- DL manuals

- ABB

- Laboratory Equipment

- PGC2000

- Operation And Service Manual

ABB PGC2000 Operation And Service Manual

Summary of PGC2000

Page 1

Operation and service manual process gas chromatograph pgc2000 2000-osm f2: october 2008.

Page 2

Notice material contained within this manual is proprietary information of abb inc. And is to be used only for the purpose of understanding and operating this product. Specifications are subject to change without notice. ©2000 - 2008, abb inc. Abb has no obligation with respect to any abb equipment ...

Page 3

2000-osm, f2 i list of effective pages—pgc2000 manual date of issue for each version of this manual: a1 february 2000 b5 january 2002 e2 april 2006 a2 august 2000 c1 august 2002 e3 september 2006 b1 january 2001 c2 november 2002 e4 july 2007 b2 march 2001 d1 august 2004 e5 september 2007 b3 august 2...

Page 4

Ii 2000-osm, f1 table of contents title page glossary .............................................................................................................................................. G-1 section 1. Introduction equipment description ........................................................

Page 5

2000-osm, f1 iii table of contents (continued) title page equipment startup .......................................................................................................................... 2-15 initial power on ..................................................................................

Page 6

Iv 2000-osm, f1 table of contents (continued) title page circuit boards .................................................................................................................................. 4-11 power supply pcb ..............................................................................

Page 7

2000-osm, f1 v table of contents (continued) title page regular report .................................................................................................................................. 4-33 short report ...................................................................................

Page 8

Vi 2000-osm, f1 table of contents (continued) title page cleaning ............................................................................................................................................... 5-2 diagnostic tests ........................................................................

Page 9

2000-osm, f1 vii table of contents (continued) title page oven temperature is greater than t-rating ................................................................................... 6-16 reasonableness ...................................................................................................

Page 10

Viii 2000-osm, f1 table of contents (continued) title page section 7. Test procedures tp 1: carrier, makeup, and utility gas supplies .................................................................... 7-1 tp 2: carrier and makeup gas flow adjustments ..................................................

Page 11

2000-osm, f1 ix table of contents (continued) title page section 8. Repair replacing heaters ............................................................................................................................ 8-1 isothermal temperature oven heater ..............................................

Page 12

X 2000-osm, f2 table of contents (continued) title page removing the catalytic tubes ........................................................................................................... 8-36 installing the catalytic tubes ..........................................................................

Page 13

2000-osm, f2 xi table of contents (continued) title page information display ............................................................................................................................ 8-66 menu items .....................................................................................

Page 14

Xii 2000-osm, f1 table of contents (continued) title page section 10. Vista basic introduction ...................................................................................................................................... 10-1 using the editor ...................................................

Page 15

2000-osm, f1 xiii table of contents (continued) title page get outstanding requests function .................................................................................. 10-13 get peak type parameter function ........................................................................................

Page 16

Xiv 2000-osm, f1 table of contents (continued) title page power fail alarm function ...................................................................................................... 10-24 previous inject time function ................................................................................

Page 17

2000-osm, f1 xv table of contents (continued) title page valve command ........................................................................................................................... 10-34 write digital output command..........................................................................

Page 18

Xvi 2000-osm, f1 illustrations figure title page 1-1 typical process gas chromatograph pgc2000 .................................................................... 1-1 1-2 pgc with flame photometric detector .................................................................................. 1-2 2-1 l...

Page 19

2000-osm, f1 xvii illustrations (continued) figure title page 4-14 method table #?? Screen .................................................................................................... 4-16 4-15 cal define & cycle time screen ......................................................................

Page 20

Xviii 2000-osm, f1 illustrations (continued) figure title page 4-65 solenoid valves .................................................................................................................... 4-75 5-1 recommended preventive maintenance schedule .................................................

Page 21

2000-osm, f2 xix illustrations (continued) figure title page 7-11 background screen .............................................................................................................. 7-26 7-12 commands screen ..................................................................................

Page 22

Xx 2000-osm, f2 illustrations (continued) figure title page 8-47 dual air cleanup assembly .................................................................................................. 8-72 8-48 typical m2cp valve ....................................................................................

Page 23

2000-osm, f1 g-1 glossary a/d converter device that converts an analog signal to a digital value analyzer process gas chromatograph ascii american standard code for information interchange; standardized computer coding for printed characters auto zero procedure bringing the detector signal as close ...

Page 24

G-2 2000-osm, f1 glossary (continued) digital i/o digital input/output pcb; enables the use of additional stream valves and/or alarm sensors dip switch pcb switch that is used to set values through hardware instead of software drift the variances from the baseline or the norm; generally associated w...

Page 25

2000-osm, f1 g-3 glossary (continued) host link serial communications link which allows the transmitting of analysis results to the host computer integer whole numbers that do not contain decimal points i/o input/output lcd liquid crystal display led light emitting diode ll low limits, entered into ...

Page 26

G-4 2000-osm, f1 glossary (continued) post analysis the portion of the controller program that calculates the value for the routine components from the collected data, after completion of the analysis postan abbreviation for the post analysis routine prom programmable read only memory psfc process s...

Page 27

2000-osm, f1 g-5 glossary (continued) trend output analog signal related to concentration of specified component vn vistanet; analytical network that links analyzers, dcs, and support people using the data vnsa vistanet name service administrator; pc software that serves as the address book for the ...

Page 28

G-6 2000-osm, f1 caution all analyzers bearing the ce mark imprint on their nameplates have electromagnetic compatibility (emc) shielding that meets the requirements for ce marking. When working with one of these analyzers, you must handle it carefully to avoid damaging the shielding. If any shieldi...

Page 29

2000-osm, f1 1-1 section 1. Introduction equipment description the process gas chromatograph pgc2000 separates and measures the individual components of gas or liquid samples. It automatically samples and analyzes process streams, using the analyzer's gas chromatograph controller (gcc) to control an...

Page 30

1-2 2000-osm, f1 each analyzer has a temperature code (t-rating) listed on the nameplate. This t-rating indicates the temperature classification of the area in which the analyzer has been designed to operate. T- ratings and area classifications for analyzer locations are determined and supplied by t...

Page 31

2000-osm, f1 1-3 system variations this manual supports the pgc2000 basic analyzer. An appendix to the main manual presents additional instructions for special applications such as pgc2002 (simulated distillation), pgc2003 (pna), pgc2005 (temperature programmed gc), pgc2007 (fuel sulfur), pgc2008 (o...

Page 32

1-4 2000-osm, f1 power warning the neutral and ground (earth) connections to the pgc2000 must be at earth (0 volts) potential. Failure to maintain earth (0 volts) potential at these connection points constitutes a serious safety hazard. Voltage and frequency: 100 vac (+15, -6 vac), 50/60 hz ± 10% 12...

Page 33

2000-osm, f1 1-5 temperature control method: closed loop pid ambient oven temperature: + 30° to 180° c (settings and display in °c only) setpoint resolution: 1° c temperature stability: steady ambient: ±0.1° c ambient range: ±1.0° c gas control (analog) control method: mechanical regulators filtrati...

Page 34

1-6 2000-osm, f1 gas control (digital) control method: closed loop pid; temperature stabilized number of zones: 1 to 5 filtration: 2 microns at inlet, provided inlet pressure: minimum: setpoint + 10 psig (69 kpa, 0.7 bar) maximum: 100 psig (689 kpa, 6.89 bar) note it is the customer's responsibility...

Page 35

2000-osm, f1 2-1 section 2. Installation and start-up safety considerations before starting to install the analyzer, read the safety information below. Warning before beginning installation, repair, or maintenance on the analyzer, contact the local safety department to ensure that all safety guideli...

Page 36

2-2 2000-osm, f1 3/16-inch flat blade screwdriver 1/8-inch flat blade screwdriver 9/64-inch ball driver 7/16-inch open end wrenches (2) 1/2-inch open end wrenches (2) 9/16-inch open end wrenches (2) 5/8-inch open end wrenches (2) 6-inch adjustable wrench 12-inch adjustable wrench 3/8-inch drive sock...

Page 37

2000-osm, f1 2-3 purge air alarm the analyzer contains circuits that detect the loss of purge air to the analyzer and generate alarm signals to the operator. The customer has the responsibility to connect the purge alarm to a visual or audible annunciator located in a constantly monitored area, as r...

Page 38

2-4 2000-osm, f1 new analyzers have the sample lines connected to a mounting plate attached to the lsv's mounting flange, as shown in figure 2-2. Customer connections figure 2-2. Lsv connection methods, new analyzers you must take extreme care to avoid having the sample lines exert force on the samp...

