132

Xx0600002657 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c connection rod, m16, length= 400 mm d nut, 3hac5507-1 e nut, 3hac023963-028 g sleeve, 3hac023963-037 m mounting tool, tilthouse shaft the tool for fitting the tilthou...

Page 133

Xx0500002581 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c connection rod, m16, length= 400 mm d nut, 3hac5507-1 e pad, 3hac023963-029 j press washer, 3hac023963-014 k mounting tool, bearing race and sealing, upper arm the to...

Page 134

Xx0500002582 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c nut, 3hac5507-1 e connection rod, 3hac025192-006 i press head, 3hac023963-039 l press sleeve, 3hac023963-015 n mounting tool, bearing race, tilthouse shaft the tool f...

Page 135

Xx0600002658 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c connection rod, m16, length= 400 mm d nut, 3hac5507-1 e nut, 3hac023963-028 g sleeve, 3hac023963-037 h removal, shaft and bearings the procedure below details how to ...

Page 136

Note/illustration action xx0600002590 insert the dismantling tool, tilthouse shaft through the shaft. Fit the nut (a) to the end of the bar and use the pad (b) when pulling out the shaft. 6 art. No. Is specified in required equipment on page 129 . Connect the hydraulic pump to the cylinder and pull ...

Page 137

Note/illustration action art. No. For the toolkit is specified in required equipment on page 129 . Gather the required parts to assemble a mounting tool for the bearing race and sealings from the toolkit for service . 3 the assembly of the tool is shown in the figure mounting tool, bearing race and ...

Page 138

Note/illustration action xx0500002584 insert the bar (a) through the shaft and secure with press washer (b). 14 shown in the figure mounting tool, tilthouse shaft on page 132 . If not already fitted, fit the press washer to the hydraulic cylinder with the two m6 bolts . 15 thread the remaining beari...

Page 139

Note/illustration action detailed in section refitting, upper rod on page 152 . Refit the upper parallel rod. 23 calibration is detailed in a separate calibration manual enclosed with the calibration tools. Recalibrate the robot. 24 general calibration information is in- cluded in the section calibr...

Page 140

4.4.2 replacement of turning disk location of turning disk the turning disk is located at the frontmost part of the robot, as shown in the figure below. A more detailed view of the component and its position may be found in section tilthouse, exploded view on page 256 in part 2 of the product manual...

Page 141

Note art. No. Spare part no. Equipment these procedures include references to the tools re- quired. Other tools and proced- ures may be required. See references to these procedures in the step- by-step instructions be- low. Removal, turning disk the procedure below details how to remove the turning ...

Page 142

Note action danger make sure all safety requirements are met when performing the first test run. These are further detailed in the section danger - first test run may cause injury or damage! On page 44 . 8 142 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 4 repair 4.4.2 ...

Page 143

4.4.3 replacement of complete upper arm location of upper arm the upper arm is located as shown in the figure below. A more detailed view of the component and its position may be found in section robot irb 260, exploded view 1 of 2 on page 242 in part 2 of the product manual. Xx0600002601 upper arm ...

Page 144

Note art. No. Spare part no. Equipment 2 pcs. 3hac12165-2 vk-cover for lubrication of mounting surfaces. 3hab3537-1 grease loctite 243 - locking liquid for lifting the upper arm. - lifting straps 3 pcs required. Length: 62 mm. Diameter: 6 mm. Thread: m6x12. Used for guiding the shaft end of the uppe...

Page 145

Note/illustration action detailed in section removal, parallel bar on page 167 . Remove the parallel bar. 4 caution the complete upper arm weighs 23 kg without any additional equipment fitted! Use a suitable lifting device to avoid injury to personnel! 5 xx0500002549 fit the lifting equipment to the...

Page 146

Note/illustration action note! The tilthouse is movable, be careful not to damage it! Make sure the cabling lies freely inside the upper arm. Then lift the upper arm while feeding the cabling from inside the arm. 14 refitting, upper arm the procedure below details how to refit the upper arm to the r...

Page 147

Note/illustration action xx0600002603 secure the upper arm to the lower arm by fastening the shaft end (a) with the attachment screw and washer (b), as shown in the figure to the right. 7 shaft end 1 pc, m12 x 60, (unbrako 12.9) and washer. Tightening torque: 90 nm. Reused screws may be used, provid...

