- DL manuals

- ABB

- Robotics

- M2000

- Reference Manual

ABB M2000 Reference Manual

Summary of M2000

Page 1

Product manual (part 2 of 2), reference information articulated robot irb 140 m2000, m2000a, m2004.

Page 3

Product manual (part 2 of 2), reference information irb 140 m2000 m2000a m2004 document id: 3hac023297-001 revision: a.

Page 4

The information in this manual is subject to change without notice and should not be construed as a commitment by abb. Abb assumes no responsibility for any errors that may appear in this manual. Except as may be expressly stated anywhere in this manual, nothing herein shall be construed as any kind...

Page 5

Table of contents 3 3hac023297-001 revision: a overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 product documentation, m2000/m2000a . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Table of contents 3hac023297-001 revision: a 4.

Page 7

Overview 5 3hac023297-001 revision: a overview about this manual this manual contains reference information for all procedures in part 1: product manual, procedures . Usage this manual should be used during: • installation • maintenance work • repair work. Who should read this manual? This manual is...

Page 8

Overview 3hac023297-001 revision: a 6 revisions revision description - first edition replaces previous manuals: • installation and commissioning manual • maintenance manual • repair manual, part 1 • repair manual, part 2 changes made in the material from the previous manuals: • model m2004 implement...

Page 9

Product documentation, m2000/m2000a 7 3hac023297-001 revision: a product documentation, m2000/m2000a general the complete product documentation kit for the m2000 robot system, including controller, robot and any hardware option, consists of the manuals listed below: hardware manuals all hardware, ro...

Page 10

Product documentation, m2004 3hac023297-001 revision: a 8 product documentation, m2004 general the robot documentation may be divided into a number of categories. This listing is based on the type of information contained within the documents, regardless of whether the products are standard or optio...

Page 11

Product documentation, m2004 9 3hac023297-001 revision: a • how to use the application • examples of how to use the application operator’s manuals this group of manuals is aimed at those having first hand operational contact with the robot, i.E. Production cell operators, programmers and trouble sho...

Page 12

Product documentation, m2004 3hac023297-001 revision: a 10

Page 13: 1 Reference Information

1 reference information 1.1. Introduction 11 3hac023297-001 revision: a 1 reference information 1.1. Introduction general this chapter includes general information, complementing the more specific information in the product manual (part 1 of 2), procedures ..

Page 14

1 reference information 1.2. Applicable safety standards 3hac023297-001 revision: a 12 1.2. Applicable safety standards standards, general the robot is designed in accordance with the requirements of: • en iso10218-1 : 2005, robots for industrial environments - safety requirements - part 1 robot • a...

Page 15

1 reference information 1.3. Unit conversion 13 3hac023297-001 revision: a 1.3. Unit conversion converter table use the table below to convert units used in this manual. Quantity units length 1 m 3.28 ft 39.37 in weight 1 kg 2.21 lb pressure 1 bar 100 kpa 14.5 psi force 1 n 0.738 lbf moment 1 nm 0.7...

Page 16

1 reference information 1.4. Screw joints 3hac023297-001 revision: a 14 1.4. Screw joints general this section details how to tighten the various types of screw joints on the robot and the controller. The instructions and torque values are valid for screw joints comprised of metallic materials and d...

Page 17

1 reference information 1.4. Screw joints 15 3hac023297-001 revision: a • only use correctly calibrated torque keys. • always tighten the joint by hand, and never use pneumatical tools. • use the correct tightening technique, i.E. Do not jerk. Tighten the screw in a slow, flowing motion. • maximum a...

Page 18

1 reference information 1.4. Screw joints 3hac023297-001 revision: a 16 the table below specifies the recommended standard tightening torque for water and air connectors when one or both connectors are made of brass. Dimension tightening torque nm - nominal tightening torque nm - min. Tightening tor...

Page 19

1 reference information 1.5. Weight specifications 17 3hac023297-001 revision: a 1.5. Weight specifications definition in all repair and maintenance procedures, weights of the components handled are sometimes specified. All components exceeding 22 kg (50 lbs) are high-lighted in this way. To avoid i...

Page 20

1 reference information 1.6. Document references 3hac023297-001 revision: a 18 1.6. Document references general the contents of this manual may include references to additional documentation necessary to perform certain procedures. This section specifies the article numbers for the referenced docume...

Page 21

1 reference information 1.6. Document references 19 3hac023297-001 revision: a additional documentation document name document id note external axes 3hac 9299-1.

Page 22

1 reference information 1.7. Standard toolkit 3hac023297-001 revision: a 20 1.7. Standard toolkit general all service (repair, maintenance and installation) instructions contain lists of tools required to perform the specified activity. All special tools, i.E. All tools that are not considered stand...

Page 23

1 reference information 1.8. Performing a leak-down test 21 3hac023297-001 revision: a 1.8. Performing a leak-down test general after refitting any motor and any gearbox, the integrity of all seals enclosing the gearbox oil must be tested. This is done in a leak-down test. Required equipment procedu...

Page 24

1 reference information 1.9. Lifting equipment and lifting instructions 3hac023297-001 revision: a 22 1.9. Lifting equipment and lifting instructions general many repair and maintenance activities require different pieces of lifting equipment, which are specified in each procedure. The use of each p...

Page 25

1 reference information 1.10. Mounting instructions for bearings 23 3hac023297-001 revision: a 1.10. Mounting instructions for bearings general this section details how to mount and grease different types of bearings on the manipulator. Equipment assembly of all bearings follow the instructions belo...