Page 39

2000-osm, f1 2-5 1. Do not remove the tube caps, provided at the analyzer tubing ports to prevent deterioration of the columns, until immediately before making each connection. 2. Use an anticorrosion material for the lines and fittings. 3. To ensure using proper size tubing and pipe, refer to the o...

Page 40

2-6 2000-osm, f1 the manifold vent must be plumbed from the analyzer to a safe area at 0 psia or atmospheric vent. To do this, connect appropriate tubing to the manifold vent (see figure 2-3) and run this tubing to a hazard-free area. Manifold vent figure 2-3. Side view of analyzer, showing manifold...

Page 41

2000-osm, f1 2-7 • contact output error alarms, timing signal, status signal, and annunciator • contact input operation start/stop, mode-selection request, etc. • analog output (4 to 20 ma) analog hold output, chromatogram recorder output • analog input (-10 to +10 volts) • detector output (10 volts...

Page 42

2-8 2000-osm, f1 sample system checkout verify that the sample system has been leak and flow checked and is known to be operating correctly. Gcc pre-checks caution before opening any analyzer doors, ensure the area is safe and hazard-free and will remain so the entire time the analyzer is open. 1. V...

Page 43

2000-osm, f1 2-9 5. Refer to figure 2-4 (when epc is installed, the pressure control panel will be blank). The purge air and heater air pressures should be as specified on the label below the corresponding regulator. Purge air panel pressure control panel figure 2-4. Analyzer adjustments 6. Turn on ...

Page 44

2-10 2000-osm, f1 matching column flows when you are matching column flows, refer to the data package for flow rates and valve configurations. Although methods of matching column flows vary with valve configurations, the following procedures apply to most configurations. Verify flows using a flow me...

Page 45

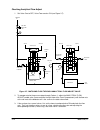

2000-osm, f1 2-11 checking total column flow to check column flow using a 10-port sample valve and an 8-port selector valve, perform the following steps (other valve configurations use similar procedures): 1. Turn all valves off as described in the previous paragraph. 2. See figure 2-6. To check tot...

Page 46

2-12 2000-osm, f1 checking analytical flow adjust 1. Set valve one to off; valve two remains on (see figure 2-7). Column pressure adj air in air out air out air in analytical flow adj backflush vent sample in sample vent column 2 sample loop column 1 selector flow adj selector vent cell vent detecto...

Page 47

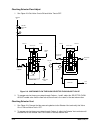

2000-osm, f1 2-13 checking backflush flow 1. Connect the flow-measuring device to the backflush vent and verify that valves one and two are off (see figure 2-8). 2. Adjust the backflush vent restrictor to the flow rate stated in the data package. 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 9 9 10 10 carrier in ...

Page 48

2-14 2000-osm, f1 checking selector flow adjust 1. See figure 2-9. Set valve one to on and valve two to off. Column pressure adj air out air in air in air out analytical flow adj backflush vent sample in sample vent column 2 sample loop column 1 selector flow adj selector vent cell vent detector car...

Page 49

2000-osm, f1 2-15 equipment startup caution before opening any analyzer doors, ensure the area is safe and hazard-free and will remain so the entire time the analyzer is open. The following instructions assume that all equipment has been properly installed and checked, that the analyzer has been app...

Page 50

2-16 2000-osm, f1 caution it is the customer’s responsibility to ensure that the hydrogen supply to the analyzer does not exceed 100 psig (689 kpa, 6.89 bar) and that the customer’s pressure relieving devices are set to relieve at 200 psig (1380 kpa, 13.8 bar). Failure to control the hydrogen pressu...

Page 51

2000-osm, f1 2-17 caution do not ignite fpd/fid flame if the isothermal oven temperature is below operational level. Low oven temperature will result in condensation damage to the flame cell. Check oven temperature on the temperature control screen (see "temperature control table" in section 4). 13....

Page 52

2-18 2000-osm, f1 b. On the chroma board screen, verify that the fpd temp zone is the same as that specified in the data package (see figure 2-10). C. On the chroma board screen, observe the "ignitor" line. "manual" should be underlined. D. Press the f1 (exit) soft key. E. On the manual control mode...

Page 53

2000-osm, f1 2-19 g. On the manual temperature control mode screen (see figure 2-11), verify that the actual temperature for the fpd is at least 120 degrees. **** manual temperature control mode **** zone config actual sp rate iso-oven iso 79.9 80.0 0.0 prog. Oven prog/c 220.1 220.0 0.0 fpd iso 120....

Page 54

2-20 2000-osm, f1 1. Verify that the background screen is displayed (see figure 2-12). If it is not displayed, press the f1 soft key several times until the background screen appears. ********** b a c k g r o u n d ********** abb analytical gcc remote 0.1 803v029-1r (std gcc) (c) 2001 **alarm** **al...

Page 55

2000-osm, f1 2-21 4. Press the f2 (test printer) soft key. A string of characters should print. If characters print go to step 5. If a string of characters does not print go to step 9. 5. Verify that the cursor is on printer. 6. Press the f3 (print tables) soft key. 7. Select a table to print. Repea...

Page 56

2-22 2000-osm, f1 8. On the request analysis screen (see figure 2-13), select the method number for a calibration run. ****** request analysis ****** analysis requests: for a benchmark or calibration enter the method#, otherwise enter the stream#:[1 ] none stream bench cal pending: 00 00 00 accept c...

Page 57

2000-osm, f1 2-23 20. On the commands screen cursor to analysis control, if necessary, and press the f4 (start/stop analysis) soft key. 21. On the start/stop analysis screen, cursor to “at end of analysis?” and then press the f2 (stop analyzer) soft key. 22. Press the f1 soft key as necessary to ret...

Page 58

2-24 2000-osm, f1 note each time one of these address switches is changed, you must initialize the switch selections. To do this, open the gcc front panel, press and release the reset switch on the single board computer pcb, and then close the front panel. Additionally, you must restore the tables f...

Page 59

2000-osm, f1 2-25 5. Set the switch positions to the desired remote number, using figure 2-15 as a guide. #10 #6 #22 #7 #23 #9 #25 #26 #1 #17 #8 #24 #2 #18 #3 #19 #4 #20 #5 #21 #11 #27 #12 #28 #13 #29 #14 #30 #15 #31 #16 #32 remote no. Switch no. Switch no. 1 1 1 1 1 5 4 3 2 1 1 1 1 1 0 1 1 1 0 1 1 ...

Page 60

2-26 2000-osm, f1 • the screen saver option lets you blank the display screen when it is not being used. Sw1-8 off activates the screen saver, while sw1-8 on disables this feature. If the gcc has user nameable inputs option, you may insert names for up to five sensor inputs (digital inputs on the ch...

Page 61

2000-osm, f1 2-27 2. On the manual control mode screen (see figure 2-16), cursor down to chroma, then left to off. ****** manual control mode ****** valves:- - - - - - - - time:00000 enter valve: [0] cycle time:00000 recorder: method tbl: 000 offset : 0 % stream: 01 attn : 5 purging: 01 off chroma b...

Page 62

2-28 2000-osm, f1 3. A message line appears above the soft key, similar to the following: “zero offset used 004%.” a value less than 10% is good. 4. When you have completed the zero offset check, press the f1 soft key as necessary to return to the background screen. Time cycle check perform a comple...

Page 63

2000-osm, f1 2-29 3. Press f2 (printer report type) soft key to display printer report type screen (see figure 2-17). Highlighted or underlined items on this screen indicate current selections. 4. Cursor right or left to the report type you want to print: raw data, regular, or short (see "other tabl...

Page 64

2-30 2000-osm, f1 component definition screen and the benchmark stream must be defined (see "preparing a method table" in section 4). To run a benchmark test: 1. On the background screen press the f1 (exit to commands) soft key. 2. On the commands screen cursor to table edit and then press the f2 (m...

Page 65

2000-osm, f1 2-31 21. On the start/stop analysis screen, cursor to “at end of analysis?” and then press the f2 (stop analyzer) soft key. 22. Press the f1 soft key as necessary to return to the background screen. Tcd zero adjust (filament tcd only) to adjust the thermal conductivity detector (tcd) ze...

Page 66

2-32 2000-osm, f1 2. On the commands screen cursor to analysis control, if necessary, and then press the f4 (start/stop analysis) soft key. 3. On the start/stop analysis screen, verify that the highlighted area is on "at end of analysis?" and press the f2 (stop analyzer) soft key. The analyzer will ...

