- DL manuals

- ABB

- Robotics

- IRB 6700

- Product Manual

ABB IRB 6700 Product Manual

Summary of IRB 6700

Page 1

Abb robotics product manual irb 6700

Page 2

Trace back information: workspace r13-2 version a3 checked in 2013-10-15 skribenta version 4.0.378.

Page 3

Product manual irb 6700 - 235/2.65 irb 6700 - 205/2.80 irb 6700 - 175/3.05 irb 6700 - 150/3.20 irc5 document id: 3hac044266-001 revision: - © copyright 2013 abb. All rights reserved..

Page 4

The information in this manual is subject to change without notice and should not be construed as a commitment by abb. Abb assumes no responsibility for any errors that may appear in this manual. Except as may be expressly stated anywhere in this manual, nothing herein shall be construed as any kind...

Page 5: Table Of Contents

Table of contents 9 overview of this manual ................................................................................................................... 11 product documentation, irc5 .......................................................................................................... 13...

Page 6

93 2.5 restricting the working range .............................................................................. 93 2.5.1 introduction ............................................................................................ 94 2.5.2 mechanically restricting the working range of axis 1 ..........

Page 7

246 4.5 upper and lower arms ........................................................................................ 246 4.5.1 replacing the upper arm .......................................................................... 274 4.5.2 replacing the wrist ..............................................

Page 8

This page is intentionally left blank.

Page 9: Overview Of This Manual

Overview of this manual about this manual this manual contains instructions for: • mechanical and electrical installation of the robot • maintenance of the robot • mechanical and electrical repair of the robot. Usage this manual should be used during: • installation, from lifting the robot to its wo...

Page 10

Contents chapter reference to the spare part list for the robot. Spare parts and exploded views reference to the circuit diagram for the robot. Circuit diagram references documentation referred to in the manual, is listed in the table below. Document id document name 3hac044268-001 product manual, s...

Page 11

Product documentation, irc5 categories for manipulator documentation the manipulator documentation is divided into a number of categories. This listing is based on the type of information in the documents, regardless of whether the products are standard or optional. All documents listed can be order...

Page 12

An application manual generally contains information about: • the purpose of the application (what it does and when it is useful). • what is included (for example cables, i/o boards, rapid instructions, system parameters, dvd with pc software). • how to install included or required hardware. • how t...

Page 13

How to read the product manual reading the procedures the procedures contain references to figures, tools, material, and so on. The references are read as described below. References to figures the procedures often include references to components or attachment points located on the manipulator/cont...

Page 14

This page is intentionally left blank.

Page 15: 1 Safety

1 safety 1.1 introduction to safety information overview the safety information in this manual is divided into two categories: • general safety aspects, important to attend to before performing any service work on the robot. These are applicable for all service work and are found in general safety i...

Page 16

1.2 general safety information 1.2.1 introduction to general safety information definitions this section details general safety information for personnel performing installation, repair and maintenance work. Sections the general safety information is divided into the following sections. Containing c...

Page 17

1.2.2 safety in the manipulator system validity and responsibility the information does not cover how to design, install and operate a complete system, nor does it cover all peripheral equipment that can influence the safety of the entire system. To protect personnel, the complete system must be des...

Page 18

1.2.3 safety risks 1.2.3.1 safety risks during installation and service work on manipulators overview this section includes information on general safety risks to be considered when performing installation and service work on the manipulator. These safety instructions have to be read and followed by...

Page 19

• turntables or the like should be used to keep the operator out of the manipulator's working space. • the axes are affected by the force of gravity when the brakes are released. In addition to the risk of being hit by moving manipulator parts, there is a risk of being crushed by the parallel arm (i...

Page 20

Cabling description safety risk caution the cable packs are sensitive to mechanical damage! They must be handled with care, especially the connectors, in order to avoid damaging them! Cable packs are sensitive to mechanical damage! Gearboxes and motors description safety risk caution whenever partin...

Page 21

1.2.3.2 caution - hot parts may cause burns! Description during normal operation, many manipulator parts become hot, especially the drive motors and gears. Sometimes areas around these parts also become hot. Touching these may cause burns of various severity. Because of a higher environment temperat...

Page 22

1.2.3.3 safety risks related to tools/work pieces safe handling it must be possible to safely turn off tools, such as milling cutters, etc. Make sure that guards remain closed until the cutters stop rotating. It should be possible to release parts by manual operation (valves). Safe design grippers/e...

Page 23

1.2.3.4 safety risks related to pneumatic/hydraulic systems general special safety regulations apply to pneumatic and hydraulic systems. Note all components that remain pressurized after separating the machine from the power supply must be provided with clearly visible drain facilities and a warning...

Page 24

1.2.3.5 safety risks during operational disturbances general • the industrial manipulator is a flexible tool that can be used in many different industrial applications. • all work must be carried out professionally and in accordance with the applicable safety regulations. • care must be taken at all...

Page 25

1.2.3.6 risks associated with live electric parts voltage related risks, general work on the electrical equipment of the manipulator must be performed by a qualified electrician in accordance with electrical regulations. • although troubleshooting may, on occasion, need to be carried out while the p...

Page 26

Voltage related risks, manipulator a danger of high voltage is associated with the manipulator in: • the power supply for the motors (up to 800 vdc). • the user connections for tools or other parts of the installation (max. 230 vac). See chapter installation and commissioning on page 51 . Voltage re...

Page 27

1.2.4 safety actions 1.2.4.1 safety fence dimensions general install a safety cell around the manipulator to ensure safe manipulator installation and operation. Dimensioning dimension the fence or enclosure to enable it to withstand the force created if the load being handled by the manipulator is d...

Page 28

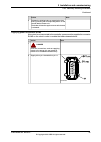

1.2.4.2 fire extinguishing note use a carbon dioxide (co 2 ) extinguisher in the event of a fire in the manipulator system (manipulator or controller)! 28 3hac044266-001 revision: - © copyright 2013 abb. All rights reserved. 1 safety 1.2.4.2 fire extinguishing.

Page 29

1.2.4.3 emergency release of the manipulator’s arm description in an emergency situation, any of the manipulator's axes may be released manually by pushing the brake release buttons on the manipulator. How to release the brakes is detailed in the section: • manually releasing the brakes on page 82 ....

Page 30

1.2.4.4 brake testing when to test during operation, the holding brake of each axis normally wears down. A test can be performed to determine whether the brake can still perform its function. How to test the function of the holding brake of each axis motor may be checked as described below: 1 run ea...

Page 31

1.2.4.5 risk of disabling function "reduced speed 250 mm/s" note do not change transm gear ratio or other kinematic system parameters from the flexpendant or a pc. This will affect the safety function "reduced speed 250 mm/s". 3hac044266-001 revision: - 31 © copyright 2013 abb. All rights reserved. ...

Page 32

1.2.4.6 safe use of the flexpendant enabling device the enabling device is a manually operated, constant pressure push-button which, when continuously activated in one position only, allows potentially hazardous functions but does not initiate them. In any other position, hazardous functions are sto...

Page 33

1.2.4.7 work inside the manipulator's working range warning if work must be carried out within the manipulator’s work area, the following points must be observed: • the operating mode selector on the controller must be in the manual mode position to render the enabling device operational and to bloc...

Page 34

1.2.5 safety stops 1.2.5.1 what is an emergency stop? Definition of emergency stop an emergency stop is a state that overrides any other manipulator control, disconnects drive power from the manipulator motors, stops all moving parts, and disconnects power from any potentially dangerous functions co...

Page 35

Classification of stops the safety standards that regulate automation and manipulator equipment define categories in which each type of stop applies: ... Then it is classified as... If the stop is... Category 0 (zero) uncontrolled category 1 controlled emergency stop devices in a manipulator system ...

Page 36

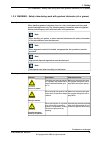

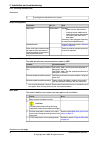

1.3 safety related instructions 1.3.1 safety signals in the manual introduction to safety signals this section specifies all dangers that can arise when doing the work described in this manual. Each danger consists of: • a caption specifying the danger level (danger, warning, or caution) and the typ...

Page 37

Significance designation symbol describes important facts and conditions. Note xx0100000004 describes where to find additional information or how to do an operation in an easier way. Tip xx0100000098 3hac044266-001 revision: - 37 © copyright 2013 abb. All rights reserved. 1 safety 1.3.1 safety signa...

