- DL manuals

- ABB

- Robotics

- IRB 360

- Product Manual

ABB IRB 360 Product Manual

Summary of IRB 360

Page 1

Product manual parallel robot irb 360 irb 360/3 irb 360/1 - 800 m2004.

Page 3

© copyri ght 200 8 abb . All ri ghts res erved. Product manual irb360 irb360/3 irb360/1 - 800 m2004 document id: 3hac030005-001 revision: -.

Page 4

© copyri ght 200 8 abb . All ri ghts res erved. The information in this manual is subject to change without notice and should not be construed as a commitment by abb. Abb assumes no responsibility for any errors that may appear in this manual. Except as may be expressly stated anywhere in this manua...

Page 5

Table of contents 3 3hac030005-001 revision: - © copyri ght 200 8 abb . All ri ghts res erved. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 product documentation, m2004 . . . . . ....

Page 6

Table of contents 4 3hac030005-001 revision: - © copyri ght 200 8 abb . All ri ghts res erved. 3.2 maintenance schedule and component life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 3.2.1 maintenance schedule irb 360 . . . . . . . . . . . . . . . . ....

Page 7

Table of contents 5 3hac030005-001 revision: - © copyri ght 200 8 abb . All ri ghts res erved. 5.3 calibration movement directions for all axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173 5.4 calibration scales and correct axis position . . . . . . . ...

Page 8

Table of contents 6 3hac030005-001 revision: - © copyri ght 200 8 abb . All ri ghts res erved..

Page 9

Overview 7 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Overview about this manual this manual contains instructions for: • mechanical and electrical installation of the robot • maintenance of the robot • mechanical and electrical repair of the robot. The manual also co...

Page 10

Overview 3hac030005-001 revision: - 8 © copyri ght 200 6 abb . All ri ghts res erved. References revisions reference information useful information when performing installation, maintenance or repair work. Includes lists of necessary tools, additional documents, safety standards etc. Spare part / pa...

Page 11

Product documentation, m2004 9 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Product documentation, m2004 general the robot documentation is divided into a number of categories. This listing is based on the type of information contained within the documents, regardless o...

Page 12

Product documentation, m2004 3hac030005-001 revision: - 10 © copyri ght 200 6 abb . All ri ghts res erved. Operating manuals this group of manuals is aimed at those having first hand operational contact with the robot, that is production cell operators, programmers and trouble shooters. The group of...

Page 13

How to read the product manual 11 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. How to read the product manual reading the procedures the procedures contain references to figures, tools, material etc. The references are read as described below. References to figures the ...

Page 14

How to read the product manual 3hac030005-001 revision: - 12 © copyri ght 200 6 abb . All ri ghts res erved..

Page 15: 1 Safety

1 safety 1.1. Introduction 13 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 1 safety 1.1. Introduction overview the safety information in this manual is divided in two categories: • general safety aspects, important to attend to before performing any service or installat...

Page 16

1 safety 1.2.1. Safety in the robot system 3hac030005-001 revision: - 14 © copyri ght 200 6 abb . All ri ghts res erved. 1.2 general safety information 1.2.1. Safety in the robot system validity and responsibility the information does not cover how to design, install and operate a complete system, n...

Page 17

1 safety 1.2.2.1. Safety risks during installation and service work on robot 15 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 1.2.2. Safety risks 1.2.2.1. Safety risks during installation and service work on robot overview this section includes information of general saf...

Page 18

1 safety 1.2.2.1. Safety risks during installation and service work on robot 3hac030005-001 revision: - 16 © copyri ght 200 6 abb . All ri ghts res erved. Complete robot cabling gearboxes and motors safety risk description hot components! Caution! Motors and gears are hot after running the robot! To...

Page 19

1 safety 1.2.2.2. Safety risks related to tools/workpieces 17 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 1.2.2.2. Safety risks related to tools/workpieces safe handling it must be possible to safely turn off tools, such as milling cutters, etc. Make sure that guards r...

Page 20

1 safety 1.2.2.3. Safety risks related to pneumatic/hydraulic systems 3hac030005-001 revision: - 18 © copyri ght 200 6 abb . All ri ghts res erved. 1.2.2.3. Safety risks related to pneumatic/hydraulic systems general special safety regulations apply to pneumatic and hydraulic systems. Residual energ...

Page 21

1 safety 1.2.2.4. Safety risks during operational disturbances 19 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 1.2.2.4. Safety risks during operational disturbances general • the industrial robot is a flexible tool which can be used in many different industrial applicat...

Page 22

1 safety 1.2.2.5. Risks associated with live electric parts 3hac030005-001 revision: - 20 © copyri ght 200 6 abb . All ri ghts res erved. 1.2.2.5. Risks associated with live electric parts voltage related risks, general • although troubleshooting may, on occasion, need to be carried out while the po...

Page 23

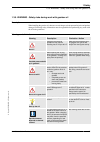

1 safety 1.3.1. Safety signals, general 21 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 1.3 safety related instructions 1.3.1. Safety signals, general general this section specifies all dangers that may arise from performing the work detailed in the manual. Each danger ...

Page 24

1 safety 1.3.1. Safety signals, general 3hac030005-001 revision: - 22 © copyri ght 200 6 abb . All ri ghts res erved. Electrostatic discharge (esd) electrostatic discharge (esd) the electrostatic discharge (esd) symbol indicates electrostatic hazards which could result in severe damage to the produc...

Page 25

1 safety 1.3.2. Danger - moving robots are potentially lethal! 23 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 1.3.2. Danger - moving robots are potentially lethal! Description any moving robot is a potentially lethal machine. When running the robot, it may perform unex...

Page 26

1 safety 1.3.3. Danger - first test run may cause injury or damage! 3hac030005-001 revision: - 24 © copyri ght 200 6 abb . All ri ghts res erved. 1.3.3. Danger - first test run may cause injury or damage! Description since performing a service activity often requires disassembly of the robot there a...

Page 27

1 safety 1.3.4. Warning - the unit is sensitive to esd! 25 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 1.3.4. Warning - the unit is sensitive to esd! Description esd (electrostatic discharge) is the transfer of electrical static charge between two bodies at different p...

Page 28

1 safety 1.3.4. Warning - the unit is sensitive to esd! 3hac030005-001 revision: - 26 © copyri ght 200 6 abb . All ri ghts res erved. Xx0500002171 a wrist strap button continued.

Page 29

1 safety 1.3.5. Warning - safety risks during work with gearbox oil 27 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 1.3.5. Warning - safety risks during work with gearbox oil description when handling the gearbox oil, there are several dangers to both personal injuries ...

Page 30

1 safety 1.3.5. Warning - safety risks during work with gearbox oil 3hac030005-001 revision: - 28 © copyri ght 200 6 abb . All ri ghts res erved..

Page 31

2 installation and commissioning 2.1. Introduction 29 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2 installation and commissioning 2.1. Introduction general this chapter contains information for installing the robot to the working site. More detailed technical data, su...

Page 32

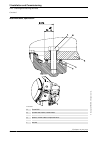

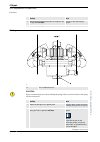

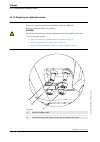

2 installation and commissioning 2.2. Structure manipulator 3hac030005-001 revision: - 30 © copyri ght 200 6 abb . All ri ghts res erved. 2.2. Structure manipulator manipulator structure the figure shows the manipulator structure and components. Xx0700000451 a upper arm axis 1 b upper arm axis 2 c u...

Page 33

2 installation and commissioning 2.3.1. Weight specifications 31 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2.3 unpacking 2.3.1. Weight specifications definition in installation, repair and maintenance procedures, weights of the components handled are sometimes specif...

Page 34

2 installation and commissioning 2.3.2. Transport 3hac030005-001 revision: - 32 © copyri ght 200 6 abb . All ri ghts res erved. 2.3.2. Transport general this section describes how to transport the manipulator. Note! The transport shall be made by qualified personnel and should conform to all nationa...