Page 67

2000-osm, f1 2-33 5. On the vn menu screen (see figure 2-19), cursor to startup and then press the f2 (essential addresses) soft key. ************ vn menu ********** tables startup testing essential access refresh escape addresses level vnsa tables f1 f2 f3 f4 figure 2-19. Vn menu screen (startup hi...

Page 68

2-34 2000-osm, f1 13. When you have completed and verified your entries, press the f2 (exit and update) soft key to save your entries. ******* vistanet essential addresses ******* name: [gcc10 ] tag: gcc10 board address: 0.10 domain 1: 0.1 domain 2: 0.2 vnsa address: 0.1.0.199 router address: 0.1.0....

Page 69

2000-osm, f1 2-35 1. At the vn menu screen, cursor to startup and press the f3 (access level) soft key (see figure 2-21). 2. Select level desired from scroll list and select exit and update. ***** vistanet access level ***** access level: unrestricted exit escape and update f1 f2 f3 f4 figure 2-21. ...

Page 70

2-36 2000-osm, f1 1. At the vn menu screen cursor to tables (see figure 2-22). **** vn menu ***** tables startup testing subscriber sqc escape list config table f1 f2 f3 f4 figure 2-22. Vn menu screen (tables highlighted).

Page 71

2000-osm, f1 2-37 2. Press the f2 (subscriber list) soft key to access the vistanet subscriber list (see figure 2-23). ***** vistanet subscriber list ***** command: previous next add delete type: hiu primary address: 0.1.0.100 secondary address: 0.2.0.100 time out: 7000 ms this entry: 1 total entrie...

Page 72

2-38 2000-osm, f1 1. On the vn menu screen with startup highlighted, press the f4 (refresh vnsa tables) soft key and then press the escape soft key to return to the commands screen. 2. On the commands screen, cursor to testing/setup and then press the f4 (status display) soft key. 3. On the controll...

Page 73

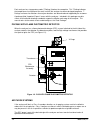

2000-osm, f1 3-1 section 3. Operation controls and indicators gas chromatograph controller (gcc) the gcc’s internal controls and indicators are as shown in figure 3-1. Time out halt single board computer (sbc) pcb chroma i/o pcb reset switch (resets sbc pcb) run highway 2 transmit highway 2 receive ...

Page 74

3-2 2000-osm, f1 regulator and gauge panels the purge air panel contains the pressure regulators and gauges for controlling the purge air and heater air (see figure 3-3). Purge air panel pressure control panel figure 3-3. Regulator and gauge panels if the analyzer has mechanical regulators and gauge...

Page 75

2000-osm, f1 3-3 display screen this analyzer operates from a series of menus and screens, using the display on the gcc. The background screen is the default screen, from which you can select the other screens. Since all screens are divided into the same basic elements, you should understand this sc...

Page 76

3-4 2000-osm, f1 1. On the background screen press the f1 (exit to commands) soft key. 2. On the commands screen cursor to analysis control, if necessary, and then press the f2 (request analysis) soft key. 3. On the request analysis screen (see figure 3-5) select the method number to be calibrated. ...

Page 77

2000-osm, f1 3-5 checking streams to verify the operation of each stream, perform a single analysis on each one, as follows: 1. On the background screen press the f1 (exit to commands) soft key. 2. On the commands screen cursor to analysis control, if necessary, and then press the f3 (streams) soft ...

Page 78

3-6 2000-osm, f1 4. On the start/stop analysis screen press the f2 (start analyzer) soft key. The analyzer will run the stream for which it is purging, according to the method designated in the stream assignment screen. The analyzer will continue in analytical operation until you command it to stop....

Page 79

2000-osm, f1 3-7 alarm messages are of two primary types: main alarms and subordinate alarms. Main alarms identify a major alarm category. These alarms appear on the alarm screen at the left margin (e.G., “post analysis error:” in figure 3-6). If a main alarm has subordinate alarms, the main alarm t...

Page 80

3-8 2000-osm, f1 6. If the chromatogram is too large for the recorder or too small to read, press the f1 soft key as necessary to return to the manual control mode screen. 7. On the manual control mode screen, cursor down to the attenuation line (attn:) and change the attenuation value as necessary ...

Page 81

2000-osm, f1 3-9 command tree the menu system (command tree) branches out from general to specific topics, eventually leading you to a screen that allows you to view or edit the desired parameters. The soft key selections move you down the command tree one level at a time. Figure 3-8 shows the comma...

Page 82

4-1 2000-osm, f1 section 4. Technical description functional description figure 4-1 shows a typical analytical flow system, using the flame ionization detector for illustration. Connections at the right side of the analyzer cabinet provide all gas and air inputs. Sliding plate valves, liquid sample ...

Page 83

2000-osm, f1 4-2 the carrier gas has three purposes: to purge the columns and cell prior to introducing a sample, to sweep the sample into the detector cell, and to backflush the backflush column. An externally mounted pressure regulator and gauge regulate the input flow. The sample system, together...

Page 84

4-3 2000-osm, f1 4. If, after six attempts to light the flame, it still is not lit, the ignition sequence terminates and the hydrogen is shut off. ***** chroma board ***** detector: fid flame: lit ignitor: off h2: none hardware zero: 5.10mv ( 4.7%) software zero: - 3.18mv detector reading: 1.98mv ig...

Page 85

2000-osm, f1 4-4 the cell consists of a polarized jet, a collector, and a chamber in which hydrogen fuel and sample are burned in air. A current, whose magnitude is proportional to the concentration of the sample, flows between the jet and the collector. This current goes to the fid amplifier assemb...

Page 86

4-5 2000-osm, f1 flame photometric detector (fpd) flame photometric detection works on the principle that when sulfur is burned in a hydrogen-rich atmosphere, luminescence (light) characteristic to sulfur is produced. The fpd cell (see figure 4-5) consists of a teflon burner chamber equipped with a ...

Page 87

2000-osm, f1 4-6 simultaneous dual detectors simultaneous dual detectors function in parallel using any two detectors. To accomplish this simultaneous processing requires one chroma i/o board in the analyzer for each detector. Chroma i/o board #1 is in gcc card cage slot 2 and chroma i/o board #2 is...

Page 88

4-7 2000-osm, f1 figure 4-6). While the background screen provides information on both detectors, other screens will show the data from only one of the two detectors at a time. ********** b a c k g r o u n d ********** abb analytical gcc remote 0.1 803v031-1r (sim dual det) (c) 2001 19-jun-2002 wed ...

Page 89

2000-osm, f1 4-8 to view the data from the second chroma i/o board, enter "2" in the highlighted box on the screen and then press the f2 (select chroma bd and view) soft key. The chroma board #2 screen will appear (see figure 4-8) and all screens showing chroma i/o board data will now show the data ...

Page 90

4-9 2000-osm, f1 parameters) soft key. On the control parameters screen (see figure 4-9), cursor down the selections until "detector 1 mode" and "detector 2 mode" appear. Select the desired mode for detector 2 and then press the f2 (exit and update) soft key to save this setting. ********** control ...

Page 91

2000-osm, f1 4-10 since there is no dummy stream in master/master mode, all link column entries are "00". In master/slave mode, the link column in the stream assignment screen shows which stream the slave is using. Because only the master detector controls the actual streams used, this slave stream ...

Page 92

4-11 2000-osm, f1 • vista basic commands identify the detector by placing the chroma i/o board number after the alarm name (e.G., cur_strm (1) or integer = rai (1,0), where the first digit identifies the chroma i/o board). Before starting an analysis, the gcc prompts for the chroma i/o board to use ...

Page 93

2000-osm, f1 4-12 tcd amplifier pcb the tcd amplifier pcb, on the left side wall of the gcc, amplifies the thermal conductivity detector output signal and provides it to the chroma i/o board for processing. Fpd amplifier and interface pcbs the fpd amplifier pcb linearizes and amplifies the flame pho...

Page 94

4-13 2000-osm, f1 communications pcb (option) the communications pcb, in any open slot in the gcc card cage, provides a two-channel interface between the gcc and the vistanet. This pcb is not used when the analyzer has the optional ethernet pcb. See "vistanet option" for a detailed explanation of th...

Page 95

2000-osm, f1 4-14 rf = cc/a, for peak area analysis of a given component or rf = cc/h, for peak height analysis of a given component • normalized, in which the controller calibrates the analyzer against the external standard, then calculates the sum of all peak areas and determines the percent contr...

Page 96

4-15 2000-osm, f1 between the various components is established (at installation), only the k-factor is changed during calibration. Preparing a method table this subsection explains how to prepare a method table by constructing a sample method table. Figure 4-12 shows a chromatogram of the analysis ...