Page 38

1.3.2 safety symbols on manipulator labels introduction to labels this section describes safety symbols used on labels (stickers) on the manipulator. Symbols are used in combinations on the labels, describing each specific warning. The descriptions in this section are generic, the labels can contain...

Page 39

Description symbol see user documentation xx0900000813 read user documentation for details. Which manual to read is defined by the symbol: • no text: product manual . • eps: application manual - electronic position switches . Before dismantling see product manual xx0900000816 do not dismantle xx0900...

Page 40

Description symbol crush xx0900000817 risk of crush injuries. Heat xx0900000818 risk of heat that can cause burns. Moving robot xx0900000819 the robot can move unexpectedly. Xx1000001141 brake release buttons xx0900000820 xx1000001140 continues on next page 40 3hac044266-001 revision: - © copyright ...

Page 41

Description symbol lifting bolt xx0900000821 chain sling with shortener xx1000001242 lifting of robot xx0900000822 oil xx0900000823 can be used in combination with prohibition if oil is not allowed. Mechanical stop xx0900000824 no mechanical stop xx1000001144 stored energy xx0900000825 warns that th...

Page 42

Description symbol pressure xx0900000826 warns that this part is pressurized. Usually contains additional text with the pressure level. Shut off with handle xx0900000827 use the power switch on the controller. 42 3hac044266-001 revision: - © copyright 2013 abb. All rights reserved. 1 safety 1.3.2 sa...

Page 43

1.3.3 danger - moving manipulators are potentially lethal! Description any moving manipulator is a potentially lethal machine. When running, the manipulator may perform unexpected and sometimes irrational movements. Moreover, all movements are performed with great force and may seriously injure any ...

Page 44

1.3.4 danger - first test run may cause injury or damage! Description since performing a service activity often requires disassembly of the robot, there are several safety risks to take into consideration before the first test run. Elimination follow the procedure below when performing the first tes...

Page 45

1.3.5 warning - the brake release buttons may be jammed after service work description the brake release unit has push-buttons for the brake release of each axis motor. When service work is performed inside the smb recess that includes removal and refitting of the brake release unit, the brake relea...

Page 46

1.3.6 danger - make sure that the main power has been switched off! Description working with high voltage is potentially lethal. Persons subjected to high voltage may suffer cardiac arrest, burn injuries, or other severe injuries. To avoid these dangers, do not proceed working before eliminating the...

Page 47

1.3.7 warning - the unit is sensitive to esd! Description esd (electrostatic discharge) is the transfer of electrical static charge between two bodies at different potentials, either through direct contact or through an induced electrical field. When handling parts or their containers, personnel not...

Page 48

1.3.8 warning - safety risks during handling of batteries description under normal conditions of use, the electrode materials and liquid electrolyte in the batteries are not exposed to the outside, provided the battery integrity is maintained and seals remain intact. There is a risk of exposure only...

Page 49

1.3.9 warning - safety risks during work with gearbox lubricants (oil or grease) description when handling gearbox lubricants, there is a risk of both personal injury and product damage occurring. The following safety information must be regarded before performing any work with lubricants in the gea...

Page 50

Elimination/action description warning make sure not to overfill the gearbox when filling it with oil or grease! Overfilling of gearbox lubricant can lead to internal over-pres- sure inside the gearbox which in turn may: • damage seals and gas- kets • completely press out seals and gaskets • prevent...

Page 51

2 installation and commissioning 2.1 introduction general this chapter contains information for installing the robot at the working site. See the product specification for the robot for more detailed technical data, such as: • load diagram • permitted extra loads (equipment) • location of extra load...

Page 52

2.2 unpacking 2.2.1 pre-installation procedure introduction this section is intended for use when unpacking and installing the robot for the first time. It also contains information useful during later re-installation of the robot. Checking the pre-requisites for installation installation craftsmen ...

Page 53

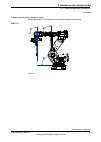

Loads on foundation, robot the illustration shows the directions of the robots stress forces. The directions are valid for all floor mounted and suspended robots. Xy xy z z t f f t xx1100000521 force in any direction in the xy plane f xy force in the z plane f z bending torque in any direction in th...

Page 54

Requirements, foundation the table shows the requirements for the foundation where the weight of the installed robot is included: note value requirement flat foundations give better repeatability of the resolver calibration compared to original settings on delivery from abb. 0.2 mm maximum deviation...

Page 55

2.2.2 working range working range note working range type of motion axis ±170° rotation motion axis 1 -65°/+85° arm motion axis 2 -180°/+70° arm motion axis 3 default value. ±300° wrist motion axis 4 ±130° i bend motion axis 5 default value. ±360° ii turn motion axis 6 maximum value. ± 93.7 revoluti...

Page 56

Illustration, working range irb 6700 - 235/2.65 this illustration shows the unrestricted working range of the robot. 1187 920 1908 2650 3114 320 xx1300000281 reach (m) handling capacity (kg) robot type 2.65 235 irb 6700 illustration, working range irb 6700 - 205/2.80 this illustration shows the unre...

Page 57

Reach (m) handling capacity (kg) robot type 2.80 205 irb 6700 illustration, working range irb 6700 - 175/3.05 1527 2314 1109 3056 726 3520 xx1300000283 reach (m) handling capacity (kg) robot type 3.05 175 irb 6700 continues on next page 3hac044266-001 revision: - 57 © copyright 2013 abb. All rights ...

Page 58

Illustration, working range irb 6700 - 150/3.20 1604 2445 1067 3200 713 3665 xx1300000284 reach (m) handling capacity (kg) robot type 3.20 150 irb 6700 continues on next page 58 3hac044266-001 revision: - © copyright 2013 abb. All rights reserved. 2 installation and commissioning 2.2.2 working range...

Page 59

Turning radius r2 r1 170° 170° xx1300001082 r2 r1 robot variant 2650 mm 920 mm irb 6700 - 235/2.65 2794 mm 958 mm irb 6700 - 205/2.80 3056 mm 1109 mm irb 6700 - 175/3.05 3200 mm 1067 mm irb 6700 - 150/3.20 3hac044266-001 revision: - 59 © copyright 2013 abb. All rights reserved. 2 installation and co...

Page 60

2.2.3 risk of tipping/stability risk of tipping if the robot is not fastened to the foundation and standing still, the robot is not stable in the whole working area. Moving the arms will displace the center of gravity, which may cause the robot to tip over. The shipping position is the most stable p...

Page 61

2.2.4 main dimensions illustration (c) (b) 1029 360 360 745 186 209 320 377 1004 780 200 200 (a) (d) (e) (f) (g) 456 xx1300000241 description pos 350 mm for leanid (option 780-4) a radius = 532 mm (axis 1 front side) b radius = 634 mm (axis 1 back side) c dimensions for different robot variants g f ...

Page 62

2.3 on-site transportation 2.3.1 robot transportation precautions general this section describes abb approved transportation precautions for abb robots. Caution all transportation in or outside the plant, must be carried out according to description in method 1. If transportation according to method...

Page 63

Always follow these instructions when transporting an abb robot according to method 1: • always remove the tool before transportation of the robot. • always place the robot in the abb recommended transport position, described in section risk of tipping/stability on page 60 . • always read and follow...

Page 64

Irb 6700 xx0800000037 transport support a hexagon socket head cap screw m16x140 b threaded bar m10x200 c nut m10 d continues on next page 64 3hac044266-001 revision: - © copyright 2013 abb. All rights reserved. 2 installation and commissioning 2.3.1 robot transportation precautions continued.

Page 65

Transport position with a transport support all transportation of the robot with tool must follow these instructions. Irb 6700 xx0800000040 continues on next page 3hac044266-001 revision: - 65 © copyright 2013 abb. All rights reserved. 2 installation and commissioning 2.3.1 robot transportation prec...

Page 66

Recommended transport support always use the recommended transport support when transporting a robot with tool. Irb 6700 220 250 r 90 r 110 200 30 65 130 (10) r3 m10 (52) (62) b 50 50 40 18 60 12 r 20 30° a 5 irb6700 2.65 2.8 3.05 3.2 lower arm l 1135 1280 1135 1280 a 1000 1160 630 860 b 21 21 21 21...

Page 67

2.3.2 securing the robot general this section describes how to secure the robot using the transport support. Danger releasing the brakes is a hazardous action that may cause injury and damage property. It must be done with great care and only when absolutely necessary. Securing the robot xx080000006...

Page 68

Note action do not tighten the screw. Fit the transport support’s lower end to the robot using the recommended screw joint, (a) in figure. 1 see attachment point for the specific ro- bot in the section transport position with a transport support on page 65 . Caution do not try to jog the robot to th...