Page 35

2 installation and commissioning 2.3.3. Pre-installation procedure 33 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2.3.3. Pre-installation procedure general this instruction is primarily intended for use when unpacking and installing the robot for the first time. It als...

Page 36

2 installation and commissioning 2.3.3. Pre-installation procedure 3hac030005-001 revision: - 34 © copyri ght 200 6 abb . All ri ghts res erved. Loads on foundation the table below shows the various forces and torques working on the robot during different kinds of operation. Xx0700000586 force n max...

Page 37

2 installation and commissioning 2.3.3. Pre-installation procedure 35 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Requirements, foundation the subsections below show the requirements for the foundation regarding stiffness and forces. Stiffness the stiffness of the fram...

Page 38

2 installation and commissioning 2.3.4. Assemble the robot irb360 3hac030005-001 revision: - 36 © copyri ght 200 6 abb . All ri ghts res erved. 2.3.4. Assemble the robot irb360 overview follow these steps to assemble the robot after unpacking. Assemble action note 1. Prepare the working site accordi...

Page 39

2 installation and commissioning 2.3.4. Assemble the robot irb360 37 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Caution! Before mounting external equipment on the robot, first read the section fitting equipment on robot on page 53 . Assemble options to facilitate clea...

Page 40

2 installation and commissioning 2.3.5. Working range and type of motion 3hac030005-001 revision: - 38 © copyri ght 200 6 abb . All ri ghts res erved. 2.3.5. Working range and type of motion motion pattern xx0700000448 continues on next page.

Page 41

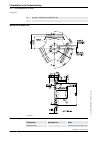

2 installation and commissioning 2.3.5. Working range and type of motion 39 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Working range xx0700000473 model/dimensions a mm Øb mm Øc mm d mm irb 360 250 1132 967 50 irb 360/800 200 800 continued.

Page 42

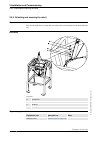

2 installation and commissioning 2.4.1. Lifting robot with fork lift 3hac030005-001 revision: - 40 © copyri ght 200 6 abb . All ri ghts res erved. 2.4 on-site installation 2.4.1. Lifting robot with fork lift warning! Never walk under a suspended load! Lifting robot xx0700000434 recommended equipment...

Page 43

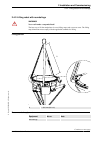

2 installation and commissioning 2.4.2. Lifting robot with roundslings 41 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2.4.2. Lifting robot with roundslings warning! Never walk under a suspended load! The best way to lift the manipulator is to use lifting straps and a t...

Page 44

2 installation and commissioning 2.4.2. Lifting robot with roundslings 3hac030005-001 revision: - 42 © copyri ght 200 6 abb . All ri ghts res erved. Lifting the robot with roundslings action note 1. Attach the roundslings to the robot base box see figure lifting position on page 41 caution! The irb ...

Page 45

2 installation and commissioning 2.4.3. Amount of required space 43 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2.4.3. Amount of required space required space the amount of space required to operate the manipulator is illustrated in figure xx0700000489 dimensions model...

Page 46

2 installation and commissioning 2.4.4. Orienting and securing the robot cage 3hac030005-001 revision: - 44 © copyri ght 200 6 abb . All ri ghts res erved. 2.4.4. Orienting and securing the robot cage general this section details how to orient and secure the robot cage at a horizontal level at the i...

Page 47

2 installation and commissioning 2.4.4. Orienting and securing the robot cage 45 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Orienting and securing shim drawing example of shim. Xx0700000623 chemical bolts or mechanical expanding bolts. Standard tools standard toolkit ...

Page 48

2 installation and commissioning 2.4.5. Orienting and securing the robot 3hac030005-001 revision: - 46 © copyri ght 200 6 abb . All ri ghts res erved. 2.4.5. Orienting and securing the robot general this section details how to orient and secure the robot at a horizontal level at the installation sit...

Page 49

2 installation and commissioning 2.4.5. Orienting and securing the robot 47 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Hole configuration, base xx0700000467 the three support points of the manipulator base box shall be mounted against three flat surfaces with a flatne...

Page 50

2 installation and commissioning 2.4.5. Orienting and securing the robot 3hac030005-001 revision: - 48 © copyri ght 200 6 abb . All ri ghts res erved. Attachment bolts, specification xx0700000522 a screw m12 b bonded seal washer, rubber/metal. C spacer, metal d washer, epdm-rubber compressed 50%. E ...

Page 51

2 installation and commissioning 2.4.5. Orienting and securing the robot 49 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Orienting and securing attachments dimensions attachment bolts, 3 pcs. M12x (50) (the length of the screws depends on the design of the frame). Bonde...

Page 52

2 installation and commissioning 2.4.6. Manually releasing the brakes 3hac030005-001 revision: - 50 © copyri ght 200 6 abb . All ri ghts res erved. 2.4.6. Manually releasing the brakes danger! Releasing the brakes is a hazardous action that may cause injury and damage property. It must be done with ...

Page 53

2 installation and commissioning 2.4.6. Manually releasing the brakes 51 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 3. Check the motors off button, make sure that the button twinkle. En0400000795 4. The internal brake release unit is located at the base of the robot. ...

Page 54

2 installation and commissioning 2.4.6. Manually releasing the brakes 3hac030005-001 revision: - 52 © copyri ght 200 6 abb . All ri ghts res erved. Using the brake release unit with an external power supply this section details how to release the holding brakes with the internal brake release unit u...

Page 55

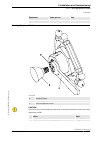

2 installation and commissioning 2.4.7. Fitting equipment on robot 53 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2.4.7. Fitting equipment on robot overview this section details how to fit equipment on the irb 360. Mechanical interface (std) xx0700000471 a free space, ...

Page 56

2 installation and commissioning 2.4.7. Fitting equipment on robot 3hac030005-001 revision: - 54 © copyri ght 200 6 abb . All ri ghts res erved. Mechanical interface (3d) xx0700000709 required equipment d key grip = width 22 mm height 5.5 mm e Ø25 h8 depth 6 equipment spare part no. Note standard to...

Page 57

2 installation and commissioning 2.4.7. Fitting equipment on robot 55 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Mounting equipment r1/4” xx0700000490 caution! Never drill a hole in the manipulator without first consulting maintenance staff or the design department at...

Page 58

2 installation and commissioning 2.4.7. Fitting equipment on robot 3hac030005-001 revision: - 56 © copyri ght 200 6 abb . All ri ghts res erved. Mounting equipment flange xx0700000523 2. Caution! Always use an open-end spanner 22 m or similar on the mounting flange, when tightening. 3. Note! If axia...

Page 59

2 installation and commissioning 2.4.7. Fitting equipment on robot 57 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Attachment screws 2. Caution! Always use an open-end spanner 22 mm or similar on the mounting flange, when tightening. Action note attachments note suitabl...

Page 60

2 installation and commissioning 2.4.8. Loads 3hac030005-001 revision: - 58 © copyri ght 200 6 abb . All ri ghts res erved. 2.4.8. Loads general this section describes loads from external equipment, for information about general loads and diagrams see: product specification parallel robot 3hac029963...

Page 61

2 installation and commissioning 2.5.1. Installation of (optional) safety lamp 59 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2.5 installation of options 2.5.1. Installation of (optional) safety lamp general this section details installation of safety lamp. Danger! Tur...

Page 62

2 installation and commissioning 2.5.1. Installation of (optional) safety lamp 3hac030005-001 revision: - 60 © copyri ght 200 6 abb . All ri ghts res erved. Installation xx0700000577 references replacement of base cover gasket on page 116 standard toolkit on page 196 a safety lamp connectors r3.H1an...

Page 63

2 installation and commissioning 2.5.2. Installation of (optional) customer connections irb 360 61 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2.5.2. Installation of (optional) customer connections irb 360 general this section details installation of customer connectio...

Page 64

2 installation and commissioning 2.5.2. Installation of (optional) customer connections irb 360 3hac030005-001 revision: - 62 © copyri ght 200 6 abb . All ri ghts res erved. Connections in customer cable connection point a connection point b wire spec. Des- igna- tion. Term. Type des- igna- tion. Te...