Page 97

2000-osm, f1 4-16 2. On the commands screen, cursor down to table edit and then press the f2 (methods) soft key. 3. The method table #?? Screen will appear (see figure 4-14). Use the number keys on the gcc front panel to enter the number “1” for this method (the method number given in figure 4-13 da...

Page 98

4-17 2000-osm, f1 5. Cursor to the calibration type line. The current choice is underlined. To change the choice, cursor right or left to the desired type (in this case ext std) and then cursor to the next line. Moving the cursor up or down sets the new choice. 6. Cursor to each line in turn and cho...

Page 99

2000-osm, f1 4-18 14. Enter “30” for component #1’s time and then cursor right to select “component.” since this is the first component entered into the table, “undefined” will appear in the value column. 15. Cursor right to the value column. The component definition screen will appear (see figure 4...

Page 100

4-19 2000-osm, f1 3. In steps 4 through 7, review the cal define & cycle time screen and make changes as necessary. 4. When the method table #01 (or other number you have chosen) appears, locate the specific line you want to change. 5. If necessary, cursor to the time column, and then cursor down to...

Page 101

2000-osm, f1 4-20 4. On the second print tables screen, enter the method table number and then press the f2 (print selected table) soft key. The method table and component table will print (see figure 4-19). Method table #01 8:25:29 fri 30 sep 1994 cycle time = 00140 time function value 0001 noise c...

Page 102

4-21 2000-osm, f1 method has forced gating and slope detection on at the same time, the controller uses the one turned on first, ignoring the second one and sending an alarm to tell you that both peak detection methods were on. Forced gating when a component's elution time is known, forced gating ca...

Page 103

2000-osm, f1 4-22 higher number causes the system to respond less quickly but is more sensitive. For that reason the default is set at 8, a median value that provides both good response and sensitivity for most applications. Peak width only has meaning when slope detect is running. Slope detect on t...

Page 104

4-23 2000-osm, f1 peak which begins on a valley point (see figure 4-22). Since the tangent skim termination search operates only during a single peak, it is activated by setting tangent skim at the proper time in the method table (no on/off is required). To use tangent skim, choose a time in the met...

Page 105

2000-osm, f1 4-24 different peak areas in adjacent analyses (see figure 4-23). By selecting “pk end =vly” you can force the routine to call it a valley each time it occurs, thus removing the indecision and stabilizing the calculations. “pk end =base” is used the same way as “pk end =vly.” selecting ...

Page 106

4-25 2000-osm, f1 “proj reverse” is a reverse projection flag that identifies the end of a desired peak or group of peaks. It is set in the baseline after the end of the peak (see “hbr” in figure 4-25). With reverse projection, “proj term” is set before the start of the peak—and before “proj reverse...

Page 107

2000-osm, f1 4-26 another method for handling badly tailing peaks is “end=crest+” (see figure 4-27). This code forces the end of the peak to be the crest time plus the time specified in the code, providing a reproducible end to the peak even if the crest of the peak is moving. To use this command, i...

Page 108

4-27 2000-osm, f1 note if any of the above conditions exist, an error will occur. Stream step stream step begins the automatic sample purge of the sample stream being analyzed. It must occur after completion of the sample inject for this stream. This is particularly important when the current stream...

Page 109

2000-osm, f1 4-28 skip next tcf if stream = this allows you to skip the next time-coded function when this stream value equals the stream number entered in the method table. This function allows you to skip a tcf on a particular stream, usually because that tcf does not apply to that stream. Do next...

Page 110

4-29 2000-osm, f1 6. Press the f1 soft key as necessary to return to the background screen. Printing tables 1. On the background screen, press the f1 (exit to commands) soft key. 2. On the commands screen, cursor down to printer and then press the f2 (print tables) soft key. 3. On the print tables s...

Page 111

2000-osm, f1 4-30 operator orders a different sequence. Figure 4-28 shows the random streams screen and figure 4- 29 shows the printed table. ****** random streams ****** stream 0001 0002 0001 0003 0004 0001 0005 0006 more below insert delete exit line line f1 f2 f3 f4 figure 4-28. Random streams sc...

Page 112

4-31 2000-osm, f1 time table this table contains the schedules for automatic calibrations, benchmarks and stream analyses (see figure 4-30). The time table lists information by the day of the month and time of day (using a 24- hour clock). If you enter “00” as the day, hour, or minute, the specified...

Page 113

2000-osm, f1 4-32 10. Cursor right one column and select the value for the desired function (method number, valve number, vista basic program, etc.). Use the keyboard number keys to enter the number and then press enter. 11. Add more lines by inserting lines and repeating steps 6 through 10 as neede...

Page 114

4-33 2000-osm, f1 4. When you finish editing the stream data, press the f1 (exit) soft key. 5. On the next screen, press the f2 (exit and update) soft key to save the new stream data, or press the f1 (escape) soft key to retain the original data. 6. Press the f1 soft key as necessary to return to th...

Page 115

2000-osm, f1 4-34 short report this report (see figure 4-34) gives basic information on the analysis, which you can use to check analyzer operation periodically. It is a one-line report which provides the stream number, injection time, and concentration for each component by number. The short report...

Page 116

4-35 2000-osm, f1 will reduce the classification to nonhazardous/general purpose. Since the y and z purge systems are identical except for nomenclature, the following explanation applies to both. The purge air enters the analyzer system through a pressure regulator, an orifice, and a gauge used to s...

Page 117

2000-osm, f1 4-36 the x purge cycle time depends totally on the application, but it may vary with analyzer configuration and condition. Refer to the analyzer label or data package for specific purge specifications. Once x purge applies power to the analyzer, power continues to the analyzer as long a...

Page 118

4-37 2000-osm, f1 6. With x purge reset, the air purge timed cycle begins in the electronics housing. When you use override during start-up, it overrides the x purge control of power to the analyzer, but the air purge timed cycle continues. Once the electronics housing has pressurized and x purge co...

Page 119

2000-osm, f1 4-38 caution saving tables and functions from ram to e2prom erases tables or functions already residing in e2prom. Since these tables and functions in ram will replace the tables already in e2prom, be certain they are correct before you perform this sequence. To save tables to e2prom: 1...

Page 120

4-39 2000-osm, f1 caution restoring tables and functions from e2prom will erase any tables or functions already residing in ram. Since these tables and functions in e2prom will replace the tables already in ram, be certain they are correct before you perform this sequence. Note if tables and functio...

Page 121

2000-osm, f1 4-40 temperature configuration table low/high alarm limits zone name temperature control table zone relationship set point, by entry number in method ramp rate, by entry number in method temperature check table zone relationship alarm temperature value, by entry number in method action ...

Page 122

4-41 2000-osm, f1 4. On the manual temperature control mode screen (see figure 4-38), select the desired field using the up and down cursor keys. Enter two digits for valve numbers (e.G. 04), as some installations have more than nine valves. **** manual temperature control mode **** zone config actu...

Page 123

2000-osm, f1 4-42 3. On the pres and temp control screen (see figure 4-39), cursor to temp configuration and press the f3 (names and limits) soft key. **** pres and temp control **** temp control pres control temp configuration names escape zone and controller config limits type f1 f2 f3 f4 figure 4...

Page 124

4-43 2000-osm, f1 5. In the names field you can change the zone name by typing a new name, up to a maximum of ten characters long. When you have completed the name, cursor to another field. 6. In the low and high alarm limits field, type the desired alarm value and then cursor to another field. 7. A...

Page 125

2000-osm, f1 4-44 12. Enter a set point temperature within t-rating limits by repeating steps 5 through 10. 13. If you do not hold the switch long enough, * temp bd alarm * will also display and the new setting will not be accepted. Check the temperature with the t-rating on the manual temperature c...

Page 126

4-45 2000-osm, f1 6. Cursor to the function field and scroll to temp contrl. In figure 4-41, with temp contrl in the function field the value column lists two as the function to be performed from the temperature control table. ***** method table #01 ***** time function value [0001] temp. Contrl two ...

Page 127

2000-osm, f1 4-46 8. On the temperature control screen, move the cursor as necessary to select the zone name from among the names in the list, and to change set point and ramp rate values of the desired entries. Caution when you exit the temperature control screen, the value in the entry line highli...

Page 128

4-47 2000-osm, f1 7. Move the cursor to the value column and the temperature check table appears, with the cursor on entry line 01 (see figure 4-43). Note the entry line number when you enter the table so you can exit the table from the same, if desired. ***** temperature check ***** temperature ent...

