- DL manuals

- ABB

- Laboratory Equipment

- PGC5000 Series

- Service Instructions Manual

ABB PGC5000 Series Service Instructions Manual

Summary of PGC5000 Series

Page 1

Pgc5000 series process gas chromatographs service instructions si/pgc5000-en rev. B measurement made easy.

Page 2

Si/pgc5000-en, rev b 2 the company we are an established world force in the design and manufacture of measurement products for industrial process control, flow measurement, gas and liquid analysis and environmental applications. As a part of abb, a world leader in process automation technology, we o...

Page 3

Pgc5000 pgc5000 series service instructions contents si/pgc5000-en, rev b 3 contents 1 glossary .............................................................. 5 2 safety and symbols ............................................. 6 3 introduction ..........................................................

Page 4

Pgc5000 pgc5000 series service instructions contents si/pgc5000-en, rev b 4 6.17 replacing power distribution board ..................... 50 7 subassembly repair ........................................... 52 7.1 column repair ........................................................ 52 7.1.1 column ...

Page 5

Pgc5000 pgc5000 series service instructions 1 glossary si/pgc5000-en, rev b 5 1 glossary acl access control list aoc absence of condition bios basic input/output system can controller area network cpu central processing unit did discharge ionization detector dsp digital signal processor dtc digital ...

Page 6

Pgc5000 pgc5000 series service instructions 2 safety and symbols si/pgc5000-en, rev b 6 2 safety and symbols the following symbols are used in this manual to alert the user to possible hazards and to provide additional information. Indicates that the referred item can be hot and should not be touche...

Page 7

Pgc5000 pgc5000 series service instructions 3 introduction si/pgc5000-en, rev b 7 3 introduction 3.1 general the pgc5000 series process gas chromatograph (analyzer) separates and measures the individual components of gas or liquid samples. It automatically samples and analyzes process streams, using...

Page 8

Pgc5000 pgc5000 series service instructions 3 introduction si/pgc5000-en, rev b 8 3.4.1 liquid version the liquid version incorporates a liquid sample valve (lsv) as the input to the analysis. The duration of an analysis depends on the application and consists of the following: • the liquid sample v...

Page 9

Pgc5000 pgc5000 series service instructions 4 maintenance si/pgc5000-en, rev b 9 4 maintenance 4.1 equipment and supplies required factory data sheets from the data package flow measuring device 4.2 preventive maintenance the oven design is specifically designed to eliminate the need for extensive a...

Page 10

Pgc5000 pgc5000 series service instructions 4 maintenance si/pgc5000-en, rev b 10 when you use a single cylinder to supply a gas, check the cylinder regularly and replace it when the pressure falls below 100 psig, using another cylinder containing the specified gas. 4.2.2 cleaning prior to cleaning ...

Page 11

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 11 5 diagnostics and troubleshooting 5.1 general this section contains troubleshooting for the pgc5000 master controller and attached ovens. The analyzer is equipped with visual indicators allowing the...

Page 12

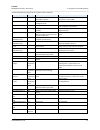

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 12 the following table gives possible issue resolutions where applicable. Source group issue resolution missing device oven board did not report to oven controller at startup. Check power to board. Che...

Page 13

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 13 source group issue resolution zone in band epc, carrier# status only. Not applicable. Zone fail zero epc, carrier# possible defective epc sensor board. Zone zeroed before pressure stabilized at zero...

Page 14

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 14 if the leds are not illuminated, check power to the unit. If the top led is green and flashing, the system is initializing. For all other instances use the table below. Led red amber green top oven ...

Page 15

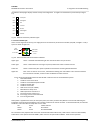

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 15 the health monitor lights display the status of the system (see figure 5.4). U48 u50 u51 u53 u47 u49 u52 u54 cr 24 cr 26 cr 28 cr 31 cr 25 cr 27 cr 29 cr 30 fig. 5.4. Sbc health monitor leds the hea...