Page 148

Note/illustration action specified in required equipment on page 143 . Return to the other side of the upper arm and prepare the lock nut by lubricating it with locking liquid . 13 xx0600002606 fit the tapered roller bearing and the lock nut (flat side outwards) to the shaft end. 14 tapered roller b...

Page 149

Note/illustration action cable run, connectors and brackets are shown in the figure location of cable unit, axis 6 on page 123 . Run the cable unit inside the upper arm. Re- connect all connectors and refit all brackets. 20 the refitting is further detailed in sec- tion refitting, cable unit axis 6 ...

Page 150

4.4.4 replacement of linkage - upper rod overview the link system consists of three basic parts - upper rod, lower rod and link. These procedures describes how to remove and refit the upper rod. Location of upper rod the upper rod is located as shown in the figure below. Xx0600002615 upper rod a sea...

Page 151

Note art no. Spare part no. Equipment replace if damaged. 3hab6432-1 needle bearing replace if damaged. 3hab6279-1 support washer used to lubricate the bear- ings. 3hab3537-1 bearing grease loctite 243 3hab7116-1 locking liquid used for pressing new bear- ings into the rod, if replaced. 3hac023963-0...

Page 152

Refitting, upper rod the procedure below details how to refit the upper rod of the linkage. Note action spare part no. Is specified in required equipment on page 150 . If needed, replace the bearings in the rod. Use the press sleeve . Note the bearings are sensitive for pushes. Make sure they are no...

Page 153

4.4.5 replacing the linkage - lower rod overview the linkage consists of three basic parts - upper rod, lower rod and link. The procedures below details how to remove and refit the lower rod. How to replace the upper rod and link, see: • replacement of linkage - upper rod on page 150 . • replacement...

Page 154

Required equipment note art no. Equipment for spare part no. See: • spare part lists and exploded views on page 237 lower rod replace if damaged. For spare part no. See: • spare part lists and exploded views on page 237 needle bearing replace if damaged. For spare part no. See: • spare part lists an...

Page 155

Note action xx1000001252 if the upper rod is removed, secure the link with a roundsling in a crane. Use the hole in the middle of the link. 2 this is done in order to prevent the link from moving if both the upper rod and lower rod are removed. Shown in the figure location of lower rod on page 153 ....

Page 156

Refitting, lower rod use this procedure to refit the lower rod of the linkage. Note action spare part no. Is specified in required equipment on page 154 . If needed, replace the bearings . Use a press sleeve . Note the bearings are sensitive for pushes. Make sure they are not damaged! 1 art. No. For...

Page 157

4.4.6 replacement of linkage - link overview the link system consists of three basic parts - upper rod, lower rod and link. The procedures below details how to remove and refit the link. Location of link the link is located at the upper arm as shown in the figure below. It is fitted to the same shaf...

Page 158

Required equipment note art. No. Spare part no. Equipment replace if damaged! 2522 2101-17 protection hood replace if damaged! 3hac12165-2 vk-cover a tool for pressing the bearing and the link to the upper arm shaft is assembled from the loose parts in the kit. 3hac023963- 026 toolkit for service th...

Page 159

Xx0600002618 hydraulic cylinder, 3hac11731-1 a nut, 3hac5507-1 e connecting rod, 3hac023081-003 o press housing, 3hac024097-002 p auxiliary shaft, 3hac024097-005 r screw, m6x12, 9ada183-24 (2 pcs) s distance, 3hac023062-001 t removal, link the procedure below details how to remove the link from the ...

Page 160

Note/illustration action shown in the figure location of link on page 157 . Use compressed air to remove the vk cover . Blow with a very low air pressure into the hole for filling grease. Note! A very low air pressure is needed! 5 put one hand with some paper on top of the vk cover in order to catch...

Page 161

Note/illustration action the assembly is shown in the press tool, link on page 158 . Gather the required parts to assemble a press tool for the link and bearing from the toolkit for service . 5 art. No. For the toolkit is specified in required equipment on page 158 . Fit the auxiliary shaft to the s...

Page 162

4.5 lower arm 4.5.1 replacement of complete lower arm location of lower arm the lower arm is located as shown in the figure below. A more detailed view of the component and its position may be found in section axes 1-3, spare part view 2 on page 247 in part 2 of the product manual. Xx0500002548 lowe...