Page 69

2.4 on-site installation 2.4.1 lifting robot with fork lift general the robot may be moved using a fork lift, provided that available special aids are used. This section describes how to attach the fork lift equipment to the robot. Fork lift device set the fork lift device set is fitted to the robot...

Page 70

Note art. No. Equipment content is defined in section standard toolkit on page 559 . - standard toolkit lifting the robot with fork lift this procedure details how to secure the fork lift set in order to lift the robot and move it using fork lift only! Note action release the brakes if required as d...

Page 71

Note action caution the irb 6700 robot weighs 1300 kg. All lifting accessories used must be sized accordingly! 5 caution lifting the robot with fork lift shall only be done with all four fork lift pockets fitted! If lifting with fewer than four fork lift pockets fitted, there is a risk of accidents ...

Page 72

2.4.2 lifting the base plate required equipment note art. No. Equipment 3 pcs 3hac14457-4 lifting eye, m16 3 pcs lifting slings length: approx. 2 m hole configuration xx0200000096 attachment holes for lifting eyes (x3) a lifting, base plate note action caution the base plate weighs 353 kg! All lifti...

Page 73

2.4.3 securing the base plate base plate, dimensions a a b b c d g h e f 2x r525 598,31 560,85 487,01 243,5 0 73,84 111,30 1020 857,3 73,84 132,64 317,3 502,04 560,85 634,68 0 2x 50x45º 231,5 2x 450 950 (Ø 800) 12x m24 Ø1 a 455 c a 4x48 13 (2) 1,6 3x45º 0.2 Ø 45p7 a-a Ø1.5 (4x) 6,3 (48) (2) 1,6 3x45...

Page 74

840,9 699,5 625 (2x) 325 (2x) 250,5 109,1 0 874,6 (2x) 790 (2x) 706 (2x) 290 (2x) 0 0 119 138,4 241,1 225,8 r50 (12x) 4x Ø18. 2x206,9 2x219,8 2x31 1,1 2x365,3 0 831 811,6 724,2 708,9 50 0 27 (4x) 68 150 202 385 565 748 800 882 923 (4x) Ø16 (5x) Ø22 (16x) 861 (2x) 358 (2x) 18 0 905 813 475 137 45 0 0...

Page 75

Guide sleeve xx1000001055 guide sleeve protected from corrosion a base plate, grooves and holes the illustration below shows the orienting grooves and guide sleeve holes in the base plate. Xx0300000045 guide sleeve holes (2 pcs) a orienting grooves (3 pcs) b continues on next page 3hac044266-001 rev...

Page 76

Levelling bolts, attachment holes (4 pcs) c required equipment note art. No. Equipment includes • guide sleeves, 3hac12937-3 • levelling screws, 9ada120-79 • attachment screws and washers for securing the robot to the base plate. A drawing of the base plate itself may be ordered from abb robotics! 3...

Page 77

Note action if possible, observe the recommenda- tions specified in section recommenda- tions, quality on page 76 . Abb does not assume any responsibility for other foundation qualities, due to great vari- ations in the foundation properties. Use the base plate as a template and drill 16 attachment ...

Page 78

2.4.4 lifting the robot with roundslings attaching the roundslings c a b d roundsling, 2.5 m (4 pcs) a roundsling, 2 m (1 pc) do not strain! B length roundsling (1 pc) do not strain! C 2 m irb 6700 - 235/2.65 2 m irb 6700 - 205/2.80 2.5 m irb 6700 - 175/3.05 2.5 m irb 6700 - 150/3.20 lifting eye, m2...

Page 79

Required equipment see quantity of roundslings in figure attaching the roundslings on page 78 . Note article number equipment, etc. - overhead crane working load limit: 2,000 kg. Quantity: 4 pcs required. - lifting eye, m20 length: 2 m. Lifting capacity: 2,000 kg. - roundsling, 2 m length: 2.5 m. Li...

Page 80

Note action xx1200001301 fit lifting eyes to the outer holes on each corner of the base. 2 xx1200001302 make sure the roundslings do not rub against any sharp edges. Run roundslings through the lifting eyes and fasten them in an overhead crane. Caution if the lifting eyes have sharp edges that might...

Page 81

Note action irb 6700 - 235/2.65 and irb 6700 - 205/2.80: roundsling, 2 m attach a securing roundsling at the front according to figure. Note the securing sling must not be strained at lifting. It only secures for tipping. 5 irb 6700 - 175/3.05 and irb 6700 - 150/3.20: roundsling, 2.5 m xx1300001574 ...

Page 82

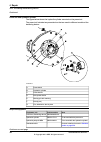

2.4.5 manually releasing the brakes introduction to manually releasing the brakes this section describes how to release the holding brakes for the motors of each axis. Location of brake release unit the internal brake release unit is located as shown in the figure. Xx1200000964 releasing the brakes ...

Page 83

Note action release the holding brake on a particular robot axis by pressing the corresponding button on the internal brake release unit. 3 the brake will function again as soon as the button is released. Supplying power to connector r1.Mp if the robot is not connected to the controller, power must ...

Page 84

2.4.6 orienting and securing the robot general this section details how to orient and secure the robot to the base plate in order to run the robot safely. Hole configuration, base this illustration shows the hole configuration used when securing the robot. D - d 8x 30 8x 53 4x 45 h7 4x 3x45 16 8x 49...

Page 85

4 mm flat washer suitable washer: 625 nm tightening torque: securing the robot use this procedure to secure robot to base plate after fitting plate to the foundation. Note action see section lifting the robot with roundslings on page 78 . Lift the robot. 1 move robot close to its installation locati...

Page 86

2.4.7 loads general any loads mounted on the robot must be defined correctly and carefully (with regard to the position of center of gravity and mass moments of inertia) in order to avoid jolting movements and overloading motors, gears and structure. Caution incorrectly defined loads may result in o...

Page 87

2.4.8 fitting equipment to the robot general extra loads can be fitted on the upper arm housing, the lower arm, and on the frame. Definitions of distances and masses are shown in the following figures. The robot is supplied with holes for fitting extra equipment (see figure in holes for fitting extr...

Page 88

Upper arm allowed extra load on the upper arm housing, in addition to the maximum handling weight, is m1 ≤ 50 kg with a distance ≤ 500 mm from the center of gravity in the axis-3 extension. (a) m1 m1 a xx1000000417 mass center a 200 400 (a) xx1300000866 center of gravity 50 kg a continues on next pa...

Page 89

Holes for fitting extra equipment allowed positions for attachment holes 652,5 3 6 5 0,3 80 1 2 0 3x m10 a a 349 428 12 (2x m12) 147 (2x m12) cl axis 5 2x m8 16 8 0 4 0 100 cl axis 3 4x m12 22 220 190 110 90 3 2 8 3 3 1 0 2 19 2x m12 197 m12 19 22) 106 (4x m12 53 52 ,5° 117 r 1 3 4 x m 8 m12 20 52 ,...

Page 90

Upper arm, lower arm and frame 190 90 3 2 8 cl axis 5 8 0 4 0 100 2x m8 12 cl axis 1 2 6 5 465 30 33 6 0 50 50 4 9 9 .9 304 2x m12 25 20 m12 320 4x m10 2x m12 255 80 349 428 (b) (2x m12) (c) (m12) (d) (2x m12) 20) (4x m120 456 b d (1 3,8) b (a) d c c c - c 186 (2x m8) 208.5 (2x m8) xx1300000264 r= 4...

Page 91

Tool flange, standard below is the standard tool flange. 160 1 2 x 3 0 ° c b 0.05 b b 0.3 c 1 0 11x m12 2 2 h8 100 200 h7 h7 15 18 12 1 x 4 5 b b b - b xx1300000280 continues on next page 3hac044266-001 revision: - 91 © copyright 2013 abb. All rights reserved. 2 installation and commissioning 2.4.8 ...

Page 92

Tool flange, leanid below is the tool flange for option 780-4, leanid. C - c 200 h8 12 h7 15 100 h7 11x m12 18 8 15 0,05 d 0,3 d e d e 160 12x 30° c c xx1300000290 92 3hac044266-001 revision: - © copyright 2013 abb. All rights reserved. 2 installation and commissioning 2.4.8 fitting equipment to the...

Page 93

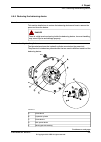

2.5 restricting the working range 2.5.1 introduction general when installing the robot, make sure that it can move freely within its entire working space. If there is a risk that it may collide with other objects, its working space should be limited. The working range of the following axes may be re...