Page 65

2 installation and commissioning 2.5.2. Installation of (optional) customer connections irb 360 63 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 1. Dual press both shields, and connect them to earth. 2. Use green/yellow shrinking hose on free conductors, in both ends. In...

Page 66

2 installation and commissioning 2.5.3. Installation of vacuum system (optional) 3hac030005-001 revision: - 64 © copyri ght 200 6 abb . All ri ghts res erved. 2.5.3. Installation of vacuum system (optional) general this section describes installation of (optional) vacuum system on a irb 360. Danger!...

Page 67

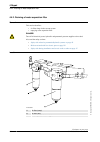

2 installation and commissioning 2.5.3. Installation of vacuum system (optional) 65 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Mechanical installation ejector xx0700000545 a attachment b bracket c hexagon head screw, m8x35 (steel 8.8-a2f) d ejector unit e hexagon bolt...

Page 68

2 installation and commissioning 2.5.3. Installation of vacuum system (optional) 3hac030005-001 revision: - 66 © copyri ght 200 6 abb . All ri ghts res erved. Installation of hoses xx0700000710 electrical installation action note 1. Follow the refitting instructions in section replacement of vacuum ...

Page 69

2 installation and commissioning 2.6.1. Connections 67 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2.6 electrical connections 2.6.1. Connections general this section details connections between manipulator and controller. For information about controller connections se...

Page 70

2 installation and commissioning 2.6.2. Connecting the controller to the manipulator 3hac030005-001 revision: - 68 © copyri ght 200 6 abb . All ri ghts res erved. 2.6.2. Connecting the controller to the manipulator overview two cables are used to connect the controller to the manipulator, one for me...

Page 71

2 installation and commissioning 2.6.2. Connecting the controller to the manipulator 69 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Robot connections xx0700000565 continued.

Page 72

2 installation and commissioning 2.6.3. Manipulator cables irb360 3hac030005-001 revision: - 70 © copyri ght 200 6 abb . All ri ghts res erved. 2.6.3. Manipulator cables irb360 general connect the robot and controller to each other after securing them to the foundation. The lists below specify which...

Page 73

2 installation and commissioning 2.6.3. Manipulator cables irb360 71 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Customer connections customer connection (optional) these cables including both power and signals are optional and can not be combined with customer vacuum ...

Page 74

2 installation and commissioning 2.6.3. Manipulator cables irb360 3hac030005-001 revision: - 72 © copyri ght 200 6 abb . All ri ghts res erved..

Page 75: 3 Maintenance

3 maintenance 3.1.1. Introduction 73 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 3 maintenance 3.1 overview 3.1.1. Introduction structure of this chapter this chapter details all maintenance activities recommended for the robot and any external units of the robot. It i...

Page 76

3 maintenance 3.1.2. Regular maintenance 3hac030005-001 revision: - 74 © copyri ght 200 6 abb . All ri ghts res erved. 3.1.2. Regular maintenance recommendation the robot is designed to be able to work under very demanding conditions with a minimum of maintenance. Time between services can vary depe...

Page 77

3 maintenance 3.2.1. Maintenance schedule irb 360 75 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 3.2 maintenance schedule and component life 3.2.1. Maintenance schedule irb 360 maintenance schedule 1. Only if option is chosen. Change interval is dependant on the materi...

Page 78

3 maintenance 3.3.1. Telescopic shaft, axis 4, standard 3hac030005-001 revision: - 76 © copyri ght 200 6 abb . All ri ghts res erved. 3.3 inspection activities 3.3.1. Telescopic shaft, axis 4, standard general this section describes maintenance on the telescopic shaft, axis 4 with interval 500 and 4...

Page 79

3 maintenance 3.3.1. Telescopic shaft, axis 4, standard 77 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Xx0700000556 required equipment and references interval 500 h interval 4,000 h or 2 years a telescopic shaft (std) b universal joint c set screw, dog point required e...

Page 80

3 maintenance 3.3.2. Telescopic shaft, wash down, axis 4 3hac030005-001 revision: - 78 © copyri ght 200 6 abb . All ri ghts res erved. 3.3.2. Telescopic shaft, wash down, axis 4 general this section describes maintenance on the telescopic shaft (wash down), axis 4 interval 500 and 4000 h danger! Tur...

Page 81

3 maintenance 3.3.2. Telescopic shaft, wash down, axis 4 79 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Interval 500 h interval 4000 h action note 1. Check and retighten set screws. 2. If the linear bushings are worn out or if the backlash is excessive, change the tele...

Page 82

3 maintenance 3.3.3. Telescopic shaft, stainless, axis 4 3hac030005-001 revision: - 80 © copyri ght 200 6 abb . All ri ghts res erved. 3.3.3. Telescopic shaft, stainless, axis 4 general this section describes maintenance on the telescopic shaft (stainless), axis 4 interval 500 and 4000 h danger! Tur...

Page 83

3 maintenance 3.3.3. Telescopic shaft, stainless, axis 4 81 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references interval 500 h interval 4000 h required equipment spare part no. Note shot lubricator grease oil and grease specification on page 1...

Page 84

3 maintenance 3.3.4. Vacuum system (optional) 3hac030005-001 revision: - 82 © copyri ght 200 6 abb . All ri ghts res erved. 3.3.4. Vacuum system (optional) general this section describes maintenance on the vacuum system, with interval 500 and 4000 hour. Note! Only use un lubricated air. Danger! Turn...

Page 85

3 maintenance 3.3.4. Vacuum system (optional) 83 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references interval 500 h interval 4,000 h or 2 years required equipment spare part no. Note pneumatic valve unit spare parts, ejector unit on page 225 ....

Page 86

3 maintenance 3.3.5. Bar system 3hac030005-001 revision: - 84 © copyri ght 200 6 abb . All ri ghts res erved. 3.3.5. Bar system general this section describes maintenance on the bar system, with interval 500 and 4000 hour. Danger! Turn off all electrical power, hydraulic and pneumatic pressure suppl...

Page 87

3 maintenance 3.3.5. Bar system 85 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Interval 500 hrs or 1 year. Interval 4,000 hrs or 2 years references replacement of bearing rings on page 127 action note 1. Check for wear on bearing rings, listen for screeching. If necess...

Page 88

3 maintenance 3.3.6. Joint balls 3hac030005-001 revision: - 86 © copyri ght 200 6 abb . All ri ghts res erved. 3.3.6. Joint balls general this section describes maintenance on the joint balls, with interval 4000 hour. Danger! Turn off all electrical power, hydraulic and pneumatic pressure supplies t...

Page 89

3 maintenance 3.3.7. Upper arms 87 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 3.3.7. Upper arms general this section describes maintenance on the upper arms, with interval 4000 hour. Danger! Turn off all electrical power, hydraulic and pneumatic pressure supplies to t...

Page 90

3 maintenance 3.3.7. Upper arms 3hac030005-001 revision: - 88 © copyri ght 200 6 abb . All ri ghts res erved. Interval 4,000 hrs or 2 years action note 1. Check the surface of tube for cracks. If necessary replace the part as described in section replacement of upper arm on page 124 2. Check surface...

Page 91

3 maintenance 3.3.8. Hoses 89 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 3.3.8. Hoses general this section describes maintenance on the hoses with interval 500 hour. Danger! Turn off all electrical power, hydraulic and pneumatic pressure supplies to the robot! Also re...

Page 92

3 maintenance 3.3.8. Hoses 3hac030005-001 revision: - 90 © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references interval 500 hrs required equipment spare part no. Note standard tools standard toolkit on page 196 references replacement of vacuum hoses on page 158 action not...

Page 93

3 maintenance 3.3.9. Spring units 91 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 3.3.9. Spring units general this section describes maintenance on the spring units with interval 500 hour. Danger! Turn off all electrical power, hydraulic and pneumatic pressure supplies ...

Page 94

3 maintenance 3.3.9. Spring units 3hac030005-001 revision: - 92 © copyri ght 200 6 abb . All ri ghts res erved. Interval 500 hrs references replacement of parallel arms on page 120 action note 1. Check the forks for wear. If necessary exchange the part as described in replacement of parallel arms on...