Page 163

Attachment screw (12 pcs) c spring tension plate d required equipment note art. No. Spare part no. Equipment, etc. 3hac025729-001 lower arm replace if damaged. 3hab3732-13 sealing ring (v-ring) used to lubricate the sealing ring. 3hab3537-1 bearing grease - hoisting equipment the content is defined ...

Page 164

Note/illustration action xx0200000439 fit the lifting equipment to the lower arm to secure its weight. 4 detailed in section removal, parallel bar on page 167 . Remove the parallel bar. 5 detailed in section removal, parallel arm on page 179 . Remove the parallel arm. 6 pull down the cabling from in...

Page 165

Note action spare part no. Is specified in required equipment on page 163 . Make sure that the sealing ring is fitted prop- erly to the gearbox, undamaged and properly lubricated with grease . If damaged, replace with a new one. 3 shown in the figure location of lower arm on page 162 . Caution the r...

Page 166

4.5.2 replacement of parallel bar location of parallel bar the parallel bar is located as shown in the figure below. A more detailed view of the component and its position may be found in section axes 1-3, spare part view 1 on page 246 in part 2 of the product manual. Xx0500002552 parallel bar a att...

Page 167

Note art. No. Spare part no. Equipment, etc. One at each end of the bar. (item d in the figure loca- tion of parallel bar on page 166 .) 3hac10088-4 bearing sealing one at each end of the bar. (item e in the figure loca- tion of parallel bar on page 166 .) 3hac10089-2 bearing sealing loctite 243 3ha...

Page 168

Note action if the upper arm is also to be re- moved, secure the weight as shown in the figure below. Xx0500002549 use a crane to secure the weight of the upper arm. 3 shown in the figure location of parallel bar on page 166 . Remove the attachment screw from the upper and lower end. 4 shown in the ...

Page 169

Note action shown in the figure location of parallel bar on page 166 . Refit the locking washer. 7 m8 x 16. Refit the attachment screw at both ends of the bar, using locking liquid . 8 loctite 243 shown in the figure location of parallel bar on page 166 . Calibration is detailed in a separate calib-...

Page 170

4.6 frame and base 4.6.1 replacement of smb unit location of smb unit the smb unit (smb = serial measurement board) is located on the left hand side of the base, as shown in the figure below. A more detailed view of the component and its position may be found in section axes 1-3, spare part view 5 o...

Page 171

A b c xx1300000289 smb battery cable a smb battery rmu (3-pole battery contact) b smb unit rmu 101 c required equipment note there are different variants of smb units and batteries. The variant with the 3-pole battery contact has longer lifetime for the battery. It is important that the smb unit use...

Page 172

Note art. No. Spare part no. Equipment contains serial measure- ment board 3hac031851- 001 and battery pack 3hac16831-1. 3hac17396-1 serial measurement unit contains serial measure- ment board 3hac044168- 001 and battery pack 3hac044075-001. 3hac046277-001 serial measurement unit the content is defi...

Page 173

Smb unit, layout xx0600002645 connector r2.Smb4-6 a connector r2.Smb1-3 b connector r2.Smb1-2 (external axis) c connector r2.Smb d connector r2.G (battery unit) e continues on next page 3hac026048-001 revision: e 173 © copyright 2006-2013 abb. All rights reserved. 4 repair 4.6.1 replacement of smb u...

Page 174

A b c d e xx1300000310 connector r2.Smb4-6 a connector r2.Smb1-3 b connector r2.Smb1-2 (external axis) c connector r2.Smb d connector r2.G (battery unit) e replacement, smb unit the procedure below details how to replace the smb unit. Note action danger turn off all electric power, hydraulic and pne...

Page 175

Note action remove the smb cover by unscrewing its at- tachment screws. 4 pull the battery cable through the hole in the smb cover. Remove the two locknuts and washers from the pins securing the board. 5 all connectors are shown in the figure smb unit, layout on page 173 . Gently disconnect the conn...

Page 176

4.6.2 replacement of brake release unit location of brake release unit the brake release unit is located behind the flange plate at the robot base, as shown below. Xx0200000463 brake release unit with buttons a required equipment note spare part no. Equipment, etc. 3hac16035-1 bu w. Buttons dsqc 563...

Page 177

Action reconnect the cable to the new brake release unit and fit it to the base. 5 secure the unit with its six attachment screws on the outside of the base. 6 refit the cover to the rear of the base. 7 danger make sure all safety requirements are met when performing the first test run. These are fu...