Page 129

2000-osm, f1 4-48 4. On the controller type screen (see figure 4-44), verify that the controller type is the same as specified in the data package. ***** controller type ***** controller type: regular exit escape and update f1 f2 f3 f4 figure 4-44. Controller type screen 5. If you want to change the...

Page 130

4-49 2000-osm, f1 4. On the temp config table screen (see figure 4-45), select the desired field using the cursor keys. **** temp config table **** remove heat on num config sensor air loss 1 iso probe yes 2 iso probe yes 3 inact probe no 4 inact probe no 5 iso tc yes exit f1 f2 f3 f4 figure 4-45. T...

Page 131

2000-osm, f1 4-50 10. “hold switch on temp board” will appear on the screen. Caution before opening any analyzer doors, ensure the area is safe and hazard-free, and will remain so the entire time the analyzer is open. If the analyzer has x purge, operate the override function as described in "x purg...

Page 132

4-51 2000-osm, f1 note on power loss, set points and ramp rates for all programmable zones (prog and prog/c) are lost. You must re-enter the values manually or execute the method stored in the method table. Alarms digital temperature controller alarms are described in "temperature board" alarms in s...

Page 133

2000-osm, f1 4-52 1. On the background screen press f2 (manual control). 2. On the manual control mode screen press f4 (press. & temp. Control). 3. On the pres and temp control screen (see figure 4-46), cursor to pres control and press f2 (manual pressure control). **** pres and temp control **** te...

Page 134

4-53 2000-osm, f1 4. On the manual pressure control mode screen (see figure 4-47), select the desired field to change using the cursor arrow keys. Enter two digits for valve numbers (e.G., 04), as some installations have more than nine valves. **** manual pressure control mode **** zone config actua...

Page 135

2000-osm, f1 4-54 3. On the pres and temp control screen, cursor to pres control and press f3 (pressure config). 4. On the pressure config table screen (see figure 4-48), select the desired field using the cursor keys. **** pressure config table **** zone num name config range 1 column iso 30 2 anal...

Page 136

4-55 2000-osm, f1 13. If the gcc accepts the change, an acknowledging message appears. Release the switch and close the front panel. 14. On the pres and temp control screen, cursor to pres control and press f3 (pressure config). 15. Verify that changes have been accepted and then press f1 as necessa...

Page 137

2000-osm, f1 4-56 11. If the set point is not accepted, the pres zone name flashes and * pres bd alarm * flashes on the message line. If this happens, release the switch and check the pressure with the pressure limits prescribed for this zone. 12. Enter a set point pressure within these limits by re...

Page 138

4-57 2000-osm, f1 6. Cursor to the function field and scroll to pres contrl. In figure 4-49, with pres contrl displayed, the value column lists two as the function to be performed. ***** method table #01 ***** time function value [0001] pres contrl two 0010 pres check one 0120 noise calc on 0125 noi...

Page 139

2000-osm, f1 4-58 8. On the pressure control screen, move the cursor as necessary to select the zone name from among the names in the list, and to change set point and ramp rate values of the desired entries. Caution when you exit the pressure control screen, the entry line highlighted when you exit...

Page 140

4-59 2000-osm, f1 7. Move the cursor to the value column and the pressure check table appears, with the cursor on entry line 01 (see figure 4-51). Note the entry line number when you enter the table so you can exit the table from the same, if desired. ***** pressure check ***** pressure entry zone p...

Page 141

2000-osm, f1 4-60 the raw chromatogram storage and reprocessing option allows only one chromatogram of each type to be saved (last, calibration, benchmark, typical or alarm), regardless of the length of the cycle. When the chromatogram is saved, the raw data report is saved also (but method tables a...

Page 142

4-61 2000-osm, f1 2. On the display saved data screen, cursor to memory used/left and press the f2 (execute the command) soft key. The raw chromatogram memory used/left screen will appear (see figure 4-53). **** raw chromatogram memory used/left **** total used = 038208 bytes total left = 272916 byt...

Page 143

2000-osm, f1 4-62 3. On the define save/release screen, cursor to manual release and then press the f2 (execute the command) soft key. 4. On the manually release analysis screen, select the type of data to release and press the f2 (manually release analysis) soft key. If you want to release more tha...

Page 144

4-63 2000-osm, f1 4. Note the number under alarm mask. This represents the alarm configuration set on the define alarm mask screen. If you want to verify or change the alarm mask, press the f4 (expand alarm mask) soft key. ****** automatically save analyses ****** save this type alarm cal bench last...

Page 145

2000-osm, f1 4-64 2. On the graphics setup screen, select the type of chromatogram to save: calibration (cal), benchmark (bench), most recent (last), alarm, or typical (typ). 3. Next select the amount of screen offset, which determines where on the screen the chromatogram will display. Start with “0...

Page 146

4-65 2000-osm, f1 reprocessing saved chromatograms the reprocess saved data screen (soft key f3 on the command screen) allows you to select type of raw data to reprocess, how to process it. Reprocessing takes saved data and sends it back through peak detection in an off-line mode, then produces a re...

Page 147

2000-osm, f1 4-66 remote gc operation option the analyzer can operate with other abb gcc front panels. To implement this option requires the following changes to the analyzer: an optional pcb and several changes in wiring connections and switch settings. This section of the manual explains how to pr...

Page 148

4-67 2000-osm, f1 the first five switch positions on sw1 (labeled 0 through 4 on the pcb), determine the analyzer's address. Switch positions 6, 7 and 8 are always on ("1"). Figure 4-58 shows how to identify the address from the switch positions. #10 #6 #22 #7 #23 #9 #25 #26 #1 #17 #8 #24 #2 #18 #3 ...

Page 149

2000-osm, f1 4-68 when you set the no analyzer switch on, the front panel will communicate only with other gc’s; the front panel will not communicate with an attached analyzer. When the lock out remote switch is on, another front panel on the network cannot access this front panel, but this front pa...

Page 150

4-69 2000-osm, f1 3. Enter the number of the remote analyzer you want to access. Verify you have entered the number correctly and then press the f3 (execute) soft key. 4. If you entered the remote number incorrectly, press the f2 (clear entry) soft key, re-enter the number, and then press the f3 (ex...

Page 151

2000-osm, f1 4-70 analog output option this option provides analog outputs to a printer, computer, or other external device. Up to two optional pcbs, installed in the gcc card cage, provide different combinations of current and voltage outputs. These combinations are: • one current board, with up to...

Page 152

4-71 2000-osm, f1 6. When you have completed the changes to this trend table screen, review them to ensure all items are correct and then press the f1 (exit) soft key. ****** trend table ****** range range chan stream comp low high 01 01 01 1.0000 100.00 03 01 03 0.5000 100.00 04 02 01 1.0000 100.00...

Page 153

2000-osm, f1 4-72 range values for that component (see figure 4-62). If you select stream “00” for a particular channel, the specified component will apply on that channel for all streams. ****** digital table ****** range range chan stream comp low high 01 01 01 1.0000 100.00 02 01 02 0.5000 100.00...

Page 154

4-73 2000-osm, f1 note before making changes to vistanet screens, verify all data with your network administrator to ensure proper connection and operation with vistanet. 1. On the background screen press the f1 (exit to commands) soft key. 2. On the commands screen, cursor to testing/setup and then...

Page 155

2000-osm, f1 4-74 6. On the vistanet essential addresses screen (see figure 4-64), enter the gcc's identification number on the name line. ******* vistanet essential addresses ******* name: [gcc10 ] tag: gcc10 board address: 0.10 domain 1: 0.1 domain 2: 0.2 vnsa address: 0.1.0.199 router address: 0....

Page 156

4-75 2000-osm, f1 solenoid valves the pgc2000 uses two different types of solenoid valves in the purge air panel, a vented type and a non-vented type (see figure 4-65). Since these solenoids are not interchangeable, you must ensure that a replacement solenoid is the same type as the solenoid being r...

Page 157

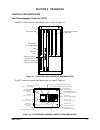

2000-osm, f1 5-1 section 5. Maintenance preventive maintenance the analyzer design eliminates the need for extensive and complex maintenance. Where preventive maintenance procedures require specific time frames or intervals, you should maintain an inspection log and inspection data. Figure 5-1 lists...

Page 158

5-2 2000-osm, f1 (100 psig or less). When your check indicates an exhausted cylinder, replace the cylinder with another containing the specified gas. When you use a single cylinder to supply a gas, you should check this cylinder regularly and replace it when the pressure falls below 100 psig, using ...