Page 94

2.5.2 mechanically restricting the working range of axis 1 general the working range of axis 1 is limited by fixed mechanical stops and adjustment of the system parameter configuration. The working range can be reduced by adding additional mechanical stops giving 15° graduation, between ±5° and ±125...

Page 95

Note art. No. Equipment, etc. Content is defined in section standard toolkit on page 559 . - standard toolkit art. No. Is specified in section references on page 10 . - technical reference manual - system parameters installation, mechanical stops axis 1 use this procedure to fit the additional mecha...

Page 96

2.6 electrical connections 2.6.1 robot cabling and connection points introduction connect the robot and controller to each other after securing them to the foundation. The lists below specify which cables to use for each respective application. Main cable categories all cables between the robot and ...

Page 97

2.7 installation of options 2.7.1 installing the signal lamp (option) signal lamp see the assembly instruction delivered with the signal lamp. 3hac044266-001 revision: - 97 © copyright 2013 abb. All rights reserved. 2 installation and commissioning 2.7.1 installing the signal lamp (option).

Page 98

This page is intentionally left blank.

Page 99: 3 Maintenance

3 maintenance 3.1 introduction structure of this chapter this chapter describes all the maintenance activities recommended for the irb 6700. It is based on the maintenance schedule found at the beginning of the chapter. The schedule contains information about required maintenance activities includin...

Page 100

3.2 maintenance schedule and expected component life 3.2.1 specification of maintenance intervals introduction the intervals are specified in different ways depending on the type of maintenance activity to be carried out and the working conditions of the irb 6700: • calendar time: specified in month...

Page 101

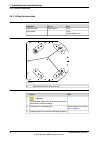

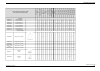

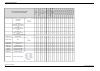

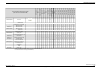

3.2.2 maintenance schedule scheduled and non-predictable maintenance the robot must be maintained regularly to ensure proper function. The maintenance activities and intervals are specified in the table below. Non-predictable situations also give rise to inspections of the robot. Any damages must be...

Page 102

Reference every 40,000 hours i every 20,000 hours i every 12,000 hours i every 36 months every 12 months regularly maintenance activities inspecting the dampers on page 134 x inspecting the mechanical stop replacement/changing activities changing oil, axis-1 gearbox on page 138 x changing the oil in...

Page 103

3.2.3 expected component life general the expected life of a specific component of the robot can vary greatly depending on how hard it is run. Expected component life - protection type standard note expected life component not including: • possible spotpack harnesses • optional upper arm harnesses 4...

Page 104

3.3 inspection activities 3.3.1 inspecting the oil level in axis-1 gearbox location of oil plug the oil plug through which the oil level is inspected is located as shown in the figure. Xx1200000950 tightening torque: 24 nm required tools note article number equipment content is defined in section st...

Page 105

Inspecting the oil level in axis-1 gearbox use this procedure to inspect the oil level in the gearbox. Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 1 warning handling gearbox oil invol...

Page 106

Note action type of oil and total amount is detailed in technical reference manual - lubrication in gearboxes . Add or drain oil, if required. 5 further information about how to drain or fill with oil is found in section changing oil, axis-1 gearbox on page 138 . Tightening torque: 24 nm. Refit the ...

Page 107

3.3.2 inspecting the oil level in axis-2 gearbox location of oil plug the gearbox has a level plug that is located as shown in the figure. Xx1200000952 tightening torque: 24 nm required tools note article number equipment, etc. Content is defined in section standard toolkit on page 559 . - standard ...

Page 108

Inspecting the oil level in axis-2 gearbox use this procedure to inspect the oil level in the gearbox. Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 1 warning handling gearbox oil invol...

Page 109

3.3.3 inspecting the oil level in axis-3 gearbox location of oil plug the gearbox has a level plug that is located as shown in the figure. Xx1200000955 tightening torque: 24 nm required tools note article number equipment, etc. Content is defined in section standard toolkit on page 559 . - standard ...

Page 110

Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 2 warning handling gearbox oil involves several safety risks. Before proceeding, please read the safety information in the section warning ...

Page 111

3.3.4 inspecting the oil level in axis-4 gearbox location of oil plug the gearbox has a level plug that is located as shown in the figure. Xx1200000957 tightening torque: 24 nm required tools note article number equipment, etc. Content is defined in section standard toolkit on page 559 . - standard ...

Page 112

Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 2 warning handling gearbox oil involves several safety risks. Before proceeding, please read the safety information in the section warning ...

Page 113

3.3.5 inspecting the oil level in axis-5 gearbox location of oil plug the gearbox has a level plug that is located as shown in the figure. Xx1200000959 tightening torque: 24 nm required tools note article number equipment, etc. Content is defined in section standard toolkit on page 559 . - standard ...

Page 114

Note action warning handling gearbox oil involves several safety risks. Before proceeding, please read the safety information in the section warning - safety risks during work with gearbox lubricants (oil or grease) on page 49 . 3 xx1200000959 open the oil plug. 4 check the oil level. 5 required oil...

Page 115

3.3.6 inspecting the oil level in axis-6 gearbox location of oil plug the oil plug through which the oil level is inspected is located as shown in the figure. Xx1200000963 tightening torque: 24 nm required tools note article number equipment, etc. Content is defined in section standard toolkit on pa...

Page 116

Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 2 warning handling gearbox oil involves several safety risks. Before proceeding, please read the safety information in the section warning ...

Page 117

Note action tightening torque:24 nm. Refit the oil plug. 8 danger make sure all safety requirements are met when performing the first test run. These are further detailed in the section danger - first test run may cause injury or damage! On page 44 . 9 3hac044266-001 revision: - 117 © copyright 2013...

Page 118

3.3.7 inspecting the balancing device general several points are to be checked on the balancing device during the inspection. This section describes how to perform the inspection regarding: • dissonance • damage • leakage • contamination / lack of free space. Inspection points, balancing device the ...

Page 119

Required material note art. No. Equipment includes: • bearing and seals • vk cover. 3hac045815-001 maintenance kit, link ear includes: • bearings and seals • vk cover. 3hac045822-001 maintenance kit, rear attachment check for dissonance the check points are shown in the figure inspection points, bal...

Page 120

Check the o-rings and sealings in the front ear of the balancing device for leaks. Xx1000000207 shaft a sealing ring (radial (2 pcs) b o-ring c sealing spacer d note action clean the area at the front ear from contamina- tion. 1 run the robot for some minutes, in order to move the balancing device p...

Page 121

Check for contamination / lack of free space note action danger turn off all: • electric power supply to the robot • hydraulic pressure supply to the robot • air pressure supply to the robot before entering the robot working area. 1 xx1300000423 check that there are no obstacles inside the frame, th...

Page 122

3.3.8 inspecting the cable harness location of cable harness the cable harness is located as shown in the figure. Xx1300001096 required tools visual inspection, no tools are needed. Continues on next page 122 3hac044266-001 revision: - © copyright 2013 abb. All rights reserved. 3 maintenance 3.3.8 i...

Page 123

Inspecting the cable harness use this procedure to inspect cable harness of axes 1-6. Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 1 xx1300001095 make an overall inspection of the cabl...

Page 124

3.3.9 inspection, information labels location of labels these figures show the location of the information labels to be inspected. The symbols are described in section safety symbols on manipulator labels on page 38 . Illustration 1 of 2 h j n n e f f f e e e e b k m continues on next page 124 3hac0...

Page 125

Illustration 2 of 2 a p s r c j l j j n n n t d e g illustration description calibration label a xx0900000816 instruction label before dismantling see product manual b 45° 20° 70° 890 50 570 55 65° ! ! ! 4x irb 6700, m = 1160 - 1600 kg / 2557 - 3527 lbs 3hac 046732-001 / 00 4x, 2000kg, 2,5 m 1x, 200...

Page 126

3 h a c 8 2 2 5 -1 /0 4 ! Xx1300001083 instruction label brake release moving robot brake release buttons d oil specification label e grease specification label f complete oil specification g 3hac 9526-1/04 ! Xx1300001086 warning label do not dismantle stored energy h 3 h a c 4 4 3 1 -1 /0 6 ! Xx130...

Page 127

3hac 020611-001/ 03 ! Xx1300001090 warning label keep areas around the balancing device free from objects m xx1300001091 warning label flash n rating label p absolute accuracy label r ul label s ± 220° 3hac 021761-001/02 eps ! Xx1300001092 label extended rotation no mechanical stop see user document...