Page 178

4.6.3 replacement of parallel arm location of parallel arm the parallel arm is located at the frame, as shown in the figure below. Xx0600002591 parallel arm a parallel bar b required equipment note art. No. Spare part no. Equipment includes: • groove ball bearing • sealing ring 3hac025727-001 parall...

Page 179

Note art. No. Spare part no. Equipment these procedures include references to the tools re- quired. Other tools and procedures may be required. See refer- ences to these procedures in the step-by-step instruc- tions below. Removal, parallel arm the procedure below details how to remove the parallel ...

Page 180

Assembly, parallel arm the figure below shows the assembly of the parallel arm. Xx0200000450 parallel arm a sealing v- ring (2 pcs) b groove ball bearing c attachment screws and washers (8 pcs) d refitting, parallel arm the procedure below details how to refit the complete parallel arm to the robot....

Page 181

Note action detailed in section refitting, parallel bar on page 168 . Refit the parallel bar. 3 calibration is detailed in a separate calibration manual enclosed with the calibration tools. Recalibrate the robot! 4 general calibration information is included in the section calibration information on...

Page 182

4.7 motors 4.7.1 replacement of motor, axis 1 location of motor, axis 1 the motor, axis 1, is located on the left hand side of the robot as shown in the figure below: a more detailed view of the component and its position may be found in section axes 1-3, spare part view 1 on page 246 . Xx0200000465...

Page 183

Required equipment note art. No. Spare part no. Equipment 3hac025712-001 motor unit, axes 1 and 3 always fit a new one! 3hab 3772-1 o-ring 3hab 3676-1 gasket 3hab7887-1 measuring tool, motor 24 vdc, max. 1.5 a. For releasing the brakes. - power supply the content is defined in the section special to...

Page 184

Note/illustration action xx0600002646 use a marker pen to mark the position of the motor (a), if the same motor is to be refitted. 5 shown in the figure location of motor, axis 1 on page 182 . Unscrew the four attachment screws and washers of the motor. 6 gently lift the motor straight up, making su...

Page 185

Note/illustration action the tip of the dial indicator must measure on a 50 mm radius from the center of the motor shaft. Xx0200000473 place the tip of a dial indicator against the scribed mark on the measuring tool. 9 measuring tool set the gear play to 0.02 mm, which corresponds to a reading on th...

Page 186

Note/illustration action danger make sure all safety requirements are met when performing the first test run. These are further detailed in the section danger - first test run may cause injury or damage! On page 44 . 18 186 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 4...

Page 187

4.7.2 replacement of motor, axis 2 location of motor, axis 2 the motor, axis 2, is located on the left hand side of the robot as shown in the figure below: xx0200000470 attachment screws, cover (5 pcs) a cover b connection box c gasket d motor, axis 2 e attachment screws, motor (4 pcs) f o-ring g co...

Page 188

Required equipment note art. No. Spare part no. Equipment, etc. 3hac025713-001 motor unit, axis 2 always fit a new one! 3hab3772-1 o-ring 3hab3676-1 gasket 3hab7887-1 measuring tool, motor 24 vdc, max. 1.5 a. For re- leasing the brakes. Power supply the content is defined in the section standard too...

Page 189

Note/illustration action secure the robot arms before un- screwing any of the attachment screws of the axis 2 motor. Xx0300000107 danger secure the weight of the lower arm properly before releasing the brakes of motor, axis 2! When releasing the holding brakes of the motor, the lower arm will be mov...

Page 190

Note/illustration action 4 pcs. Tightening torque: 2 nm. Fit the four attachment screws and tighten them slightly. Make the adjustments described below before tightening the screws properly. 5 connect to connector r3.Mp2: • +: pin 7 • -: pin 8 in order to release the brakes, connect the 24 vdc power...

Page 191

Note/illustration action xx0200000401 reconnect connectors r3.Mp2 and r3.Fb2. 17 • a: r3.Mp2 • b: r3.Fb2 • c: connection box shown in the figure location of mo- tor, axis 2 on page 187 . Refit the cover of the connection box. 18 calibration is detailed in a separate calibration manual enclosed with ...