Page 26

1 reference information 1.11. Mounting instructions for seals 3hac023297-001 revision: a 24 1.11. Mounting instructions for seals general this sections details how to mount different types of seals to the manipulator. Equipment rotating seals the procedure below details how to fit rotating seals. Ca...

Page 27

1 reference information 1.11. Mounting instructions for seals 25 3hac023297-001 revision: a flange seals and static seals the procedure below details how to fit flange seals and static seals. O-rings the procedure below details how to fit o-rings. Step action note 1. Check the flange surfaces. They ...

Page 28

1 reference information 1.11. Mounting instructions for seals 3hac023297-001 revision: a 26.

Page 29: 2 Spare Part / Part List

2 spare part / part list 2.1. Introduction 27 3hac023297-001 revision: a 2 spare part / part list 2.1. Introduction definitions this chapter specifies all spare parts and replacement articles of the robot..

Page 30

2 spare part / part list 2.2. Spare part / part list 3hac023297-001 revision: a 28 2.2. Spare part / part list spare part / part list the table below details all replacement articles on the robot. The items refer to chapter foldouts. Item qty art. No. Name rem. 1 1 3hac 10470-1 base spare 2 1 3hac 8...

Page 31

2 spare part / part list 2.2. Spare part / part list 29 3hac023297-001 revision: a 35 1 3hac 10477-2 control cable spare cr l = 7 m 36 1 3hac 11331-1 control cable spare std/f l = 15 m 37 1 3hac 11331-2 control cable spare cr l = 15 m 38 1 3hac 13089-1 control cable spare std/f l = 30 m 39 1 3hac 13...

Page 32

2 spare part / part list 2.2. Spare part / part list 3hac023297-001 revision: a 30 111 4 3hab 3402-15 hex. Socket head cap screw m5x20 8.8 gleitmo 610 112 12 9ada 312-5 plain washer 5.3x10x1 113 1 3hac 9258-1 indicator lamp 114 1 3hac 10468-4 lower arm, spare cr 115 1 3hac 10471-3 cover, without lam...

Page 33

2 spare part / part list 2.2. Spare part / part list 31 3hac023297-001 revision: a 179 2 2125 2052-178 distance bolt m5x55 180 1 3hac 6598-1 hose nipple g 1/4" 181 1 3hab 8964-1 damper axis 5 182 550 ml 3hac 0860-1 lubricating oil optimol opti- gear bm 100 183 1 3hac 10466-3 upper arm, spare cr 184 ...

Page 34

2 spare part / part list 2.2. Spare part / part list 3hac023297-001 revision: a 32.

Page 35: 3 Foldouts

3 foldouts 3.1. Introduction 33 3hac023297-001 revision: a 3 foldouts 3.1. Introduction overview the foldouts in this chapter refer to the part list..

Page 36

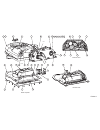

1 15 18 27 8 13 21 r1/4 4 5 7 16 17 24 6 8 11 9 26 2 3 25 12 10 3 30 32 35 nm base complete 29 31 inside of base 22 23 28 3 3 31 20 19 inside of cover foldout 1 33 34 36 35 37 38 39.

Page 37

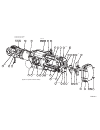

Foldout 2 51 62 56 8 57 58 52 53 62 52 55 54 53 52 51 63 31 59 31 63 63 64 60 61 61 50 54 53 52 31 32 15,5 nm 52 53 67 63 70 68 69 71 ax.1 1,2 litre ax.2 1,0 litre a 65 25 31 72 25 a (1 : 2).

Page 38

109 110 3 100 17 16 108 107 103 101 102 64 3 105 104 112 111 106 8 18 113 4,1 nm 35 nm lower arm (shown without cables) do not loosen these screws 0,4 litre 67 66 lower arm complete with cables (shown without cover) do not loosen these screws foldout 3 114 115 116.

Page 39

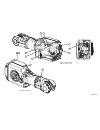

Foldout 4 174 175 8 12 112 163 169 172 169 170 165 166 171 176 156 108 157 158 173 162 164 162 160 163 112 112 163 111 112 161 112 111 181 152 151 153 154 180 159 upper arm (shown without cables) 4,1 nm 35 nm 6 nm 4,1 nm 4,1 nm 6 nm 4,1 nm 3 nm 182 28 nm 0,30 litre oil (new wrist) 182 0,2 litre oil ...

Page 40

Upper arm with cables (shown without cover) 178 155 upper arm complete foldout 5 177 3 20 168 165 179 167 150 187 183.

Page 42: 4 Circuit Diagram

4 circuit diagram 4.1. Introduction 35 3hac023297-001 revision: a 4 circuit diagram 4.1. Introduction overview this chapter includes the circuit diagram for the robot..

Page 43

Circuit diagram contents page irb 140 manipulator, diagram 3hac 6816-3, rev. 0 ..............................................................101-108.

Page 44

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 101 list of contents.

Page 45

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 102 connection point locations.

Page 46

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 103 serial measurement board.

Page 47

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 104 motor axis 1 - 3.

Page 48

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 105 feedback axis 1 - 3.

Page 49

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 106 motor axis 4 - 6.

Page 50

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 107 feed-back axis 4 - 6.

Page 51

Manipulator circuit diagram 3hac 6816-3 irb 140 no. Of sheets 8 sheet no. 108 customer connections.

Page 54

Abb automation technologies ab robotics s-721 68 vÄsterÅs sweden telephone: +46 (0) 21 344000 telefax: +46 (0) 21 132592 3h ac 02 329 7-0 01 p a rt 2, re vi s ion a , en.