Page 16

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 16 the network activity lights display network activity and configuration. The lights are viewed from top to bottom (see figure 5.5). Cr7 cr3 cr2 cr1 cr6 cr5 cr4 full duplex 10 megabit link transmit re...

Page 17

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 17 these leds blink green; they may appear solid during heavy traffic. If a can communication error is detected, an led will turn red. Cr2 can a transmit cr4 can a receive cr6 can b transmit cr8 can b ...

Page 18

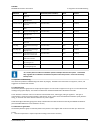

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 18 amber off off off temperature zone setup amber off amber off temperature conversion setup amber amber off off a/d converter setup amber amber amber off number valves detection off amber red off relo...

Page 19

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 19 5.3.4 dtc digital pcb, version 2 this dtc digital pcb has eight leds (cr1 to cr8) on the upper left-hand edge for basic troubleshooting. Cr1 through cr6 are green; cr7 and cr8 are red. Their display...

Page 20

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 20 if cr7 remains solid red and cr8 is off, an unexpected fatal condition occurred. Cr1 (msb) through cr6 form a binary code as follows indicating the error: 000001 flash erase error 000010 flash write...

Page 21

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 21 5.4 indicator troubleshooting procedures most system errors are identified by the condition monitoring system, resulting in indicator activation. If an indicator is placed in one or more of the user...

Page 22

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 22 column description indicator: “name” listed on status tab screen issue: possible problem triggering indicator reset: displays the means of reset. The ‘absence of condition’ (aoc) is the most common....

Page 23

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 23 indicator issue resolution (check & correct) reset source hardware error roll up of all dtc check oven.Dtc group indicators for aoc oven.Dtc1 indicators more information. T-rating conflict dtc -rati...

Page 24

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 24 indicator issue resolution (check & correct) reset source dtc digital input electronic section purge check purge pressure setting at aoc ovn#dtc#.15 15 alarm input . Oven’s front panel gauge. Adjust...

Page 25

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 25 indicator issue resolution (check & correct) reset source low-low concentration is below information only. Adjust limits under when component concentration low-low setpoint the setup tab as needed. ...

Page 26

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 26 indicator issue resolution (check & correct) reset source calibrating schedule running an information only. Aoc schedule analysis on calibration stream validating schedule runnign an information onl...

Page 27

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 27 indicator issue resolution (check & correct) reset source vol flow high volumetric flow exceeds information only. Aoc fastloop high limit vol flow high high volumetric flow exceeds information only....

Page 28

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 28 2. Contaminated or missing carrier gas, hydrogen fuel or burner air. Verify the supplied cylinders are analytical grade. Replace cylinders one at a time; activate the pressure zones and relight the ...

Page 29

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 29 5.6.6 individual peak missing on report chromatogram indicates all peaks are present; however, the data report shows the peak to be nonexistent or unknown. The gating in the method needs to be modif...

Page 30

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 30 4. Purge, atmospheric vents plugged. Inspect and clear vents. 5. Tubing to and from pressure switches leaking or disconnected. Inspect and replace if necessary. 6. Purge orifice is obstructed. Remov...

Page 31

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 31 if only option names show, you do not have enough rights to use the backup and restore options. Stop all schedules before creating a recovery usb or backing up the stream files to a usb flash drive....

Page 32

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 32 message to appear. Select the usb eject icon and wait for the eject complete message to appear and then remove the usb flash drive. Eject – selecting the usb flash drive or the sd card icon allows y...

Page 33

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 33 5.9 upgrading software software upgrades may be available through the abb support on a need basis. Please follow the reporting guidelines as described in the section 8 of these instructions. 5.10 op...

Page 34

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 34 reaction gas is connected, there is an air leak, or there is no reaction gas flow. Turn off the power to the plasma and check the gas supply. Check for leaks and check flow rate. Signal cable proble...

Page 35

Pgc5000 pgc5000 series service instructions 5 diagnostics and troubleshooting si/pgc5000-en, rev b 35 5.10.5 high baseline bad gas: when operating in the hid mode, background signal is directly linked to the quality of the gases being used. Therefore, at a minimum, it is important to have an oxygen ...