Page 192

4.7.3 replacement of motor, axis 3 location of motor, axis 3 the motor, axis 3, is located on the right hand side of the robot, as shown in the figure below: a more detailed view of the component and its position may be found in section axes 1-3, spare part view 2 on page 247 . Xx0200000471 attachme...

Page 193

Required equipment note art. No. Spare part no. Equipment 3hac025712-001 motor unit, axes 1 and 3 3hab3676-1 gasket always fit a new one. 3hab3772-1 o-ring 3hab7887-1 measuring tool, motor 24 vdc, max. 1.5 a. For re- leasing the brakes. - power supply the content is defined in the section standard t...

Page 194

Note/illustration action secure the upper arm before loosening any of the screws on the motor! Xx0300000107 danger secure the weight of the upper arm properly be- fore releasing the brakes of motor, axis 3. When releasing the holding brakes of the motor, the upper arm will be movable and may fall do...

Page 195

Note/illustration action connect to connector r3.Mp3: • +: pin 7 • -: pin 8 in order to release the brakes, connect the 24 vdc power supply to the motor. 6 see the figure below. Fit the measuring tool to the rear of the motor. 7 art. No. Is specified in required equip- ment on page 193 . See the fig...

Page 196

Note/illustration action xx0200000401 reconnect the motor connectors r3.Mp3 and r3.Fb3. 17 • a: r3.Mp3 • b: r3.Fb3 • c: connection box shown in the figure location of motor, axis 3 on page 192 . Refit the cover of the connection box. 18 calibration is detailed in a separate calibration manual enclos...

Page 197

4.7.4 replacement of motor, axis 6 location of motor, axis 6 the motor, axis 6 is located in the tilthouse, as shown in the figure below. A more detailed view of the component and its position may be found in section tilthouse, exploded view on page 256 in part 2 of the product manual. Xx0500001940 ...

Page 198

Removal, motor, axis 6 the procedure below details how to remove the motor, axis 6 from the robot. Note action danger turn off all electric power, hydraulic and pneumatic pressure supplies to the robot! 1 disconnect the motor connectors r2.Mp6 and r2.Fb6. 2 connect to connector r3.Mp6: • +: pin 4 • ...

Page 199

Note action danger make sure all safety requirements are met when performing the first test run. These are further de- tailed in the section danger - first test run may cause injury or damage! On page 44 . 9 3hac026048-001 revision: e 199 © copyright 2006-2013 abb. All rights reserved. 4 repair 4.7....

Page 200

4.8 gearboxes 4.8.1 replacement of gearbox, axis 1-3 location of gearbox, axis 1-3 the axis 1 gearbox is located between the frame and base as shown in the figure below. Axis 1 gearbox is of the conventional type, manufactured with high precision. Together with the gearboxes for axes 2 and 3, it for...

Page 201

Removal, gearbox axis 1-3 the procedure below details how to remove the gearbox, axis 1-3. Note action danger turn off all electric power, hydraulic and pneumatic pressure supplies to the robot! 1 detailed in section removal, cable unit, axes 1-3 on page 118 . Remove the cable unit, axes 1-3. 2 deta...

Page 202

Note action refit the bottom plate to the base. 5 further detailed in section orienting and securing the robot on page 66 . Turn the base and gearbox unit around and se- cure to the installation site. 6 detailed in section refitting, motor axis 1 on page 184 . Refit the motor, axis 1. 7 detailed in ...

Page 203

4.8.2 replacement of gearbox, axis 6 location of gearbox, axis 6 the gearbox, axis 6, is located at the frontmost part of the robot, as shown in the figure below. Xx0500001939 gearbox, axis 6 a attachment screws, gearbox (8 pcs) b required equipment note art. No. Spare part no. Equipment 3hac025110-...

Page 204

Removal, gearbox, axis 6 the procedure below details how to remove the gearbox, axis 6 from the robot. Note action danger turn off all electric power, hydraulic and pneumat- ic pressure supplies to the robot! 1 detailed in section draining oil, gearbox axis 6 on page 102 . Drain the oil from the gea...

Page 205

Note action danger make sure all safety requirements are met when performing the first test run. These are further detailed in the section danger - first test run may cause injury or damage! On page 44 . 9 3hac026048-001 revision: e 205 © copyright 2006-2013 abb. All rights reserved. 4 repair 4.8.2 ...

Page 206

This page is intentionally left blank.