Page 159

2000-osm, f1 5-3 2. On the commands screen (see figure 5-2), cursor down to testing/setup and then press the f2 (diagnostic tests) soft key. ***** commands ***** analysis control reports table edit printer storage & config. Names misc. [testing/setup] chromatogram storage vistanet diagnostic diagnos...

Page 160

5-4 2000-osm, f1 4. When the test is complete, this message will appear on the screen: “rom check passed. Any key to continue.” press any soft key to return to the diagnostic tests screen. If the rom check fails, contact your service representative. 5. After you complete diagnostic testing, press f1...

Page 161

2000-osm, f1 5-5 4. On the diagnostic tests screen (see figure 5-4), cursor to diagnostic tools and press the f2 (digital output test) soft key. ***** diagnostic tests ***** diagnostic tests [diagnostic tools] digital trend exit output output test test f1 f2 f3 f4 figure 5-4. Diagnostic tests screen...

Page 162

5-6 2000-osm, f1 6. Cursor down to the line marked “pin number” and enter the desired chroma i/o board pin number. On the corresponding line below the pin number, the digital value will change from 0 to 1 or from 1 to 0. 7. When the digital value changes, check the output circuit to verify that it c...

Page 163

2000-osm, f1 5-7 9. On the manual control of trend outputs screen (see figure 5-6), select the trend channel you want to check. 10. Cursor down and enter the desired trend value. This value is a percentage of the total trend range. Check your output to verify the trend value changed. If it did not c...

Page 164

5-8 2000-osm, f1 3. On the serial configuration screen (see figure 5-7), verify that the setup data is the same as that specified in the data package. *** serial configuration *** printer setup baud rate: 300 1200 2400 4800 9600 parity: none even odd data bits: 7 8 stop bits: 1 2 exit test escape an...

Page 165

2000-osm, f1 5-9 4. On the commands screen, cursor to storage & config and then press the f4 (update digital config) soft key. 5. On the first digital configuration screen, enter resetdigio as the password and then press the f2 (accept entered password) soft key. 6. On the second digital configurati...

Page 166

5-10 2000-osm, f1 2. On the first chroma board 1 digital output screen, cursor to vistaii and press the f1 (continue) soft key. 3. On the second chroma board 1 digital output screen (see figure 5-9), verify each pin and function. ***** chroma board 1 digital output ***** pin function number state j1...

Page 167

2000-osm, f1 5-11 2. On the digital board 1 digital input screen (see figure 5-10), verify each pin and function. ***** digital board 1 digital input ***** pin function number state tb6-1 vistabasic #5 no tb6-2 vistabasic #6 no tb6-3 vistabasic #7 no tb6-4 vistabasic #8 no tb6-5 vistabasic #9 no tb6...

Page 168

5-12 2000-osm, f1 2. On the digital board 1 digital output screen (see figure 5-11), verify each pin and function. ***** digital board 1 digital output ***** pin function number state tb5-18 stream #11 no tb5-19 stream #12 no tb5-20 stream #13 no tb5-21 stream #14 no tb5-22 stream #15 no tb5-23 stre...

Page 169

2000-osm, f1 5-13 trend and detector 1. Cursor to other on the second digital configuration screen and press the f2 (trend & detector) soft key. 2. On the trend and detector config screen (see figure 5-12), verify each trend setting and detector configuration. ***** trend and detector config ***** t...

Page 170

5-14 2000-osm, f1 2. On the screen with instructions on saving the tables, press any soft key. 3. On the commands screen, cursor to storage & config. And press the f2 (save or restore tables) soft key. 4. On the table storage screen cursor to save tables to e2prom and press the f2 (save tables) soft...

Page 171

2000-osm, f1 6-1 section 6. Troubleshooting troubleshooting guidelines this section provides troubleshooting information by category. Included in this information are symptoms, causes, and suggested tests for further fault isolation. These tests are described in section 7, listed by test procedure (...

Page 172

6-2 2000-osm, f1 8. A continuous presence of sample at the detector due to sample valve leakage. Perform test procedure 3 (sample valve leaking/column flooding). 9. Filament failure. Perform test procedure 6 (filament tcd test). Cyclic short term drift symptom: baseline (detector signal) is experien...

Page 173

2000-osm, f1 6-3 perform test procedure 3 (sample valve leaking/column flooding); or test procedure 30 (checking temperature table values), steps 1 to 3, 8, and 9. Another possible cause could be detector filament deterioration. Baseline continuous noise symptom: baseline (detector signal) with no s...

Page 174

6-4 2000-osm, f1 b. The gases may be pure, but contaminated tubing or hardware components in the analyzer or cylinder regulator(s) contaminate the makeup gases as they pass through them. The fid detects theses contaminants, resulting in a noisy baseline. C. An fid is generally equipped with a cataly...

Page 175

2000-osm, f1 6-5 perform test procedure 11 (common usage of gases), test procedure 13 (burner air catalytic cleanup unit), or test procedure 14 (coaxial cable), as applicable. Replace or clean the fid (see "fid repair" in section 8). Signal offset (fpd) note because of the sulfur addition in the fpd...

Page 176

6-6 2000-osm, f1 a. Electrical noise from the fpd amplifier could result from a noisy power supply or defective component of the pcb. B. Loose electrical connections can cause electrical signals to be sporadic. C. Since the fpd amplifier input impedances are extremely high, low noise coaxial cable c...

Page 177

2000-osm, f1 6-7 5. Baseline offset extreme. See "baseline or signal offset (tcd)" or "baseline or signal offset (fid)." 6. Column broken or connection in the column train disconnected. Perform test procedure 7 (column train problems). 7. Tcd failure. Perform test procedure 5 (tc detector balance) a...

Page 178

6-8 2000-osm, f1 additional peaks of unknown origin (mystery peaks) symptom: chromatograph displays extra peaks or a noted difference in composite chromatograph appearance from that of the calibration (see figure 6-10). Normal mystery peaks time time unknown figure 6-10. Mystery peaks cause: if only...

Page 179

2000-osm, f1 6-9 above the bubble point of the sample, the sample will bubble in the sample chamber, causing an inconsistent liquid fill of the sample loop. This results in a continuously variable sample size. A defective sample valve stem or leaking seal(s) can also cause nonrepeatability. Perform ...

Page 180

6-10 2000-osm, f1 cause: the gating in the method needs to be modified to ensure gating of the missing peak in the report. This can be done by modifying the gate on/off time in the method table. See "peak detection" in section 4 for detailed instructions. Peak inversion symptom: the peaks on the str...

Page 181

2000-osm, f1 6-11 the peaks may in fact be too large and saturating the detector or column. The splitter may be out of adjustment, or the liquid sample size may be too large. Possibly the detector gain jumper at the detector electronics is not setup correctly. The sample valve may be injecting an ex...

Page 182

6-12 2000-osm, f1 peak discrimination symptom: discrimination is the non linear unequal dilution of hydrocarbons in the column train. Typically the heavier components will tend to dilute more than the lighter components. Cause: discrimination is usually the result of a leak or incorrectly adjusted s...

Page 183

2000-osm, f1 6-13 any one of the following alarm messages or conditions could be present: on background screen ***alarm:*** (flashing) on manual temperature zone (3) (flashing) control mode screen *temp bd alarm* (flashing) on alarm screen temperature board: *zone specific *analysis shutdown *** tem...

Page 184

6-14 2000-osm, f1 any one of the following alarm messages or conditions could be present: on background screen ***alarm:*** (flashing) on manual temperature zone (#) (flashing) control mode screen *temp bd alarm* (flashing) on alarm screen temperature board: *zone specific *analysis shutdown *** tem...

Page 185

2000-osm, f1 6-15 on manual temperature zone (#) (flashing) control mode screen *temp bd alarm* (flashing) on alarm screen temperature board: *zone specific *** temp zone (#) alarm *** *triac failure cause: the output of the triac is connected to the zone heater(s). An optical isolator connected par...

Page 186

6-16 2000-osm, f1 exclusion jumper disagreement symptom: the temperature board has shut down and all the led’s are off. The zone temperatures are reducing and will approach ambient. Any one of the following alarm messages or conditions could be present: on background screen ***alarm:*** (flashing) o...

Page 187

2000-osm, f1 6-17 any one of the following alarm messages or conditions could be present: on background screen ***alarm:*** (flashing) on manual temperature zone (#) (flashing) control mode screen *temp bd alarm* (flashing) on alarm screen temperature board: *zone specific *** temp zone (#) alarm **...