Page 128

3.3.10 inspecting, mechanical stop pin, axis 1 warning mechanical stop pin can not be mounted on robot if option 810-1 electronic position switch is used. Location of mechanical stop pin the mechanical stop axis 1 is located at the base as shown in the figure. Xx1200001073 required equipment visual ...

Page 129

Inspecting, mechanical stop pin use this procedure to inspect the mechanical stop pin axis 1. Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 1 shown in figure location of mechan- ical st...

Page 130

3.3.11 inspecting, additional mechanical stops location of mechanical stops the figure shows the location of additional mechanical stops. A b c b xx1300001971 attachment screws m12x70 quality 12.9 gleitmo 603 (2 pcs per additional mechanical stop) a movable mechanical stop b mechanical stop pin axis...

Page 131

Inspecting, mechanical stops use this procedure to inspect the additional mechanical stops. Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 1 shown in figure location of mechanical stops ...

Page 132

3.3.12 inspecting the fork lift device set location of fork lift device set the fork lift device set is fitted to the robot as shown in the figure. A b xx1300001602 fork lift device (4 pcs) a hex socket head cap screw m20x60 quality steel 8.8-a3f (2 pcs per fork lift device) b required equipment not...

Page 133

Inspecting, fork lift device set use this procedure to inspect the fork lift device set. Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 1 check the fork lift devices for damage. 2 check ...

Page 134

3.3.13 inspecting the dampers location of dampers the figure below shows the location of all the dampers to be inspected. Xx1300000414 axis-2 damper, 2 pcs a axis-3 damper, 2 pcs b required equipment visual inspection, no tools are required. A damper must be replaced if damaged! Inspecting, dampers ...

Page 135

Note action xx1300000414 a axis-2 damper, 2 pcs b axis-3 damper, 2 pcs check all dampers for damage, and for cracks or existing impressions larger than 1 mm. 2 check attachment screws for deformation. 3 spare part number is found in product manual, spare parts - irb 6700 . If any damage is detected,...

Page 136

3.3.14 inspecting, signal lamp (option) location of signal lamp the signal lamp is located as shown in this figure. Required equipment note art. No. Equipment, etc. To be replaced if damage is detected. See spare parts on page 565 . Signal lamp kit content is defined in section stand- ard toolkit on...

Page 137

3.4 replacement/changing activities 3.4.1 type of lubrication in gearboxes introduction this section describes where to find information about the type of lubrication , article number and the amount of lubrication in the specific gearbox. It also describes the equipment needed when working with lubr...

Page 138

3.4.2 changing oil, axis-1 gearbox usage of oil dispenser the oil change procedure in this section describes usage of an oil dispenser. Location of oil plugs the oil plugs of the gearbox are located as shown in the figure. Xx1200000950 xx1200000948 vent hole plug oil hole with nipple used for both v...

Page 139

Required documents note document number document name 3hac042927-001 technical reference manu- al - lubrication in gearboxes draining the axis-1 gearbox use this procedure to drain the gearbox. Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply...

Page 140

Note action xx1200000950 remove the plug from the vent hole. Warning if the vent hole is not open when the oil dispenser is working, there is a risk of damaging vital parts in the gear! 5 suck out the oil with the oil dispenser. Note there will be some oil left in the gear after draining. 6 warning ...

Page 141

Note action warning handling gearbox oil involves several safety risks. Before proceeding, please read the safety information in the section warning - safety risks during work with gearbox lubricants (oil or grease) on page 49 . 2 xx1200000948 remove the protective cap from the nipple of the oil hol...

Page 142

Note action xx1200000950 inspect the oil level. 6 required oil level: 58 mm ± 5 mm below the sealing surface of the oil plug. Xx1300000692 remove the oil dispenser and refit the protective cap to the nipple. 7 tightening torque: 24 nm refit the vent hole plug. 8 danger make sure all safety requireme...

Page 143

3.4.3 changing oil, axis-2 gearbox usage of oil dispenser the oil change procedure in this section describes usage of an oil dispenser. Location of oil plugs the oil plugs of the gearbox are located as shown in the figure. Xx1200000952 xx1200000951 vent hole plug / level plug oil hole with nipple us...

Page 144

Required documents note document number document name 3hac042927-001 technical reference manu- al - lubrication in gearboxes draining the axis-2 gearbox use this procedure to drain the gearbox. Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply...

Page 145

Note action xx1200000952 remove the plug from the vent hole. Warning if the vent hole is not open when the oil dispenser is working, there is a risk of damaging vital parts in the gear! 5 suck out the oil with the oil dispenser. Note there will be some oil left in the gear after draining. 6 warning ...

Page 146

Note action warning handling gearbox oil involves several safety risks. Before proceeding, please read the safety information in the section warning - safety risks during work with gearbox lubricants (oil or grease) on page 49 . 2 xx1200000951 remove the protective cap from the nipple of the oil hol...

Page 147

Note action xx1200000952 inspect the oil level at the vent hole (level plug). 6 required oil level is: 0 - 10 mm below the oil plug hole. More information is found in inspecting the oil level in axis-2 gearbox on page 108 . Remove the oil dispenser and refit the protective cap to the nipple. 7 tight...

Page 148

3.4.4 changing oil, axis-3 gearbox usage of oil dispenser the oil change procedure in this section describes usage of an oil dispenser. Location of oil plugs the oil plugs of the gearbox are located as shown in the figure. Xx1200000955 xx1200000954 vent hole plug / level plug oil hole with nipple us...

Page 149

Draining the axis-3 gearbox use this procedure to drain the gearbox. Note action run the robot to calibration position. 1 danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 2 warning handling gearbox oi...

Page 150

Note action xx1200000955 remove the plug from the vent hole. Warning if the vent hole is not open when the oil dispenser is working, there is a risk of damaging vital parts in the gear! 6 suck out the oil with the oil dispenser. Note there will be some oil left in the gear after draining. 7 warning ...

Page 151

Note action xx1200000954 remove the protective cap from the nipple of the oil hole and connect the oil dis- penser. 4 xx1200000955 remove the plug from the vent hole. Note the vent hole is opened to let out air during the filling process. 5 type of oil and total amount is detailed in technical refer...

Page 152

Note action danger make sure all safety requirements are met when performing the first test run. These are further detailed in the section danger - first test run may cause injury or damage! On page 44 . 10 152 3hac044266-001 revision: - © copyright 2013 abb. All rights reserved. 3 maintenance 3.4.4...

Page 153

3.4.5 changing oil, axis-4 gearbox location of oil plugs the oil plugs of the gearbox are located as shown in the figure. Xx1200000957 xx1200000956 oil fill plug / level plug oil drain plug tightening torque: 24 nm. Tightening torque: 24 nm. Required material note material information about the oil ...

Page 154

Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 2 warning handling gearbox oil involves several safety risks. Before proceeding, please read the safety information in the section warning ...

Page 155

Note action tightening torque: 24 nm. Refit the oil plugs. 9 filling oil into the axis-4 gearbox use this procedure to refill the gearbox with oil. Note action run the robot to calibration position. 1 danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to t...

Page 156

Note action the level is measured at the fill hole. Xx1200000957 inspect the oil level. 6 required oil level is: 0 - 10 mm below the oil plug hole. See inspecting the oil level in axis-4 gear- box on page 111 . Tightening torque: 24 nm refit the oil plug. 7 danger make sure all safety requirements a...

Page 157

3.4.6 changing oil, axis-5 gearbox location of oil plugs the oil plugs of the gearbox are located as shown in the figure. Xx1200000959 xx1200000958 oil fill plug / level plug oil drain plug tightening torque: 24 nm. Tightening torque: 24 nm. Required material note material information about the oil ...

Page 158

Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 2 warning handling gearbox oil involves several safety risks. Before proceeding, please read the safety information in the section warning ...

Page 159

Filling oil into the axis-5 gearbox use this procedure to refill the gearbox with oil. Note action run the robot to calibration position. 1 danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 2 warning h...

Page 160

Note action danger make sure all safety requirements are met when performing the first test run. These are further detailed in the section danger - first test run may cause injury or damage! On page 44 . 8 160 3hac044266-001 revision: - © copyright 2013 abb. All rights reserved. 3 maintenance 3.4.6 ...

Page 161

3.4.7 changing oil, axis-6 gearbox location of oil plugs the oil plugs of the gearbox are located as shown in the figure. Xx1200000963 xx1200000962 oil fill plug oil drain plug tightening torque: 24 nm. Tightening torque: 24 nm. Required material note material information about the oil is found in t...