Page 207: 5 Calibration Information

5 calibration information 5.1 introduction general this chapter includes general information about the different calibration methods and also the detailed procedures that do not require specific calibration equipment. When the robot system must be recalibrated, it is done according to the documentat...

Page 208

5.2 calibration methods overview this section specifies the different types of calibration and the calibration methods that are supplied by abb. Types of calibration calibration method description type of calibration calibration pendulum (standard method) the calibrated robot is positioned at home p...

Page 209

5.3 calibration scale and correct axis position introduction this section specifies the calibration scale positions and/or correct axis position for all robot models. Calibration scales, irb 260 when axis 3 is put in calibration position, the mark on the calibration plate is visible above the mechan...

Page 210

5.4 calibration movement directions for all axes overview when calibrating, the axis must consistently be run towards the calibration position in the same direction in order to avoid position errors caused by backlash in gears and so on. Positive directions are shown in the graphic below. This is no...

Page 211

5.5 updating revolution counters introduction this section describes how to do a rough calibration of each manipulator axis, which is updating the revolution counter value for each axis using the flexpendant. Step 1 - manually running the manipulator to the calibration position use this procedure to...

Page 212

Action tap the mechanical unit in question. 2 a screen is displayed, tap rev. Counters . En0400000771 tap update revolution counters... . A dialog box is displayed warning that updating the revolution counters may change programmed manipulator positions: • tap yes to update the revolution counters. ...

Page 213

5.6 checking the calibration position introduction check the calibration position before beginning any programming of the robot system. This may be done: • using a moveabsj instruction with argument zero on all axes. • using the jogging window on the flexpendant. Using a moveabsj instruction use thi...

Page 214

This page is intentionally left blank.

Page 215: 6 Decommissioning

6 decommissioning 6.1 environmental information hazardous material the table specifies some of the materials in the product and their respective use throughout the product. Dispose components properly to prevent health or environmental hazards. Example application material serial measurement board b...

Page 216

This page is intentionally left blank.

Page 217: 7 Reference Information

7 reference information 7.1 introduction general this chapter includes general information, complementing the more specific information in the different procedures in the manual. 3hac026048-001 revision: e 217 © copyright 2006-2013 abb. All rights reserved. 7 reference information 7.1 introduction.

Page 218

7.2 applicable safety standards standards, en iso the manipulator system is designed in accordance with the requirements of: description standard safety of machinery - basic concepts, general principles for design - part 1: basic terminology, methodology en iso 12100 -1 safety of machinery - basic c...

Page 219

Description standard safety standard for robots and robotic equipment ansi/ul 1740 (option 429-1) industrial robots and robot systems - general safety require- ments can/csa z 434-03 (option 429-1) 3hac026048-001 revision: e 219 © copyright 2006-2013 abb. All rights reserved. 7 reference information...

Page 220

7.3 unit conversion converter table use the following table to convert units used in this manual. Units quantity 39.37 in 3.28 ft. 1 m length 2.21 lb. 1 kg weight 0.035 ounces 1 g weight 14.5 psi 100 kpa 1 bar pressure 0.225 lbf 1 n force 0.738 lbf-ft 1 nm moment 0.264 us gal 1 l volume 220 3hac0260...

Page 221

7.4 screw joints general this section describes how to tighten the various types of screw joints on the irb 260. The instructions and torque values are valid for screw joints comprised of metallic materials and do not apply to soft or brittle materials. Unbrako screws unbrako is a special type of sc...

Page 222

• always tighten the joint by hand, and never use pneumatic tools. • use the correct tightening technique , that is do not jerk. Tighten the screw in a slow, flowing motion. • maximum allowed total deviation from the specified value is 10% ! Oil-lubricated screws with slotted or cross-recess head sc...

Page 223

Tightening torque (nm) class 12.9, lubricated i tightening torque (nm) class 10.9, lubricated i dimension 950 790 m24 i lubricated with molycote 1000, gleitmo 603 or equivalent water and air connectors the following table specifies the recommended standard tightening torque for water and air connect...

Page 224

7.5 weight specifications definition in installation, repair, and maintenance procedures, weights of the components handled are sometimes specified. All components exceeding 22 kg (50 lbs) are highlighted in this way. To avoid injury, abb recommends the use of a lifting accessory when handling compo...