Page 95

3 maintenance 3.3.10. Movable plate with swivel 93 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 3.3.10. Movable plate with swivel general this section describes maintenance on the movable plate, with interval 500 hour. Danger! Turn off all electrical power, hydraulic an...

Page 96

3 maintenance 3.3.10. Movable plate with swivel 3hac030005-001 revision: - 94 © copyri ght 200 6 abb . All ri ghts res erved. Interval 4000 hrs caution! Never force axial movement to the swivel or tool interface without first releasing the brakes, it will damage the telescopic shaft. Action note 1. ...

Page 97

3 maintenance 3.4.1. Changing the battery in the measuring system 95 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 3.4 replacement/changing activities 3.4.1. Changing the battery in the measuring system general the robot is delivered with a 3-cell lithium battery. The li...

Page 98

3 maintenance 3.4.1. Changing the battery in the measuring system 3hac030005-001 revision: - 96 © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references changing the battery danger! Turn off all electric power, hydraulic and pneumatic pressure supplies to the robot. Tools an...

Page 99

3 maintenance 3.4.1. Changing the battery in the measuring system 97 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 5. Connect (a) the new battery to the serial measurement board. Connection (x3). Xx0700000520 6. Refit the battery to the smb, using a strap. 7. Check the b...

Page 100

3 maintenance 3.5.1. Gearboxes, axes 1- 4 3hac030005-001 revision: - 98 © copyri ght 200 6 abb . All ri ghts res erved. 3.5 lubrication activities 3.5.1. Gearboxes, axes 1- 4 general this section describes maintenance on gearboxes 1-4, regarding oil change (3d version only 1-3). Warning! Gearbox oil...

Page 101

3 maintenance 3.5.1. Gearboxes, axes 1- 4 99 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references interval 30,000 hrs or 5 years oil change in axis 4, (not in 3d version) note! Oil should only be changed once after the first 30,000 h. Required ...

Page 102

3 maintenance 3.5.1. Gearboxes, axes 1- 4 3hac030005-001 revision: - 100 © copyri ght 200 6 abb . All ri ghts res erved. Interval 30,000 hrs or 5 years oil change in axis 1-3 3. Remove the oil plug, and drain the oil from gearbox 4. Xx0700000728 4. Fill new oil through the plug holes, with specified...

Page 103

3 maintenance 3.5.1. Gearboxes, axes 1- 4 101 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 4. Remove the 3 pcs vk- covers. Use a screwdriver 5. Remove the 3x6 pcs m6x40 holding the upper arms. Described in section replacement of upper arm on page 124 . 6. Remove the 6 p...

Page 104

3 maintenance 3.5.1. Gearboxes, axes 1- 4 3hac030005-001 revision: - 102 © copyri ght 200 6 abb . All ri ghts res erved. 8. Remove the 6 pcs m6x20 flange screws (b) holding the trans- mission cover (a). Caution! On the wd. Or wds. Robots the transmission cover and sealing is glued on to the robot us...

Page 105

3 maintenance 3.5.1. Gearboxes, axes 1- 4 103 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 12. Refit the magnetic plug (a), change the sealing washers if necessary. Tightening torque 10-12 nm. 13. The oil is filled through the plug holes (a) with specified volume, check...

Page 106

3 maintenance 3.5.1. Gearboxes, axes 1- 4 3hac030005-001 revision: - 104 © copyri ght 200 6 abb . All ri ghts res erved. 16. Refit the 3 pcs upper arm sealing rings. Apply locking liquid (loctite 243). (change the sealings if necessary.) 17. Refit the 3 upper arms using the 6 x 3 pcs m6x40. Apply lo...

Page 107

3 maintenance 3.6.1. Cleaning of robot standard and wash down 105 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 3.6 cleaning activities 3.6.1. Cleaning of robot standard and wash down general the manipulator is tested to fulfill, ip69k according to iec 529. Danger! Turn ...

Page 108

3 maintenance 3.6.1. Cleaning of robot standard and wash down 3hac030005-001 revision: - 106 © copyri ght 200 6 abb . All ri ghts res erved. Wash down cleaning sensitive spots for direct flushing. Xx0800000005 note! This applies for irb 360 wd, and irb 360 wds, versions. Danger! Always read the inst...

Page 109

3 maintenance 3.6.1. Cleaning of robot standard and wash down 107 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Usable detergents the stainless version is verified against the following detergents. 2. Foam with “p3-topax 12” with a concentration of approximately 3% depen...

Page 110

3 maintenance 3.6.1. Cleaning of robot standard and wash down 3hac030005-001 revision: - 108 © copyri ght 200 6 abb . All ri ghts res erved. Optional assemble to facilitate cleaning , it is possible to use the spring units without the rubber bellows. Xx0700000707 to remove the rubber bellows, see se...

Page 111: 4 Repair

4 repair 4.1. Introduction 109 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 4 repair 4.1. Introduction structure of this chapter this chapter details all repair activities recommended for the robot and any external units of the robot. It is made up of separate procedure...

Page 112

4 repair 4.2.1. Mounting instructions for bearings 3hac030005-001 revision: - 110 © copyri ght 200 6 abb . All ri ghts res erved. 4.2 general procedures 4.2.1. Mounting instructions for bearings general this section details how to mount and grease different types of bearings on the robot. Equipment ...

Page 113

4 repair 4.2.1. Mounting instructions for bearings 111 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Greasing of bearings the bearings must be greased after assembly, according to instructions below: • the bearings must not be completely filled with grease. However, if s...

Page 114

4 repair 4.2.2. Mounting instructions for seals 3hac030005-001 revision: - 112 © copyri ght 200 6 abb . All ri ghts res erved. 4.2.2. Mounting instructions for seals general this sections details how to mount different types of seals to the robot. Equipment rotating seals the procedure below details...

Page 115

4 repair 4.2.2. Mounting instructions for seals 113 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Flange seals and static seals the procedure below details how to fit flange seals and static seals. O-rings the procedure below details how to fit o-rings. Action 1. Check t...

Page 116

4 repair 4.2.3. Screw joints 3hac030005-001 revision: - 114 © copyri ght 200 6 abb . All ri ghts res erved. 4.2.3. Screw joints general this section details how to tighten the various types of screw joints on the robot. The instructions and torque values are valid for screw joints comprised of metal...

Page 117

4 repair 4.2.3. Screw joints 115 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. The table below specifies the recommended standard tightening torque for molycote- lubricated screws with allen head screws. The table below specifies the recommended standard tightening torqu...

Page 118

4 repair 4.3.1. Replacement of base cover gasket 3hac030005-001 revision: - 116 © copyri ght 200 6 abb . All ri ghts res erved. 4.3 complete robot 4.3.1. Replacement of base cover gasket general this section describes how to replace the base cover gasket. Danger! Turn off all electrical power, hydra...

Page 119

4 repair 4.3.1. Replacement of base cover gasket 117 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references removal refitting d 12 pcs plastic washer equipment spare part no. Note base cover gasket spare parts in the base on page 214 standard too...

Page 120

4 repair 4.3.2. Replacement of serial measurement board unit 3hac030005-001 revision: - 118 © copyri ght 200 6 abb . All ri ghts res erved. 4.3.2. Replacement of serial measurement board unit general this section details how to replace the smb unit , (serial measurement board unit). Danger! Turn off...

Page 121

4 repair 4.3.2. Replacement of serial measurement board unit 119 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and refereces removal smb unit note! This product contains certain materials considered hazardous. This product must be disposed of in accord...

Page 122

4 repair 4.3.3. Replacement of parallel arms 3hac030005-001 revision: - 120 © copyri ght 200 6 abb . All ri ghts res erved. 4.3.3. Replacement of parallel arms general this section describes how to change the parallel arms. Danger! Turn off all electrical power, hydraulic and pneumatic pressure supp...