Page 162

Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 2 warning handling gearbox oil involves several safety risks. Before proceeding, please read the safety information in the section warning ...

Page 163

Note action warning used oil is hazardous material and must be disposed of in a safe way. See section decommissioning on page 545 for more in- formation. 8 tightening torque: 24 nm. Refit the oil plugs. 9 filling oil into the axis-6 gearbox use this procedure to refill the gearbox with oil. Note act...

Page 164

Note action the level is measured at the fill hole. Xx1200000963 inspect the oil level. 6 required oil level is: 50 mm ± 5 mm below the sealing surface of the oil plug. Xx1300000693 more information is found in inspecting the oil level in axis-6 gearbox on page 115 . Tightening torque: 24 nm refit t...

Page 165

3.4.8 replacing the smb battery note the battery low alert (38213 battery charge low ) is displayed when the battery needs to be replaced. The recommendation to avoid an unsynchronized robot is to keep the power to the controller turned on until the battery is to be replaced. Warning see instruction...

Page 166

Required spare parts note art. No. Spare part battery includes protection circuits. Only replace with a specified spare part or an abb-approved equivalent. For spare part no. See: • spare parts on page565 battery pack removing, battery use this procedure to remove the smb battery. Note action this i...

Page 167

Refitting, battery use this procedure to refit the smb battery. Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 1 electrostatic discharge (esd) the unit is sensitive to esd. Before handli...

Page 168

3.5 lubrication activities 3.5.1 lubricating the spherical roller bearing, balancing device location of spherical roller bearing the spherical roller bearing is located in the link ear of the balancing device. Xx1300000773 attachment screws m6x10 quality 8.8-a2f (2 pcs) a end cover b radial sealing ...

Page 169

Lubricating the spherical roller bearing use this procedure to lubricate the spherical roller bearing. Note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 1 grease: 3hac042534-001 xx130000078...

Page 170

3.6 cleaning activities 3.6.1 cleaning, robot warning turn off all electrical power supplies to the manipulator before entering its work space. General to secure high uptime it is important that the robot is cleaned regularly. The frequency of cleaning depends on the environment in which the robot w...

Page 171

Note equipment, etc. • max. Water pressure at the nozzle: 700 kn/m 2 (7 bar) i • fan jet nozzle should be used, min. 45° spread • distance from nozzle to encapsulation: min. 0.4 m • flow: max. 20 liters/min i . Water cleaner • water pressure at nozzle: max. 2,500 kn/m 2 (25 bar) • type of nozzle: fa...

Page 172

This page is intentionally left blank.

Page 173: 4 Repair

4 repair 4.1 introduction structure of this chapter this chapter describes all repair activities recommended for the irb 6700 and any external unit. It is made up of separate procedures, each describing a specific repair activity. Each procedure contains all the information required to perform the a...

Page 174

4.2 general procedures 4.2.1 performing a leak-down test when to perform a leak-down test after refitting any motor and gearbox, the integrity of all seals enclosing the gearbox oil must be tested. This is done in a leak-down test. Required equipment note article number equipment, etc. 3hac0207-1 le...

Page 175

4.2.2 mounting instructions for bearings general this section describes how to mount and grease different types of bearings on the robot. Equipment note art. No. Equipment, etc. Used to grease the bearings, if not specified otherwise. 3hab3537-1 grease assembly of all bearings follow the following i...

Page 176

• ensure that grease is handled and stored properly to avoid contamination. Grease the different types of bearings as following description: • grooved ball bearings must be filled with grease from both sides. • tapered roller bearings and axial needle bearings must be greased in the split condition....

Page 177

4.2.3 mounting instructions for seals general this section describes how to mount different types of seals onto the robot. Equipment note art. No. Equipment, etc. Used to lubricate the seals. 3hab3537-1 grease rotating seals the procedure below describes how to fit rotating seals. Caution please obs...

Page 178

Flange seals and static seals the following procedure describes how to fit flange seals and static seals. Action check the flange surfaces. They must be even and free from pores. 1 it is easy to check flatness using a gauge on the fastened joint (without sealing com- pound). If the flange surfaces a...

Page 179

4.3 attaching lifting accessories 4.3.1 arm system (including the frame) definition of the complete arm system the complete arm system consists of the following parts of the robot: • upper arm • wrist • lower arm • frame. Attachment points of lifting accessory required tools note article number equi...

Page 180

Note article number equipment, etc. M12 3hac16131-1 lifting eye outer diameter: minimum 26 mm, hole diameter: 13 mm, thickness: 3 mm. - fender washer sa-10-8-na1 - lifting shackle length: 1.5 m. Lifting capacity: 1,000 kg. - roundsling, 1.5 m length: 1 m. Lifting capacity: 1,000 kg. - roundsling, 1 ...

Page 181

Note action lifting eye: 3hac16131-1 xx1200001133 fit a lifting eye to the wrist. 2 lifting shackle: sa-10-8-na1 xx1200001234 fit a lifting shackle in the wrist lifting eye. 3 caution the complete arm system weigh 1100 kg. All lifting accessories used must be sized accord- ingly! 4 roundsling, 1.5 m...

Page 182

Note action xx1200001235 attach the roundsling to the shackle on the wrist and jog axis-3 slowly to stretch the roundsling. Note make sure the roundsling is stretched, so it can carry the weight of the frame. 6 lifting eye: 3hac16131-1 fit a lifting eye in the arm house, with a fender washer underne...

Page 183

4.3.2 lower and upper arm unseparated attachment points of lifting accessory xx1200001254 required tools note article number equipment, etc. M12 3hac16131-1 lifting eye m12 3hac16131-1 lifting eye outer diameter: minimum 26 mm, hole diameter: 13 mm, thickness: 3 mm. - fender washer sa-10-8-na1 - lif...

Page 184

Note article number equipment, etc. Content is defined in section standard toolkit on page 559 . - standard toolkit attaching the lifting accessories robot position note action note when jogging the axis-2 into position check that the balancing device ear and the ear on the lower arm is not collidin...

Page 185

Attaching the lifting accessories use this procedure to attach the lifting accessories. Note action lifting eye: 3hac16131-1 xx1200001133 fit a lifting eye to the wrist. 1 lifting shackle: sa-10-8-na1 xx1200001234 fit a lifting shackle in the wrist lifting eye. 2 xx1200001251 in order to secure the ...

Page 186

Note action roundsling, 1.5 m: length: 1.5 m. Lifting capacity: 1,000 kg. Xx1200001252 run a roundsling around the lower arm, place it accordingly: • no dresspack cable package installed: place the roundsling beneath the securing screw. • with dresspack cable package installed: place the roundsling ...

Page 187

Note action if the robot is equipped with dresspack, unscrew the attachment screws of the brackets that holds the ball joint housings on the wrist. 11 then move the dresspack cable package over to the other side of where the lifting accessory will be attached to the shackle on the arm house. 12 lift...

Page 188

4.3.3 lifting the upper arm attachment points of lifting accessory xx1200001308 required equipment note article number equipment, etc. M12 3hac16131-1 lifting eye m12 3hac16131-1 lifting eye outer diameter: minimum 26 mm, hole diameter: 13 mm, thickness: 3 mm. - fender washer lifting instruction 3ha...

Page 189

Lifting the upper arm attaching the lifting accessories use this procedure to attach the lifting accessories to the upper arm. Note action lifting eye: 3hac16131-1 xx1200001133 fit a lifting eye to the wrist. 1 lifting eye: 3hac16131-1 fit a lifting eye in the arm house, with a fender washer underne...

Page 190

Note action in case of necessary adjustments, use the shortening loops on the lifting accessory (chain), making sure to place the chain the right way through the loops! 6 release the brakes in order to find the most level lifting position of the upper arm as possible, before lifting. 7 24 vdc power ...

Page 191

4.4 complete robot 4.4.1 removing the cable harness location of the cable harness the cable harness is located as shown in the figure. Xx1300000555 required tools and equipment note article number equipment, etc. Content is defined in section standard toolkit on page 559 . - standard toolkit continu...

Page 192

Removing the cable harness - upper arm and wrist these procedures describes how to remove the cable harness in the upper arm and wrist. Preparations before removing the cable harness note action note the specified position shown below is a recommended position. Depending on what tool is used, one or...

Page 193

Note action a b c xx1300000821 attachment screws a ball joint housing b bracket c if dresspack is installed: • remove the complete ball joint housing fitted on the bracket. Leave the dresspack cable package fitted in the ball joint housing. • remove the bracket. 4 see ball joint housing in the back ...