Page 225

7.6 standard tools general all service (repairs, maintenance, and installation) procedures contains lists of tools required to perform the specified activity. All special tools required are listed directly in the procedures while all the tools that are considered standard are gathered in the standar...

Page 226

7.7 special tools general all service instructions contain lists of tools required to perform the specified activity. The required tools are a sum of standard tools, defined in the section standard tools on page 225 , and of special tools, listed directly in the instructions and also gathered in thi...

Page 227

Note art. No. Description item d= 28 mm 3hac023963-028 nut g d= 48.8 mm 3hac023963-038 press sleeve h m16, length= 280 mm 3hac025192-006 connection rod i 3hac023963-029 pad j d= 70 mm 3hac023963-014 press washer k d= 55 mm 3hac023963-039 press head l d= 55 mm 3hac023963-037 sleeve m d= 70 mm 3hac023...

Page 228

Special tools, location of usage the toolkit for service includes loose parts that are assembled into different tools, depending on usage. The following figure shows some of the assembled tools and where to use them on the robot. The detailed assemblies are shown in separate figures, referred to in ...

Page 229

Dismantling tool, tilthouse shaft the tool for removing the tilthouse shaft from the tilthouse is assembled with the parts shown in the following figure (included in the toolkit for service). Note the parts cannot be ordered separately, but are included in the complete toolkit! The article numbers a...

Page 230

Xx0500002581 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c connection rod, m16, length= 400 mm d nut, 3hac5507-1 e pad, 3hac023963-029 j press washer, 3hac023963-014 k mounting tool, bearing race and sealing, upper arm the to...

Page 231

Xx0500002582 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c nut, 3hac5507-1 e connection rod, 3hac025192-006 i press head, 3hac023963-039 l press sleeve, 3hac023963-015 n dismantling tool, bearing race, upper arm the tool for ...

Page 232

Xx0600002656 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c nut, 3hac5507-1 e sleeve, 3hac023963-027 f nut, 3hac023963-028 g press sleeve, 3hac023963-038 h connection rod, 3hac025192-006 i dismantling tool, bearing race, tilth...

Page 233

Xx0600002657 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c connection rod, m16, length= 400 mm d nut, 3hac5507-1 e nut, 3hac023963-028 g sleeve, 3hac023963-037 m mounting tool, bearing race, tilthouse shaft the tool for fitti...

Page 234

Xx0600002658 hydraulic cylinder, 3hac11731-1 a press washer, 3hac023963-007 b hex socket head cap screw, 9ada183-25, 2 pcs, m6 x 25 c connection rod, m16, length= 400 mm d nut, 3hac5507-1 e nut, 3hac023963-028 g sleeve, 3hac023963-037 h press tool, link the tool for fitting the bearing and the link ...

Page 235

Xx0600002618 hydraulic cylinder, 3hac11731-1 a nut, 3hac5507-1 e connecting rod, 3hac023081-003 o press housing, 3hac024097-002 p auxiliary shaft, 3hac024097-005 r screw, m6x12, 9ada183-24 (2 pcs) s distance, 3hac023062-001 t calibration equipment, calibration pendulum the following table specifies ...

Page 236

7.8 lifting accessories and lifting instructions general many repair and maintenance activities require different pieces of lifting accessories, which are specified in each procedure. The use of each piece of lifting accessories is not detailed in the activity procedure, but in the instruction deliv...

Page 237

8 spare part lists and exploded views 8.1 introduction definitions this chapter specifies all spare parts and replacement articles of the robot. 3hac026048-001 revision: e 237 © copyright 2006-2013 abb. All rights reserved. 8 spare part lists and exploded views 8.1 introduction.

Page 238

8.2 spare parts - overview overview - spare parts the location of the different plates, labels and signs are shown in section inspection of information labels on page 98 . Note/ specified in section: spare part no. Description qty item spare parts - cover on page 239 - cover foundry 1 1 warning of b...

Page 239

8.3 spare parts - cover cover, spare part list the items specified below are shown in the figure cover, spare part view on page 240 . Dimension/note spare part no. Description qty item 9ada629-43 torx pan head roll. Screw 9 63 3hac8722-1 cover 2400 machined 1 104 3hac3200-1 gasket, cover 1 105 recom...

Page 240

Cover, spare part view xx0500002436 240 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 8 spare part lists and exploded views 8.3 spare parts - cover continued.