Page 123

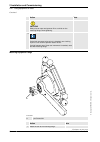

4 repair 4.3.3. Replacement of parallel arms 121 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references caution! Never use unnecessary force when removing the springs. Only work on one side or the spring will be overstressed. Removal xx0700000525...

Page 124

4 repair 4.3.3. Replacement of parallel arms 3hac030005-001 revision: - 122 © copyri ght 200 6 abb . All ri ghts res erved. Refitting xx0700000629 caution! Never use unnecessary force when refitting the springs. Only work on one side or the spring will be overstressed. Action note 1. Remove the para...

Page 125

4 repair 4.3.3. Replacement of parallel arms 123 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 3. Refit the parallel arm to the movable plate by hand or using tool, left or right side not both. By hand or tool according to figures note! Always mount the movable plate wit...

Page 126

4 repair 4.3.4. Replacement of upper arm 3hac030005-001 revision: - 124 © copyri ght 200 6 abb . All ri ghts res erved. 4.3.4. Replacement of upper arm general this section details replacement of upper arm. Danger! Turn off all electrical power, hydraulic and pneumatic pressure supplies to the robot...

Page 127

4 repair 4.3.4. Replacement of upper arm 125 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references removal equipment spare part no. Note standard tools standard toolkit on page 196 upper arm spare parts - upper arm, irb 360 on page 218 . Sealing...

Page 128

4 repair 4.3.4. Replacement of upper arm 3hac030005-001 revision: - 126 © copyri ght 200 6 abb . All ri ghts res erved. Refitting 6. Remove the two flange- screws (b) holding the flange (c). If necessary, change the sealing ring (a) and the flange gasket (d). Xx0700000601 action note action note 1. ...

Page 129

4 repair 4.3.5. Replacement of bearing rings 127 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 4.3.5. Replacement of bearing rings general this section describes how to change bearing rings in the parallel arms. Danger! Turn off all electrical power, hydraulic and pneuma...

Page 130

4 repair 4.3.5. Replacement of bearing rings 3hac030005-001 revision: - 128 © copyri ght 200 6 abb . All ri ghts res erved. Refitting xx0700000524 2. Remove the bearing ring using a screwdriver. Xx0700000486 action note a parallel bar b bearing ring c drifter d dolly continued continues on next page.

Page 131

4 repair 4.3.5. Replacement of bearing rings 129 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Caution! Never use unnecessary force when refitting the springs. Only work on one side or the spring will be overstressed. Action note 1. Place a new bearing ring into the join...

Page 132

4 repair 4.3.6. Replacement of movable plate 3hac030005-001 revision: - 130 © copyri ght 200 6 abb . All ri ghts res erved. 4.3.6. Replacement of movable plate general this section describes how to change the movable plate std, wds or 3d. Danger! Turn off all electrical power, hydraulic and pneumati...

Page 133

4 repair 4.3.6. Replacement of movable plate 131 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Removal caution! The spring units must be removed according to description in section replacement of parallel arms on page 120 or they will be damaged. Refitting xx0700000629 s...

Page 134

4 repair 4.3.6. Replacement of movable plate 3hac030005-001 revision: - 132 © copyri ght 200 6 abb . All ri ghts res erved. Caution! Never use unnecessary force when refitting the springs. Only work on one side or the spring will be overstressed. Action note 1. Refit the set screw (b) locking the un...

Page 135

4 repair 4.3.7. Replacement of telescopic shaft 133 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 4.3.7. Replacement of telescopic shaft danger! Turn off all electrical power, hydraulic and pneumatic pressure supplies to the robot! Also read the safety sections: • safety...

Page 136

4 repair 4.3.7. Replacement of telescopic shaft 3hac030005-001 revision: - 134 © copyri ght 200 6 abb . All ri ghts res erved. Removal refitting replacement of movable plate on page 130 references action note 1. Remove the parallel arms described in section replacement of parallel arms on page 120 2...

Page 137

4 repair 4.3.7. Replacement of telescopic shaft 135 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2. Refit the upper set screw use locking liquid (loctite 243). Xx0700000613 tip! Use a 90° angled bit holder. Tightening torque 7 nm 3. Refit the movable plate use locking l...

Page 138

4 repair 4.3.8. Replacement of universal joint 3hac030005-001 revision: - 136 © copyri ght 200 6 abb . All ri ghts res erved. 4.3.8. Replacement of universal joint general this section describes how to change the universal joint. Danger! Turn off all electrical power, hydraulic and pneumatic pressur...

Page 139

4 repair 4.3.8. Replacement of universal joint 137 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Refitting 2. Remove the set screw locking the universal joint on the telescopic shaft. Use standard tools. 3. Remove the universal joint. Action note action note 1. Refit the...

Page 140

4 repair 4.3.9. Replacement of joint balls 3hac030005-001 revision: - 138 © copyri ght 200 6 abb . All ri ghts res erved. 4.3.9. Replacement of joint balls general this section describes how to change the joint balls. Danger! Turn off all electrical power, hydraulic and pneumatic pressure supplies t...

Page 141

4 repair 4.3.9. Replacement of joint balls 139 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references removal xx0700000500 caution! Never use unnecessary force when removing the springs. Only work on one side or the spring will be overstressed. E...

Page 142

4 repair 4.3.9. Replacement of joint balls 3hac030005-001 revision: - 140 © copyri ght 200 6 abb . All ri ghts res erved. Refitting caution! Never use unnecessary force when refitting the springs. Only work on one side or the spring will be overstressed. Action note 1. Refit the joint balls using lo...

Page 143

4 repair 4.3.10. Replacement of gearbox unit 1- 3 141 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 4.3.10. Replacement of gearbox unit 1- 3 note! This action demands standard calibration of the robot. Described in section calibration methods on page 172 . Danger! Turn o...

Page 144

4 repair 4.3.10. Replacement of gearbox unit 1- 3 3hac030005-001 revision: - 142 © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references removal c gearbox ax 2 d motor ax 2 e gearbox ax 3 f motor ax 3 equipment spare part no. Note standard tools standard toolkit on page 196...

Page 145

4 repair 4.3.10. Replacement of gearbox unit 1- 3 143 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Refitting action note 1. Refitting the gearbox unit, using the four hex socket head cap screw m10 x 30 with washer 16.5x20x2 steel a3f. Note! Gearbox unit weight 16 kg. Ti...

Page 146

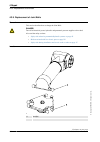

4 repair 4.3.11. Replacement of gearbox unit 4 3hac030005-001 revision: - 144 © copyri ght 200 6 abb . All ri ghts res erved. 4.3.11. Replacement of gearbox unit 4 general this section describes replacing gearbox 4 with motor (gearbox unit) note! This action demands standard calibration of the robot...

Page 147

4 repair 4.3.11. Replacement of gearbox unit 4 145 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references removal refitting equipment spare part no. Note gearbox unit axis 4 spare parts, gear unit axis 4 on page 205 standard tools standard toolki...

Page 148

4 repair 4.3.12. Replacement of motor axis 1-3 3hac030005-001 revision: - 146 © copyri ght 200 6 abb . All ri ghts res erved. 4.3.12. Replacement of motor axis 1-3 general this section details replacement of motor axis 1-3. Note! This action demands standard calibration of the robot. Described in se...

Page 149

4 repair 4.3.12. Replacement of motor axis 1-3 147 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references removal c hex socket head cap screw m6x20 8.8 gleitmo605 d washer 6,4x12x1,6 steel a2f e nitrile rubber o-ring 67,5x3,0 f oil plug g oil plu...

Page 150

4 repair 4.3.12. Replacement of motor axis 1-3 3hac030005-001 revision: - 148 © copyri ght 200 6 abb . All ri ghts res erved. Refitting xx0700000616 a motor pinion b gear z2/1-3, 90 cog action note 1. Mount new o-ring (e) onto the motor flange, lubricate the o-ring with grease fm222. Shown in figure...

Page 151

4 repair 4.3.12. Replacement of motor axis 1-3 149 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 4. Push on the motor flange gently in direction (a), at the same time as you feel for the backlash by moving the upper arm back and forward. Xx0700000620 5. Ensure that the g...