Page 36

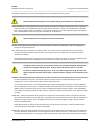

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 36 6 component repair 6.1 general 6.1.1 preparation and procedures the following instructions assume that all equipment has been properly installed and checked, that the analyzer has been application engineered, and ...

Page 37

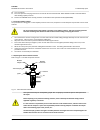

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 37 6.2 master controller cabinet the master controller houses the following components, located as shown in figure 6.1. • single board computer (sbc) and card cage assembly • oven controller pcb • power supply • opti...

Page 38

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 38 if equipped with a wago module, ensure electrical can connection is removed from the top of the controller board before sliding board out. 3. Release board clips at top and bottom. 4. Slide board out. 5. Reverse s...

Page 39

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 39 6.3.1 front panel pcb transformers for the backlight converter are protected on this. Be careful when opening and closing the master controller door to ensure safety. Removal and replacement procedure for the pcb ...

Page 40

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 40 6.4 oven component locations 6.4.1 class b oven component locations, version 1 the oven components are mounted on the inside of the door and within the electronics compartment. The compartment or compartments are ...

Page 41

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 41 6.4.3 class c oven component locations the class c oven incorporates pcbs mounted on the inside of the front and side doors and on walls of the electronics compartment (see figure 6.6). Before removing any boards ...

Page 42

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 42 be sure that the epc control assembly has cooled to ambient temperature (approximately one hour) before proceeding. Use an esd wrist strap and proper grounding procedures before handling any components in the epc ...

Page 43

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 43 10. On the wall inside the left side of the oven, remove the lock nut on the pipe nipple which retains the epc panel cables (see figure 6.7, which shows class c oven). Lock nut fig. 6.7. Epc cable lock nut 11. Dis...

Page 44

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 44 6.6.4 removing a sensor pcb the zones are arranged in the epc control assembly enclosure with zone 1 on the left and zone 5 on the right (see figure 6.8). Proportional valve sensor pcb heater control pcb fig. 6.8....

Page 45

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 45 6.6.5 installing a new sensor pcb install the new sensor pcb, using figure 6.10 as a guide. Screw screw washer washer retainer gasket sensor pcb fig. 6.10. Installing the new sensor pcb 1. Place a belleville washe...

Page 46

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 46 you may need to remove the sensor pcb cable from the control pcb to allow access to the connector of some zones. 7. Using 3 mm hex socket wrench abb tool tl1009, remove the screws and washers that secure the valve...

Page 47

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 47 6.6.10 removing the heater be sure that the epc control assembly has cooled to ambient temperature (approximately one hour) before proceeding. Use an esd wrist strap and proper grounding procedures before handling...

Page 48

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 48 6.8 flame photometric detector electrometer in the class b oven, the fpd electrometer is attached to inside of electronics compartment door (left side of oven) on the center section of the door. In the class c ove...

Page 49

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 49 6.11 replacing the optional zone board in both the class b and class c oven, a maximum of two optional zone boards are attached to the dtc master analog board. Note cable routing and markings (locate pin 1 on the ...

Page 50

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 50 4. Remove the dtc digital pcb. 5. Remove hex head screws attaching the heat sink from the outside of the oven door. 6. Remove the remaining hex head bolts on the inside of the door. 7. Remove the dtc analog pcb. 8...

Page 51

Pgc5000 pgc5000 series service instructions 6 component repair si/pgc5000-en, rev b 51 4. Reinstall fuse and blanks in unused plugs. 5. Attach new board to mounting bracket using hex head screws. 6. Reattach all plugs and tighten. 7. Test..

Page 52

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 52 7 subassembly repair 7.1 column repair 7.1.1 column removal 1. If analyzer is running and a column is to be replaced, stop the analysis. 2. Reduce isothermal oven temperature by reducing oven air pressure to zer...