Page 241

8.4 spare parts - robot irb 260 robot irb 260, spare part list the items specified below are shown in the figures robot irb 260, exploded view 1 of 2 on page 242 and robot irb 260, exploded view 2 of 2 on page 243 . Note spare part no. Description qty item spare parts are shown in section spare part...

Page 242

Note spare part no. Description qty item 9ada312-6 plain washer 3 30 - flanged bolt 3 31 m6x20 steel 12.9 gleitmo 610 3hab3409-25 hex socket head cap screw 3 32 2522 2101-17 protection hood 1 33 2179 090-25 lifting eye 1 35 13x24x2,5 9ada312-9 plain washer 1 37 3hac10089-2 bearing sealing 1 38 robot...

Page 243

Robot irb 260, exploded view 2 of 2 xx0500001937 3hac026048-001 revision: e 243 © copyright 2006-2013 abb. All rights reserved. 8 spare part lists and exploded views 8.4 spare parts - robot irb 260 continued.

Page 244

8.5 spare parts - axes 1-3 axes 1-3, spare part list the items specified below are shown in the figures axes 1-3, spare part view 1 on page 246 and axes 1-3, spare part view 2 on page 247 . Dimension spare part no. Description qty item recommended spare part. 3hac025710-001 base foundry 1 1 recommen...

Page 245

Dimension spare part no. Description qty item loctite 243 - locking liquid 1 ml 43 3hab6687-1 stop, axis 1 1 46 6.1x20x2 21512082-150 washer 6 48 3hac0447-1 friction washer 1 49 3hab5522-1 calibration mark, axis 2 1 50 3hac025714-001 parallel bar complete 1 51 included in the complete parallel bar. ...

Page 246

Axes 1-3, spare part view 1 xx0500002047 continues on next page 246 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 8 spare part lists and exploded views 8.5 spare parts - axes 1-3 continued.

Page 247

Axes 1-3, spare part view 2 xx0500002065 axes 1-3, spare part list the items specified below are shown in the figures axes 1-3, spare part view 3 on page 250 , axes 1-3, spare part view 4 on page 251 and axes 1-3, spare part view 5 on page 252 . Dimension/note spare part no. Description qty item rec...

Page 248

Dimension/note spare part no. Description qty item contains serial measure- ment board 3hac031851- 001 and battery pack 3hac16831-1. 3hac17396-1 serial measurement unit 1 115 replacement is described in section replacement of smb unit on page 170 . Contains serial measure- ment board 3hac044168- 001...

Page 249

Dimension/note spare part no. Description qty item 25222101-8 protective hood 1 141 3hac4419-1 gasket 3 147 3hab7160-1 gasket 1 149 12340011-116 flange sealing 1 ml 150 11699198-301 adhesive tape 300 mm 151 3hab5921-1 bracket 1 152 3hac3785-3 parallel pin, hardened 1 156 3hac5479-4 sealing 1 161 186...

Page 250

Axes 1-3, spare part view 3 xx0500002084 continues on next page 250 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 8 spare part lists and exploded views 8.5 spare parts - axes 1-3 continued.

Page 251

Axes 1-3, spare part view 4 xx0500002085 the housing must be removed from the cabling for foundry option a conductors from r2.Bu, r2.Bu1-3, r2.Bu4-6 and pe conductors under strap b option: internal connectors c option: external connectors d continues on next page 3hac026048-001 revision: e 251 © cop...

Page 252

Axes 1-3, spare part view 5 xx0500002086 252 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 8 spare part lists and exploded views 8.5 spare parts - axes 1-3 continued.

Page 253

8.6 spare parts - upper arm upper arm, spare part list the items specified below are shown in the figure upper arm, exploded view on page 254 . Dimension spare part no. Description qty item spare parts are specified in section spare parts - tilt- house on page 255 . - tilthouse 1 1 recommended spare...

Page 254

Upper arm, exploded view xx0500001934 254 3hac026048-001 revision: e © copyright 2006-2013 abb. All rights reserved. 8 spare part lists and exploded views 8.6 spare parts - upper arm continued.

Page 255

8.7 spare parts - tilthouse tilthouse, spare part list the items specified below are shown in the figure tilthouse, exploded view on page 256 . Dimension spare part no. Description qty item 3hac025733-001 tilthouse, machining 1 1 recommended spare part. Replacement is detailed in section replacement...

Page 256