Page 188

6-18 2000-osm, f1 any one of the following alarm messages or conditions could be present: on background screen ***alarm:*** (flashing) on manual temperature *temp bd alarm* (flashing) control mode screen on alarm screen temperature board: *overtemp test fail* possible zone specific triac failures ca...

Page 189

2000-osm, f1 6-19 caution see "air purging" in section 4 for the override function. Do not perform override until you have read section 4 completely and you understand and can perform the procedure requirements. Install a temperature monitor and verify ambient temperature. Ensure air flow into the c...

Page 190

6-20 2000-osm, f1 caution see "air purging" in section 4 for the override function. Do not perform override until you have read section 4 completely and you understand and can perform the procedure requirements. The temperature controllers must be stable with respect to tracking the set point. Sympt...

Page 191

2000-osm, f1 6-21 low oven temperature caution it is the customer’s responsibility to ensure that the area is safe and and hazard- free, and will remain so the entire time the analyzer is open. This responsibility includes ensuring adequate ventilation in analyzer shelter and obtaining proper work p...

Page 192

6-22 2000-osm, f1 2. Air supply pressure is low. Verify correct air pressures. If necessary make adjustment. 3. Vortex cooler not adjusted. Perform test procedure 41 (programmed temperature oven cool down). 4. Listen for cool down solenoid to operate and introduce increased vortex cooler air flow. I...

Page 193

2000-osm, f1 6-23 no analyzer keypad response symptom: pressing keypad on analyzer front panel produces no response on crt or other analyzer output. Cause: no response by keypad could indicate defective keypad or malfunction or defect in keypad cabling from keypad to keypad assembly pcb. The crt con...

Page 194

6-24 2000-osm, f1 6. Replace locom pcb (set-up address switch). Symptom: cannot contact or use remote networking feature. Cause: previous remote communication was not terminated. 7. Search for analyzer that is accessing another remote, or that is itself being accessed, then terminate the access. See...

Page 195

2000-osm, f1 6-25 low carrier pressure hardware alarm symptom: low carrier gas alarm. If carrier is in short supply and not corrected, carrier flow rates will reduce as the gas is depleted. Analyzer data will become erroneous as carrier pressure drops below the analyzer requirement. Causes: the foll...

Page 196

6-26 2000-osm, f1 symptom: if x purge system is installed, analyzer power will be removed and cannot be restored until purge air is restored. Causes: the following can be the causes of loss of purge. 1. Air supply to analyzer has been shut off. Perform test procedure 1 (carrier, makeup, and utility ...

Page 197

2000-osm, f1 6-27 cause: possible causes for analyzer not powering up are as follows: 1. If attempting to override x-purge, light intensity may not be sufficient to energize override, or cover to x-purge electronics housing is not removed. 2. Power is disconnected. Check power distribution circuit b...

Page 198

6-28 2000-osm, f1 electronic pressure control troubleshooting the pressure control assembly (see figure 6-15) requires special tools and equipment for repair. If you suspect a problem with this assembly please contact your abb service representative. Figure 6-15. Epc pressure control assembly.

Page 199

2000-osm, f1 6-29 controller problems input power input power is connected to one or more of the following locations on the backplane pcb in the controller housing (see figure 6-16): tb1, which is called vac #1 j1a, which is called vac #2 j1b, which is called vac #3 tb1 j1a j1b 1 2 3 4 5 6 tb1 j1a j...

Page 200

6-30 2000-osm, f1 power distribution the analyzer uses three power distribution circuits to route the power (see figure 6-17): vac #1, which provides heater power vac #2, which powers the electronics through the power supply pcb vac #3, which power the detectors, solenoid drivers, and epc 115 to 230...

Page 201

2000-osm, f1 6-31 when checking input power make sure to note the connections for source power to determine how power is routed. Poor display contrast if the analyzer is on but it is difficult to read the lcd display, you may need to adjust the display. 1. Ensure the area is safe to open the analyze...

Page 202

6-32 2000-osm, f1 when an alarm signal appears on the background screen, press the f4 (alarms) soft key to display the alarms screen with the alarm message (see figure 6-19). ****** alarms ****** ****** alarm ****** post analysis error: *valve manually switched clear exit alarms and exit f1 f2 f3 f4...

Page 203

2000-osm, f1 6-33 sensors active when “sensors active:” appears as the main alarm, one or more sensor alarms appears below the main alarm. “sensors active” appears when an alarm is active at the time you look at the alarms screen. Typical sensors active alarms and their descriptions are: note sensor...

Page 204

6-34 2000-osm, f1 * retention time high—activates when retention time exceeds the upper setpoint. * response factor high—activates when response factor exceeds the upper setpoint. Component low when “component low:” appears as the main alarm, one or more component alarms appears below the main alarm...

Page 205

2000-osm, f1 6-35 * auto zero during slope detect—activates when auto zero is performed during slope detection. * gated during noise—activates when slope detection is turned on at the same time that a noise calculation is being performed. * gated during slope detect—activates when slope detection is...

Page 206

6-36 2000-osm, f1 communications error when “communications error:” appears as the main alarm, one or more communications alarms appears below the main alarm. Typical communication alarms and their description are: * block not transmitted—activates when a vistanet message is passed to the communicat...

Page 207

2000-osm, f1 6-37 * set point failed—activates when zone is inactive; zone is switch zone and switch not depressed or set point is greater than the configured pressure range. * ramp rate failed—activates when the ramp rate settings exceed an acceptable range. * reconfiguration failed—activates when ...

Page 208

6-38 2000-osm, f1 * analysis shutdown—activates when the temperature board alarm has signaled the sbc with information that will be used to determine whether to abort the analysis. If the “*zone specific” subordinate alarm appears, at least two additional lines appear below that. The first line iden...

Page 209

2000-osm, f1 6-39 raw chromatogram storage when “raw chromatogram storage:” appears as the main alarm, one or more chromatogram alarms appears below the main alarm. Typical chromatogram alarms and their descriptions are: * memory below 20%—activates when the memory pool used for chromatogram storage...

Page 210

6-40 2000-osm, f1 • not report the alarm to vistareporter (if the gc is configured to send reports to vistareporter); • not report the alarm to the printer (if the gc is configured to send reports to a printer); • report the alarm to the opc server (if the gc is configured to send reports to the opc...

Page 211

2000-osm, f1 6-41 3. On the control parameters screen (see figure 6-20), press the f3 (alarm mask) soft key. ***** control parameters ***** analyzer name: [abb analytical gcc ] unknown peak alarm: no yes missing comp alarm: no yes update trends on alarm: no yes auto update of rf: no yes max rf varia...

Page 212

6-42 2000-osm, f1 6. If the selected alarm has "(expanded)" after the alarm name, the alarm has subordinate indicators. To view these subordinates, cursor to the desired alarm line and press the f2 (expand mask) soft key. 7. On the expanded alarm screen, repeat steps 4 and 5 to change a specific ala...

Page 213

2000-osm, f1 6-43 led or software fault led) and will send an alarm signal to the customer's alarm indicator (when that indicator is connected to j111a or j111b on the backplane pcb). When the common digital output mask screen has "masked" selected for a given alarm, no alarm signals will be generat...

Page 214

6-44 2000-osm, f1 4. On the common do mask, main screen (see figure 6-24), cursor down to the desired alarm name and verify the selection in the right-hand column. ***** common do mask, main ***** active sensors: (expand) common do component high: common do component low: common do hardware: common ...

Page 215

2000-osm, f1 7-1 section 7. Test procedures tp 1: carrier, makeup and utility gas supplies if you suspect a gas supply (flame, fuel, air) problem, perform the following test. 1. Stop analysis at end of current analysis, and make no sample injection until procedure is completed. 2. Check gas supply p...

Page 216

7-2 2000-osm, f1 caution it is the customer’s responsibility to ensure that the area is safe and and hazard- free, and will remain so the entire time the analyzer is open. This responsibility includes ensuring adequate ventilation in analyzer shelter and obtaining proper work permits, etc. 1. Stop a...

Page 217

2000-osm, f1 7-3 4. Leak check every connection outside the analyzer on the entire carrier flow path. Perform step 5 only after step 4 has been completed and all leaks are repaired. 5. Loosen inlet fitting nut and check for presence of carrier or makeup gas using a leak detector solution. 6. If carr...

Page 218

7-4 2000-osm, f1 caution see "air purging" in section 4 for the override function. Do not perform override until you have read section 4 completely and you understand and can perform the procedure requirements. 1. Stop analysis at the end of the current analysis cycle, and make no sample injection u...