Page 53

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 53 10. Turn on analyzer. 11. Set carrier pressure and purge column for at least 30 minutes and leak check. Note: snoop™ is not recommended for leak checking capillary columns. 12. Perform the pgc5000 series startup...

Page 54

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 54 7.2.1 fid cell access 1. If power is applied to the analyzer, turn it off. 2. Turn off oven air to the isothermal oven and allow all temperature zones to cool. 3. Turn off carrier and other utility gases, as app...

Page 55

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 55 7. Roll each end of the green wire of the new polarizer between your forefinger and thumb, causing the wire ends to be tightly spiral wrapped. 8. Using the 40 watt soldering iron and approved high temperature so...

Page 56

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 56 7.2.7 replacing the fid cable assembly this procedure requires a special tool, insertion tool abb p/n tl799m013-1, to assist in passing the cable through the insulation between the electronic housing and the ove...

Page 57

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 57 it is the customer’s responsibility to ensure that the area is safe and hazard free, and will remain so the entire time the analyzer is open. This responsibility includes ensuring adequate ventilation in analyze...

Page 58

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 58 6. Repeat this measurement for each of the other three filament wires. If all resistance measurements are correct, go to "connecting the filaments." if any resistance is too low, go to step 8. 7. If the resistan...

Page 59

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 59 7.4 repairing the multiport thermal conductivity detector this repair should only be attempted by people who are properly trained and possess the expertise for this repair. 7.4.1 accessing the detector 1. Turn o...

Page 60

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 60 abb recommends using an alcohol such as methanol to check for leaks as it dries quickly and leaves no residue. 15. Power down the oven. 16. Isolate carrier and utility gases. 17. Slowly loosen and remove cell ve...

Page 61

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 61 7.5 repairing the flame photometric detector 7.5.1 replacing the photomultiplier assembly it is the customer’s responsibility to ensure that the area is safe and hazard free, and will remain so the entire time t...

Page 62

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 62 7.5.3 replacing the burner block o-rings refer to figure 7.7 when performing this procedure. Perform steps 1 through 4 of "replacing the burner block." to remove a particular o-ring, carefully remove the associa...

Page 63

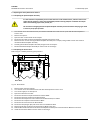

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 63 7.6 liquid sample valve repair the analyzer’s sample lines are connected to the liquid sample valve as shown in figure 7.8. Sample line lsv body mounting clamps lsv body mounting clamps sample line fig. 7.8. Liq...

Page 64

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 64 7.6.1 lsv disassembly on the analyzer see figure 7.9 for typical sample valve component location. Stem stem seals piston rod o-ring body body o-rings tensioning nut o-ring belleville springs rear valve seat samp...

Page 65

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 65 3. Lightly lubricate the tensioning nut o-ring and the tensioning nut threads, internal threads and bore of the body with high vacuum grease. 4. Install the o-ring onto the tensioning nut. 5. Screw the tensionin...

Page 66

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 66 17. Slide the first cleaned seal over the stem using the “a” end of seal insertion tool tl-791a006b. The 30° angle (pointed end) of the seal must face the belleville springs. Figure 7.11 shows the orientation of...

Page 67

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 67 5. Reconnect all tubing on the liquid sample valve. 6. Close the isothermal oven door. 7.7 cp valve repair this section describes how to replace the cp valve slider, wedges, valve plate, and o-rings. The bulleti...

Page 68

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 68 9. Insert the carrier assembly on the valve plate. 10. Close the back carrier assembly latch. This ensures the carrier assembly is locked into the hole in the piston stem. 11. Close the front carrier assembly la...

Page 69

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 69 8. Remove the carrier assembly from the valve plate and valve body, being careful to keep the latches in their open position. 9. Push the piston rod into the valve body to release the piston, being careful not t...

Page 70

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 70 26. Close the front carrier assembly latch. 27. Install the valve body over the screws on the mounting plate and rotate the valve body clockwise to seat it. The port connections must face the same direction as w...

Page 71

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 71 3. Turn off power and carrier gas. 4. Open the isothermal oven door. 5. Locate the valve to be replaced. 6. Tag all valve connections. Service or replacement of the o-rings, plungers, or springs must be performe...