Page 152

4 repair 4.3.13. Replacement of motor axis 4 3hac030005-001 revision: - 150 © copyri ght 200 6 abb . All ri ghts res erved. 4.3.13. Replacement of motor axis 4 general this section details replacement of motor axis 4. Note! This action demands standard calibration of the robot. Described in section ...

Page 153

4 repair 4.3.13. Replacement of motor axis 4 151 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references removal refitting b rotational ac motor c o-ring, nitrile rubber d hex socket head cap screw m6x25 8.8 e washer 6,4x12x1,6 a2f h oil plug equi...

Page 154

4 repair 4.3.13. Replacement of motor axis 4 3hac030005-001 revision: - 152 © copyri ght 200 6 abb . All ri ghts res erved. 2. Insert the new motor, do not tighten the screws. Caution! Fit the motor, making sure the motor pinion is properly mated to the gear wheel, do not use force or the motor pini...

Page 155

4 repair 4.3.14. Replacement of labels 153 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 4.3.14. Replacement of labels general this section details replacement and positioning of labels on the irb 360. Label positioning xx0700000691 continues on next page.

Page 156

4 repair 4.3.14. Replacement of labels 3hac030005-001 revision: - 154 © copyri ght 200 6 abb . All ri ghts res erved. Xx0700000692 1 label, flex picker-red 190x23 2 abb-logotype 69x157 3 calibration values 5 instruction plate (brake release) 6 warning sign 24x21 (electric warning) 7 rating label 8 u...

Page 157

4 repair 4.3.14. Replacement of labels 155 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references assemble equipment spare part no. Note label-set spare parts, transmission cover on page 207 action note 1. Make sure the surface is clean. 2. Assem...

Page 158

4 repair 4.3.15. Replacing of calibration marks 3hac030005-001 revision: - 156 © copyri ght 200 6 abb . All ri ghts res erved. 4.3.15. Replacing of calibration marks overview this section describes replacement of calibration marks on a irb 360. Replace a calibration mark if it is damaged. Danger! Tu...

Page 159

4 repair 4.3.15. Replacing of calibration marks 157 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references remove refitting equipment spare part no. Note standard tools standard toolkit on page 196 . Calibration mark spare parts in the base on pa...

Page 160

4 repair 4.4.1. Replacement of vacuum hoses 3hac030005-001 revision: - 158 © copyri ght 200 6 abb . All ri ghts res erved. 4.4 vacuum system 4.4.1. Replacement of vacuum hoses general this section details replacement of hoses in the vacuum system. Danger! Turn off all electrical power, hydraulic and...

Page 161

4 repair 4.4.1. Replacement of vacuum hoses 159 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Required equipment removal refitting equipment spare part no. Note standard tools spare hose set action note 1. Open all straps. 2. Pull the hose out from the swivel. 3. Pull th...

Page 162

4 repair 4.4.2. Draining of water separation filter 3hac030005-001 revision: - 160 © copyri ght 200 6 abb . All ri ghts res erved. 4.4.2. Draining of water separation filter general this section describes: • air filter chage in the vacuum system • emptying water separation filter danger! Turn off al...

Page 163

4 repair 4.4.2. Draining of water separation filter 161 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Removal water action note 1. Drain the water separation filter opening the bottom nipple (c). Continued.

Page 164

4 repair 4.4.3. Replacement of ejector unit 3hac030005-001 revision: - 162 © copyri ght 200 6 abb . All ri ghts res erved. 4.4.3. Replacement of ejector unit general this section describes replacement of ejector unit. Danger! Turn off all electrical power, hydraulic and pneumatic pressure supplies t...

Page 165

4 repair 4.4.3. Replacement of ejector unit 163 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Removal xx0700000704 spare parts spare parts, ejector unit on page 225 . References spare parts, ejector unit on page 225 replacement of base cover gasket on page 116 . Equipmen...

Page 166

4 repair 4.4.3. Replacement of ejector unit 3hac030005-001 revision: - 164 © copyri ght 200 6 abb . All ri ghts res erved. Refitting action note 1. Disconnect the air supply, vacuum hoses and signal cable from the ejector unit. 2. Remove the base cover. Described in section replacement of base cover...

Page 167

4 repair 4.5.1. Replacement of cable harness 165 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 4.5 cable harness 4.5.1. Replacement of cable harness general this section details replacement of complete cable harness. Danger! Turn off all electrical power, hydraulic and p...

Page 168

4 repair 4.5.1. Replacement of cable harness 3hac030005-001 revision: - 166 © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references removal refitting e r3.Mp3 f r3.Mp1 g r3.Fb1 h r3.Fb2 i r3.Fb3 j r3.Fb4 m x1(smb) l x2(smb) - r3.Fb1-4 equipment spare part no. Note standard ...

Page 169

4 repair 4.5.2. Replacement of brake release button 167 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 4.5.2. Replacement of brake release button general this section describes replacement of brake release button on the irb 360. Danger! Turn off all electrical power, hydr...

Page 170

4 repair 4.5.2. Replacement of brake release button 3hac030005-001 revision: - 168 © copyri ght 200 6 abb . All ri ghts res erved. Required equipment and references removal xx0700000644 equipment spare part no. Note standard tools standard toolkit on page 196 . References spare parts, brake release ...

Page 171

4 repair 4.5.2. Replacement of brake release button 169 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Refitting action note 1. Remove the base cover. Replacement of base cover gasket on page 116 . Caution! The base cover has sharp edges, use protective gloves. 2. Remove ...

Page 172

4 repair 4.5.2. Replacement of brake release button 3hac030005-001 revision: - 170 © copyri ght 200 6 abb . All ri ghts res erved. 2. Press to refit the contact. Xx0800000011 tip! Refit the cables to the contact before this step. 3. Refit the base cover. Replacement of base cover gasket on page 116 ...

Page 173: 5 Calibration Information

5 calibration information 5.1. Introduction 171 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 5 calibration information 5.1. Introduction general this chapter includes general information about different calibration methods and also details procedures that do not require...

Page 174

5 calibration information 5.2. Calibration methods 3hac030005-001 revision: - 172 © copyri ght 200 6 abb . All ri ghts res erved. 5.2. Calibration methods overview this section specifies the different types of calibration and the calibration methods that are supplied from abb. Types of calibration c...

Page 175

5 calibration information 5.3. Calibration movement directions for all axes 173 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 5.3. Calibration movement directions for all axes overview when calibrating, the axis must consistently be run towards the calibration position i...

Page 176

5 calibration information 5.4. Calibration scales and correct axis position 3hac030005-001 revision: - 174 © copyri ght 200 6 abb . All ri ghts res erved. 5.4. Calibration scales and correct axis position introduction this section specifies the calibration scale positions and/or correct axis positio...

Page 177

5 calibration information 5.5. Calibration irb 360 axis 1-3 175 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 5.5. Calibration irb 360 axis 1-3 general this section is valid for irb 360 all models. It details how to perform the actual fine calibration of axis 1-3. Note! ...

Page 178

5 calibration information 5.5. Calibration irb 360 axis 1-3 3hac030005-001 revision: - 176 © copyri ght 200 6 abb . All ri ghts res erved. Calibration steps xx0700000624 action note 1. On the flex pendant tap program stop (a) in figure. 2. On the controller, set the key switch into manual position. ...

Page 179

5 calibration information 5.5. Calibration irb 360 axis 1-3 177 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 4. Release the brakes, using the brake release button (a). Xx0700000435 5. Push the upper arm very gently against the calibration device (a). Note! Always calibr...

Page 180

5 calibration information 5.5. Calibration irb 360 axis 1-3 3hac030005-001 revision: - 178 © copyri ght 200 6 abb . All ri ghts res erved. 8. Note! Release the brakes and gently draw the calibrated upper arm in to a horizontal position. 9. Return to step 4, and proceed with axis 2 and 3. Action note...

Page 181

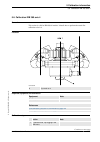

5 calibration information 5.6. Calibration irb 360 axis 4 179 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 5.6. Calibration irb 360 axis 4 general this section is valid for irb 360 all models. It details how to perform the actual fine calibration of axis 4. Location xx0...