Page 194

Note action 24 vdc power supply xx1200001081 if axis-5 is not already in position +90°, connect the 24 vdc power supply, release the brakes and move the axis manually into that position. Connect to r2.Mp5-connector: • + = pin 2 • - = pin 5 2 xx1300000486 remove the wrist cover. 3 xx1300000489 cut th...

Page 195

Note action xx1300000490 pull the cable harness to the side and re- move the heat protection plate. Note keep the heat protection plate somewhere safe until it shall be refitted. 5 disconnecting the axis-6 motor cables note action danger make sure that all supplies for electrical power, hydraulic pr...

Page 196

Note action xx1300000488 disconnect the motor cables. 3 disconnecting the axis-5 motor cables note action danger make sure that all supplies for electrical power, hydraulic pressure, and air pressure are turned off. 1 xx1200001135 unscrew the attachment screws and washers and remove the motor cover....

Page 197

Note action xx1300000656 remove the cable gland cover by perform- ing the following steps: 1 open the inner screw a little (the one the arrow is pointing at). No need to remove this screw. 2 remove the outer screw. 3 slide the cable gland cover away from the inner screw. Make sure the gasket is not ...

Page 198

Note action xx1200001066 disconnect the motor cables. 3 xx1200001067 remove the cable gland cover. Make sure the gasket is not damaged! Tip make a note in which direction the cable exit hole is facing, if the motor also will be removed. The motor shall be refitted in the same position. 4 use caution...

Page 199

Note action xx1300000657 remove the cable guide by unscrewing the attachment screws. 2 xx1200000042 if used, remove the insert that guides the dresspack through the hole in the upper arm, by unscrewing the attachment screws. 3 the figure show irb 6640. Xx1300000658 if used, push the tube containing ...

Page 200

Note action xx1300000557 remove the side cover on the arm tube. 6 xx1300000592 loosen the axis-4 metal clamp that holds the cable harness inside the arm tube by unscrewing the attachment screws. Note the screws are reached from outside the upper arm! 7 xx1300000543 remove the armhouse metal clamp. 8...

Page 201

Note action xx1300000544 open the velcro straps at the cable fixing bracket. Note if dresspack is fitted, the cable fixing bracket is replaced by the cable guide. Xx1300001973 9 xx1300000541 remove the metal clamp on top of the armhouse. 10 continues on next page 3hac044266-001 revision: - 201 © cop...

Page 202

Note action person 1, working at the side hole: xx1300000745 tip this step is best performed by two persons working together. Use caution and remove the cable harness from the wrist like this: • person 1: put one hand inside the side hole and take a hold of the cable harness. • person 2: take a hold...

Page 203

Removing the cable harness - base, frame and lower arm these procedures describes how to remove the cable harness from base, frame and lower arm. Preparations before removing the cable harness note action danger make sure that all supplies for electrical power, hydraulic pressure, and air pressure a...

Page 204

Note action b a xx1300001972 m6x16 and plain washer large 6.4x17x3 a earth b disconnect the earth cable. 4 disconnecting the axis-1 and axis-2 motor cables note action danger make sure that all supplies for electrical power, hydraulic pressure, and air pressure are turned off. 1 xx1200001135 unscrew...

Page 205

Note action xx1200001066 disconnect the motor cables. 3 xx1200001067 remove the cable gland cover. Make sure the gasket is not damaged! Tip make a note in which direction the cable exit hole is facing, if the motor also will be removed. The motor shall be refitted in the same position. 4 use caution...

Page 206

Note action xx1300000829 open the small cover on the smb cover, disconnect the battery cable and remove the battery. 3 xx1300000669 remove the smb cover. 4 disconnecting the bu unit note action danger make sure that all supplies for electrical power, hy- draulic pressure, and air pressure are turned...

Page 207

Removing the cable harness in the base note action if used, use caution and pull out the dresspack hoses through the protection tube in the base. 1 if used, use caution and pull out the dresspack cables through the protection tube and place it safely over the balancing device. 2 xx1300000732 use cau...

Page 208

Note action xx1200001237 cut the cable tie inside the hole in the frame. 5 xx1300001114 disconnect connectors on the smb unit. 6 xx1300000730 unscrew the screws and washers that holds the bracket with the smb unit, and remove the smb unit. 7 put the smb unit in an esd bag until it shall be refitted....

Page 209

Note action xx1300000655 unscrew the three attachment screws that hold the smb/bu cover from inside the smb recess. 9 xx1300000560 use caution and pull out the cable harness from the smb recess. 10 xx1300000593 use caution and pull out the cable harness through the hole in the frame. 11 continues on...

Page 210

Removing the cable harness in the lower arm note action xx1200001282 loosen the axis-2 lower arm metal clamp and the axis-3 lower arm metal clamp loc- ated on the inside of the lower arm by re- moving the attachment screws. Note the screws are reached from the outside of the lower arm. 1 xx130000073...

Page 211

4.4.2 refitting the cable harness location of the cable harness the cable harness is located as shown in the figure. Xx1300000555 spare part note spare part number spare part see product manual, spare parts - irb 6700 . Cable harness required tools and equipment note article number equipment, etc. C...

Page 212

Consumables note article number consumable used to lubricate o-rings. 3hab3537-1 grease d=84.5x3 21522012-429 o-ring used on the smb/bu cover. D=169.5x3 3hab3772-111 o-ring used on axis-1 motor cover. D=169.5x3 3hab3772-111 used on axis-2 motor cover. D=169.5x3 3hab3772-111 used on axis-3 motor cove...

Page 213

Note action xx1300000733 run the upper end of the cable harness up through the lower arm. 3 xx1300000734 secure the axis-2 lower arm cable bracket. Note do not secure the axis-3 lower arm cable bracket at this point. Note screws are reached from the outside of the lower arm. 4 xx1300000735 run the c...

Page 214

Note action xx1300000737 fit the o-ring. 3 the figure shows the position of the o-ring. Apply sikaflex on the o-ring before as- sembly. 4 xx1300000560 run the smb/bu cables into the smb re- cess. 5 xx1300000655 use caution and fit the smb/bu cover in its hole with three attachment screws from inside...

Page 215

Note action xx1300000593 adjust the cables running through the hole in the frame by carefully moving the smb/bu cover on its screws, while at the same time checking the position of the cable harness through the hole. Note the cables must be placed so that they don't rub against any part of the robot...

Page 216

Note action xx1300000542 refit the frame metal clamp. 11 refitting the cable harness in the base note action xx1300000732 use caution and run the cables down through the protection tube in this order: • r1.Mp • r1.Smb 1 xx1300000736 • make sure that the cables are not twisted. The cables shall be in...

Page 217

Note action xx1300000591 connect r1.Mp and r1.Smb. 4 b a xx1300001972 m6x16 and plain washer large 6.4x17x3 a earth b connect the earth cable. 5 if used, run the dresspack cables down through the protection tube in the base. 6 if used, run the dresspack hoses down through the protection tube in the ...

Page 218

Note action xx1300000561 refit the base cover. 9 refit and reconnect the smb and bu units note action danger make sure that all supplies for electrical power, hydraulic pressure, and air pressure are turned off. 1 electrostatic discharge (esd) the unit is sensitive to esd. Before handling the unit p...

Page 219

Note action xx1300000728 connect all connectors to the smb board: r1.Smb1-3, r1.Smb4-6 and r2.Smb 4 xx1300000730 use caution, push in the smb unit into position and fit the bracket that hold the smb unit. 5 xx1300000670 if disconnected, reconnect the connectors x8, x9 and x10 to the brake release bo...

Page 220

Note action xx1300000669 secure the smb cover with its attachment screws. 8 reconnecting the axis-1 and axis-2 motor cables note action xx1300000738 push the motor cables in through the cable gland opening. 1 xx1200001067 refit the cable gland cover. Note replace the gasket if damaged! 2 continues o...

Page 221

Note action xx1200001066 connect the motor cables. Connect in accordance with the markings on the connectors. 3 o-ring, axis-1: 3hab3772-111 check the o-ring. 4 o-ring, axis-2: 3hab3772-111 replace if damaged! O-ring, axis-3: 3hab3772-111 o-ring, axis-4: 3hab3772-110 xx1200001070 wipe clean o-ring a...