Page 219

2000-osm, f1 7-5 1. Stop analysis at the end of the analysis and make no sample injection until procedure is completed. 2. Reduce isothermal and programmed temperature oven air temperatures by reducing oven air pressures to zero psig. 3. Open isothermal oven. 4. Inspect for disconnected or loose tub...

Page 220

7-6 2000-osm, f1 2. Perform test procedure 30 (checking temperature table values) and test procedure 9 (baseline cyclic carrier regulator), as applicable. Tp 11: common usage of gases 1. Are other analyzers serviced from the same burner air, carrier, or burner fuel source, experiencing noise? If yes...

Page 221

2000-osm, f1 7-7 2. Gently move or touch coaxial cable, while monitoring detector output on recorder. Some movement of signal is normal, but spikes of noise should not occur. 3. If noise spikes are systematically generated, check the coaxial cable connections. 4. If the connections are correct and t...

Page 222

7-8 2000-osm, f1 tp 16: fid will not light caution do not ignite the fid flame if the temperature is below operational level. Low oven temperature will result in condensation damage to the flame cell. 1. Ensure burner air and burner fuel are adjusted to the values shown on application data sheets. 2...

Page 223

2000-osm, f1 7-9 1. Disconnect the cell vent and hold a reflective surface such as a mirror, wrench or other suitable object at such an angle that you can see the reflective surface. 2. If the flame is ignited, you will be able to see the condensed water vapor form on the reflective surface. Tp 18: ...

Page 224

7-10 2000-osm, f1 14. Remove power and disconnect the cable between j9a and j9. Check continuity between j9a terminals 1, 2, and 3 and j9 terminals 1, 2, and 3, respectively. If any wires are open replace the cable, apply power and repeat step 11. 15. Apply power to analyzer and switch dc solenoid d...

Page 225

2000-osm, f1 7-11 4. Compare the temperature zone temperatures with those of your application data sheets sent with your chromatograph. Perform test procedure 30 (checking temperature table values) and make any necessary table corrections. Bubbles at the sample valve effluent generally indicate the ...

Page 226

7-12 2000-osm, f1 temperature j48a zone board terminals assignment 1 4 & 5 isothermal oven 2 4 & 5 programmed temperature oven 3 4 & 5 lsv 4 4 & 5 detector 5 4 & 5 methanizer/air cleanup 5. If temperature probe is open, replace the temperature probe. 6. Close and tighten the controller side door. Tp...

Page 227

2000-osm, f1 7-13 caution see "air purging" in section 4 for the override function. Do not perform override until you have read section 4 completely and you understand and can perform the procedure requirements. 1. Disconnect power and shut off air to analyzer. 2. Open the controller side door. 3. D...

Page 228

7-14 2000-osm, f1 tp 24: isothermal oven overtemp sensor open caution it is the customer’s responsibility to ensure that the area is safe and and hazard- free, and will remain so the entire time the analyzer is open. This responsibility includes ensuring adequate ventilation in analyzer shelter and ...

Page 229

2000-osm, f1 7-15 extremely high, the rtd is open. Replace the rtd. The respective probes may be tested at the locations given below: temperature j49a zone board terminals assignment 1 4 & 5 isothermal oven 2 4 & 5 programmed temperature oven 3 4 & 5 lsv 4 4 & 5 detector 5 4 & 5 methanizer/air clean...

Page 230

7-16 2000-osm, f1 9. Close and tighten the controller side door. Tp 27: open fuse to ac conditioning board caution it is the customer’s responsibility to ensure that the area is safe and and hazard- free, and will remain so the entire time the analyzer is open. This responsibility includes ensuring ...

Page 231

2000-osm, f1 7-17 4. Connect a dc voltmeter from detector amplifier tb16 terminal 5 to chassis ground. The meter should indicate -110 volts dc. If voltage is -110 vdc, test procedure 29 is complete. If the voltage is less than -110 vdc continue with step 5. 5. Disconnect the wire to the polarizer at...

Page 232

7-18 2000-osm, f1 1. Stop analysis at the end of analysis cycle and make no sample injections until procedure is completed. 2. Perform test procedure 1 (carrier, makeup, and utility gas supplies) and test procedure 2 (carrier and makeup gas flow adjustments), if not previously checked. 3. Remove pow...

Page 233

2000-osm, f1 7-19 15. Perform fid cell maintenance for cleaning jet and flame out thermocouple (see “fid repair/cleaning the fid jet” in section 8). 16. Replace the plastic shield, cover, and thumb nuts on the detector amplifier. 17. Close and tighten the controller front door. Tp 30: checking tempe...

Page 234

7-20 2000-osm, f1 3. On the manual control mode screen (see figure 7-4), press the f4 (press. & temp. Control) soft key. ****** manual control mode ****** valves:- - - - - - - time:00000 enter valve: [0] cycle time:00000 recorder: chroma bd:1 method tbl: 000 offset: 0% stream: 01 attn: 5 purging: 01...

Page 235

2000-osm, f1 7-21 5. Press the f3 (names and limits) soft key to view the 5 zone names and limits table screen (see figure 7-6). This table is factory set and is not intended to be field modified. In the unlikely event that one of the parameters was changed, the values should be compared to those in...

Page 236

7-22 2000-osm, f1 9. On the pressure and temperature control screen (figure 7-5), cursor up or down until temp control is highlighted. Press the f2 (manual temp control) soft key to access the manual temperature control mode screen (see figure 7-7). **** manual temperature control mode **** zone con...

Page 237

2000-osm, f1 7-23 14. On the commands screen(see figure 7-8), cursor up or down to highlight table edit. Then press the f2 (methods) soft key to access the methods tables. ****** commands ****** analysis control reports table edit printer storage & config. Names misc. Testing/setup sim distillation ...

Page 238

7-24 2000-osm, f1 17. Move the cursor up or down to highlight the time associated with temperature control function two. Then move the cursor to the right to highlight the value “two”. The temperature control screen appears (see figure 7-10). ***** temperature control ***** entry zone set point ramp...

Page 239

2000-osm, f1 7-25 3. Extinguish flame by reducing burner air, fuel and carrier to zero by rotating regulator adjustment counterclockwise until burner air fuel and carrier gauges indicate zero. When flame is out, the “flame out” led will illuminate. 4. Connect flow meter (e.G. Bubble tower) to fid ve...

Page 240

7-26 2000-osm, f1 5. Routine validation comparisons will help in the early detection of discrimination. Tp 33: checking method table configuration verify the method configuration tables as follows: 1. Press the f1 soft key until the background screen is displayed (see figure 7-11). ********** b a c ...

Page 241

2000-osm, f1 7-27 3. On the commands screen (see figure 7-12) cursor to highlight table edit. Then press the f2 (methods) soft key. ****** commands ****** analysis control reports table edit printer storage & config. Names misc. Testing/setup sim distillation go to other background methods tables f1...

Page 242

7-28 2000-osm, f1 6. Refer to the table listings provided with your chromatograph. The function scheduling should be similar to the following: process stream method table method table #01 time function value 0001 temp. Contrl one 0128 auto zero n/a 0130 skp, nxt,str= nine 0132 valve on one 0155 valv...

Page 243

2000-osm, f1 7-29 calibration stream method table method table #10 time function value 0001 temp. Contrl one 0120 noise calc on 0125 noise calc off 0128 auto zero n/a 0132 valve on one 0155 valve off one 0160 slope detect on now 0160 peak width eight 0175 component one 0175 component one 0182 compon...

Page 244

7-30 2000-osm, f1 0120 noise calc on 0125 noise calc off this function samples the baseline to determine the random noise level of the baseline and is applicable only to slope detection. 0128 auto zero n/a this function establishes a baseline zero reference point in the controller. It in effect comp...

Page 245

2000-osm, f1 7-31 tp 35: printer test 1. On the background screen, press the f1 (exit to commands) soft key. 2. Cursor to printer and then press the f2 (test printer) soft key. A string of characters should print. 3. If characters do not print, cursor to testing/setup and then press the f3 (hardware...

Page 246

7-32 2000-osm, f1 1. Remove power from analyzer. 2. Remove access cover to terminals on right hand side of electronics housing. 3. Verify if trend board output is set up for 4 to 20 ma or 0 to 5 vdc. 4. If current output, disconnect one wire from the output to be tested, and place the milliammeter i...

Page 247

2000-osm, f1 7-33 a. With authorized permission, remove one wire from input device of loop to be tested and connect the ammeter in series (voltage parallel). Perform step 9 to determine if loop wiring to input device is functional. B. Check and verify input device input requirement and configuration...

Page 248