Page 182

5 calibration information 5.6. Calibration irb 360 axis 4 3hac030005-001 revision: - 180 © copyri ght 200 6 abb . All ri ghts res erved. 2. Tap motion mode to choose group of axes to jog. 3. Tap axis 4-6 to jog axis 4, 5, or 6. 4. Jog axis 4 with the flex pendant joystick so that the calibration mar...

Page 183

5 calibration information 5.7. Fine calibration procedure on flexpendant 181 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 5.7. Fine calibration procedure on flexpendant overview this section describes how to use the flexpendant when performing a fine calibration of the ...

Page 184

5 calibration information 5.8. Updating revolution counters 3hac030005-001 revision: - 182 © copyri ght 200 6 abb . All ri ghts res erved. 5.8. Updating revolution counters general this section details how to perform a rough calibration of each robot axis, that is updating the revolution counter val...

Page 185

5 calibration information 5.8. Updating revolution counters 183 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 2. Tap the mechanical unit in question. A screen is displayed: tap rev. Counters. En0400000771 3. Tap update revolution counters.... A dialog box is displayed, w...

Page 186

5 calibration information 5.9. Serial measurement board memory 3hac030005-001 revision: - 184 © copyri ght 200 6 abb . All ri ghts res erved. 5.9. Serial measurement board memory serial measurement board, smb the serial measurement board, smb, primarily gathers resolver data from the robot’s (or add...

Page 187

5 calibration information 5.9. Serial measurement board memory 185 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. View smb data status this section describes how to view the data status in the serial measurement board and the controller. Update controller data from smb me...

Page 188

5 calibration information 5.9. Serial measurement board memory 3hac030005-001 revision: - 186 © copyri ght 200 6 abb . All ri ghts res erved. Delete smb data this section describes how to delete the data stored on the smb memory or the controller memory, when creating spare parts. Related informatio...

Page 189

5 calibration information 5.10. Checking the calibration position 187 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 5.10. Checking the calibration position general check the calibration position before beginning any programming of the robot system. This may be done: • in...

Page 190

5 calibration information 5.10. Checking the calibration position 3hac030005-001 revision: - 188 © copyri ght 200 6 abb . All ri ghts res erved. 4. Release the brakes, using the break release button (a). Xx070000043 5. Push the upper arm axis 1-3 very gently against the calibration device (a). Note!...

Page 191: 6 Decommissioning

6 decommissioning 6.1. Introduction 189 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 6 decommissioning 6.1. Introduction introduction this section contains information to consider when taking a product, robot or controller, out of operation. It deals with how to handle ...

Page 192

6 decommissioning 6.2. Environmental information 3hac030005-001 revision: - 190 © copyri ght 200 6 abb . All ri ghts res erved. 6.2. Environmental information hazardous material this product contains certain materials considered hazarous to anyone handling them. The table specifies these materials a...

Page 193: 7 Reference Information

7 reference information 7.1. Document references 191 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 7 reference information 7.1. Document references general the contents of this manual may include references to additional documentation necessary to perform certain procedu...

Page 194

7 reference information 7.2. Introduction 3hac030005-001 revision: - 192 © copyri ght 200 6 abb . All ri ghts res erved. 7.2. Introduction general this chapter includes general information, complementing the more specific information in the different procedures in the manual..

Page 195

7 reference information 7.3. Applicable safety standards 193 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 7.3. Applicable safety standards standards, general the robot is designed in accordance with the requirements of: • en iso 10218-1: 2006 robots for industrial envir...

Page 196

7 reference information 7.4. Unit conversion 3hac030005-001 revision: - 194 © copyri ght 200 6 abb . All ri ghts res erved. 7.4. Unit conversion converter table use the table below to convert units used in this manual. Quantity units length 1 m 3.28 ft 39.37 in weight 1 kg 2.21 lb pressure 1 bar 100...

Page 197

7 reference information 7.5. Weight specifications 195 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 7.5. Weight specifications definition in installation, repair and maintenance procedures, weights of the components handled are sometimes specified. All components exceed...

Page 198

7 reference information 7.6. Standard toolkit 3hac030005-001 revision: - 196 © copyri ght 200 6 abb . All ri ghts res erved. 7.6. Standard toolkit general all service (repairs, maintenance and installation) procedures contain lists of tools required to perform the specified activity. All special too...

Page 199

7 reference information 7.7. Special tools 197 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 7.7. Special tools general all service instructions contain lists of tools required to perform the specified activity. The required tools are a sum of standard tools, defined in ...

Page 200

7 reference information 7.8. Lifting equipment and lifting instructions 3hac030005-001 revision: - 198 © copyri ght 200 6 abb . All ri ghts res erved. 7.8. Lifting equipment and lifting instructions general many repair and maintenance activities require different pieces of lifting equipment, which a...

Page 201

7 reference information 7.9. Oil and grease specification 199 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 7.9. Oil and grease specification oil in gearboxes xx0700000721 pos. For: type spare part no. Amount liter/gallons a gearbox 1 mobil dte fm 220 3hac031493-001 0.9l...

Page 202

7 reference information 7.9. Oil and grease specification 3hac030005-001 revision: - 200 © copyri ght 200 6 abb . All ri ghts res erved. Grease in robot xx0700000725 pos. For: type spare part no. Amount e telescopic shaft wds food accepted fm 222 3hac029132-001 f spring units food accepted fm 222 3h...

Page 203

7 reference information 7.9. Oil and grease specification 201 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Grease on sealings xx0700000706 pos. For: type spare part no. Amount g o-rings in gear units food accepted fm 222 3hac029132-001 continued continues on next page.

Page 204

7 reference information 7.9. Oil and grease specification 3hac030005-001 revision: - 202 © copyri ght 200 6 abb . All ri ghts res erved. Xx0800000003 xx0800000004 pos. For: type spare part no. Amount i grease in svivel food accepted fm 222 3hac029132-001 pos. For: type spare part no. Amount j grease...

Page 205

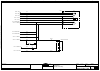

8 spare parts and exploded views 8.1.1. Spare parts, gear units axis 1- 3 203 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 8 spare parts and exploded views 8.1 spare parts in robot base 8.1.1. Spare parts, gear units axis 1- 3 illustration xx0700000667 continues on next...

Page 206

8 spare parts and exploded views 8.1.1. Spare parts, gear units axis 1- 3 3hac030005-001 revision: - 204 © copyri ght 200 6 abb . All ri ghts res erved. Spare part list part description spare part no. Note/qty 1 motor and gear unit ax 1-3 3hac028017-001 3 pcs 1.1 motor with pinion ax1-3 3hac023938-0...

Page 207

8 spare parts and exploded views 8.1.2. Spare parts, gear unit axis 4 205 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 8.1.2. Spare parts, gear unit axis 4 illustration xx0700000668 continues on next page.

Page 208

8 spare parts and exploded views 8.1.2. Spare parts, gear unit axis 4 3hac030005-001 revision: - 206 © copyri ght 200 6 abb . All ri ghts res erved. Spare part list part description spare part no. Note/qty 1 motor and gearbox unit ax 4 3hac028018-001 1 pcs 1.1 motor with pinion ax 4 3hac021799-001 1...

Page 209

8 spare parts and exploded views 8.1.3. Spare parts, transmission cover 207 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 8.1.3. Spare parts, transmission cover illustration xx0700000670 3 continues on next page.

Page 210

8 spare parts and exploded views 8.1.3. Spare parts, transmission cover 3hac030005-001 revision: - 208 © copyri ght 200 6 abb . All ri ghts res erved. Spare part list parts description spare part no. Note/qty 1 base cover 3hac028899-001 without labels, 1 pcs 2 sealing ring 3hac3934-1 3 pcs 3 flange ...

Page 211

8 spare parts and exploded views 8.1.4. Spare parts - cable harness 209 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 8.1.4. Spare parts - cable harness illustration power cable xx0700000672 continues on next page.