Page 222

Refitting the cable harness - lower arm note action xx1300000595 before fitting the remaining axis-3 lower arm cable bracket inside the lower arm, make sure that it will stay twisted between the metal clamps, after fitting, as shown in the figure. 1 xx1300000558 refit the axis-3 lower arm metal clam...

Page 223

Refitting the cable harness - upper arm and wrist these procedures describes how to refit the cable harness in upper arm and wrist. Refitting the cable harness - upper arm note action xx1300000541 refit the metal clamp on top of the arm house. 1 xx1300000543 refit the arm house metal clamp. 2 make s...

Page 224

Note action person 1, working at the side hole: xx1300000745 tip this step is best performed by two persons working together: • person 1: put one hand inside the side hole of the arm tube and take a hold of the cable harness. • person 2: take a hold on the cable harness at the back of the robot. • t...

Page 225

Note action use caution and push the cable harness into the upper arm tube. 8 person 1, working at the side hole: xx1300000745 tip this step is best performed by two persons working together. Use caution and push the cable harness into the wrist like this: • person 1: put one hand inside the side co...

Page 226

Note action xx1200000042 if used, refit the insert that guides the dresspack cable package through the hole in the upper arm. 12 the figure show irb 6640. Xx1300000658 if used, refit the tube containing the dresspack into the insert. 13 the figure show irb 6640. Xx1200000045 if used, refit the cover...

Page 227

Note action xx1300000544 secure the cable harness to the cable fixing bracket with the velcro strap. Note if dresspack is fitted, the cable fixing bracket is replaced by the cable guide. Xx1300001973 15 connecting the axis-3 and axis-4 motor cables note action xx1300000738 push the motor cables in t...

Page 228

Note action xx1200001066 connect the motor cables. Connect in accordance with the markings on the connectors. 3 o-ring, axis-1: 3hab3772-111 check the o-ring. 4 o-ring, axis-2: 3hab3772-111 replace if damaged! O-ring, axis-3: 3hab3772-111 o-ring, axis-4: 3hab3772-110 xx1200001070 wipe clean o-ring a...

Page 229

Connecting the axis-5 motor cables note action xx1300000738 push the motor cables in through the cable gland opening. 1 xx1200001016 refit the cable gland cover by performing the following steps: • slide the cable gland cover onto the inner screw. • refit and tighten the outer screw. • tighten the i...

Page 230

Note action o-ring, axis-5, 3hab3772-110 xx1200001021 check the o-ring on the motor. Replace if damaged! 4 xx1200001013 refit the motor cover with its attachment screws. Note do not refit the screws that will hold the heat protection plate at this point. Note do not reuse the self-threading attachme...

Page 231

Note action xx1300000489 secure the cable harness with the cable straps to the heat protection plate. 7 make sure that the cover is tightly sealed. 8 connecting the axis-6 motor cables note action xx1300000596 make sure that the cable harness will be placed in a way that it will not be damaged when ...

Page 232

Note action xx1300000667 use caution and push the cable harness into the wrist recess and up into the axis-6 motor. 3 xx1300001113 use caution and push the carrier into posi- tion. 4 xx1300000485 secure the carrier with the m4 screw. Note the screw is located at the bottom of the carrier. Tip the at...

Page 233

Note action xx1300000488 reconnect the connectors to the axis-6 motor. Note place the resolver cable under the motor cable. 7 gasket, 3hac033489-001 xx1200001095 check the gasket. Replace if damaged! 8 xx1200001080 refit the motor cover. 9 disconnect the 24 vdc power supply (if used). 10 continues o...

Page 234

Concluding procedures note action tightening torque: 10 nm. Xx1300000772 use caution and refit the wrist cover. In order not to damage the cable harness when the wrist cover is refitted, by following this method: 1 hold the cover in an angle. See figure! 2 catch any part of the cable harness hanging...

Page 235

4.4.3 replacing the smb location of smb unit the smb unit (smb = serial measurement board) is located inside the smb/bu recess, as shown in the figure. Xx1300000740 spare part note art. No. Equipment, etc. See product manual, spare parts - irb 6700 . Smb unit see product manual, spare parts - irb 67...

Page 236

Removing the smb unit use these procedures to disconnect and remove the smb unit. Preparations before disconnecting the smb unit note action danger make sure that all supplies for electrical power, hy- draulic pressure, and air pressure are turned off. 1 electrostatic discharge (esd) the unit is sen...

Page 237

Note action xx1300000730 remove the screws and washers that holds bracket with the smb unit. 3 xx1300000728 use caution, pull out the smb unit a little and discon- nect the connectors from the smb board: r1.Smb1-3, r1.Smb4-6 and r2.Smb 4 xx1300000731 use caution and pull out the smb unit and put it ...

Page 238

Note action xx1300000729 connect the battery cable to the smb unit. 3 xx1300000728 connect all connectors to the smb board: r1.Smb1-3, r1.Smb4-6 and r2.Smb 4 xx1300000730 use caution, push in the smb unit into position and fit the bracket that hold the smb unit. 5 xx1300000670 if disconnected, recon...

Page 239

Note action xx1300000834 pull out the battery cable through the recess for the battery. 7 xx1300000669 secure the smb cover with its attachment screws. 8 refitting the smb battery note action electrostatic discharge (esd) the unit is sensitive to esd. Before handling the unit please read the safety ...

Page 240

Concluding procedures note action see updating revolution counters on page 542 . Update the revolution counter! 1 danger make sure all safety requirements are met when performing the first test run. These are further detailed in the section danger - first test run may cause injury or damage! On page...

Page 241

4.4.4 replacing the brake release unit location of bu unit the brake release unit (bu unit) is located inside smb/bu recess, as shown in the figure. Xx1300000741 spare part note art. No. Equipment, etc. See product manual, spare parts - irb 6700 . Brake release unit see product manual, spare parts -...

Page 242

Removing the brake release unit preparations note action danger turn off all: • electric power supply • hydraulic pressure supply • air pressure supply to the robot, before entering the robot working area. 1 electrostatic discharge (esd) the unit is sensitive to esd. Before handling the unit please ...

Page 243

Disconnecting the bu unit note action danger make sure that all supplies for electrical power, hy- draulic pressure, and air pressure are turned off. 1 electrostatic discharge (esd) the unit is sensitive to esd. Before handling the unit please read the safety information in the section warning - the...

Page 244

Refitting the brake release unit use this procedure to refit the brake release unit. Note action electrostatic discharge (esd) the unit is sensitive to esd. Before handling the unit please read the safety information in the section warning - the unit is sensitive to esd! On page 47 1 xx1300000744 re...

Page 245

Note action xx1300000743 refit the push button guard to the smb cover. 6 see updating revolution counters on page 542 . The revolution counters must be updated if the battery has been disconnected. 7 danger make sure all safety requirements are met when performing the first test run. These are furth...

Page 246

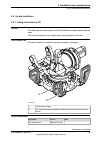

4.5 upper and lower arms 4.5.1 replacing the upper arm location of the upper arm the upper arm is located as shown in the figure. These sections describe how to replace the complete upper arm, which includes the wrist unit. Xx1300000483 spare part note spare part number spare part see product manual...

Page 247

Note article number equipment, etc. Used for putting down removed parts from robot. Pallet always use guide pins in pairs! 3hac13056-2 guide pin, m12x150 always use guide pins in pairs! 3hac13056-3 guide pin, m12x200 used to release the motor brakes. - 24 vdc power supply 3hac15716-1 calibration pen...

Page 248

Note action xx1300000818 if dresspack is installed: 1 remove the complete ball joint housing. 2 remove the bracket fitted between the ball joint housing and the wrist cover. 4 retrieving access to the wrist cabling use this procedure to open the wrist and access the axis-5 and axis-6 motor cables. N...

Page 249

Note action xx1300000486 remove the wrist cover. 3 xx1300000489 cut the cable straps that hold the cable harness to the heat protection plate. 4 xx1300000490 pull the cable harness to the side and re- move the heat protection plate. Note keep the heat protection plate somewhere safe until it shall b...

Page 250

Note action xx1200001080 unscrew the attachment screws and re- move the motor cover. 2 xx1300000488 disconnect the motor cables. 3 disconnecting the axis-5 motor cables note action danger make sure that all supplies for electrical power, hydraulic pressure, and air pressure are turned off. 1 xx12000...

Page 251

Note action xx1200001066 disconnect the motor cables. 3 xx1300000656 remove the cable gland cover by perform- ing the following steps: 1 open the inner screw a little (the one the arrow is pointing at). No need to remove this screw. 2 remove the outer screw. 3 slide the cable gland cover away from t...

Page 252