Page 72

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 72 7.8.4 replacing the diaphragm (one screw type) 1. Remove the hex head cap screw from the center of the valve cap (see figure 7.18). Port 1 cap screw fig. 7.18. Typical 1 screw cap, showing port 1 orientation 2. ...

Page 73

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 73 7.9 optional discharge ionization detector replacing the reactor tube while it is in the oven is not advised. Due to the small pieces and awkward angles involved in the procedure, it is highly recommended the di...

Page 74

Pgc5000 pgc5000 series service instructions 7 subassembly repair si/pgc5000-en, rev b 74 2. Secure the shield with the phillips head screw retained earlier. 3. Remove, inspect, and replace if necessary, the ptfe ferrule in the reaction gas assembly before continuing. The plasma cell is marked with a...

Page 75

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 75 8 replacement parts 8.1 ordering information since the particular application defines the component parts specific to any given system, please refer to the “recommended spare parts lists” in the analyzer’s data p...

Page 76

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 76 8.1.3 oven configuration identification the oven nameplate (see figure 8.2) lists the oven configuration information. Model number sales order number fig. 8.2. Typical oven nameplate 8.1.4 software configuration ...

Page 77

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 77 8.2 master controller 8.2.1 back of door (see figure 8.4) description part number front panel pcb, version 1 852a004-1 front panel pcb, version 2 852a009-1 lcd display, version 1 857z002-1 lcd display, version 2 ...

Page 78

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 78 8.3 class b1 oven components this section lists components specific to the class b1 oven. Components common to all class b ovens are in 8.5. 8.3.1 left side components (see figure 8.6) description part number epc...

Page 79

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 79 8.4 class b2 oven components this section lists components specific to the class b2 oven. Components common to all class b ovens are in 8.5. 8.4.1 left side components (see figure 8.8) description part number epc...

Page 80

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 80 8.5 class b main interior, both versions (see figure 8.10) description part number oven heater kit, 115 v 1000 w 800k007-1 oven heater kit, 230 v 1000 w 800k007-2 oven heater kit, 115 v 500 w 800k007-3 oven heate...

Page 81

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 81 8.5.1 liquid sample valve (see figure 8.11) description part number o-ring seal kit 791k003n-1 0.125 inch stem (per application) 791a008b-_ 0.125 inch seal (per application) 791m001b-_ 0.062 inch stem (per applic...

Page 82

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 82 8.5.2 flame ionization detector (see figure 8.12) description part number maintenance kit 799k003-1 jet 3617156-2 ignitor assy 794a007b-2 thermocouple assy 794a008b-1 polarizer assy 794a009b-1 column kits are app...

Page 83

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 83 8.5.4 multiport thermal conductivity detector (see figure 8.14) description part number filament kit 865k001-1 fig. 8.14. Multiport tcd 8.5.5 flame photometric detector description part number transformer 3617648...

Page 84

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 84 8.5.6 burner block components (see figure 8.15) description part number burner block assy 867a008-1 adapter, jet 804m004-1 jet 3617432-1 o-ring 15/16-in od, fluorocarbon 45051-4-106 o-ring 11/16-in od, teflon 450...

Page 85

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 85 8.5.8 optional did replacement parts (see figure 8.17) description part number 12v power supply 8230878-2210 power supply did 835a001-1 plasma cell 885z001-1 top nut o-ring 885z002-1 ss noise shield 885z003-1 det...

Page 86

Pgc5000 pgc5000 series service instructions 8 replacement parts si/pgc5000-en, rev b 86 8.7 class c oven the class c ovens have the same components as the class b ovens, although the quantities may differ..

Page 87: Notes

Pgc5000 pgc5000 series service instructions notes si/pgc5000-en, rev b 87 notes.

Page 88

S i/pgc5000-en rev. B 08.2 01 6 contact us note we reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. Abb does not accept any responsibility whatsoever for potential errors or...