Page 212

8 spare parts and exploded views 8.1.4. Spare parts - cable harness 3hac030005-001 revision: - 210 © copyri ght 200 6 abb . All ri ghts res erved. Spare part list power cable part description spare part no. Note 1 cable harness power irb 360 3hac029695-001 1.1 r1.Mp1-3 motor power 1.2 r1.Mp4-6 motor...

Page 213

8 spare parts and exploded views 8.1.4. Spare parts - cable harness 211 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Illustration signal cable xx0700000673 continued continues on next page.

Page 214

8 spare parts and exploded views 8.1.4. Spare parts - cable harness 3hac030005-001 revision: - 212 © copyri ght 200 6 abb . All ri ghts res erved. Spare part list signal cable part description spare part no. Note 1 cable harness signal irb 360 3hac1762-1 1.1 r2.Fb1-4 1.2 r3.Fb2 1.3 r3.Fb4 1.4 r3.Fb3...

Page 215

8 spare parts and exploded views 8.1.5. Spare parts, smb unit 213 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 8.1.5. Spare parts, smb unit illustration xx0700000666 sparepart list 1 1.2 part description spare part no. Note/qty 1 serial measurement unit 3hac17396-1 1 pc...

Page 216

8 spare parts and exploded views 8.1.6. Spare parts in the base 3hac030005-001 revision: - 214 © copyri ght 200 6 abb . All ri ghts res erved. 8.1.6. Spare parts in the base illustration xx0700000685 continues on next page.

Page 217

8 spare parts and exploded views 8.1.6. Spare parts in the base 215 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Spare part list part description spare part no. Note/qty 1 gasket (top cover) 3hac029556-001 1 pcs 2 screw 3hac029879-001 m6x20, 12 pcs 3 washer 3hac029877-0...

Page 218

8 spare parts and exploded views 8.1.7. Spare parts, brake release button 3hac030005-001 revision: - 216 © copyri ght 200 6 abb . All ri ghts res erved. 8.1.7. Spare parts, brake release button illustration xx0700000718 continues on next page.

Page 219

8 spare parts and exploded views 8.1.7. Spare parts, brake release button 217 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Spare part list, brake release button part description spare part no. Note/qty a membrane sk615503-2 1 pcs b push button 1sfa611100r1006 1 pcs c ho...

Page 220

8 spare parts and exploded views 8.2.1. Spare parts - upper arm, irb 360 3hac030005-001 revision: - 218 © copyri ght 200 6 abb . All ri ghts res erved. 8.2 spare parts arm system 8.2.1. Spare parts - upper arm, irb 360 illustration xx0700000663 continues on next page.

Page 221

8 spare parts and exploded views 8.2.1. Spare parts - upper arm, irb 360 219 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Spare part list part description spare part no. Note/qty 1 upper arm 3hac029743-001 (800) 3pcs 1.1 joint ball 3hac5176-1 12pcs 2 upper arm 3hac02112...

Page 222

8 spare parts and exploded views 8.2.2. Spare parts, telescopic shafts 3hac030005-001 revision: - 220 © copyri ght 200 6 abb . All ri ghts res erved. 8.2.2. Spare parts, telescopic shafts illustration xx0700000677 continues on next page.

Page 223

8 spare parts and exploded views 8.2.2. Spare parts, telescopic shafts 221 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Spare part list part description spare part no. Note 1 telescopic shaft 3hac029293-001 1pcs, std., (without joints) 2 telescopic shaft 3hac029425-001 ...

Page 224

8 spare parts and exploded views 8.2.3. Spare parts - parallell arm system, irb 360 3hac030005-001 revision: - 222 © copyri ght 200 6 abb . All ri ghts res erved. 8.2.3. Spare parts - parallell arm system, irb 360 illustration xx0700000665 spare part list 1.2 1 2 part description spare part no. Note...

Page 225

8 spare parts and exploded views 8.2.4. Spare parts, movable plate 223 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 8.2.4. Spare parts, movable plate illustration xx0700000662 continues on next page.

Page 226

8 spare parts and exploded views 8.2.4. Spare parts, movable plate 3hac030005-001 revision: - 224 © copyri ght 200 6 abb . All ri ghts res erved. Spare part list part description spare part no. Note/qty 1 movable plate with swivel 3hac028021-001 (std), 1pcs 1.1 joint ball 3hac5176-1 6 pcs 2 movable ...

Page 227

8 spare parts and exploded views 8.3.1. Spare parts, ejector unit 225 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 8.3 spare parts, customer options 8.3.1. Spare parts, ejector unit illustration xx0700000684 spare part list part description spare part no. Note/qty 1 3ha...

Page 228

8 spare parts and exploded views 8.3.2. Spare parts - customer options signal lamp irb 360 3hac030005-001 revision: - 226 © copyri ght 200 6 abb . All ri ghts res erved. 8.3.2. Spare parts - customer options signal lamp irb 360 illustration xx0700000719 continues on next page.

Page 229

8 spare parts and exploded views 8.3.2. Spare parts - customer options signal lamp irb 360 227 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. Spare part list part description spare part no. Note/qty a lamp unit (compl) 3hac022235-005 1 pcs b indicator lamp 3hac9249-1 1 pc...

Page 230

8 spare parts and exploded views 8.3.2. Spare parts - customer options signal lamp irb 360 3hac030005-001 revision: - 228 © copyri ght 200 6 abb . All ri ghts res erved..

Page 231: 9 Circuit Diagram

9 circuit diagram 8.3.2. Spare parts - customer options signal lamp irb 360 229 3hac030005-001 revision: - © copyri ght 200 6 abb . All ri ghts res erved. 9 circuit diagram.

Page 232

We reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb latest revision: prepared by, date: approved by, date: lab/office: copyright page title page/cover sh...

Page 233

We reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb latest revision: prepared by, date: approved by, date: lab/office: title page title page/cover sheet ...

Page 234

We reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb latest revision: prepared by, date: approved by, date: lab/office: table of contents: (1 - 109) table...

Page 235

We reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb latest revision: prepared by, date: approved by, date: lab/office: revision note text view status: do...

Page 236

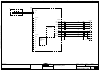

Prepared by, date: 6 we reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb page 5 13 total 3hac028647-009 latest revision: approved by, date: legend locati...

Page 237

Prepared by, date: 103 we reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb page 6 13 total 3hac028647-009 latest revision: approved by, date: connection ...

Page 238

Prepared by, date: 104 we reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb page 103 13 total 3hac028647-009 latest revision: approved by, date: serial me...

Page 239

Prepared by, date: 105 we reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb page 104 13 total 3hac028647-009 latest revision: approved by, date: motor axi...

Page 240

Prepared by, date: 106 we reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb page 105 13 total 3hac028647-009 latest revision: approved by, date: motor axi...

Page 241

Prepared by, date: 107 we reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb page 106 13 total 3hac028647-009 latest revision: approved by, date: feed-back...

Page 242

Prepared by, date: 108 we reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb page 107 13 total 3hac028647-009 latest revision: approved by, date: feed-back...

Page 243

Prepared by, date: 109 we reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb page 108 13 total 3hac028647-009 latest revision: approved by, date: option: e...

Page 244

Prepared by, date: we reserve all rights in this document and in the information contained therein.Reproduction, use or disclosure to third parties without express authority is strictly forbidden. © copyright 2003 abb page 109 13 total 3hac028647-009 latest revision: approved by, date: option: exter...

Page 245

Index 231 3hac030005-001 revision: - © copyri ght 200 8 abb . All ri ghts res erved. B burndy connector 68 c calibrating roughly 182 smb memory 184 calibration fine calibration 181 marks/scales 174 rough 182 standard type 172 when to calibrate 171 calibration manual, article number 191 calibration p...

Page 246

Index 232 3hac030005-001 revision: - © copyri ght 200 8 abb . All ri ghts res erved..

Page 248

Abb ab robotics products s-721 68 vÄsterÅs sweden telephone: +46 (0) 21 344000 telefax: +46 (0) 21 132592 3h a c 03 000 5-0 01, re vi s ion - , en.